Electrical Safety

- 1. Electrical Safety Equipment in Hazardous Areas Dave Nicewicz ADM Grain Co.

- 2. Topics to be Presented Classification Rules for Hazardous Areas How to Determine which Areas Meet Category Specifications Motors, Equipment, Devices to be used Maintain the Integrity of Area Requirements

- 3. Why is this Important? Prevent Electrical Hazards from Starting Fires and Explosions These can be Devastating Loss of Life Loss of Facilities Preventable by Following Guidelines Established Cost of Installing Wrong Type of New & Replacement Electrical Equipment

- 6. National Electric Code NFPA 70 Technical Information Provided “…to ensure the practical safeguarding of persons and property from the hazards arising from the use of electricity” NEC Preface Revised every 3 years Article 500 – Classification of Hazardous Areas Technical, can be confusing

- 7. “CLASS” Designation Primary Designation Three Classes Listed with Roman Numeral Nomenclature

- 8. “Class I” Hazardous Areas Flammable Gasses and Vapors Present During Normal Operation Possibly Present During Breakdown Conditions Long List of Gasses in NEC Example Fuels – Gasoline & Propane Example Process Chemicals – Hexane & Ammonia

- 9. “Class II” Hazardous Areas Combustible Dust Present During Normal Operations Could be Present During a Breakdown Example – Corn, Wheat, Soybean Dust Example – Flour Example – Dust from Wood or Plastic

- 10. “Class III” Hazardous Areas Easily Ignitable Fibers and Materials that Produce Flammable Flyings Present Where Materials are Handled, Manufactured or Used Example – Where Raw Cotton is Handled and Stored

- 11. Review Class I – Flammable Gasses & Vapors Class II – Combustible Dust Class III – Easily Ignitable Fibers These are the Three Primary Designations of Hazardous Areas

- 12. “DIVISION” Designation Secondary Designation Two Divisions Listed with Numeric Nomenclature

- 13. “Class I, Division 1” Ignitable Concentrations of Flammable Gasses & Vapors Exist During Normal Operations Ignitable Concentrations are Present Frequently Because of Repair, Maintenance, or Leakage Ignitable Concentrations Present During a Breakdown or Faulty Operation Example – Where Process is being Conducted with Hexane or Ammonia Example -Where Delivery Trucks are Unloaded

- 15. “Class II, Division 1” Combustible Dust Present in the Air During Normal Operating Conditions in Quantities Sufficient to Produce Explosive or Ignitable Mixtures Where Mechanical Failure or Abnormal Operations Might Produce Explosive or Ignitable Mixtures Contains Dust of Electrically Conductive Nature Example -Areas by Open Conveyors or Open Top Bins Example - Dust of Magnesium or Aluminum

- 16. Picture of Class II area

- 18. “Class I, Division 2” Where Flammable Gasses and Vapors are Handled but Normally Enclosed Would only be Present During Accidental Rupture or Breakdown Concentrations are Present but Below Ignitable Concentrations Because of Positive Ventilation Example – Areas or Rooms Adjacent to Class I, Division 1 Areas

- 19. Rooms Maintained with Positive Pressure Mechanical Ventilation Air Source is from Clean Air Effective Safeguards to Prevent Ventilation Failure Examples – MCC and Control Rooms Can Contain Equipment Not Approved for Hazardous Locations

- 20. “Class II, Division 2” Where Combustible Dust Present During Infrequent Malfunction but Not Normally Present in Ignitable Concentrations Areas Near Electrical Equipment Where Abnormal Operations May Cause High Heat Example – Areas Around Closed Conveyors Example – Areas Around Enclosed Process Equipment

- 21. “GROUP” Designation Secondary Designation Several Groups Listed with Alphabetic Nomenclature Materials are Grouped by Ones with Similar Characteristics Each Group has Specific Rules that Apply

- 22. “Class I, Group …” Class I has 4 groups Designated A, B, C & D Various Flammable Gasses & Vapors Arranged by Similar Characteristics Ignition Temperatures Safe Clearance Distances

- 23. “Class II, Group …” Class II has 3 groups Designated E, F & G Various Combustible Dusts Arranged by Similar Characteristics Ignition Temperatures Blanketing Effect of Dust Layers How Tight Equipment Seals Need to be to Prevent Dust from Entering the Equipment

- 24. “Class II, Group G” Combustible Dusts Such as Flour, Grain, Wood, Plastic, and Chemicals not contained in Groups E or F Primary Concern of Grain Elevators Electric Motors Have Internal Temperature Controls Called “P” Leads The “P” Leads Have to be Properly Connected for the Motor to be Approved Shuts Down Motor if Gets Too Hot

- 25. Review Class I – Flammable Gasses & Vapors Class II – Combustible Dust Class III – Easily Ignitable Fibers Division 1 – Hazard is Normally Present Division 2 – Hazard Not Normally Present but Could Be During Abnormal Situations Class I Groups – A, B, C & D Class II Groups – E, F & G Group G Includes Grain Dust

- 26. Designating a Hazardous Area Who Can Legally Designate Areas? Hierarchy 1. Electrical Engineer Who Designed Plant 2. Owner is Responsible to Get Designations for Older Plants Hire an Electrical Engineer Ask Local Electrical Authority – City or County Inspector Ask for Insurance Company to Provide Professional 3. Whole Plant is Considered Division 1

- 27. Designating a Hazardous Area NFPA 70E Specific Requirement “Classification of areas and selection of equipment and wiring methods shall be under the supervision of a qualified Registered Professional Engineer.” Could be Ramifications if Injury or Facility Damage Resulted from Using Improper Equipment and No Evidence of Consulting the Proper Authority Most Cost Effective to Designate Areas

- 28. Importance of Area Designations Can Select Equipment Approved for an Area Motors, Switches, Conduit, Junction Boxes, etc Old Motor ID Tag Not Present or Legible So It Is Not Approved for Hazardous Location Why? Motor Rebuilt for Non-Hazardous Area Motor Shop Not an “Approved UL Shop” Hint – Always Use “UL Approved Shop” Wrong Motor was Installed Previously U L

- 29. Importance of Area Designations Cost Considerations Potential Problems Using Unapproved Equipment Costly to Install Rated Equipment in Non-Hazardous Areas Example 25 HP Motor Standard Type - $850 Approved for Hazardous Locations - $1,100 29% Difference

- 30. Label Hazardous Areas Idea - Post Normal Entrances with Sign Informs Electrical Contractor of Area They are Working In Easy to Know Equipment Requirements Informs Employees Where Electrical Devices Can and Cannot Be Used Consider Signs as a Good Investment

- 31. Example of a Notice Sign NOTICE Electrical Safety Designation – Classified Area Entering “Class II, Division 1” Area Special Safety Requirements Apply in this Area

- 32. Replacing Equipment Difficult Unless Area Classification is Known New Equipment has Approval on Nameplate Approved for Hazardous Locations Approved for Class I, Division 1 Areas for example Look at Equipment in Place Once Area Classification is Known Do Not Just Replace with Same Nameplate of Equipment Being Removed

- 33. Replacing Equipment Possible Problems from Past Operated by Someone on a Tight Budget Operated by Someone Who Did Not Know Classifications Replaced by Someone Who Was Confused About Area Boundaries or Requirements Don’t Let Someone Else’s Problem Affect the Safety of your Plant Check All Nameplates in Hazardous Areas

- 35. Description of Label on Switch Approved for Hazardous Locations Class I Groups C, D Class II Groups E, F & G Class III U L

- 38. Inspecting Control Rooms Control Rooms and MCCs Adjacent to Hazardous Areas Is Positive Pressure Ventilation Installed? Is It Working Properly? Keeps Dust Out? Safeguards to Ensure Ventilation System is On When Any Equipment is Running? Protection From It Shutting Down?

- 39. Inspecting Control Rooms Required by NFPA Standard NFPA 496 – “The Standard for Purged and Pressurized Enclosures for Electrical Equipment” Electrical Equipment Not Approved for Hazardous Locations Can Be Used Here Household Outlets, Grain Inspection Equipment, Heaters, Radios, Etc. Only if Pressurization is Utilized

- 40. Adjacent Control Rooms & MCCs

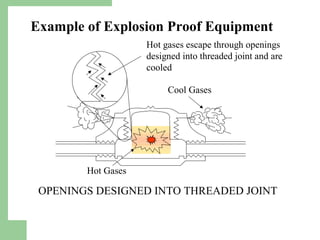

- 41. Equipment Selection “Explosion Proof” Used in “Class I, Division 1” Areas Designed to withstand an explosion within the enclosure and prevent any ignition source getting to the surrounding flammable gasses or vapors it was designed to be installed in. Ignition Source will Not Escape the Enclosure

- 46. Equipment Selection “Dust Ignition Proof” Used in “Class II, Division 1” Areas Designed to not let arcs, sparks or heat inside the enclosure to cause ignition to the dust in the environment it was installed in. Does not let dust get inside the enclosure. Sealed with a electrical sealing putty, or Pressurized Does not have to be explosion proof

- 47. Equipment Selection NEMA – National Electrical Manufacturer’s Association Rating System to Categorize Equipment Types 1 – 13 Application Environmental Conditions for Use Approved when Completely & Properly Installed

- 48. Equipment Selection Hazardous Locations NEMA 7 – 10 NEMA 7 – Indoor Use – Class I, Division 1, Groups A, B, C or D NEMA 8 – Indoor or Outdoor Use – Class I, Div. 1, Groups A, B, C or D NEMA 9 – Indoor Use – Class II, Division 1, Groups E, F or G & Class III, Division 1 NEMA 10 – Approved for Mine Safety Requirements

- 49. Equipment Selection “Explosion Proof” NEMA 7 & 8 “Dust Ignition Proof” NEMA 9 Use Differences Price Differences Some Equipment Rated for More Than One Type

- 50. Equipment Selection Example – Price Quote from Supplier 2 Enclosures of Similar Size “Explosion Proof” Box – NEMA 7&9 – $2,100 “Dust Ignition Proof” Box – NEMA 9 – $980 114% Price Difference Need to Know Area Requirements Need to Know Equipment Differences Can be Costly &/or Dangerous

- 51. Equipment Selection Outside Uses? NEMA 8 for “Explosion Proof” Combined NEMA 7 & 4 (watertight & dusttight) or maybe only NEMA 4 Needed Change an Area Classification Example – Enclose an Outside Pit Area Make Certain Equipment Requirements vs. Equipment in Place

- 52. Equipment Selection Class II, Division 2 “Explosion Proof” & “Dust Ignition Proof” Allowed “Dust tight” Can Be Used in Certain Applications Less Expensive & Equally Safe

- 53. Equipment Selection Group Rating Some Equipment Rated for Heat Release Know the Chemicals or Dusts Present Consider Light Fixtures Maximum Light Bulb Size Specified Larger Bulb – More Heat Check Wattage Rating on Fixture in Hazardous Areas – Do Not Depend on Removed Bulb Being Correct

- 54. Equipment Selection Class II Areas – Heat is an Important Factor No Floodlights No Quartz Lights Look for These During Inspections

- 55. Equipment Selection Summary Have Plant Area Designations Determined Take Steps to Make Designations Known Signs Documentation for Contractors Require Electrical Contractor to Install Only Approved Equipment Safety & Profitability are Factors

- 56. Accessories Considerations for Portable Equipment Insert & Twist Plug Electric Power Tools Radios – Communications or Music Flashlights Cell Phones, Digital Cameras, Pagers Grain & Bearing Temperature Sensors Grain Level Sensors & Measuring Devices

- 57. Insert & Twist Plugs “Pigtail” Used to Connect Unapproved Electrical Equipment into a Plug Connection Rated for Hazardous Areas Only Approved with the Use of a Permit No Dust Present, No Grain Being Moved, No Housekeeping in Progress

- 58. Insert & Twist Plugs Electrician Makes a Short Adapter Called a “Pigtail” Potential Hazards Spark if Tool Plug Pulls Apart from “Pigtail” Spark When Tool is Energized or De-energized Untrained Employees – Unaware of Hazards

- 59. Insert & Twist Plug

- 60. Insert & Twist Plugs Solutions to Problems: Use only Tools & Lights Approved for Hazardous Areas Equip Portable Light or other Tool with Plug End to fit Rated Outlet Keep “Pigtails” Locked in Supervisors Control Use Permit System Train Employees of Potential Hazards & How to Use a Permit System

- 61. Electric Power Tools Sparks from an Open Motor Possible Electric Drills, Saws, Shop Vac, Electric Radio Keep Out of Plant – or Use Under Permit Conditions

- 62. Flashlight

- 64. Intrinsically Safe Device Approved for Hazardous Areas Low Energy Device with Protective Circuitry Hermetically Sealed (i.e. Soldering) Circuit Design so No Arcs or Sparks Generated Has to be Approved by a Third Party Factory Mutual FM Underwriter’s Laboratory UL

- 65. Intrinsically Safe Devices to Consider Using Intrinsically Safe Portable Work Radios Cell Phones Digital Cameras Pagers Grain & Bearing Temperature Monitoring Systems Measuring Devices Grain Level Sensors

- 66. Intrinsically Safe Check the Label of All of These Types of Equipment before Allowing into the Plant Post Signs in Office and at Plant Restrict Use of Unapproved Equipment Utilize Low Voltage Device Permits Warns User of Dangers Reminds User to Keep Device Turned Off until Informed that it is OK to Use No Dust Present & No Hazardous Conditions

- 67. Example of Sign to Warn Visitors WARNING Hazardous Areas Present in Plant Low Voltage Devices Must NOT Be Taken Into Plant Without Supervisor’s Approval Items Such As Cell Phones, Pagers, Cameras, Flashlights

- 68. Example of Low Voltage Permit Low Voltage Portable Device Permit Device____________________________ Date______________________________ Time Started_____________________ This Permit Expires _______________ Area(s) in which device will be used____________________________________________ Device Operator(s)__________________________________________________________ I am familiar with the operation of this device and I will not use this device in the presence of suspended dust. Device Operator________________________ (Signature) I have personally examined the device and found it to be in good working order. In addition, I have verified that the operator is familiar with operating the device. Permit Authorized by _____________________________ (Signature) **For the purpose of this permit, a low voltage device is less than 16 volts and battery operated.

- 69. Maintain Area Integrity How Can We Make Sure Our Plants are Safe? Can Everyone Identify Hazardous Areas of the Plant? Are Proper Motors and other Electrical Equipment Installed and Installed Correctly? Are Proper Maintenance Procedures in Place Such as Light Bulb Size? Are Proper Work Procedures are Followed in Hazardous Areas? Is Portable Equipment Used in the Plant Approved for Use in Hazardous Locations?

- 70. Maintain Area Integrity Use a Five Point Plan Labeling Pressurized Rooms & Enclosures Periodic Inspections Reputable Electrical Contractor Restrict Use – Permitting Procedures

- 71. Labeling Determine Hazardous Areas Use the Proper Authority Make Sure Everyone Affected Know Areas & Understand Requirements Document Authoritative Determination Signs – Boundaries, Requirements Train Employees

- 72. Pressurized Rooms & Enclosures Pressurized MCC & Control Rooms Adjacent to Hazardous Areas Install Safeguards to Make Sure Fan Operating Supervisor Lock/Secure Fan Stop/Start Control Tie Fan Operation to Equipment Operation Supply Air From Clean Source 60 Cubic Feet per Minute Through Any Opening with all Openings Open

- 73. Periodic Inspections Safety Inspections Important for Compliance Check Every Motor, Box, Outlet, Switch Initially after Hazardous Locations Determined Inspect After Construction and Maintenance Inspect for a Closed Electrical System Covers Secure on Junction Boxes No Breaks in Conduit (i.e. Flex) All Signs Posted

- 74. Periodic Inspections Observe Daily Operations & Talk to Employees Aware of Hazardous Areas Proper Use & Storage of Pigtail Outlets Portable Lighting Use of Low Voltage Devices Use of Hot Work & Low Voltage Permits

- 75. Electrical Contractor Knowledgeable of Hazardous Locations for Specialized Industries (i.e. Grain Elevators) Willing to Use Required PPE Reputation for Quality Work – Willing to Maintain Integrity of Hazardous Areas Plant Operators Performing Electrical Maintenance are Knowledgeable Electrician Checks Up on Plant Maintenance Periodically

- 76. Permitting to Restrict Use Establish Strict Rules for Hazardous Areas Train Employees Use Hot Work & Low Voltage Permits as Necessary Post Signs by Office and Plant Entrances

- 77. Conclusion Many Aspects of Electrical Safety to Consider Need to Deal with All Issues Follow All Safe Work Practices and Procedures

- 78. Questions?? May 2004 Be Safe & Rewarding for You