Cranes2.ppt

- 1. OSHA Office of Training & Education 1 Cranes

- 2. OSHA Office of Training & Education 2 Major Causes of Crane Accidents • Contact with power lines • Overturns • Falls • Mechanical failures

- 3. OSHA Office of Training & Education 3 •Instability – unsecured load, load capacity exceeded, or ground not level or too soft •Lack of communication - the point of operation is a distance from the crane operator or not in full view of the operator •Lack of training •Inadequate maintenance or inspection How Do Accidents Occur?

- 4. OSHA Office of Training & Education 4 Who is at Risk • Operators • Persons at Crane Site

- 5. OSHA Office of Training & Education 5 Definitions • Crane – Consists of a rotating structure for lifting and lowering horizontally on rubber tires or crawler treads • Hoist - Used to lift and lower load. • Boom – An inclined spar, strut, or other long member supporting the hoisting tackle • Boom stops – A device used to limit the angle of the boom at its highest position • Brake – To slow or stop motion by friction or power • Block – Sheaves or grooved pulleys in a frame with hook, eye and strap • Jib – Extension attached to the boom point to provide added boom length for lifting specified loads.

- 6. OSHA Office of Training & Education 6 Crane Parts

- 7. OSHA Office of Training & Education 7 Types of Cranes • Mobile • Hydraulic • Overhead • Gantry • Tower

- 8. OSHA Office of Training & Education 8 • Improper load rating • Excessive speeds • No hand signals • Inadequate inspection and maintenance • Unguarded parts • Unguarded swing radius Crane Hazards • Working too close to power lines • Improper exhaust system • Shattered windows • No steps/guardrails walkways • No boom angle indicator • Not using outriggers

- 9. OSHA Office of Training & Education 9 Planning Before Start-Up • Level the crane and ensure support surface is firm and able to support the load • Contact power line owners and determine precautions. Know the location and voltage of overhead power lines. • Know the basic crane capacities, limitations, and job site restrictions, such as the location of power lines, unstable soil, or high winds. • Make other personnel aware of hoisting activities. • Barricade areas within swing radius. • Ensure proper maintenance and inspections. • Determine safe areas to store materials and place machinery.

- 10. OSHA Office of Training & Education 10 Competent Person The competent person must inspect all machinery and equipment prior to each use, and during use, to make sure it is in safe operating condition. If it needs fixing, take it out of service and don’t use it until it is fixed Broken Track

- 11. OSHA Office of Training & Education 11 Load Capacity - Speed - Warnings • Make sure the crane operator can see the: Rated Load Capacities Operating Speeds Special Hazard Warning or Instruction Load Rating Chart

- 12. OSHA Office of Training & Education 12 Know the Weight of the Load • Refer to shipping ticket or other documentation • Ensure lift calculations are correct • Ensure load is within load chart rating for boom length and load radius of crane • Crane is rated by the maximum weight it will lift at a minimum radius and minimum boom length – the further from its centerpoint, the less it will lift

- 13. OSHA Office of Training & Education 13 Load Limiting Factors • Not level • Wind • Side loads • On its wheels • Lifting over the side • Use of extensions, jibs and other attachments • Limits of wire rope, slings and lifting devices

- 14. OSHA Office of Training & Education 14 Mobile Cranes – Lifting Principles • Center of Gravity • Leverage • Stability • Structural Integrity

- 15. OSHA Office of Training & Education 15 Load Example – 30 ton crane • Will lift 60,000 pounds at 10 feet from the center pin of the crane • Based on level surface, no wind, and outriggers fully extended • At 25 feet from the center pin with an 80 foot boom, the capacity is only 14,950 pounds • At 74 feet from the center pin, the capacity is only 4,800 pounds

- 16. OSHA Office of Training & Education 16 Improper Load Improper loads or speeds can result in the tipping of the crane

- 17. OSHA Office of Training & Education 17 Improper Load

- 18. OSHA Office of Training & Education 18 Improper Load

- 19. OSHA Office of Training & Education 19 Stay clear from power lines at least 10 feet Power Lines

- 20. OSHA Office of Training & Education 20 An illustration of the signals must be posted at the job site Hand Signals

- 21. OSHA Office of Training & Education 21 Guard Moving Parts Unguarded Chain Drive Guard moving parts such as gears or belts

- 22. OSHA Office of Training & Education 22 Swing Radius Stay out of the swing radius of the crane – Make sure there are barrier guards showing swing radius

- 23. OSHA Office of Training & Education 23 Operator Visibility Broken Window Make sure broken windows or other obstructions do not prevent the operator from seeing

- 24. OSHA Office of Training & Education 24 Ladders Ladder Use ladders to get to the upper portion of the cab

- 25. OSHA Office of Training & Education 25 Guardrails Runways and steps need to have guardrails, handholds and slip resistant surfaces

- 26. OSHA Office of Training & Education 26 Suspended Loads Don’t stand under suspended loads

- 27. OSHA Office of Training & Education 27 Boom Angle Indicator A boom angle indicator must be on the crane

- 28. OSHA Office of Training & Education 28 Supporting Surface Cranes must be on a firm supporting surface and level within 1 percent

- 29. OSHA Office of Training & Education 29 The grooves must be smooth and free from surface defects which could cause rope damage Sheaves

- 30. OSHA Office of Training & Education 30 Rigging Equipment Slings Types of slings include alloy steel chain, wire rope, metal mesh, natural or synthetic fiber rope, and synthetic web. Chain Wire rope Metal mesh Synthetic

- 31. OSHA Office of Training & Education 31 Annual Inspections Inspection of the hoisting machinery must be made by a competent person The employer must maintain a record of these inspections Crane wasn’t inspected and tipped over

- 32. OSHA Office of Training & Education 32 What to Inspect • Correct air pressure and no leaks • Tires properly inflated • Clearance for tail swing • Wire rope wear • Physical damage to crane • Loose or missing hardware, nuts, or bolts • Fluid leaks

- 33. OSHA Office of Training & Education 33 Remove From Service Immediately remove damaged or defective slings from service

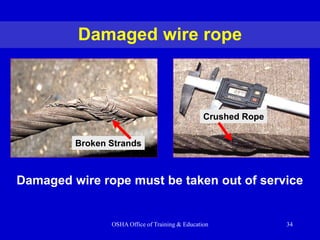

- 34. OSHA Office of Training & Education 34 Damaged wire rope Broken Strands Damaged wire rope must be taken out of service Crushed Rope

- 35. OSHA Office of Training & Education 35 Worn Part

- 36. OSHA Office of Training & Education 36 Conduct regular inspections of tires for excessive wear or damage Tire Inspections

- 37. OSHA Office of Training & Education 37 Training • Operators: must qualify on specific crane type Must include on-the-job training • Supervisor / competent person

- 38. OSHA Office of Training & Education 38 Summary • An unstable load, lack of communication, lack of training, and inadequate maintenance or inspection are major contributors to crane accidents. • Operators or others working in the area can be victims to “struck by" and "caught in" injuries. • Contact with power lines causes many accidents. • A competent person must inspect a crane regularly to insure it is in proper order. • Planning and training reduces accidents.