High Efficiency Solutions EEV & Monitoring Systems

- 1. High Efficiency Solutions EEV & Monitoring Systems HAVCR Indonesia September 2017

- 2. We lead the evolution of control technology and humidification for air conditioning and refrigeration. Our products support customers with the most efficient energy savings solutions. Data-driven services through our IoT platform grant personalised value.

- 3. We want to be closer to the customers for a better understanding of their needs We operate worldwide offering everywhere the same superior class quality We invest in innovation with the objective to ensure higher energy saving We are specialists in HVAC and Refrigeration We pursue financial solidity We offer integrated solutions Our key values

- 4. 7 Production facilities CAREL in snapshot 231 Mln€ Turnover (2016) 6,200 Part numbers 7 Mln Pcs per year 19 Subsidiaries 4,200+ Customers 1250+ Employees

- 5. 7% turnover in R&D Continuous innovation Each year we invest… 3% turnover in Production

- 6. High quality plants worldwide

- 7. CAREL Thermo-dynamic centre EMC rooms CAREL Humidification CAREL Labs

- 10. Refrigeration: supermarket, c-store, restaurant chain, refrigerated warehouse… HVAC: residential, commercial, industrial process, hospitals, data centre... CAREL system solutions: for which applications?

- 11. Local Monitoring systems IR33+ PJEASY Cella Range EEV Smartcella CAREL solutions for Coldrooms

- 12. CAREL Electronic Expansion Valves

- 13. • Weak actuation forces= very narrow capacity • Slow movments= flooding risk / unefficiencies • It is refrigerant specific • It needs periodical re-tuning • Not directly monitored • It requires a solenoid valve on liquid line Why preferring an EEV? Mechanical limits of TEV

- 14. A mechanical device will hunt and allow a nominal less efficient superheat duty An ExV will find quickly a stable and more efficient superheat duty BLDC & EEV technologies Unitefficiency Unit start-up Time It is incomparably more precise, allowing running at lower average SH for a better stability and quicker duty achievement, exploiting the evaporator hence higher efficiency of the system. Why preferring an EEV? Better evaporator feeding…

- 15. Data taken from Select 7.8 Copeland (Emerson Climate Technology) compressors selection software Valve auto adapts to different outdoor conditions so it will not limit the unit to work @ nominal discharge/suction pressures. Floating discharge control can be exploited to bring further energy savings during night operation and /or colder climate Why preferring an EEV? Auto adaptability

- 16. Cooling capacity From 2kW to 11kW Advantages One ExV size replacing many TXVs sizes. Why preferring an EEV? Offering a wide capacity

- 17. • Suits many different refrigerants • Constant behavior in time, no need of periodical adjustment, maintenance or replacement • The most suitable solution for variable speed compressors • Bi-directional to simplify heat-pump application Why preferring an EEV? Further benefits…

- 19. Application: Low temperature cold room 90m3 for meat storage (set - 20°C) Evaporator: 5,5kW, heater defrost 3PH 5kW, 4 fans 200W 1PH; Condensing unit: outdoor, hermetic condensing unit 5,5kW Refrigerant: R404a Field Test: System automatically switches from ExV to TEV each 3 days Energy consumption (kWh) is measured in both cases considering all cold room loads Refrigerant Cold room Evaporatore Solenoid valve EEV Solenoid valve TEV Field Test Protocol

- 20. Ambient T Defrost T Compressor duty cycle on time with TEV Compressor duty cycle on time with EEV LOWER!! Thanks to ExV, compressor duty cycle “on” time is lower this means an effective energy saving for the system Compressor duty cycle with TEV Compressor duty cycle with EEV Performance EEV vs TEV

- 21. STEPPER valves continuously and instantly modulate refrigerant flow at all times (as simple as that). PWM valves obtain a variation of refrigerant flow as an “average” over a consistent time window. When measuring instant refrigerant flow, it is either 100% or 0%. Stepper & PWM: refrigerant flow Description and principles What about EEV vs PWM performance?

- 22. CAREL ExV-products leading technology is the result of over 40 years long experience on HVAC application and on today most-advanced development-processes. ExVs F.E.M. structural analysisExVs C.F.D fluido-dynamic analysis Why we recommend our EEV?

- 23. CAREL ExV-products top-quality comes from a company continuous- innovation process and on severe production quality-controls. Why we recommend our EEV?

- 24. LIFECYCLE Why we recommend our EEV?

- 25. • In a real ref-circuit (in both direct+reverse flow) • In air (without compressor-oil lubrication) • in a climatic-chamber (from -40˚up to +70˚C) Life test performed

- 26. 1 million cycles test* means: >1200 million steps, or >2.4 billion pulses… Higher reliability over time(*): • Non-rotating shutter • Oil free circuit operation • Stainless steel ball bearing sets *this equals to > 10 years of lifetime in a standard application Life test performed

- 27. PRECISION Why we recommend our EEV?

- 28. → the same flow % variation at any same aperture change! Resolution It means that at any position, a valve movement produces the most precise flow variation compared to the currently given flow. Precision: equal-percentage characteristic

- 29. • Precision in the most utilized range (i.e. low flow) more stable and accurate process control higher efficiency • The highest precision at low flow rates • The fastest reaction at high flow rates Equal-percentage flow control means

- 30. AIRTIGHT SEALING Why we recommend our EEV?

- 31. The non-rotating shutter will land on its seat without scratching, tightly sealed by a high quality teflon gasket and blocking spring Airtight: teflon gasket sealing

- 32. Compressor Condenser Liquid Receiver Refrigerant Filter Sight Glass Evaporator Electric Expansion Valve No solenoid valve is required with CAREL drivers Carel control with ULTRACAP technology Airtight: benefits EDLC CAPACITOR

- 33. SERVICEABILITY Why we recommend our EEV?

- 34. Serviceability • The coil can be removed without uninstalling the valve or the cabling • Removable cartridge (*) for: − Valve body brazing without the risk of the motor overheating − Ease of inspection during maintenance • Sight glass (*) to inspect also correct valve shutter operation (*): Standard on all the large valve. Instead available on specific E2V – E3V model (smart range). E2V one body, different sizes

- 35. Up to 49KW/14Tons 168KW/48tons 335KW/95Tons 795KW/226Tons 1570KW/446Tons 2530KW/716Tons R410A Tcond = 38C Tevap = 4,4 SC = 1K ExV sistema – the range E2V, E3V, E4V hot-gas series (up to 100◦C continuous operation)

- 36. • UL recognized (for both USA and Canada): • EN - european norms approved: PED: Art. 3.3 E2V used with hydrocarbons meets the requirements of EN 60079-15:2005-10, as required by EN 60335-2-40/A1:2006-04 and EN 60335-2-89:2002-12, EN 60335-2- 89/A1:2005-04, EN 60335-2-89/A11:2004-07, EN 60335-2-89/A2:2007-03. E2V has been tested in accordance with ATEX Directive 94/9/EC for Group II, Category 3G refrigerants, in accordance with harmonised standards EN 60079- 15:2005 (only the parts required by EN60335-2-40 and EN 60335-2-89). ExV particulars: certifications

- 37. A web-based software to select the right ExV: https://exvselectiontool.carel.com/ExVLab/ ExV sistema: online selection tool

- 38. Mechanical strainers A simple tool to allow the manual driving of any CAREL ExV ExV sistema: accessories

- 39. IR33+ PJEASY Cella Range EEV Smartcella CAREL coldroom solutions Local Monitoring systems

- 40. EVD modules Power module 3ph modules EVD Ice Coldwatch, gas leakage

- 41. CAREL monitoring systems Complete, scalable and reliable supervisory solutions (Local & Remote) for the management, monitoring and optimisation of HVACR applications.

- 45. pChronoCS • Single and efficient solution for the integration of the different areas of small stores (e.g. Alfamart…): refrigeration, air conditioning and lighting. • Wherever you are, your store is under control with a simple Internet connection from your PC or smartphone/tablet. • Intuitive graphic dashboards to have the store status at a glance

- 46. PlantWatchPRO • Compact and efficient solution for small refrigeration and air-conditioning systems, covers up to 50 monitored units • 7 " touch screen display allows the different users to control and optimize refrigeration and air conditioning in a simple and intuitive way • Its Graphic Web interface allows remote access from PC, smartphone or tablet • Open system to be integrated to local Facility Management Local system. • Connection of 3rd party MODBUS RTU controls.

- 47. I-O Logger box • CAREL supervisory system for small plants which provides an advanced logging system through a stand alone device. • Designed to monitor up to 15 connectable units (also MODBUS compatible ) with the integration of up to 20 channels selectable as temperature/pressure (PT1000, NTC, 4…20mA, 0..5Vrat…) and digital inputs. • Such integrated channels can be combined in 13 different modes to provide a flexible solution which matches the needs of each scenario.

- 48. boss • Powerful web-based monitoring solution (Linux OS) , with hot-spot wi-fi, responsive design for medium/large refrigeration and air-conditioning systems, up to 300 monitored units • Quick commissioning procedure through wizards available also from smartphone • Customizability with Scalable Vector Graphics pages • Energy saving and optimization functions

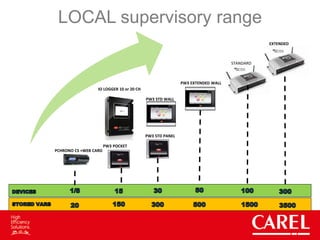

- 49. LOCAL supervisory range PW3 POCKET PW3 STD WALL PW3 EXTENDED WALL PW3 STD PANEL STANDARD EXTENDED IO LOGGER 10 or 20 CH PCHRONO CS +WEB CARD

- 50. The Remote supervision -> Interconnected stores vs -> Interconnected machines Cloud service (tERA & RemotePRO) SW license (RemotePRO) Value added reseller cooperation

- 51. RemotePRO The Call centre SW solution • RemotePRO is a secure and reliable tool for monitoring sites in a geographic network • Manages all your stores and customers with one networked solution • Site’s energy and alarms benchmarks for energy saving and system maintenance’s optimisation • Data analysis through Business Intelligence

- 52. • tERA is CAREL’s enterprise cloud solution for monitoring machines on sites with wireless (3G) or wired Internet connections • plug&play: immediately available worldwide • scalable to suit your needs modulating investments • seamlessly integrated into Carel’s controls for simple and immediate management of the machines, everywhere tERA The Cloud solution

- 53. WE ARE AT A-L 25, PLEASE FEEL FREE TO VISIT OUR BOOTH