Drying

- 1. DRYING Dr. Basavaraj K. NanjwadeM. Pharm., Ph. D Department of Pharmaceutics Faculty of Pharmacy Omer Al-Mukhtar University Tobruk, Libya. E-mail: nanjwadebk@gmail.com 2014/03/11 1 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 2. CONTENTS • Definition of drying • Importance of drying • Difference between drying and evaporation • Equipments • References 2014/03/11 2 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 3. Drying • Drying is commonly the last stage in a manufacture process. • Drying is the final removal of water from material (usually by heat) • Non-thermal drying 1- As Squeezing wetted sponge 2- Adsorption by desiccant (desiccation) 3- Extraction. 2014/03/11 3 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 4. Importance of drying • In pharmaceutical technology, drying is carried out for one or more of the following reasons: 1. To avoid or eliminate moisture which may lead to corrosion and decrease the product or drug stability. 2. To improve or keep the good properties of a material, e.g. Flowability, compressibility. 3. To reduce the cost of transportation of large volume materials ( liquids). 4. To make the material easy or more suitable for handling. 5. Preservative. 6. The final step in Evaporation, Filtration, Crystallization. 2014/03/11 4 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 5. Difference between drying and evaporationSl. No. Drying Evaporation 1. In drying processes, the main operation usually carried out on solid materials, e.g. powders, or products In evaporation processes, the main operation usually carried out on liquid materials, e.g. solution, or products 2. Drying in most of the cases means the removal of relatively small amounts of water from solids Evaporation include the removal of large amounts of water from solutions. 3. In most cases, drying involves the removal of water at temperatures below its boiling point Whereas evaporation means the removal of water by boiling a solution. 4. In drying , water is usually removed by circulating air over the material in order to carry away the water vapour While in evaporation , water is removed from the material as pure water vapour mixed with other gases. 2014/03/11 5 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 6. Equipments 1. Drum dryer (Film drying) 2. Spray dryer 3. Freeze Dryer 4. Tray drier 5. Fluidized Bed Dryer 6. Vacuum Dryer 2014/03/11 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya. 6

- 7. Drum Dryer (Film Drying) 2014/03/11 7 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 8. Drum Dryer (Film Drying) • It consists of a drum of about 0.75-1.5 m in diameter and 2-4 m in length, heated internally, usually by steam and rotated on its longitudinal axis. • Operation: The liquid is applied to the surface and spread to a film, this may be done in various ways, but the simplest method is that shown in the diagram, where the drum dips into a feed pan. Drying rate is controlled by using a suitable speed of rotation and the drum temperature. The product is scraped from the surface of the drum by means of a doctor knife. 2014/03/11 8 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

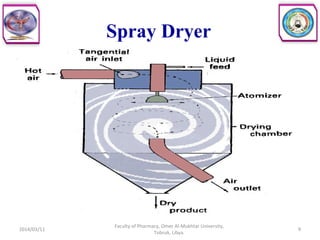

- 9. Spray Dryer 2014/03/11 9 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 10. Spray Dryer • The spray dryer provides a large surface area for heat and mass transfer by atomizing the liquid to small droplets. • These are sprayed into a stream of hot air, so that each droplet dries to a solid particle. • The drying chamber resembles the cyclone ensuring good circulation of air, to facilitate heat and mass transfer, and that dried particles are separated by the centrifugal action. • Spray dryer can be operated efficiently at various feed rates. 2014/03/11 10 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 11. Freeze Dryer 2014/03/11 11 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 12. Freeze Dryer • Freeze drying is a process used to dry extremely heat- sensitive materials. It allows the drying , without excessive damage, of proteins, blood products and even microorganisms, which retain a small but significant viability. • In this process the initial liquid solution or suspension is frozen, the pressure above the frozen state is reduced and the water removed by sublimation. • Thus a liquid-to-vapour transition takes place, but here three states of matter involved: liquid to solid, then solid to vapour. 2014/03/11 12 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 13. Tray drier 2014/03/11 13 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 14. Tray drier • Air flows in direction of the arrows over each shelf in turn. • The wet material is spread on shallow trays resting on the shelves. • Electrical elements or steam-heated pipes are positioned as shown, so that the air is periodically reheated after it has cooled by passage over the wet material on one shelf before it passes on the next. 2014/03/11 14 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

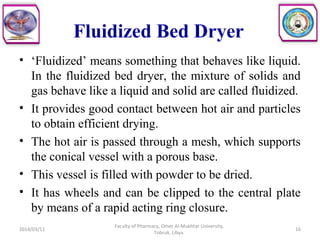

- 15. Fluidized Bed Dryer 2014/03/11 15 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 16. Fluidized Bed Dryer • ‘Fluidized’ means something that behaves like liquid. In the fluidized bed dryer, the mixture of solids and gas behave like a liquid and solid are called fluidized. • It provides good contact between hot air and particles to obtain efficient drying. • The hot air is passed through a mesh, which supports the conical vessel with a porous base. • This vessel is filled with powder to be dried. • It has wheels and can be clipped to the central plate by means of a rapid acting ring closure. 2014/03/11 16 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 17. Vacuum Dryer 2014/03/11 17 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya. Steam or Water Jacket Condenser Connection to Vaccum Pump Condensate Receiver

- 18. Vacuum Dryer • This equipment is a good example of conduction drier. The vacuum oven consists of a jacketed vessel to withstand vacuum within the oven. • There are supports for the shelves giving a larger area for conduction heat transfer. The oven can be closed by a door. • The oven is connected through a condenser and liquid receiver to a vacuum pump. • Operating pressure can be as low as 0.03-0.03 bar, at which pressures water boils at 25-35 0 C. 2014/03/11 18 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya.

- 19. 2014/03/11 19 Faculty of Pharmacy, Omer Al-Mukhtar University, Tobruk, Libya. THANK YOUE-mail: nanjwadebk@gmail.com