5 S and KAIZEN

- 2. What is 5S Scientific way of workplace management ● SORT (Seiri) ● Set IN ORDER (Seiton) ● SHINE (Seiso) ● STANDARDISE (Seiketsu) ● SUSTAIN (Shitsuke)

- 3. 1) Not needed at all 1) Needed but not now

- 4. 3) Needed but not here 4)Needed but not so much Quantity

- 5. Red tag Tactics:visual sorting. Sorting Out (Unwanted Parts) Red tag: A card containing detailed information Of unwanted things with a given time Limit for further action to be taken.

- 6. 5S Red tag

- 7. Guidelines for Sorting 1) Absolute : Parts (Jigs/Tooling) not required as the design as become obsolete(no longer used). 2) Defective :Parts can’t be used as it is . 3) Scrap 4) Not in place :Kept at wrong place. 5) Unnecessary: Extra/Not useful.

- 8. 2nd ‘S’ Set in order Place for everything and Everything in its place. Save search time

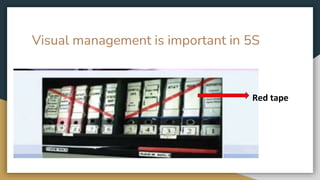

- 9. Visual management is important in 5S Red tape

- 10. How to implement Systematic arrangement 1) Analyze. 2) Decide which things will belong to where. 3) Decide how they should be put away. 4) Get everybody to follow rules through indexing ,labeling etc.

- 11. 2S (Systematic Arrangement) Benefits of ‘2S’ ● Faster retrieval of things,Result in Elimination of search time. ● Opportunity to correct the abnormalities faster as visibility improves by system itself. ● Space saving by systematic arrangements. ● Efficiency of work improves as things are available when they are actually needed.

- 12. Example Place for Everything and Everything in its place

- 13. 2nd S-Set in order helps in inventory management RYGB REDUCE INVENTORY BLUE -EXCESS GREEN -DESIGN YELLOW -RE-ORDER RED -CRITICAL

- 14. 3rd S- SHINE What do you understand by this ? AIRPORT

- 15. Set time for 5S Keep your organisation,Manufacturing,Office area Clean and shining. All the organizations dedicate 10 to 15 minutes of time for 5S. If there are lesser number of items then there is less to clean ● Cleaning with meaning ● Cleaning is inspection (shaking,leakage) (Front-Rear- Left-Right-Top-Bottom)

- 18. Standardization Making Sort,Set in order and Shine a Habit These are 1) Fix responsibilities for implementing and evaluating system. 2) Integrate these responsibility into daily routine work. 3) Check how well the system is working and sustaining itself.

- 19. 5th S- SUSTAIN Till now we have done 1S,2S,3S,4S, in 5S we have to sustain continuously Process of sustainment ● Daily monitoring . ● Improving ownership by allocating areas. ● Using red tag campaign. ● Communicating visually through fixed point photographs(Before and After photos) ● Structured communication. ● Continuous training of all team members. ● Periodic audits at all level. ● Motivation through recognition.(Rewards)

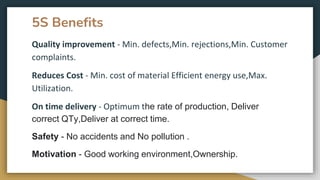

- 20. 5S Benefits Quality improvement - Min. defects,Min. rejections,Min. Customer complaints. Reduces Cost - Min. cost of material Efficient energy use,Max. Utilization. On time delivery - Optimum the rate of production, Deliver correct QTy,Deliver at correct time. Safety - No accidents and No pollution . Motivation - Good working environment,Ownership.

- 22. What is KAIZEN ? KAI means ‘CHANGE’ ZEN means ‘GOOD’ Kaizen is a term that refers to on-going or continuous improvement. Masaaki imai is known as developer of Kaizen.

- 23. Kaizen is small incremental changes made for improving productivity and minimizing waste. Everyone Everywhere Everyday

- 24. Golden Rules for kaizen 1) Don’t try to justify the past - challenge fixed ideas. 2) Be positive - think how things CAN be done ,not why they can’t be done. 3) Use data ,Not pet theories.(Take data based decision) 4) Use wisdom not money.(Think about creative ideas) 5) Work smarter than harder. 6) Set high standards. 7) Correct failures immediately - 70% now is better than 100 % never. 8) Lead by example. 9) A team is better than 1 expert - Involve people.(involve CFT team 10) Identify the root cause.

- 25. Areas of KAIZEN 1) Productivity improvement 2) Improvement in process quality. 3) Improvement in system. 4) improvement in Safety. 5) Reduction in accidents 6) Reduction in waste . 7) Reduction in Waste. 8) Reduction in duplication of work. 9) Reduction in unwanted activity 10) Energy saving. 11) Reduction in paper work. 12) Reduction in searching time. 13) Improvement in material traceability. 14) Improvement in 5S. 15) Easiness of work.

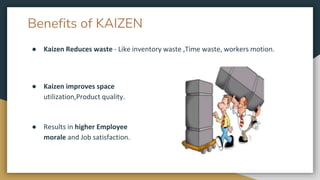

- 26. Benefits of KAIZEN ● Kaizen Reduces waste - Like inventory waste ,Time waste, workers motion. ● Results in higher Employee morale and Job satisfaction. ● Kaizen improves space utilization,Product quality.

- 27. KAIZEN EXAMPLES Before condition :When we used pallet for tools and material kit storage, fitter usually get strained and take more time to pick parts and tools from bins. After condition : Implemented racks to keep tools and material kit storage which reduces time and manpower strain. Kaizen theme : Implementation of tools and material kit storage rack for line production.

- 28. RESULTS 1. Increase in productivity. 2. Reduces man power strain. 3. Saves time.

- 29. THANK YOU