Casting (MIT 2.008x Lecture Slides)

- 2. 2.008x

- 3. 2.008x What is casting? Why is it a useful and important manufacturing process? How does it compare and contrast to processes we have studied already?

- 4. 2.008x à Casting is the process whereby a part is produced by solidification (of a molten metal) to take the shape of a mold. à Why casting? § Versatile to many types of metals § Potential for rapid and cost- effective production § Wide range of length scales (mm to m!) § Complex part geometries (including internal cavities) Engine block by 160SX (talk) - 160SX (talk)'s file, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=7899838 Brass rat by Pigsfly33 at English Wikipedia, CC BY 3.0, https://commons.wikimedia.org/w/index.php?curid=31980643,

- 5. 2.008x Casting and history Bessemer steel converter (enabled reduction of carbon content in Iron à steel), 1865 http://www.metmuseum.org/art/collection/search/257580 https://www.metmuseum.org/toah/works-of-art/28.77/ https://en.wikipedia.org/wiki/Bessemer_process#/media/File:Bessemer_converter.jpg (Public domain) Left: Bronze statue of a man, Hellenistic period, mid-2nd- 1st century B.C., H. 73 in (185.4 cm) Below: Herakles (Son of Zeus)

- 6. 2.008x The engine from the 1903 Wright Flyer had an aluminum crankcase. The Wrights contracted a local Dayton foundry, the Buckeye Iron and Brass Works, to cast the aluminum crankcase. Buckeye acquired their raw aluminum from the nearby Pittsburgh Reduction Company, renamed Alcoa in 1907, the world’s leading producer of aluminum. http://airandspace.si.edu/explore-and-learn/multimedia/detail.cfm?id=5817

- 7. 2.008x Global cast iron and steel production (millions of tons) World census of casting production: http://www.afsinc.org/multimedia/contentMCDP.cfm?ItemNumber=16433

- 8. 2.008x Agenda: Casting § Classification of casting methods § Sand casting § Die casting § Casting process physics: § Fluidity and cooling (with demonstration) § Solidification and microstructure § Investment casting § Comparison and conclusion

- 9. 2.008x Casting: 2.Classification of casting methods

- 10. 2.008x Classification of casting processes General sequence (all casting processes): § Pattern/mold making § Melt preparation § Mold filling § Cooling and solidification § Removal (‘breakout’) of the parts Kalpakjian and Schmid, Manufacturing Engineering and Technology

- 11. 2.008x Sand casting Groover, Fundamentals of Modern Manufacturing

- 12. 2.008x Important criteria for casting materials § Melting point and latent heat § Density versus temperature § Solubility with other elements § Diffusion rates § Reactivity (especially to oxygen) § Outgassing (vapor pressure)

- 13. 2.008x 3000° C 0° C 1000° C 2000° C Tungsten Carbide, WC, Silicon Carbide, SiC Molybdenum Alumina Al2O3 Platinum, Pt Titanium, Ti IronFE, Plain Carbon Steels, low alloy, stainless Nickel, Ni Nickel Allows Cubic Zirconia, ZrO2 Silicon, Si Copper, Cu, Bronze, Brass Aluminum Magnesium Zinc, Zn PTFE (Teflon) Tin, Sn HDPE Nylon Acetal Tungsten Carbide (WC) Silicon Carbide (SiC) Molybdenum Alumina (Al2O3;; 2072 oC) Platinum, Titanium (1668 oC) Iron and steels, Nickel, Silicon Copper, Bronze, Brass Aluminum (660 oC) Magnesium Zinc (420 oC) Tin

- 16. 2.008x Sand casting § Mold cavity is formed by packing sand around a pattern. § Interior geometry is defined by a core (disposable). § The pattern is removed and the cavity has the desired shape. § Sand for the mold is, for example, 90% sand, 3% water and 7% clay. Groover, Fundamentals of Modern Manufacturing

- 17. 2.008x Sand casting: key attributes § Low surface detail;; post-machining often required for high tolerances. § It’s the most common casting method (by total weight);; can make VERY large parts. § Because mold filling is gravity-driven (more to come later), must pay most careful attention to flow and shrinkage. § It’s a (relatively) labor-intensive process with long cycle time (why?) § 3D printing of molds and complex cores (though one- time use) can achieve previously impossible geometries.

- 18. 2.008x Voxeljet: 3D printed sand molds

- 20. 2.008x Die casting of aluminum wheel caps https://www.youtube.com/watch?v=N6ODcxK8_lg

- 21. 2.008x Die casting: attributes § Pressure: ~1-1000 MPa (how does this compare to IM?) § Cycle time: ~10’s of seconds for average components (tools/toys) § Parts have many similarities to IM, i.e., ejector pin marks, parting lines, gates/runners. § Dies are endangered by heat- induced cracking and corrosion (accelerated at high temperature) à need tool-grade steel or other special materials.

- 22. 2.008x Die casting: hot chamber method : cold chamber method Groover, Fundamentals of Modern Manufacturing

- 24. 2.008x Which processes? 20 for $15 (Amazon);; how is that possible?

- 25. 2.008x

- 26. 2.008x

- 28. 2.008x Ferrari F12 Berlinetta Wheelhouses: sand casting Frame components: High pressure die casting Top image: screenshot from http://auto.ferrari.com/en_US/sports-cars-models/car-range/f12-berlinetta/#design-360_exterior-5 Bottom image: http://auto.ferrari.com/en_EN/wp-content/uploads/sites/5/2013/07/architecture11.jpg

- 29. 2.008x Casting: 5. Fluidity and cooling

- 30. 2.008x Surface tension and viscosity Ux(H) = Ux Ux(y) Ux(0) = 0 h Ux y U ∂ ∂ = µτ Surface tension, σ Dynamic viscosity, μ Water (25 C) 0.07 N/m 1×10-3 kg/m-s [Pa-s] Honey (25 C) ~0.06 ~10 Liquid thermoplastic ~0.03 102-103 Molten aluminum (600 C) 0.90 3×10-3

- 31. 2.008x Fluid flow considerations for good casting Kalpakjian and Schmid, Manufacturing Engineering and Technology à If gravity-driven, pressure ‘head’ must be sufficient to overcome flow resistance to fully infiltrate mold cavity.

- 32. 2.008x Fluid flow considerations for good casting Kalpakjian and Schmid, Manufacturing Engineering and Technology à Flow must remain laminar to prevent air entrainment.avoid abrupt direction change. Trapped air leads to ‘dross’ (oxide flakes) à same as μ (viscosity)

- 33. 2.008x Testing ‘fluidity’ for casting Al with increasing content of reinforcing particles (SiC) Kalpakjian and Schmid, Manufacturing Engineering and Technology Behera et al. “Effect of Reinforcement Particles on the Fluidity and Solidification Behavior of the Stir Cast Aluminum Alloy Metal Matrix Composites”, American Journal of Materials Science, 2012;; 2(3): 53-61

- 34. 2.008x Demonstration: Cooling in sand casting vs. die casting (‘wood’s metal’)

- 35. 2.008x Solidification time Time [s] Temperature[°C] 20 Sand Casting 10 30 40 50 60 70 80 Die Casting 2000 400 600 800 1000 1200

- 36. 2.008x Chvorinov’s rule § V = volume of the casting § A = surface area of the casting § C = mold constant, depends on mold material and thermal properties of casting metal tsolidify = C ⋅ V A " # $ % & ' n Kalpakjian and Schmid, Manufacturing Engineering and Technology

- 37. 2.008x Solidification: sand cast versus die cast TM! SAND SOLID! LIQUID! T0! 0 tsolidify = C ⋅ V A " # $ % & ' 2 αsand ~0.01 cm2/s TM! METAL SOLID! LIQUID! 0 T0! αsteel ~0.1 cm2/s αaluminum ~0.9 cm2/s tsolidify = C ⋅ V A " # $ % & ' à Like injection molding, but mold has low thermal conductivity à Lower-bound (assumes constant mold temp)

- 38. 2.008x Casting: 6. Solidification and microstructure

- 39. 2.008x Solidification of pure metals § Metal releases latent heat as it freezes;; this accounts for up to ~50% of the energy transfer. § As a result, solid and liquid co-exist in the mold for a significant time. Kalpakjian and Schmid, Manufacturing Engineering and Technology 1/Temperature

- 40. 2.008x Formation of cast microstructure Columnar Shell zone (‘Chill’) grain y oy d k += σσ Hall-Petch model: smaller grains give higher strength σ0 = stress to start dislocation movement ky = material hardening constant d = grain size Grain size is inversely proportional to cooling rate. Shell has finer grains à thinner die cast parts are typically stronger Kalpakjian and Schmid, Manufacturing Engineering and Technology

- 41. 2.008x Alloys: dendrites and the ‘mushy zone’ Kalpakjian and Schmid, Manufacturing Engineering and Technology

- 43. 2.008xWhat causes the voids?

- 44. 2.008x Groover, Fundamentals of Modern Manufacturing Shrinkage!

- 45. 2.008x Kalpakjian and Schmid, Manufacturing Engineering and Technology Shrinkage!

- 46. 2.008x Casting: general defects § Misrun: solidification before complete filling § Cold shut: lack of fusion due to premature freezing § Cold shot: metal splatter entrapped in casting § Shrinkage cavity: depression in surface caused by solidification shrinkage (or hot tear = internal void) Groover, Fundamentals of Modern Manufacturing

- 48. 2.008x Investment (‘lost wax’) casting Image from http://www.custompartnet.com/wu/investment-casting

- 49. 2.008x An industrial investment casting process Screenshot from: https://www.youtube.com/watch?v=cptlGzWYFEk

- 50. 2.008x Investment casting: key points § Use of wax template enables excellent surface finish with little/no post-processing. § Ceramic shell enables casting of high melting point metals/alloys. § Metal typically poured in vacuum oven (reduces defects). § Very labor intensive à robots! Why investment casting? § Jewelry: complex geometries, high tolerances and fine features. § Jet engine parts: smooth surface finish, compatibility with high temperature alloys.

- 51. 2.008x

- 52. 2.008x Image from ATI Aerospace (http://www.slideshare.net/johnpsilk/ati-jet-engine);; see also http://www.geaviation.com/commercial/engines/genx/;; https://www.youtube.com/watch?v=S1ahHWXGx5Y

- 53. 2.008x Investment casting of turbine blades à Careful control of solidification can give single crystal blades (= very high strength and fatigue life under cyclic load at high temperature) Kalpakjian and Schmid, Manufacturing Engineering and Technology Image at right from http://www.chromalloy.com/files/newspressrelease/7ac07680-0adb-460b-8f27-f7d47745a4c4.pdf Great article: ‘The metal that brought you cheap flights’ http://www.bbc.com/news/magazine-32749262

- 54. 2.008x Casting: 9. Comparison and conclusion

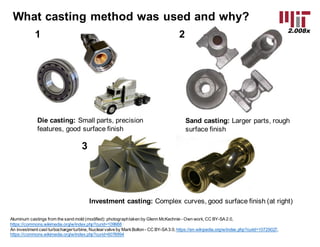

- 55. 2.008x What casting method was used and why? Die casting: Small parts, precision features, good surface finish Sand casting: Larger parts, rough surface finish Investment casting: Complex curves, good surface finish (at right) 1 2 3 Aluminum castings from the sand mold (modified): photograph taken by Glenn McKechnie - Own work, CC BY-SA 2.0, https://commons.wikimedia.org/w/index.php?curid=109988 An investment cast turbocharger turbine, Nuclear valve by Mark Bolton - CC BY-SA 3.0, https://en.wikipedia.org/w/index.php?curid=10729027, https://commons.wikimedia.org/w/index.php?curid=6078994

- 56. 2.008x Kalpakjian and Schmid, Manufacturing Engineering and Technology

- 57. 2.008x Why would I: à Choose die casting instead of injection molding? Need metal (strength, durability) instead of plastic à Choose investment casting instead of die casting? Higher melting point material, complex internal cavities, high precision à Choose machining instead of die casting? Higher tolerances;; better control of microstructure/properties (can use wrought/forged material)

- 58. 2.008x Reflection: the big four Sand Investment Die Rate Medium Low High Quality Low Medium High Cost Low Medium High Flexibility Low-Medium Medium Low

- 59. 2.008x Top image from: http://www.alcoa.com/global/en/innovation/alcoa_micromill.asp Article: Automotive News, September 14, 2015.

- 60. 2.008x Continuous casting of aluminum sheet (Alcoa ‘micromill’ process) https://www.youtube.com/watch?v=AH2QcNGM87w http://www.alcoa.com/global/en/innovation/alcoa_micromill.asp Furnace (molten Al) Continuously moving sheet

- 61. 2.008x References 1 Introduction Photo of Fire Hydrant by User: KeystonePetPlace on Pixabay. This work is in the public domain. Photo of Die Cast BMW Car by User: RockyHorror on Pixabay. This work is in the public domain. Photo of Cast Elbow Pipes by User: Dyanap on Pixabay. This work is in the public domain. Photo of Wheel Rims by User: Pashminu on Pixabay. This work is in the public domain. Photo of Jet Engine Turbine by User: Michael Schwarenberger on Pixabay. This work is in the public domain. Photo of Engine Block by 160SX (160SX (talk)'s file) on Wikimedia. (CC BY-SA) 3.0 Photo of Propeller Blade by User: seehund on Pixabay. This work is in the public domain. Photo of MIT Class Ring by User: Pigsfly33 on Wikimedia. (CC BY-SA) 3.0 Image of Herakles Statue © 2000–2016 The Metropolitan Museum of Art Image of Bronze Statue of a Man © 2000–2016 The Metropolitan Museum of Art

- 62. 2.008x References Image of Bessemer Converter Diagram from "Discoveries & Inventions of the Nineteenth Century" by R. Routledge, published 1900. This work is in the public domain. Image of Wright Brothers Engine from the National Air and Space Museum © The Smithsonian. Image of Wright Brothers Flyer from the National Air and Space Museum © The Smithsonian. Image of US and China Casting Production © American Foundry Society Image of Global Cast Iron and Steel Production © IKB Deutsche Industriebank AG 2 Classification Casting Process Classification: Figure II.3 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014). Sand Casting Mold Features: Figure 10.2 b) from "Fundamentals of Modern Manufacturing (4th Edition)" by Groover. © John Wiley & Sons Inc. (2010).

- 63. 2.008x References 3 Sand Casting Video of Sand Casting © 2006 - 2016 ChinaSavvy. All Rights Reserved. Sand Casting Mold Features: Figure 10.2 b) from "Fundamentals of Modern Manufacturing (4th Edition)" by Groover. © John Wiley & Sons Inc. (2010). 4 Die Casting Video of Die Casting © 2016 Die Castings China Hot Chamber Die Casting: Figure 11.13 1) and 2) from "Fundamentals of Modern Manufacturing (4th Edition)" by Groover. © John Wiley & Sons Inc. (2010). Cold Chamber Die Casting: Figure 11.14 1) and 2) from "Fundamentals of Modern Manufacturing (4th Edition)" by Groover. © John Wiley & Sons Inc. (2010). Image of Ferrari F12 Berlinetta by Ferrari S.p.A. Copyright 2016. All Rights Reserved. Image of Ferrari Aluminum Chassis by Ferrari S.p.A. Copyright 2016. All Rights Reserved.

- 64. 2.008x References 5 Fluidity / Cooling Gated Casting with Risers: Figure 10.8 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014). Spiral Test Casting: Figure 10.9 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014). Image of Changing Fluidity Index © 2012 Scientific & Academic Publishing Temperature Distribution at Mold Wall: Figure 10.10 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014). 6 Solidification Temperature Evolution over Time: Figure 10.1 a) from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014). Change in Specific Density: Figure 10.1 b) from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

- 65. 2.008x References Casting Cross-Section: Figure 10.2 b) from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014). Phase Diagram: Figure 10.4 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014). 7 Defects Shrinkage and Cavity Formation: Figure 10.8 2) and 3) from "Fundamentals of Modern Manufacturing (4th Edition)" by Groover. © John Wiley & Sons Inc. (2010). Shrinkage Allowances: Table 12.1 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014). Common Casting Defects: Figure 11.22 a) - d) from "Fundamentals of Modern Manufacturing (4th Edition)" by Groover. © John Wiley & Sons Inc. (2010).

- 66. 2.008x References 8 Investment Casting Image of Investment Casting Process © 2009 CustomPartNet Video of Investment Casting Process ©2011 Wisconsin Precision Casting Corporation Image of Jet Engine Materials © 2016 ATI. All Rights Reserved. Single Crystal Turbine Blade: Figure 11.25 b) and c) from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014). Image of Wax Patterns for Turbine Blades © SouthComm Publishing Company 2015. 9 Conclusion Photo of Threaded Faucet Connection by User: byrev on Pixabay. This work is in the public domain. Photo of Bearing by User: petitgiovanni on Pixabay. This work is in the public domain.

- 67. 2.008x References Photo of Toy Truck by User: da_hammer on Pixabay. This work is in the public domain. Photo of Sand Cast Parts by User: Graibeard on Wikimedia. (CC BY-SA) 2.0 Photo of Investment Cast Turbocharger Turbine Blades by MarkBolton at English Wikipedia. (CC BY-SA) 3.0 Photo of Valve for Nuclear Power Station by MarkBolton at English Wikipedia. (CC BY-SA) 3.0 Compatison of Casting Methods: Table 11.2 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014). Image of Micromill © 2016 Alcoa Inc. Article on F150 Production © Crain Communications, Inc. Image of Ford F150 Chassis © 2014 Sustainable Enterprises Media, Inc. Image of Ford F150 © 2016 Ford Motor Company Image of Micromill Plant © 2016 Alcoa Inc. Video of Micromilling © 2016 Alcoa Inc.

![2.008x

Surface tension and viscosity

Ux(H) = Ux

Ux(y)

Ux(0) = 0

h

Ux

y

U

∂

∂

= µτ

Surface tension, σ Dynamic viscosity, μ

Water (25 C) 0.07 N/m 1×10-3 kg/m-s [Pa-s]

Honey (25 C) ~0.06 ~10

Liquid thermoplastic ~0.03 102-103

Molten aluminum (600 C) 0.90 3×10-3](https://image.slidesharecdn.com/castingslides-161115034827/85/Casting-MIT-2-008x-Lecture-Slides-30-320.jpg)

![2.008x

Solidification time

Time [s]

Temperature[°C] 20

Sand Casting

10

30

40

50

60

70

80

Die Casting

2000 400 600 800 1000 1200](https://image.slidesharecdn.com/castingslides-161115034827/85/Casting-MIT-2-008x-Lecture-Slides-35-320.jpg)