bevel_gear.ppt

- 4. Introduction Bevel gears are used to transmit power between two intersecting shafts. Bevel gears are commonly used in automotive differentials. The gears are formed by cutting teeth along the elements of frustum of a cone. When teeth formed on the cones are straight, the gears are known as straight bevel. When inclined, they are known as spiral or helical bevel. Bevel gears are intersecting at 90º. It is not interchangeable. The bevel gear teeth can be cast, milled or

- 5. TYPES OF BEVEL GEARS 1. Straight Bevel Gears : If the teeth on the bevel gears are parallel to the lines generating the pitch cones, then they are called straight bevel gears. 2. Spiral Bevel Gears: When the teeth of a bevel gear are inclined at an angle to the face of the bevel, they are known as spiral bevel gear.

- 6. Continue… 3. Zerol Bevel Gears: Spiral bevel gears with curved teeth but with a zero degree spiral angle are known as zerol bevel gears. 4. Hypoid gears: Hypoid gears are similar in appearance to spiral- bevel gears. They differ from spiral gears in that the axis of pinion is offset from the axis of

- 7. Classification based on pitch angle 1. Mitre gears. When equal bevel gears (having equal teeth and equal pitch angles) connect two shafts whose axes intersect at right angle, as shown in Fig. (a), then they are known as mitre gears. 2. Angular bevel gears. When the bevel gears connect two shafts whose axes intersect at an angle other than a right angle,

- 8. Continue… 3. Crown bevel gears. When the bevel gears connect two shafts whose axes intersect at an angle greater than a right angle and one of the bevel gears has a pitch angle of 90º, then it is known as a crown gear. 4. Internal bevel gears. When the teeth on the bevel gear are cut on the inside of the pitch cone, then they are known as internal bevel gears.

- 9. Terms used in Bevel gear

- 10. Continue…

- 11. Continue…

- 12. DESIGN PROCEDURE 1. Calculation of gear ratio (i): Calculation of gear ratio and pitch angle 2. Selection of materials: From PSGDB – 1.40 or 1.9, knowing the gear ratio i, choose the suitable combination of materials for pinion and wheel. 3. If not given, assume gear life (say 20,000 hrs) 4. Calculation of initial design torque (Mt): (Mt) = Mt ×K×Kd Initially assume K×Kd = 1.3 (Mt) = Transmitted torque = N P 2 60

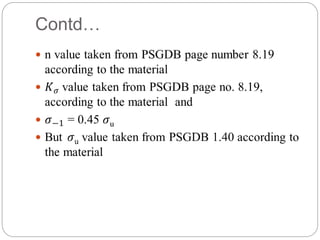

- 13. Contd…

- 14. Contd…

- 15.

- 16. Contd…

- 17. Contd… 7. Selection of number of teeth: Number of teeth on pinion, z1: Assume z1≥ 17, say 18. Number of teeth on gear, z2: z2 = i×z1 Virtual number of teeth : Zv1= Zv2= 1 1 cos z 2 2 cos z

- 18.

- 19. Contd…

- 20. Contd…

- 21. Contd…

- 22. Contd…

- 23. END