Atterberg Limits test

- 1. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 1 ATTERBERG LIMITS DEFINITION Atterberg a Swedish agricultural scientist (1911) developed a method to describe the consistency of fine-grained soils with varying moisture content, and he proposed five “limits” for fine-grained soils with varying water content. The water contents at which the soil changes from one state to another are known as consistency limits or Atterberg’s limits as shown in Fig.(1). The five limits include: 1. Liquid Limit (LL, WL): It is the water content at which the soil on a verge (border) to become viscous fluid. 2. Plastic Limit (PL, WP): It is the water content at which the soil just fails to behave plastically. 3. Shrinkage Limit (SL, WS): It is the water content at which the soil stops shrinking further and attains a constant volume. 4. Sticky Limit: It is that moisture content which soil crumbles just stick together. 5. Cohesion Limit: It is that moisture content which soil just sticks metal surface such as spatula blade. INTRODUCTION The liquid and plastic limits have been widely used all over the world. Primarily for soil identification and classification. A soil containing very high water content is offers no shearing resistance and can flow like liquids. As the water content is reduced the soil becomes stiffer and starts developing resistance to shear deformation. Hence, depending on the moisture content, the behavior of soil can be divided into four basic states- solid, semisolid, plastic, and liquid as shown in Fig. (1). The soil becomes plastic only when it has clay minerals. If the soils contains non- clay minerals, such as quartz, it would not become plastic whatever may be the fineness of soil. Strain Stress Strain Stress Strain Stress Stress-strain diagrams at various states

- 2. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 2 Solid state Semi-solid state Plastic state Liquid state Hard to stiff Workable sticky Slurry Figure (1): variation of consistency of fine-gained soils with water content. LIQUID AND PLASTIC LIMITS PURPOSES The liquid and plastic limit tests are two basic engineering experiments which characterizes the effect of water content on fine-grained soils that enable to:- Classify fine-grained soils (especially clay soil, Casagrande plasticity chart). Assess type of clay minerals composition. Assess engineering properties such as: (a) The liquid limit is sometimes used to estimate settlement in consolidation problems. (b) Both limits may be useful in predicting maximum density in compaction studies. Water content Shear strength (kpa) Phase Description Shrinkage Limit, SL Plastic Limit, PL Liquid Limit, LL Dry soil Vv Vs Min. V Water content Volume SL PL LL

- 3. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 3

- 4. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 4 1- LIQUID LIMIT TEST INTRODUCTION It has been established that liquid limit is dependent upon the percentage of clay in the No. 40 sieve fraction of the soil and the clay mineral present. The stronger surface charge and the thinner particle, the larger will be the amount of adsorbed water and, therefore, the higher will be the liquid limit. METHODS OF DETERMINING LIQUID LIMIT The following methods can be applied to determine the liquid limit: 1-CONE PENETROMETER METHOD 2-CASAGRANDE APPARATUS METHOD DEFINITION Liquid limit can be defined as that water content at which a pat of soil placed in brass cup and cut with a standard groove, and then dropped from height of 1cm will undergo a groove closer of 13 mm when dropped 25 times. APPARATUS The equipment for determination Liquid Limit includes: 1. Liquid limit device with Casagrande grooving tools as shown in Fig.(3). 2. Soil – mixture equipments [porcelain dish (mixing dish), spatula, plastic squeeze bottle]. 3. Balance sensitive to 0.01 g. 4. Container for determination of water content 5. Oven. 6. Sieve No. 40 (0.425 mm), pan and lid.

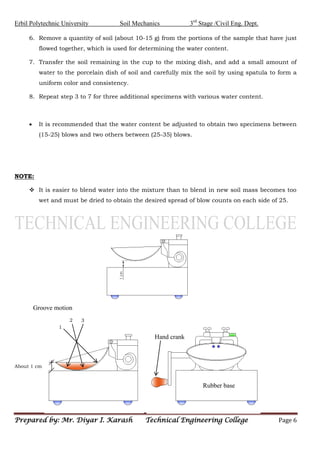

- 5. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 5 PROCEDURE 1. Calibrate the height of fall of the liquid limit device it will use for a fall exactly 1 cm (not over ± 0.1mm) as shown in figure (2.a). Use 1 cm calibration block for making the adjustment. 2. Take about 250 g of air dried soil passing No.40 (425 µm) sieve and place it in a porcelain mixing dish, add a small amount of water and carefully mix the soil by using spatula to form a uniform paste. 3. Place a portion of the paste in the brass cup of liquid limit device and level it off to a maximum depth of about 1 cm, then the surface of the paste should be smoothed off level and parallel to the base as shown in figure (2. a). 4. Draw the grooving tool from back to front through the sample along the symmetrical axis of the cup with a circular motion keeping the tool normal to the cup surface as shown in figure (2. a). 5. Turn the crank handle at a rate of 2 rps (revolution per second) so that the brass cup is lifted and dropped. Record the number of blows N required closing the groove along a distance of 13 mm as shown in figure (2. b).

- 6. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 6 6. Remove a quantity of soil (about 10-15 g) from the portions of the sample that have just flowed together, which is used for determining the water content. 7. Transfer the soil remaining in the cup to the mixing dish, and add a small amount of water to the porcelain dish of soil and carefully mix the soil by using spatula to form a uniform color and consistency. 8. Repeat step 3 to 7 for three additional specimens with various water content. It is recommended that the water content be adjusted to obtain two specimens between (15-25) blows and two others between (25-35) blows. NOTE: It is easier to blend water into the mixture than to blend in new soil mass becomes too wet and must be dried to obtain the desired spread of blow counts on each side of 25. 1 3 2 About 1 cm Groove motion Hand crank Rubber base

- 7. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 7 Mechanical Casagrande device (a) (b) (c) (b) (c) Figure (2): Casagrande Apparatus. Casagrande groove tool ASTM groove tool Divided soil after test Divided soil before test

- 8. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 8

- 9. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 9 CALCULATION i. Calculate the water content for each blow account as in the water content test. ii. Using semi-logarithmic chart plot the water content (w.c.] as [linear scale] against the corresponding number of blows (N) as [Log- scale]. iii. Draw the best straight line fitting the plotted points. This is called the “Flow Curve”. iv. Draw the ordinate representing 25 blows and where it intersects the flow curve draw the horizontal line to the water content axis. Read off this value of water content which is equal to [Liquid Limit] of the soil. v. Use equation L.L = w.c (N/25)0.121 And compute the liquid limit for each value of N and w.c. Tabulate in your "Discussion" and make a comparison with L.L from the semi-log plot. DISCUSSION 1- Why we use Atterberg limits to characterize fine-grained soil? 2- The liquid limit cannot be more than 100%. It is true or not? Explain. 3- Where shrinkage limit is useful to be known?

- 10. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 10 2- PLASTIC LIMIT TEST DEFINITION The plastic limit test is used to determine the lowest moisture content at which the soil behaves plastically. METHODS OF DETERMINING PLASTIC LIMIT The following methods can be applied to determine the plastic limit:- 1- CONE PENETROMETER METHOD 2- CONVENTION PLASTIC LIMIT TEST DEFINITION It is the popular test and is usually performed in conjunction with the liquid limit test. It is defined as the water content at which the soil begins to crumble when it can be rolled into a thread of approximately 3 mm in diameter. APPARATUS 1. Smooth glass surface for rolling the thread. 2. Container for determination of water content. 3. Balance sensitive to 0.01g. 4. Oven.

- 11. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 11 PROCEDURE 1. Take about 20g of plastic soil (set aside earlier during the preparation for liquid limit). 2. The soil is kneaded into several smaller samples, shaped into (1-2) cm diameter ball. The material should be plastic enough not to stick to the fingers when squeeze. 3. Roll the soil between fingers on a glass plate to form a uniform thread of 3 mm diameter (The rate of rolling should be a bout 80-90 strokes per minute, counting one stroke when the hand moves forward and backward to the starting point). 4. If the diameter of the thread becomes less than 3 mm without cracks, it shows that the water content is more than the plastic limit. Knead the soil to reduce the water content, and roll it again to thread. 5. Repeat the process of alternate rolling and kneading until the thread crumbles and the soil can no longer be rolled into thread. 6. Collect the pieces of the crumbled soil thread in a moisture content container, and determine its water content. 7. Repeat the procedure at least twice more with fresh samples of plastic soil each time.

- 12. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 12 CALCULATION i. Determine the plastic limit, which is taken as the average of three values. ii. Compute the plasticity index (PI): PI = LL – PL DISCUSSION What is the effect of Plastic Limit on the properties of soils? Explain ATTERBERG LIMITS DATA SHEET Name: Class : ……… Group No.: ………… 1- Liquid Limit Test No Can No. Weight of can (g) Weight of can + wet soil (g) Weight of can + dry soil (g) Weight of dry soil (g) Weight of Moisture (g) Water content % Blow count

- 13. Erbil Polytechnic University Soil Mechanics 3rd Stage /Civil Eng. Dept. Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 13 2- Plastic Limit Test No Can No. Weight of can (g) Weight of can + wet soil (g) Weight of can + dry soil (g) Weight of dry soil (g) Weight of Moisture (g) Water content % Plasticity Index = LL – PL =

![Erbil Polytechnic University Soil Mechanics 3rd

Stage /Civil Eng. Dept.

Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 4

1- LIQUID LIMIT TEST

INTRODUCTION

It has been established that liquid limit is dependent upon the percentage of clay in

the No. 40 sieve fraction of the soil and the clay mineral present.

The stronger surface charge and the thinner particle, the larger will be the amount of

adsorbed water and, therefore, the higher will be the liquid limit.

METHODS OF DETERMINING LIQUID LIMIT

The following methods can be applied to determine the liquid limit:

1-CONE PENETROMETER METHOD

2-CASAGRANDE APPARATUS METHOD

DEFINITION

Liquid limit can be defined as that water content at which a pat of soil placed in

brass cup and cut with a standard groove, and then dropped from height of 1cm will

undergo a groove closer of 13 mm when dropped 25 times.

APPARATUS

The equipment for determination Liquid Limit includes:

1. Liquid limit device with Casagrande grooving tools as shown in Fig.(3).

2. Soil – mixture equipments [porcelain dish (mixing dish), spatula, plastic squeeze

bottle].

3. Balance sensitive to 0.01 g.

4. Container for determination of water content

5. Oven.

6. Sieve No. 40 (0.425 mm), pan and lid.](https://image.slidesharecdn.com/6-atterberg-lemits-220903150430-4614f64b/85/Atterberg-Limits-test-4-320.jpg)

![Erbil Polytechnic University Soil Mechanics 3rd

Stage /Civil Eng. Dept.

Prepared by: Mr. Diyar I. Karash Technical Engineering College Page 9

CALCULATION

i. Calculate the water content for each blow account as in the water content test.

ii. Using semi-logarithmic chart plot the water content (w.c.] as [linear scale] against the

corresponding number of blows (N) as [Log- scale].

iii. Draw the best straight line fitting the plotted points. This is called the “Flow Curve”.

iv. Draw the ordinate representing 25 blows and where it intersects the flow curve draw the

horizontal line to the water content axis. Read off this value of water content which is

equal to [Liquid Limit] of the soil.

v. Use equation L.L = w.c (N/25)0.121

And compute the liquid limit for each value of N and w.c.

Tabulate in your "Discussion" and make a comparison with L.L from the semi-log plot.

DISCUSSION

1- Why we use Atterberg limits to characterize fine-grained soil?

2- The liquid limit cannot be more than 100%. It is true or not? Explain.

3- Where shrinkage limit is useful to be known?](https://image.slidesharecdn.com/6-atterberg-lemits-220903150430-4614f64b/85/Atterberg-Limits-test-9-320.jpg)