Lecture 1 introduction to ntm process

- 2. Overview • Need for NTM processes • Classification of NTM processes • Process capability and the operating parameters for NTM processes • Overview of Manufacturing sector • Comparison with the conventional processes

- 5. Need of NTM Machining Un-conventional = Non-traditional = Un-traditional Manufacturing Un-conventional ? Very popular and wide applications Sometimes only feasible solutions

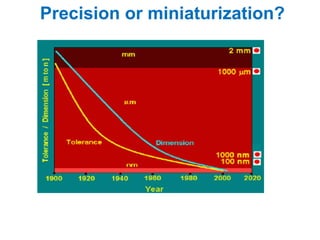

- 6. Need of NTM Limitations of Conventional processes • Machining invariably uses K.E., i.e., forces and motions. – Forces are accompanied by friction, heat, vibration, deflection etc. These lead to tool wear, inaccuracy (precise and miniature features not possible), poor surface finish, surface integrity (surface cracks, residual stresses, hot spots), low MRR. – Motions limit the shape and size of the realizable features. Eg.: Square holes, small but deep holes required in turbine blades, simple features in deep areas were the rotating tool cannot reach. NTM use simpler motions with special tools.

- 7. Need of NTM HSHTR (turbine blades, aerospace alloys, refractory metals) Un-usual and complex part geometries Avoiding surface damage Metals and Shape Non-metals Complexity machining Avoid Surface Precision and Damage Miniaturization Miniaturization Productivity

- 8. Need of NTM • Non circular blind holes • Inaccessible/ critical area de-burring • Normal size but deep • Super finishing of inner hole drilling lateral surface of a shell • Micro drilling • Finishing of fragile • Three dimensional components contour in a die • Holes along a curved axis • Micro & Nano • Elliptical piston machining components of special & finishing materials AND MANY MORE 8

- 9. NTM DEFINED A group of processes that remove excess material by various techniques involving mechanical, thermal, electrical, or chemical energy (or combinations of these energies) but do not use a cutting tool and its physical contact with the work piece in the conventional sense Absence of tool-workpiece contact or relative motion, makes the process a nontraditional

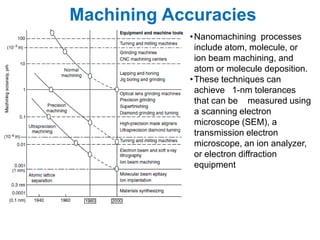

- 10. Machining Accuracies • Nanomachining processes include atom, molecule, or ion beam machining, and atom or molecule deposition. • These techniques can achieve 1-nm tolerances that can be measured using a scanning electron microscope (SEM), a transmission electron microscope, an ion analyzer, or electron diffraction equipment

- 11. Classification of Conventional Processes

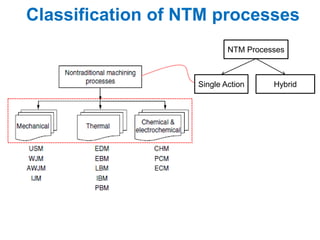

- 12. Classification of NTM processes • Mechanical - erosion of work material by a high velocity stream of abrasives or/& fluid is the typical form of mechanical action • Electrical - electrochemical energy to remove material (reverse of electroplating) • Thermal – thermal energy usually applied to small portion of work surface, causing that portion to be removed by fusion and/or vaporization • Chemical – chemical etchants selectively remove material from portions of workpiece, while other portions are protected by a mask

- 13. Classification of NTM processes NTM Processes Single Action Hybrid

- 14. Single Action Mechanical and Chemical and electrochemical Processes

- 15. Single Action Thermal Processes

- 16. Hybrid Processes

- 17. Mechanism of processes Mechanism of Energy type Energy source Processes material removal Mechanical motion of tool / Conventional Mechanical Plastic shear job machining Mechanical /Fluid motion AJM, USM Electrochemical Ion displacement Electric current ECM Mechanical and Plastic shear and ion Electric current and ECG electro-chemical displacement mechanical motion Chemical Corrosive reaction Corrosive agent CHM Electric spark EDM High speed electrons EBM Thermal Fusion and vaporization Powerful radiation LBM Ionized substance IBM, PAM

- 19. Characteristics of NTM processes Process Characteristics Operating Form of Energy parameters CHM • Sharpening of hard Chemical properties Etching material of the reagent • Used as honing process • Higher MRR than grinding EDM • Shaping and cutting V = 50-380, A = 0.1- Series of sparks complex parts made of 500, hard materials MRR ~ 300 • White layer mm^3/min • Expensive tooling and 0.03 and above equipment USM • Brittle fracture V=220, A= 12 amp Small amplitude • Abrasive embedding AC, Gap = 0.25 and high frequency

- 20. Characteristics of NTM processes Process Characteristics Operating Form of Energy parameters WEDM • Simple or complex Varies with material Series of sparks contour cutting and thickness • Expensive equipment LBM • Cutting and hole V= 4500, air PHOTONS making on thin material medium • HAZ 0.5-7.5 m/min • No need of vacuum • Expensive equipment • Low efficiency EBM • Small hole and slot V = 1,50,000 KE of electrons making 1-2 mm^3/min • Need vacuum • Expensive equipment • HAZ

- 21. Characteristics of NTM processes Process Characteristics Operating Form of Energy parameters AJM • Suitable for all material V = 110, I = 1.5 A, Abrasive propelled • Tapered surface Gap = 0.76 at in high speed air generated • Effect of standoff distance IBM • Costly process High velocity ions • Less efficiency (more energy) • Very slow PAM • HAZ V= 100, I=500 DC PLASMA • Rough surface Gap= about 150 • Heavy work ECM • Less tool wear V =10, I=10,000 A • Oxide layer Electrical and Chemical

- 22. Shape applications Feature Suitable processes Holes • For holes not less than 0.130 mm; EBM, EDM, LBM • Large and deep holes; EDM and ECM (well above 20 L/D) • For improving the geometry of holes, conventional processes like reaming and boring can be combined with the processes Through • USM, ECM, and EDM cavities • Trepanning tool • Generally EDM and USM and suitable for precision small cavities while ECM is best for large cavities Pocketing • Same as a through holes but have a flat at the bottom • Trepanning tool usage is not possible • ECM, CHM, and EDM are the principle processes • CHM is suitable for large surface area Arrayed • Arrayed microholes- beam processes structures • Arrayed protrusions- EDM, ECM, CHM Taper ECM is good as less tool wear occurs

- 24. Material applications Process applicability USM AJM ECM CHM EDM EBM LBM PAM Metals and Alloys Aluminum C B B A B B B A Steel B B A A A B B A Super alloys C A A B A B B A Titanium B B B B A B B B Refractories A A B C A A C C Non-Metals Ceramic A A D C D A A D Plastic B B D C D B B C Glass A A D B D B B D A Good C Poor B Fair D Inapplicable

- 25. Process variants Basic process Variant process USM • Ultrasonically Assisted Machining (UAM) • Rotary ultrasonically Assisted Machining (RUM) AJM • Abrasive Flow Machining (AFM) • Orbital Grinding (OG) • Abrasive Water Jet Machining (AWJM) ECM • Electro-Chemical Grinding (ECG) • Electro-Chemical Discharge Grinding (ECDG) • Electro-Chemical Deburring (ECD) • Electro-Chemical Honing (ECH) • Shaped Tube Electrolytic Machining (STEM) EDM • Wire Electrical Discharge Machining (WEDM) • Wire Electrical Discharge Grinding (WEDG) CHM • Chemical Milling (CHM) • Chemical Engraving (CHE) • Chemical Blanking (CHB) • Photo-Chemical Machining (PCM)

- 26. 26

- 27. Limitations of conventional processes • Machining processes that involve chip formation have a number of limitations – Large amounts of energy – Unwanted distortion – Residual stresses – Burrs – Delicate or complex geometries may be difficult or impossible

- 28. Advances in NTM processes • Hybrid processes • Automation • Micro-fabrications • Proper decision support by use of modern tools (FEA, AHP etc.). 28

- 29. Advantages of NTM – Complex geometries are possible – Extreme surface finish – Tight tolerances – Delicate components – Easy adaptability for automation – Little or no burring or residual stresses – Brittle materials with high hardness can be machined – Microelectronic or integrated circuits are possible to mass produce – Manufacturing otherwise impossible shapes – Production of functionally gradient materials 29

- 30. Research issues in NTM • Creating, improving unit operations • Scaling up/down manufacturing capabilities • Novel manufacturing concepts • Understanding, responding to health, safety, environmental issues • Process monitoring and control • “Application – Process- Material” system development • Metrology • Characterizations

- 31. Typical Parts Machined Nonmetallic and tiny parts by WJM WJM Metallic and very large Ceramic Parts Bullet proof glass Rack and Pinion

- 32. Typical Parts Machined EDM and WEDM

- 33. Typical Parts Machined CHM

- 34. Typical Parts Machined ECM

- 35. End

- 36. Various work samples machined by USM 1- The first picture on the left is a plastic sample that has inner grooves that are machined using USM. 2- The Second picture (in the middle is a plastic sample that has complex details on the surface 3- The third picture is a coin with the grooving done by USM

- 37. EDMing of insulating ceramics

- 38. EDMing of curved hole

- 39. Powder mixed EDM