Design of GEARBOX

- 1. Design of Multi-speed Gearbox Dr P.NALLASAMY MECH-PSGTECH

- 3. Types of Gearbox (1) Sliding mesh gear box: • When we talk about types of gearbox, this is one of the oldest type. It this, gears on the main shaft are moved right or left for meshing them with appropriate gears on the counter shaft for obtaining different speed. • This type of gear box derives its name from the fact that the gears are meshed by sliding. One disadvantage of it is that, special skill is required to operate this gear box and there are high chances of wear and tear of gearbox.

- 4. Run Video

- 7. (2) Constant mesh gear box: • This is one of the famous type used in twenty century. It this gearbox, all the gears are in constant mesh with each other all the time. The gears on the main shaft rotates freely without rotating the main shaft. • Constant mesh gear box consists two dog clutches. These clutches are provided on the main shaft, one between the clutch gear and the second gear and the other between the first gear and reverse gear. When the left side dog clutch is made to slide left by means of gearshift lever, it meshes with the clutch gear and the vehicle runs on top speed. • If this clutch slide right and mesh with second gear, then the vehicle runs on second gear speed. So in constant mesh gear box we can change the gear ratio by shifting the dog clutch. This type of gear box is more popular than sliding mesh because it creates low noise and less wear of gears.

- 8. Run Video

- 11. (3) Synchromesh gear box: • One big problem occur in constant mesh gear box is that when the driver engage the dog clutch, the main shaft and gear to be meshed running at different speed. • So when engage this gear cause wear and tear of dog clutch. This problem is solved by a synchromesh gear box. This gear box is same as the constant mesh gear box except dog clutch is replaced by synchromesh devices.

- 12. • Synchromesh gear devices works on the principle that two gears to be engaged are first brought into frictional contact which equalizes their speed after which they are engaged readily and smoothly. • The synchromesh looks like as the cone clutch where the outer surface of cone consist the frictional surface. This type of gear box is widely used in automobile.

- 13. Run Video

- 25. Selection of Speeds • A typical multispeed gear box is shown in figure. • No.of speeds available at the spindle Z = 3 x 2 x 2 = 18

- 26. Geometric Progression • Progression or Step ratio = Φ is constant • Φ – ratio between two successive speeds • Φ = N2/N1 = N6/N5 = Nz/Nz-1, z –no.of speeds • Φ=[Nmax/Nmin](1/z-1)

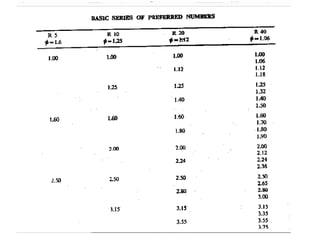

- 27. Advantages of Geometric Progression • No of gears to be used is minimum • More range of spindle speeds • Layout is compact • Speed loss is minimum (Desired optimum speed –available speed) • Speeds can be easily selected from preferred numbers, because preferred numbers on G.P

- 28. Selection of Speeds from preferred numbers • Basic series (R10 or R20, etc) • Derived series (R20/3, R10/2) • Non-standard speeds • N1 = Nmin • N2 = Nmin x Φ • N3 = Nmin x Φ2

- 31. Basic series - Example Find the progression ratio for a 12 speed gear box having speeds between 100 and 355 rpm. Also find the spindle speeds.

- 32. Derived series - Example Select spindle speeds, for a 9 speed gear box, between 80 and 1285 rpm

- 33. Non-standard speeds - Example Select spindle speeds, for a 12 speed gear box, between 50 and 800 rpm

- 42. Problem-1

- 46. Calculation of number of teeth Stage-3 Consider the ray that gives maximum reduction

- 48. Stage-2 Consider the ray that gives maximum reduction

- 49. Stage-1 Consider the ray that gives maximum reduction

- 70. Extra

](https://image.slidesharecdn.com/designofgearbox-march221-230427162447-051d739b/85/Design-of-GEARBOX-26-320.jpg)