1. Understanding the Importance of Order Accuracy

2. Common Causes of Errors in Sweep-to-Fill Order Processing

3. Implementing Quality Control Measures to Minimize Errors

4. The Role of Technology in Improving Order Accuracy

5. Training and Development Programs for Order Processing Staff

6. Establishing Clear Communication Channels with Customers

7. Utilizing Data Analytics to Identify and Address Root Causes of Errors

8. Best Practices for Maintaining Order Accuracy Over Time

9. The Benefits of Prioritizing Order Accuracy in Sweep-to-Fill Processing

Order accuracy: Minimizing Errors in Sweeptofill Order Processing

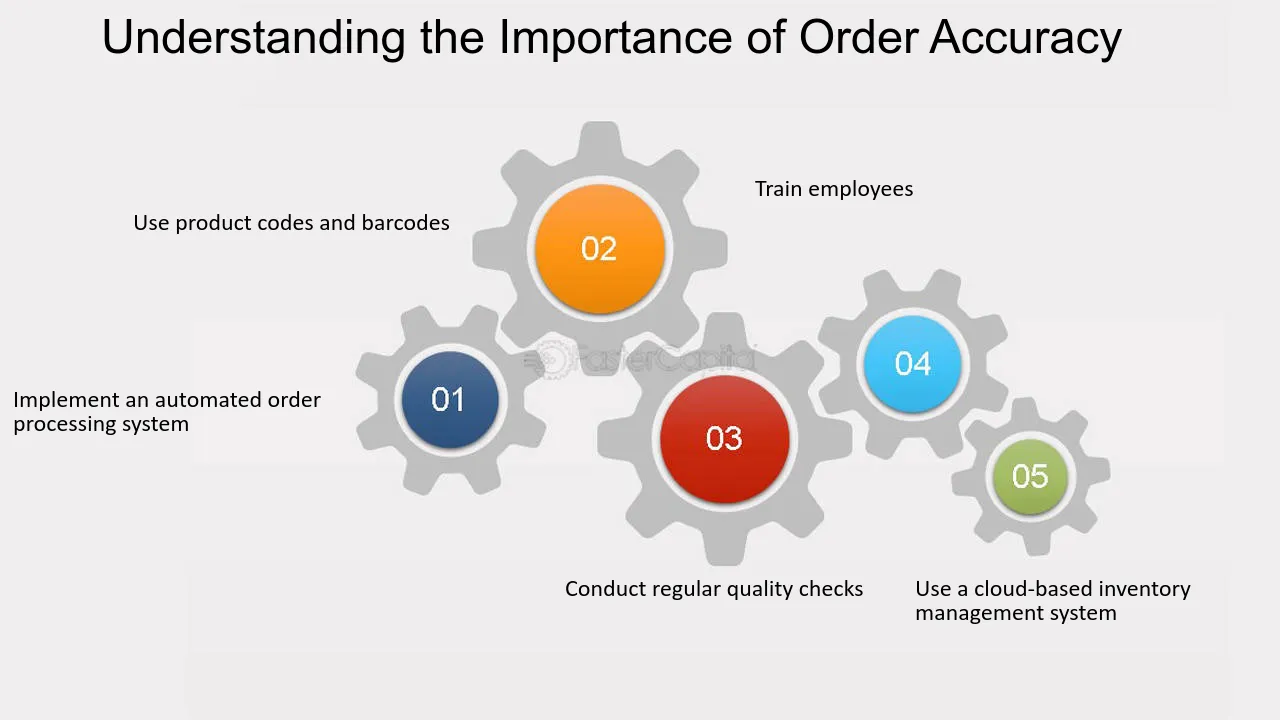

1. Understanding the Importance of Order Accuracy

Order accuracy is a crucial aspect of any business that deals with order processing. Inaccurate orders can lead to a loss of revenue, customer dissatisfaction, and damage to the reputation of the business. In today's competitive market, where customer satisfaction is the top priority, it is essential to ensure that orders are processed accurately.

From a customer's perspective, accuracy in order processing is critical. Customers expect to receive the product they ordered, in the right quantity, and within the promised delivery time. Any errors in this process can lead to frustration, disappointment, and a loss of trust in the business. In contrast, when customers receive accurate orders, they are more likely to return for future purchases and recommend the business to others.

From a business perspective, order accuracy is equally important. Inaccurate orders can lead to increased costs due to returns, reshipments, and customer service inquiries. Additionally, it can damage the reputation of the business, leading to a loss of customers and revenue. On the other hand, accurate orders can lead to increased efficiency, reduced costs, and positive customer reviews.

To ensure order accuracy, businesses must have a robust order processing system in place. Here are some steps businesses can take to minimize errors in sweep-to-fill order processing:

1. Implement an automated order processing system: Automation can significantly reduce the chances of human error in the order processing system. It can also speed up the process, leading to faster delivery times and increased customer satisfaction.

2. Use product codes and barcodes: Using product codes and barcodes can help ensure that the right product is being shipped. It can also speed up the process and reduce the chances of errors.

3. Conduct regular quality checks: Implementing a quality control process can help catch errors before they result in shipped orders. Regular checks can help identify any patterns in errors and allow businesses to make necessary changes.

4. Train employees: Properly trained employees are less likely to make errors in the order processing system. Providing regular training sessions can help ensure that employees are up to date on the latest processes and procedures.

5. Use a cloud-based inventory management system: A cloud-based inventory management system can help businesses keep track of stock levels and prevent out-of-stock situations. It can also provide visibility into the order processing system, allowing businesses to identify any bottlenecks and make necessary changes.

Order accuracy is crucial for any business that deals with order processing. It can lead to increased customer satisfaction, reduced costs, and a positive reputation. By implementing an automated order processing system, using product codes and barcodes, conducting regular quality checks, training employees, and using a cloud-based inventory management system, businesses can minimize errors in sweep-to-fill order processing.

Understanding the Importance of Order Accuracy - Order accuracy: Minimizing Errors in Sweeptofill Order Processing

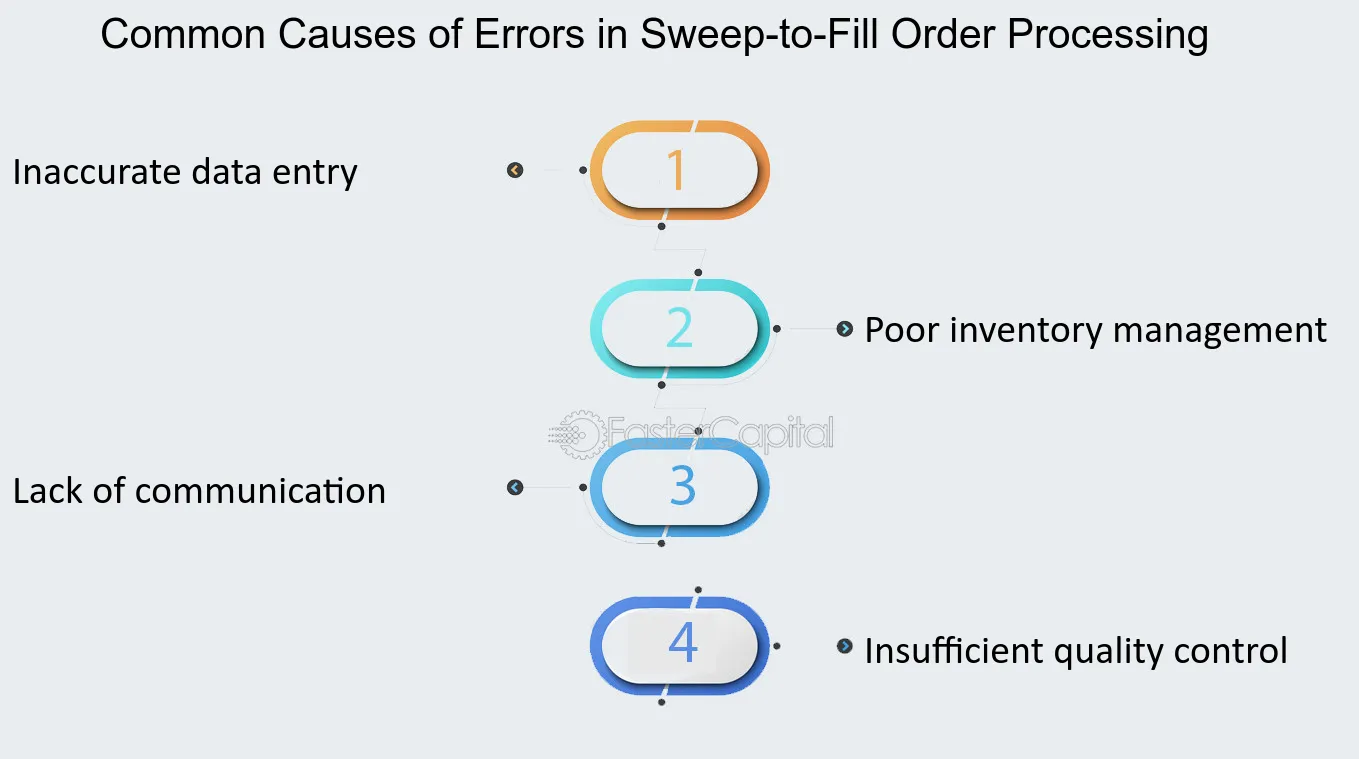

2. Common Causes of Errors in Sweep-to-Fill Order Processing

One of the biggest challenges of sweep-to-fill order processing is ensuring that orders are processed accurately. Even the slightest error can have significant consequences, such as delayed shipments, unhappy customers, and lost revenue. Unfortunately, there are several common causes of errors in sweep-to-fill order processing that businesses should be aware of. In this section, we will discuss some of these causes and offer insights from different perspectives.

1. Inaccurate data entry

One of the most common causes of errors in sweep-to-fill order processing is inaccurate data entry. This can occur when employees make mistakes while inputting customer information, product numbers, or quantities. For example, an employee may accidentally transpose the numbers in a product code, leading to the wrong item being shipped. To prevent this type of error, businesses should implement data validation checks and provide training to employees on accurate data entry.

2. Poor inventory management

Another common cause of errors in sweep-to-fill order processing is poor inventory management. This can occur when businesses do not have accurate inventory data, leading to overselling or underselling of products. For example, if a business sells a product that is out of stock, it will need to cancel the order or delay shipment, which can lead to dissatisfied customers. To prevent this type of error, businesses should invest in inventory management software and regularly conduct physical inventory counts.

3. Lack of communication

A lack of communication between departments can also lead to errors in sweep-to-fill order processing. For example, if the warehouse team does not communicate with the customer service team, they may not know that a product is out of stock and continue to accept orders for it. To prevent this type of error, businesses should implement clear communication channels between departments and regularly hold meetings to discuss any issues or concerns.

4. Insufficient quality control

Finally, insufficient quality control can also lead to errors in sweep-to-fill order processing. This can occur when businesses do not have proper quality control measures in place to check orders before they are shipped. For example, an employee may accidentally ship a damaged product, leading to a customer complaint. To prevent this type of error, businesses should implement quality control processes that include visual inspections, weight checks, and order accuracy checks.

There are several common causes of errors in sweep-to-fill order processing that businesses should be aware of. By implementing measures to prevent these errors, such as data validation checks, inventory management software, clear communication channels, and quality control processes, businesses can minimize the risk of errors and ensure that orders are processed accurately.

Common Causes of Errors in Sweep to Fill Order Processing - Order accuracy: Minimizing Errors in Sweeptofill Order Processing

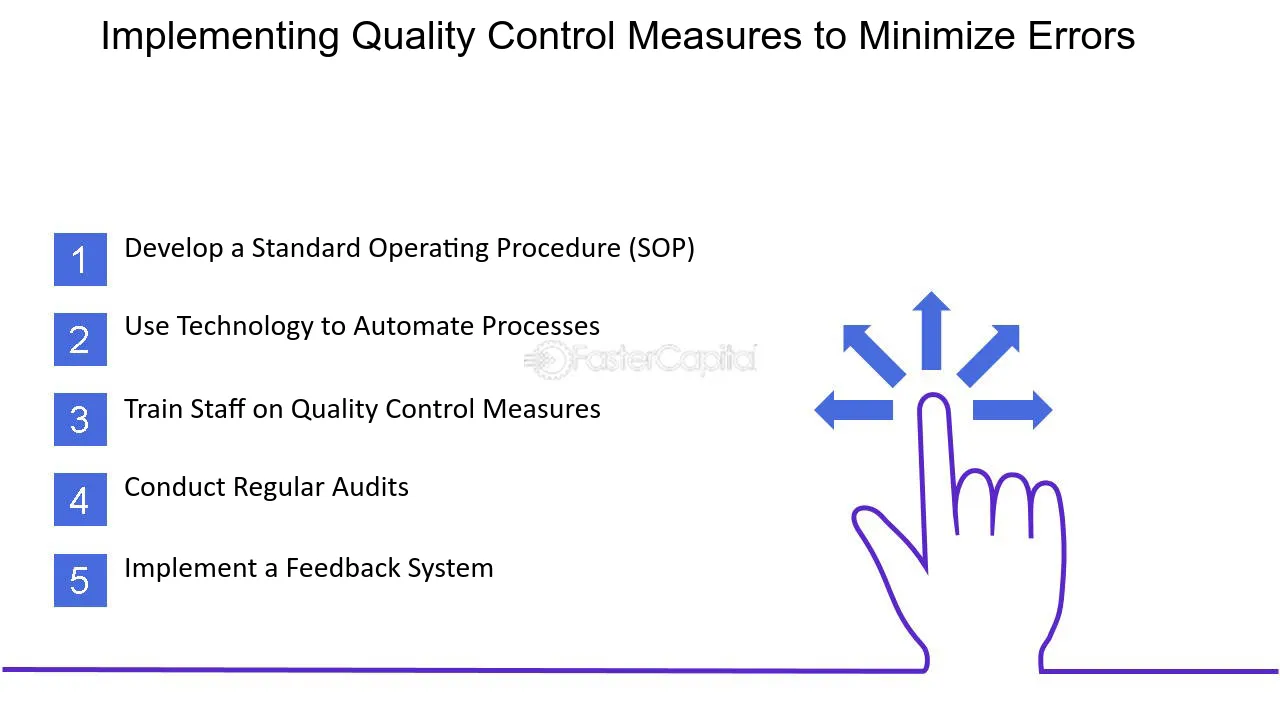

3. Implementing Quality Control Measures to Minimize Errors

Order accuracy is crucial for businesses that operate in the retail and e-commerce sectors. Failing to deliver the right products to customers can lead to negative reviews, increased costs due to returns and re-shipping, and even lost customers. implementing quality control measures is essential to minimize errors in order processing and ensure that customers receive the right products in a timely manner.

1. Develop a standard Operating procedure (SOP)

Creating a standard operating procedure (SOP) is a crucial step in ensuring order accuracy. An SOP outlines step-by-step instructions for order processing, including how to handle returns and exchanges, and how to address errors. It should also include quality control measures such as double-checking orders, verifying the accuracy of shipping addresses, and ensuring that all products are properly packaged.

2. Use Technology to Automate Processes

Using technology to automate processes can be an effective way to minimize errors in order processing. For example, implementing a barcode scanning system can ensure that the correct products are picked and packed for each order. Additionally, using software that integrates with inventory management systems can help prevent overselling and out-of-stock situations.

3. Train Staff on Quality Control Measures

Properly training staff is essential to ensuring that quality control measures are followed consistently. This includes training on how to use technology such as barcode scanners and inventory management software, as well as how to handle returns and exchanges. Regular training sessions can help reinforce the importance of order accuracy and ensure that staff members are up-to-date on the latest procedures.

4. Conduct Regular Audits

Conducting regular audits is an essential aspect of quality control. Audits can help identify areas where errors are occurring and provide insights into how to improve processes. Audits can also help ensure that SOPs are being followed consistently and that staff members are properly trained.

5. Implement a Feedback System

Implementing a feedback system can provide valuable insights into customer satisfaction and help identify areas for improvement. This can include sending surveys to customers after they receive their orders, or providing an option for customers to leave feedback on the company's website or social media pages. This feedback can be used to identify areas where errors are occurring and to develop strategies for improving order accuracy.

Implementing quality control measures is an essential aspect of minimizing errors in order processing. Developing a standard operating procedure, using technology to automate processes, training staff, conducting regular audits, and implementing a feedback system can all help ensure that customers receive the right products in a timely manner. By implementing these measures, businesses can improve customer satisfaction, reduce costs associated with errors, and increase the likelihood of repeat business.

Implementing Quality Control Measures to Minimize Errors - Order accuracy: Minimizing Errors in Sweeptofill Order Processing

4. The Role of Technology in Improving Order Accuracy

In the modern world of business, technology has become an indispensable tool in improving efficiency and accuracy in various business processes, including order processing. The use of technology in order processing has revolutionized the way businesses operate, especially in industries that deal with high volumes of orders such as retail, e-commerce, and logistics. In this section, we will explore the role of technology in improving order accuracy.

1. Automated Order Processing Systems

The use of automated order processing systems has significantly improved order accuracy in various industries. Automated systems reduce the likelihood of human error and improve the speed of processing orders. These systems use advanced algorithms and machine learning to process orders accurately and efficiently. Some of the benefits of automated order processing systems include reduced order processing time, improved order accuracy, and reduced labor costs.

2. barcode Scanning technology

Barcode scanning technology is another tool that has improved order accuracy in various industries. Barcode scanning technology enables businesses to track inventory and orders

The Role of Technology in Improving Order Accuracy - Order accuracy: Minimizing Errors in Sweeptofill Order Processing

5. Training and Development Programs for Order Processing Staff

Order processing staff plays a crucial role in ensuring customer satisfaction. They are responsible for processing orders accurately and efficiently, which can directly impact a company's reputation and bottom line. Therefore, providing adequate training and development programs for order processing staff is essential. These programs can help improve their performance, reduce errors, and enhance customer satisfaction.

1. importance of Training and development Programs

The importance of training and development programs for order processing staff cannot be overstated. These programs can help improve their knowledge, skills, and abilities, which can result in improved performance, increased productivity, and reduced errors. Additionally, training and development programs can help employees feel valued and invested in, which can lead to higher job satisfaction and retention rates.

2. Types of Training and Development Programs

There are various types of training and development programs that can be implemented for order processing staff. Some of the most common ones include:

- On-the-job training: This type of training involves learning while performing the job itself. It can include shadowing experienced employees, receiving feedback and coaching, and gradually taking on more responsibility.

- Classroom training: This type of training involves formal instruction and can be conducted in-person or online. It can cover topics such as order processing procedures, customer service, and communication skills.

- Cross-training: This type of training involves learning different aspects of the order processing process, such as handling returns or managing inventory. It can help employees gain a better understanding of the overall process and improve their problem-solving skills.

- Mentoring: This type of training involves pairing new or less experienced employees with more experienced ones. It can provide guidance, support, and feedback to help employees develop their skills and knowledge.

3. Best Practices for Training and Development Programs

When implementing training and development programs for order processing staff, it's essential to follow best practices to ensure their effectiveness. Some of the best practices include:

- Identifying specific training needs: Before implementing any training program, it's essential to identify the specific skills and knowledge gaps that need to be addressed.

- Customizing training programs: Training programs should be customized to meet the unique needs and preferences of each employee. This can help increase engagement and retention rates.

- Providing ongoing training: Training should be an ongoing process rather than a one-time event. Regularly providing training and development opportunities can help employees continue to improve their skills and knowledge.

- Measuring effectiveness: It's essential to measure the effectiveness of training programs to ensure they are achieving the desired outcomes. This can include collecting feedback from employees and tracking performance metrics.

4. Examples of effective Training and development Programs

There are many examples of effective training and development programs for order processing staff. One example is Zappos, which provides extensive customer service and communication skills training for its order processing staff. This has resulted in high levels of customer satisfaction and loyalty. Another example is Amazon, which uses gamification to train its order processing staff. This approach has resulted in increased engagement and retention rates.

Providing adequate training and development programs for order processing staff is essential for improving their performance, reducing errors, and enhancing customer satisfaction. By following best practices and customizing training programs to meet the unique needs and preferences of each employee, companies can achieve significant improvements in their order processing operations.

Training and Development Programs for Order Processing Staff - Order accuracy: Minimizing Errors in Sweeptofill Order Processing

6. Establishing Clear Communication Channels with Customers

effective communication is essential in any business, especially when it comes to order processing. Establishing clear communication channels with customers can help to minimize errors and ensure that orders are accurate. It can also help to build trust and loyalty with customers, which can lead to repeat business and positive word-of-mouth referrals.

1. Provide multiple communication channels: Customers have different preferences when it comes to communication. Some may prefer to call, while others may prefer email or text messaging. Providing multiple communication channels can help to accommodate these preferences and make it easier for customers to get in touch with your business. This can include a phone number, email address, live chat feature, and social media accounts.

2. Use clear and concise language: When communicating with customers, it's important to use clear and concise language. Avoid using technical jargon or industry-specific terms that customers may not understand. Instead, use plain language and explain things in a way that is easy for customers to understand.

3. Respond promptly: When customers reach out with questions or concerns, it's important to respond promptly. This can help to build trust and show customers that their needs are a priority. Aim to respond to all customer inquiries within 24 hours, if possible.

4. Provide order updates: Keeping customers informed about the status of their order can help to minimize errors and ensure that orders are accurate. This can include sending automated order confirmation emails, providing shipping updates, and sending notifications when an order has been delivered.

5. Collect feedback: collecting feedback from customers can help to identify areas for improvement and ensure that communication channels are effective. Consider sending follow-up surveys or asking for feedback through social media channels. Use this feedback to make improvements and enhance the customer experience.

Overall, establishing clear communication channels with customers is essential for minimizing errors in order processing and building trust and loyalty. By providing multiple communication channels, using clear and concise language, responding promptly, providing order updates, and collecting feedback, businesses can ensure that customers are satisfied and orders are accurate.

Establishing Clear Communication Channels with Customers - Order accuracy: Minimizing Errors in Sweeptofill Order Processing

7. Utilizing Data Analytics to Identify and Address Root Causes of Errors

One of the most effective ways to minimize errors in Sweeptofill order processing is to utilize data analytics to identify and address the root causes of errors. Data analytics is the process of examining large data sets to uncover hidden patterns, correlations, and other insights that can be used to make better decisions. By analyzing data related to order processing, companies can identify the root causes of errors and take proactive steps to address them.

1. collect and Analyze data: The first step in utilizing data analytics to minimize errors is to collect and analyze relevant data. This includes data related to order processing, such as order volume, order accuracy rates, and customer feedback. By analyzing this data, companies can identify patterns and trends that may be contributing to errors. For example, if certain products or order types consistently have higher error rates, this may indicate a

Looking for a CTO? Search no more!

FasterCapital provides you with full CTO services, takes the responsibility of a CTO and covers 50% of the total costs

8. Best Practices for Maintaining Order Accuracy Over Time

Order accuracy is crucial in any business that deals with order processing. Customers rely on accurate and timely delivery of their orders, and any errors can lead to dissatisfaction and loss of trust. Maintaining order accuracy over time requires a systematic approach and adherence to best practices. In this section, we will explore some of the key strategies that businesses can employ to minimize errors and ensure order accuracy.

1. Clear and Detailed Order Documentation: One of the primary causes of order errors is incomplete or unclear order documentation. To maintain order accuracy, it is essential to have a standardized process for documenting orders. This includes capturing all relevant information such as product details, quantities, customer preferences, and any special instructions. Providing a template or checklist for order documentation can help ensure that no critical information is missed.

For example, a restaurant taking online orders should have a well-designed order form that prompts customers to provide specific details like customization options, dietary restrictions, and delivery address. This not only minimizes errors but also improves the overall customer experience.

2. Regular Training and Communication: Order accuracy is a responsibility shared by the entire team involved in the order processing cycle. Regular training sessions should be conducted to educate employees about the importance of order accuracy and the specific steps they need to follow to achieve it. Clear communication channels should be established to address any doubts or queries that employees may have.

Consider a scenario where a retail store receives orders through various channels, including phone, email, and online platforms. Conducting training programs for employees on how to handle orders from different channels can help minimize errors caused by miscommunication or lack of understanding.

3. Quality Control Checks: implementing quality control checks at various stages of the order processing cycle is crucial to catch any errors before orders are fulfilled. This can include double-checking order documentation against the actual products or services being prepared, verifying quantities, and ensuring that all customer requirements are met.

For instance, an e-commerce company can have a dedicated team responsible for inspecting products before they are packaged and shipped. This team can compare the physical items with the order documentation to ensure accuracy and address any discrepancies.

Best Practices for Maintaining Order Accuracy Over Time - Order accuracy: Minimizing Errors in Sweeptofill Order Processing

9. The Benefits of Prioritizing Order Accuracy in Sweep-to-Fill Processing

In sweep-to-fill order processing, the accuracy of each order is of utmost importance. The slightest error can lead to significant consequences, such as delayed shipments, lost customers, and damaged reputation. Therefore, prioritizing order accuracy is a critical aspect of any business that deals with sweep-to-fill processing. In this section, we will discuss the benefits of prioritizing order accuracy and how it can impact your business.

1. Increased Customer Satisfaction:

Order accuracy is directly linked to customer satisfaction. When customers receive their orders accurately and on time, they are more likely to be satisfied with the service they received. This leads to increased customer loyalty and retention, which can ultimately boost your sales and revenue. On the other hand, if customers receive inaccurate orders or experience delays, they are more likely to switch to a competitor, resulting in lost sales and revenue.

2. Improved Efficiency:

Prioritizing order accuracy can also lead to improved efficiency in your operations. Accurate orders require less time and resources to correct, reducing the chances of delays and minimizing the risk of errors. This can lead to faster order processing, shorter lead times, and improved inventory management, all of which can positively impact your bottom line.

3. Reduced Costs:

Inaccurate orders can be costly for your business. They can lead to wasted inventory, increased shipping costs, and lost productivity. By prioritizing order accuracy, you can reduce these costs and improve your profitability. Accurate orders also require less time and resources to correct, freeing up your staff to focus on other essential tasks.

4. Enhanced Reputation:

Order accuracy is a critical component of your business's reputation. Customers expect their orders to be accurate and delivered on time, and any errors can damage your reputation. By prioritizing order accuracy, you can establish a reputation for reliability and quality, leading to increased customer trust and loyalty.

Accurate orders can also improve employee morale. When employees know that their work is making a positive impact on the business and its customers, they are more likely to feel valued and motivated. This can lead to increased productivity, reduced turnover, and improved job satisfaction.

Prioritizing order accuracy in sweep-to-fill processing can have numerous benefits for your business. From increased customer satisfaction to improved efficiency and reduced costs, accurate orders can positively impact your bottom line. By establishing a culture of accuracy and investing in the right tools and processes, you can ensure that your business delivers high-quality service to its customers.

The Benefits of Prioritizing Order Accuracy in Sweep to Fill Processing - Order accuracy: Minimizing Errors in Sweeptofill Order Processing