Lecture 2 Basic Concepts of Optimal Design and Optimization Techniques final1.pptx

- 1. Lecture 2-a: Introduction to Optimal Design & Optimization Techniques 17/11/2022 Subject Name : Advanced Machine Design

- 2. Lecture 2-a: Outline 17/11/2022 Introduction Conventional Versus Optimum Design Process Optimum Design Problem Formulation Classification of Optimization Problems Classical Optimization Techniques

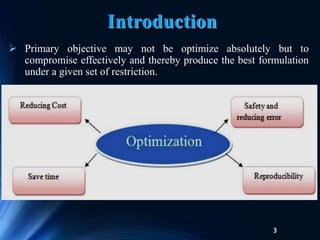

- 3. Primary objective may not be optimize absolutely but to compromise effectively and thereby produce the best formulation under a given set of restriction. 3 Introduction

- 4. Introduction 10/11/2022 Optimization is the act of obtaining the best result under given circumstances. Optimize is defined as to make perfect, effective or as functional as possible. Optimization can be defined as the process of finding the conditions that give the maximum or minimum of value a function. Optimization is a component of design process. The design of systems can be formulated as problems of optimization where a measure of performance is to be optimized while satisfying all the constraints. In design, construction, and maintenance of any engineering system, engineers have to take many technological and managerial decisions at several stages. The ultimate goal of all such decisions is either to minimize the effort required or to maximize the desired benefit.

- 5. 5 Introduction If a point x* corresponds to the minimum value of the function f (x), the same point also corresponds to the maximum value of the negative of the function, -f (x). Thus optimization can be taken to mean minimization since the maximum of a function can be found by seeking the minimum of the negative of the same function. In addition, the following operations on the objective function will not change the optimum solution x*: 1. Multiplication (or division) of f (x) by a positive constant c. 2. Addition (or subtraction) of a positive constant c to (or from) f (x).

- 6. 6 Unconstrained: In unconstrained optimization problems there are no restrictions. The making of the hardest tablet is the unconstrained optimization problem. Constrained: The constrained problem involved in it, is to make the hardest tablet possible, but it must disintegrate in less than 15 minutes. Independent variables: The independent variables are under the control of the formulator. These might include the compression force or the die cavity filling or the mixing time. Dependent variables: The dependent variables are the responses or the characteristics that are developed due to the independent variables. The more the variables that are present in the system the more the complications that are involved in the optimization. Introduction

- 7. 7 The optimum seeking methods are also known as mathematical programming techniques and are generally studied as a part of operations research. Operations research is a branch of mathematics concerned with the application of scientific methods and techniques to decision making problems and with establishing the best or optimal solutions. The beginnings of the subject of operations research can be traced to the early period of World War II. Introduction Mathematical programming techniques are useful in finding the minimum of a function of several variables under a prescribed set of constraints. Stochastic process techniques can be used to analyze problems described by a set of random variables having known probability distributions. Statistical methods enable one to analyze the experimental data and build empirical models to obtain the most accurate representation of the physical situation. Modern Optimization Methods: also sometimes called nontraditional optimization methods, have emerged as powerful and popular methods for solving complex engineering optimization problems in recent years. These methods include: genetic algorithms & simulated annealing method.

- 8. Introduction 8 In recent years several new optimization methods that do not fall in the area of traditional mathematical programming can be labeled as metaheuristic optimization methods. All the metaheuristic optimization methods have the following features: (i) They use stochastic or probabilistic ideas in various steps; (ii) They are intuitive or trial and error based, or heuristic in nature; (iii) They all use strategies that imitate the behavior or characteristics of some species such as bees, bats, birds, cuckoos, and fireflies; (iv) They all tend to find the global optimum solution; and (v) They are most likely to find an optimum solution, but not necessarily all the time. Genetic algorithms are computerized search and optimization algorithms based on the mechanics of natural genetics and natural selection. Simulated annealing method is based on the mechanics of the cooling process of molten metals through annealing. Particle swarm optimization algorithm mimics the behavior of social organisms such as a colony or swarm of insects (for example, ants, termites, bees, and wasps), a flock of birds, and a school of fish.

- 9. Ant colony optimization is based on the cooperative behavior of ant colonies, which are able to find the shortest path from their nest to a food source. Neural network methods are based on the immense computational power of the nervous system to solve perceptional problems in the presence of a massive amount of sensory data through its parallel processing capability. Fuzzy optimization methods were developed to solve optimization problems involving design data, objective function, and constraints stated in imprecise form involving vague and linguistic descriptions 9 Introduction A class of methods, termed Metaheuristic Algorithms, are being developed for the solution of optimization problems include techniques such as the firefly, harmony search, bee, cuckoo, bat, crow, teaching-learning, passing-vehicle, and salp swarm algorithms.

- 10. Introduction 10/11/2022 Table 1.1 lists various mathematical programming techniques together with other well-defined areas of operations research, including the new class of methods termed metaheuristic optimization methods. The classification given in Table 1.1 is not unique; it is given mainly for convenience.

- 12. 10/11/2022 Optimization, in its broadest sense, can be applied to solve any engineering problem. Some typical applications are: 1) Optimum design of linkages, cams, gears, machine tools, and other mechanical components 2) Design of aircraft and aerospace structures for minimum weight 3) Design of material handling equipment, such as conveyors, trucks, and cranes, for minimum cost 4) Design of pumps, turbines, and heat transfer equipment for maximum efficiency 5) Optimal production planning, controlling, and scheduling 6) Optimum design of chemical processing equipment and plants 7) Selection of a site for an industry 8) Planning of maintenance and replacement of equipment to reduce operating costs 9) Inventory control 10) Allocation of resources or services among several activities to maximize the benefit 11) Design of optimum pipeline networks for process industries 12) Optimum design of control systems 13) Optimum design of electrical networks 14) Optimum design of electrical machinery such as motors, generators, and transformers Introduction

- 13. 13 The conventional design procedures aim at finding an acceptable or adequate design which merely satisfies the functional and other requirements of the problem. In general, there will be more than one acceptable design, and the purpose of optimization is to choose the best one of the many acceptable designs available. Thus a criterion has to be chosen for comparing the different alternative acceptable designs and for selecting the best one. The criterion with respect to which the design is optimized, when expressed as a function of the design variables, is known as the objective function. Conventional Versus Optimum Design Process

- 14. 14 Conventional Versus Optimum Design Process Fig 1.4 Comparison of: (a) conventional design method; and (b) optimum design method. It is important to note that: Both methods are iterative, as indicated by a loop between blocks 6 and 3. Both methods have some blocks that require similar calculations and others that require different calculations.

- 15. 15 • In block 4, the conventional design method checks to ensure that the performance criteria are met, whereas the optimum design method checks for satisfaction of all of the constraints for the problem formulated in block 0. • In block 6, the conventional design method updates the design based on the designer’s experience and intuition and other information gathered from one or more trial designs; the optimum design method uses optimization concepts and procedures to update the current design. • In civil engineering, the objective is usually taken as the minimization of the cost. • In mechanical engineering, the maximization of the mechanical efficiency is the obvious choice of an objective function. • In aerospace structural design problems, the objective function for minimization is generally taken as weight. • In some situations, there may be more than one criterion to be satisfied simultaneously. An optimization problem involving multiple objective functions is known as a multiobjective programming problem. Conventional Versus Optimum Design Process

- 16. 16 With multiple objectives there arises a possibility of conflict, and one simple way to handle the problem is to construct an overall objective function as a linear combination of the conflicting multiple objective functions. Thus, if f1 (X) and f2 (X) denote two objective functions, construct a new (overall) objective function for optimization as: where 1 and 2 are constants whose values indicate the relative importance of one objective function to the other. 𝑓(X) = 𝛼1𝑓1(X) + 𝛼2𝑓2(X) Conventional Versus Optimum Design Process

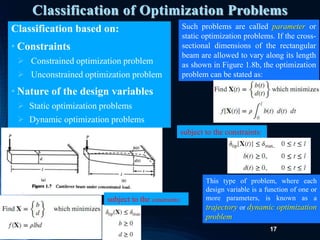

- 17. 17 Classification of Optimization Problems Classification based on: • Constraints Constrained optimization problem Unconstrained optimization problem • Nature of the design variables Static optimization problems Dynamic optimization problems subject to the constraints: Such problems are called parameter or static optimization problems. If the cross- sectional dimensions of the rectangular beam are allowed to vary along its length as shown in Figure 1.8b, the optimization problem can be stated as: subject to the constraints: This type of problem, where each design variable is a function of one or more parameters, is known as a trajectory or dynamic optimization problem

- 18. 18 Classification based on: • Physical structure of the problem • Optimal control problems • Non-optimal control problems • Nature of the equations involved • Nonlinear programming problem • Geometric programming problem • Quadratic programming problem • Linear programming problem Classification of Optimization Problems

- 19. 19 Classification based on: • Permissable values of the design variables • Integer programming problems • Real valued programming problems • Deterministic nature of the variables • Stochastic programming problem • Deterministic programming problem Classification of Optimization Problems

- 20. 20 Classification based on: • Separability of the functions • Separable programming problems • Non-separable programming problems • Number of the objective functions • Single objective programming problem • Multiobjective programming problem Classification of Optimization Problems

- 21. 21 An optimization or a mathematical programming problem can be stated as follows. • f0 : Rn R: objective function • x=(x1,…..,xn): design variables (unknowns of the problem, they must be linearly independent) • gi : Rn R: (i=1,…,m): inequality constraints • The problem is a constrained optimization problem minimize 𝑓0(𝑥) subject to 𝑔𝑖(𝑥) ≤ 𝑏𝑖, 𝑖 = 1, . . . . , 𝑚 where X is an n-dimensional vector called the design vector, f (X) is termed the objective function, and gj (X) and lj (X) are known as inequality and equality constraints, respectively. Some optimization problems do not involve any constraints Optimum Design Problem Formulation

- 22. 22 Optimum Design Problem Formulation Design problems have: An objective (a goal) to be achieved Some constraints within which the objective/goal must be achieved Some criteria by which a good solution is recognized Constraints set specific (usually quantitative) targets or limits Criteria are more flexible and might be used for judging between different design proposals, each of which meets the specific constraint targets.

- 23. 23 It is generally accepted that the proper definition and formulation of a problem take more than 50% of the total effort needed to solve it. Therefore, it is critical to follow well-defined procedures for formulating design optimization problems. The importance of properly formulating a design optimization problem must be stressed because the optimum solution will be only as good as the formulation. For example: If we forget to include a critical constraint in the formulation, the optimum solution will most likely violate it. Also, if we have too many constraints, or if they are inconsistent, there may be no solution for the problem. However, once the problem is properly formulated, good software is usually available to solve it. It is important to note that the process of developing a proper formulation for optimum design of practical problems is iterative in itself. Optimum Design Problem Formulation

- 24. 24 Optimum Design Problem Formulation Initial design problem statement Seek info Interpret Summarize Review Customer needs? Competition? continue Obtain instructor approval probe Engineering Design Specification Gain consensus Functional requirements? Targets? Constraints? Evaluation criteria? revise Preliminary problem formulation Literature, Surveys Market Studies Focus Groups Observation Studies Benchmark Studies Formulating process

- 25. 25 Formulation of an optimum design problem implies translating a descriptive statement of the problem into a well-defined mathematical statement. For most design optimization problems, we will use the following five-step procedure to formulate the problem: Step 1: Project/problem description: The statement describes the overall objectives of the project and the requirements to be met. This is also called the statement of work. Care should always be exercised in defining and developing expressions for the constraints. Step 2: Data and information collection: To develop a mathematical formulation for the problem, gather information on material properties, performance requirements, resource limits, cost of raw materials, analysis procedures (FEM), analysis tools (ABAQUS) and so forth. In many cases, the project statement is vague, and assumptions about modeling of the problem need to be made in order to formulate and solve it. Step 3: Definition of design variables: to identify a set of variables that describe the system, called the design variables. In general, these are referred to as optimization variables or simply variables that are regarded as free because we should be able to assign any value to them. Different values for the variables produce different designs. Design variables – a set of parameters that describes the system (dimensions, material, load, …) Optimum Design Problem Formulation

- 26. 26 To summarize, the following considerations should be given in identifying design variables for a problem: Generally, the design variables should be independent of each other. If they are not, there must be some equality constraints between them (explained later in several examples). All options of identifying design variables should be investigated. A minimum number of design variables is required to properly formulate a design optimization problem. Designate as many independent parameters as possible as at the beginning. Later, some of the design variables can be eliminated by assigning numerical values. A numerical value should be given to each identified design variable to determine if a trial design of the system is specified. Optimum Design Problem Formulation

- 27. 27 Step 4: Optimization criterion: The question is how do we quantify this statement and designate a design as better than another (cost, profit, weight, deflection, stress, ….). For this, a criterion has to be chosen for comparing the different alternative acceptable designs and for selecting the best one. The criterion with respect to which the design is optimized, when expressed as a function of the design variables, is known as the criterion or merit or objective function. The criterion must be a scalar function whose numerical value can be obtained once a design is specified; that is, it must be a function of the design variable vector x. Such a criterion is usually called an objective function for the optimum design problem, and it needs to be maximized or minimized depending on problem requirements. A criterion that is to be minimized is usually called a cost function in engineering literature. It is emphasized that a valid objective function must be influenced directly or indirectly by the variables of the design problem; otherwise, it is not a meaningful objective function. In some situations, two or more objective functions may be identified, these are called multiobjective design optimization problems. Optimum Design Problem Formulation

- 28. 28 Step 4: Optimization criterion or Objective Function: Optimum Design Problem Formulation 1. It must be a scalar function whose numerical values could be obtained once a design is specified. 2. It must be a function of design variables, f (x). 3. The objective function is minimized or maximized (minimize cost, maximize profit, minimize weight, maximize ride quality of a vehicle, minimize the cost of manufacturing, ….) 4. Multi-objective functions; minimize the weight of a structure and at the same time minimize the deflection or stress at a certain point.

- 29. 29 • Objective Function Surfaces: the locus of all points satisfying f (X) = c = constant is a forms a hypersurface in the design space, and for each value of c there corresponds a different member of a family of surfaces. These surfaces, called objective function surfaces, are shown in a hypothetical two-dimensional design space in the figure below. Optimum Design Problem Formulation

- 30. 30 • Once the objective function surfaces are drawn along with the constraint surfaces, the optimum point can be determined without much difficulty. • But the main problem is that as the number of design variables exceeds two or three, the constraint and objective function surfaces become complex even for visualization and the problem has to be solved purely as a mathematical problem. Optimum Design Problem Formulation

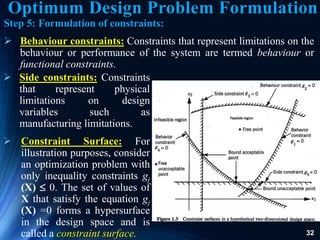

- 31. 31 Step 5: Formulation of constraints: in many practical problems, the design variables cannot be chosen arbitrarily; rather, they have to satisfy certain specified functional and other requirements. All restrictions placed on the design are collectively called constraints. The restrictions that must be satisfied to produce an acceptable design are collectively called design constraints. Constraints that represent limitations on the behavior or performance of the system are termed behavior or functional constraints. Constraints that represent physical limitations (i.e.; there can be upper and lower bounds due to manufacturing limitations) on design variables, such as availability, fabricability, and transportability, are known as geometric or side constraints. Optimum Design Problem Formulation

- 32. 32 Side constraints: Constraints that represent physical limitations on design variables such as manufacturing limitations. Constraint Surface: For illustration purposes, consider an optimization problem with only inequality constraints gj (X) 0. The set of values of X that satisfy the equation gj (X) =0 forms a hypersurface in the design space and is called a constraint surface. Step 5: Formulation of constraints: Behaviour constraints: Constraints that represent limitations on the behaviour or performance of the system are termed behaviour or functional constraints. Optimum Design Problem Formulation

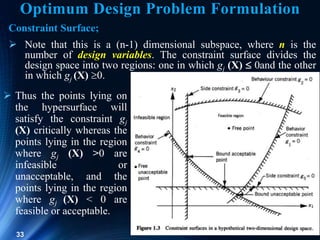

- 33. 33 Constraint Surface; Note that this is a (n-1) dimensional subspace, where n is the number of design variables. The constraint surface divides the design space into two regions: one in which gj (X) 0and the other in which gj (X) 0. Thus the points lying on the hypersurface will satisfy the constraint gj (X) critically whereas the points lying in the region where gj (X) >0 are infeasible or unacceptable, and the points lying in the region where gj (X) < 0 are feasible or acceptable. Optimum Design Problem Formulation

- 34. 34 Constraint Surface: In the below figure, a hypothetical two dimensional design space is depicted where the infeasible region is indicated by hatched lines. A design point that lies on one or more than one constraint surface is called a bound point, and the associated constraint is called an active constraint. Design points that do not lie on any constraint surface are known as free points. Depending on whether a particular design point belongs to the acceptable or unacceptable regions, it can be identified as one of the following four types: 1) Free and acceptable point 2) Free and unacceptable point 3) Bound and acceptable point 4) Bound and unacceptable point Optimum Design Problem Formulation

- 35. 35 Problem Formulation Design Constraints Feasible Design A design meeting all the requirements is called a feasible (acceptable) design. An infeasible design does not meet one or more requirements Implicit & Explicit Constraints All restrictions placed on a design are collectively called constraints. Some constraints are explicit (obvious, provided) such as min. and max. values of design variables, some are implicit (derived, deduced) which are usually more complex such as deflection of a structure.

- 36. 36 Linear and Nonlinear Constraints Constraint functions having only first-order terms in design variables are called linear constraints. More general problems have nonlinear constraint functions as well. A machine component must move precisely by a certain value (equality). Stress must not exceed the allowable stress of the material (inequality) It is easier to find feasible designs for a system having only inequality constraints. Design problems may have equality as well as inequality constraints. A feasible design must satisfy precisely all the equality constraints. Equality and Inequality Constraints Problem Formulation

- 37. 37 Standard Design Optimization Model The standard design optimization model is defined as follows: Find an n-vector x = (x1, x2, …., xn) of design variables to minimize an objective function subject to the p equality constraints and the m inequality constraints

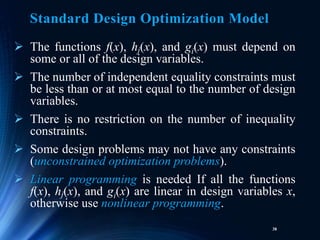

- 38. 38 The functions f(x), hj(x), and gi(x) must depend on some or all of the design variables. The number of independent equality constraints must be less than or at most equal to the number of design variables. There is no restriction on the number of inequality constraints. Some design problems may not have any constraints (unconstrained optimization problems). Linear programming is needed If all the functions f(x), hj(x), and gi(x) are linear in design variables x, otherwise use nonlinear programming. Standard Design Optimization Model

- 39. 39 Design a uniform column of tubular section to carry a compressive load P=2500 kgf for minimum cost. The column is made up of a material that has a yield stress of 500 kgf/cm2, modulus of elasticity (E) of 0.85e6 kgf/cm2, and density () of 0.0025 kgf/cm3. The length of the column is 250 cm. The stress induced in this column should be less than the buckling stress as well as the yield stress. The mean diameter of the column is restricted to lie between 2 and 14 cm, and columns with thicknesses outside the range 0.2 to 0.8 cm are not available in the market. The cost of the column includes material and construction costs and can be taken as 5W + 2d, where W is the weight in kilograms force and d is the mean diameter of the column in centimeters. Example

- 40. 40 The design variables are the mean diameter (d) and tube thickness (t): The objective function to be minimized is given by: X = 𝑥1 𝑥2 = 𝑑 𝑡 𝑓(X) = 5𝑊 + 2𝑑 = 5𝜌𝑙𝜋𝑑𝑡 + 2𝑑 = 9.82𝑥1𝑥2 + 2𝑥1 Example

- 41. • The behaviour constraints can be expressed as: 1. Stress induced ≤ yield stress 2. Stress induced ≤ buckling stress • The induced stress is given by: 41 induced stress = 𝜎i = 𝑃 𝜋𝑑𝑡 = 2500 𝜋𝑥1𝑥2 Example

- 42. 42 • The buckling stress for a pin connected column is given by: where I is the second moment of area of the cross section of the column given by: buckling stress = 𝜎b = Euler buckling load cross − sectional area = 𝜋2 𝐸𝐼 𝑙2𝜋𝑑𝑡 𝐼 = 𝜋 64 (𝑑𝑜 4 − 𝑑𝑖 4 ) = 𝜋 64 (𝑑𝑜 2 + 𝑑𝑖 2 )(𝑑𝑜 + 𝑑𝑖)(𝑑𝑜 − 𝑑𝑖) = 𝜋 64 (𝑑 + 𝑡)2 + (𝑑 − 𝑡)2 (𝑑 + 𝑡) + (𝑑 − 𝑡) (𝑑 + 𝑡) − (𝑑 − 𝑡) = 𝜋 8 𝑑𝑡(𝑑2 + 𝑡2 ) = 𝜋 8 𝑥1𝑥2(𝑥1 2 + 𝑥2 2 ) Example

- 43. 43 • Thus, the behaviour constraints can be restated as: • The side constraints are given by: 𝑔1(X) = 2500 𝜋𝑥1𝑥2 − 500 ≤ 0 𝑔2(X) = 2500 𝜋𝑥1𝑥2 − 𝜋2(0.85 × 106)(𝑥1 2 + 𝑥2 2 ) 8(250)2 ≤ 0 2 ≤ 𝑑 ≤ 14 0.2 ≤ 𝑡 ≤ 0.8 Example

- 44. 44 • The side constraints can be expressed in standard form as: 𝑔3(X) = −𝑥1 + 2 ≤ 0 𝑔4(X) = 𝑥1 − 14 ≤ 0 𝑔5(X) = −𝑥2 + 0.2 ≤ 0 𝑔6(X) = 𝑥2 − 0.8 ≤ 0 Example

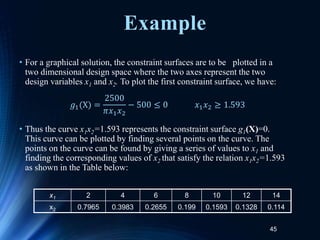

- 45. 45 • For a graphical solution, the constraint surfaces are to be plotted in a two dimensional design space where the two axes represent the two design variables x1 and x2. To plot the first constraint surface, we have: • Thus the curve x1x2=1.593 represents the constraint surface g1(X)=0. This curve can be plotted by finding several points on the curve. The points on the curve can be found by giving a series of values to x1 and finding the corresponding values of x2 that satisfy the relation x1x2=1.593 as shown in the Table below: 𝑔1(X) = 2500 𝜋𝑥1𝑥2 − 500 ≤ 0 𝑥1𝑥2 ≥ 1.593 x1 2 4 6 8 10 12 14 x2 0.7965 0.3983 0.2655 0.199 0.1593 0.1328 0.114 Example

- 46. 46 Example • The infeasible region represented by g1(X)>0 or x1x2< 1.593 is shown by hatched lines. These points are plotted and a curve P1Q1 passing through all these points is drawn as shown:

- 47. 47 • Similarly the second constraint g2(X) < 0 can be expressed as: • The points lying on the constraint surface g2 (X)=0 can be obtained as follows (These points are plotted as Curve P2Q2: 𝑥1𝑥2(𝑥1 2 + 𝑥2 2 ) ≥ 47.3 x1 2 4 6 8 10 12 14 x2 2.41 0.716 0.219 0.0926 0.0473 0.0274 0.0172 Example

- 48. 48 • The plotting of side constraints is simple since they represent straight lines. • After plotting all the six constraints, the feasible region is determined as the bounded area ABCDEA 𝑥1𝑥2(𝑥1 2 + 𝑥2 2 ) ≥ 47.3 Example

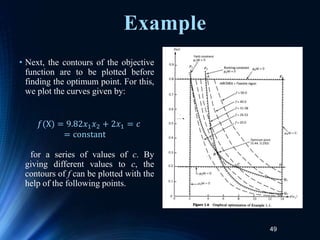

- 49. 49 • Next, the contours of the objective function are to be plotted before finding the optimum point. For this, we plot the curves given by: for a series of values of c. By giving different values to c, the contours of f can be plotted with the help of the following points. 𝑓(X) = 9.82𝑥1𝑥2 + 2𝑥1 = 𝑐 = constant Example

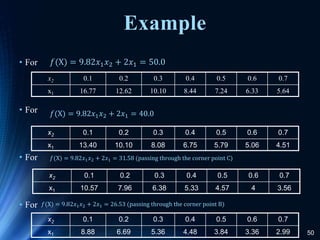

- 50. 50 Example • For • For • For • For 𝑓(X) = 9.82𝑥1𝑥2 + 2𝑥1 = 50.0 x2 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x1 16.77 12.62 10.10 8.44 7.24 6.33 5.64 𝑓(X) = 9.82𝑥1𝑥2 + 2𝑥1 = 40.0 x2 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x1 13.40 10.10 8.08 6.75 5.79 5.06 4.51 𝑓(X) = 9.82𝑥1𝑥2 + 2𝑥1 = 31.58 (passing through the corner point C) x2 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x1 10.57 7.96 6.38 5.33 4.57 4 3.56 𝑓(X) = 9.82𝑥1𝑥2 + 2𝑥1 = 26.53 (passing through the corner point B) x2 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x1 8.88 6.69 5.36 4.48 3.84 3.36 2.99

- 51. 51 Design of a Two-bar Structure The problem is to design a two-member bracket to support a force W without structural failure. Since the bracket will be produced in large quantities, the design objective is to minimize its mass while also satisfying certain fabrication and space limitation.

- 52. Ken Youssefi 52 Problem Formulation In formulating the design problem, we need to define structural failure more precisely. Member forces F1 and F2 can be used to define failure condition. Apply equilibrium conditions; Σ Fy = 0 Σ Fx = 0

- 53. 53 Problem Formulation Represent all the design variables for a problem in the vector x. x3 = outer diameter of member 1 x4 = inner diameter of member 1 x5 = outer diameter of member 2 x6 = inner diameter of member 2 x1 = height h of the truss x2 = span s of the truss

- 54. 54 Problem Formulation Objective Function Mass is selected as the objective function Mass = ( density )( area )( length ) x1 = height h of the truss x2 = span s of the truss x3 = outer diameter of member 1 x4 = inner diameter of member 1 x5 = outer diameter of member 2 x6 = inner diameter of member 2

- 55. 55 Constraints for the example problem are: member stress shall not exceed the allowable stress, and various limitations on design variables shall be met. Constraint on stress σ (applied) < σ (allowable) Problem Formulation

- 56. 56 Problem Formulation Finally, the constraints on design variables are written as Where xil and xiu are the minimum and maximum values for the ith design variable. These constraints are necessary to impose fabrication and physical space limitations.

- 57. 57 The problem can be summarized as follows Find design variables x1, x2, x3, x4, x5, and x6 to minimize the objective function, subject to the constraints of the equations x1 = height h of the truss x2 = span s of the truss x3 = outer diameter of member 1 x4 = inner diameter of member 1 x5 = outer diameter of member 2 x6 = inner diameter of member 2 Problem Formulation

- 58. 58 Example – Design of a Beer Can Design a beer can to hold at least the specified amount of beer and meet other design requirement. The cans will be produced in billions, so it is desirable to minimize the cost of manufacturing. Since the cost can be related directly to the surface area of the sheet metal used, it is reasonable to minimize the sheet metal required to fabricate the can.

- 59. 59 Example – Design of a Beer Can Fabrication, handling, aesthetic, shipping considerations and customer needs impose the following restrictions on the size of the can: 1. The diameter of the can should be no more than 8 cm. Also, it should not be less than 3.5 cm. 2. The height of the can should be no more than 18 cm and no less than 8 cm. 3. The can is required to hold at least 400 ml of fluid.

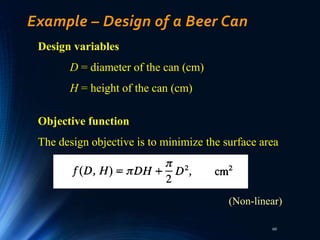

- 60. 60 Example – Design of a Beer Can Design variables D = diameter of the can (cm) H = height of the can (cm) Objective function The design objective is to minimize the surface area (Non-linear)

- 61. 61 Example – Design of a Beer Can The constraints must be formulated in terms of design variables. The first constraint is that the can must hold at least 400 ml of fluid. The problem has two independent design variable and five explicit constraints. The objective function and first constraint are nonlinear in design variable whereas the remaining constraints are linear. (Non-linear) The other constraints on the size of the can are: (linear)

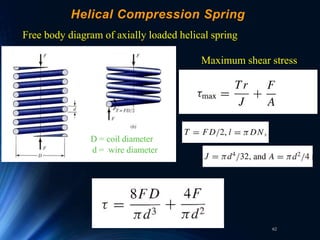

- 62. 62 Helical Compression Spring Free body diagram of axially loaded helical spring D = coil diameter d = wire diameter Maximum shear stress

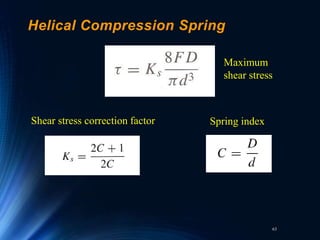

- 63. 63 Helical Compression Spring Shear stress correction factor Spring index Maximum shear stress

- 64. 64 Helical Compression Spring Deflection The total strain energy, torsional and shear components Total strain energy

- 65. 65 Helical Compression Spring Castigliano’s theorem – deflection is the partial derivative of the total strain energy. Spring rate Linear relationship

- 66. 66 Helical Compression Spring Helical spring end conditions N (total) = Na (active number of coils) + Ni (inactive number of coils)

- 67. 67 Example of unconstraint optimization problem Design a compression spring of minimum weight, given the following data:

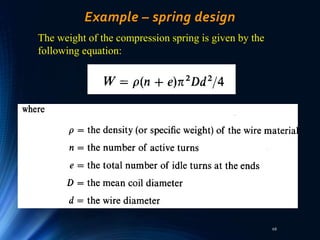

- 68. 68 Example – spring design The weight of the compression spring is given by the following equation:

- 69. 69 Example – spring design The equation can be expressed in terms of the spring index C = D/d The maximum shear stress and the deflection in the spring are given by the following equations

- 70. Ken Youssefi 70 Example – spring design Substituting all of the equations into the weight equation, we obtain the following expression in terms of spring index C: The plot of the objective function W vs. C, the spring index

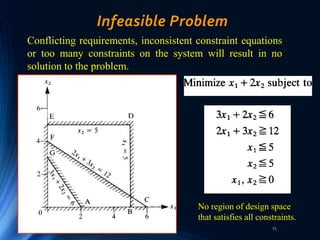

- 71. 71 Infeasible Problem Conflicting requirements, inconsistent constraint equations or too many constraints on the system will result in no solution to the problem. No region of design space that satisfies all constraints.

- 72. 72 Optimization using graphical method A wall bracket is to be designed to support a load of W. The bracket should not fail under the load. W = 1.2 MN h = 30 cm s = 40 cm 1 2

- 73. 73 Problem Formulation Design variables: Objective function: Stress constraints: Where forces on bar 1 and bar 2 are:

- 75. 75 Numerical Methods for Non-linear Optimization Graphical and analytical methods are inappropriate for many complicated engineering design problems. 1. The number of design variables and constraints can be large. 2. The functions for the design problem can be highly nonlinear. 3. In many engineering applications, objective and/or constraint functions can be implicit in terms of design variables.

- 76. 76 Structural Optimization Structural optimization is an automated synthesis of a mechanical component based on structural properties. For this optimization, a geometric modeling tool to represent the shape, a structural analysis tool to solve the problem, and an optimization algorithms to search for the optimum design are needed. Structural Optimization Geometric Modeling Structural Analysis Optimization Finite element modeling Finite element analysis Nonlinear programming algorithm

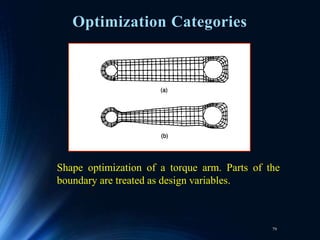

- 77. 77 Structural Optimization Categories Size Optimization Deals with parameters that do not alter the location of nodal points in the numerical problem, keeps a design’s shape and topology unchanged while changing dimensions of the design. Shape Optimization Deals with parameters that describe the boundary position in the numerical model. Design variables control the shape of the design. The process requires re-meshing of the model and results in freeform shapes Topology Optimization The goal of topology optimization is to determine where to place or add material and where to remove material. The optimization could determine where to place ribs to stiffen the structure.

- 78. 78 Optimization Categories Size and configuration optimization of a truss, design variables are the cross sectional areas and nodal coordinates of the truss. The truss could also be optimized for material. The topology or connectivity of the truss is fixed.

- 79. 79 Optimization Categories Shape optimization of a torque arm. Parts of the boundary are treated as design variables.

- 80. 80 Optimization Categories Topology optimization can be performed by using genetic algorithm. Optimum shapes of the cross section of a beam for plastic (b), aluminum (c), and steel (d)

- 81. 81 Examples Design of civil engineering structures • variables: width and height of member cross-sections • constraints: limit stresses, maximum and minimum dimensions • objective: minimum cost or minimum weight Analysis of statistical data and building empirical models from measurements • variables: model parameters • Constraints: physical upper and lower bounds for model parameters • Objective: prediction error

- 82. 82 Geometric Programming • A geometric programming problem (GMP) is one in which the objective function and constraints are expressed as posynomials in X.

- 83. 83 Quadratic Programming Problem • A quadratic programming problem is a nonlinear programming problem with a quadratic objective function and linear constraints. It is usually formulated as follows: subject to where c, qi,Qij, aij, and bj are constants. 𝐹(X) = 𝑐 + 𝑖=1 𝑛 𝑞𝑖 𝑥𝑖 + 𝑖=1 𝑛 𝑗=1 𝑛 𝑄𝑖𝑗 𝑥𝑖𝑥𝑗 𝑖=1 𝑛 𝑎𝑖𝑗 𝑥𝑖 = 𝑏𝑗, 𝑗 = 1,2, ⋯ , 𝑚 𝑥𝑖 ≥ 0, 𝑖 = 1,2, ⋯ , 𝑛

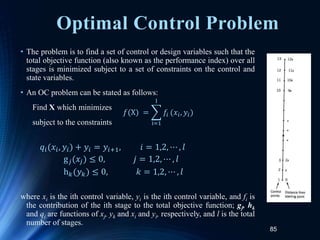

- 84. 84 Optimal Control Problem • An optimal control (OC) problem is a mathematical programming problem involving a number of stages, where each stage evolves from the preceding stage in a prescribed manner. • It is usually described by two types of variables: the control (design) and the state variables. The control variables define the system and govern the evolution of the system from one stage to the next, and the state variables describe the behaviour or status of the system in any stage.

- 85. 85 Optimal Control Problem • The problem is to find a set of control or design variables such that the total objective function (also known as the performance index) over all stages is minimized subject to a set of constraints on the control and state variables. • An OC problem can be stated as follows: Find X which minimizes subject to the constraints where xi is the ith control variable, yi is the ith control variable, and fi is the contribution of the ith stage to the total objective function; gj, hk and qi are functions of xj, yk and xi and yi, respectively, and l is the total number of stages. 𝑓(X) = i=1 l 𝑓𝑖 (𝑥𝑖, 𝑦𝑖) 𝑞𝑖(𝑥𝑖, 𝑦𝑖) + 𝑦𝑖 = 𝑦𝑖+1, 𝑖 = 1,2, ⋯ , 𝑙 g𝑗(𝑥𝑗) ≤ 0, 𝑗 = 1,2, ⋯ , 𝑙 h𝑘(𝑦𝑘) ≤ 0, 𝑘 = 1,2, ⋯ , 𝑙

- 86. 86 Integer Programming Problem • If some or all of the design variables x1,x2,..,xn of an optimization problem are restricted to take on only integer (or discrete) values, the problem is called an integer programming problem. • If all the design variables are permitted to take any real value, the optimization problem is called a real-valued programming problem.

- 87. 87 Stochastic Programming Problem •A stochastic programming problem is an optimization problem in which some or all of the parameters (design variables and/or preassigned parameters) are probabilistic (nondeterministic or stochastic). •In other words, stochastic programming deals with the solution of the optimization problems in which some of the variables are described by probability distributions.

- 88. 88 Separable Programming Problem • A function f (x) is said to be separable if it can be expressed as the sum of n single variable functions, f1(x1), f2(x2),….,fn(xn), that is, • A separable programming problem is one in which the objective function and the constraints are separable and can be expressed in standard form as: Find X which minimizes subject to 𝑓(X) = 𝑖=1 𝑛 𝑓𝑖 𝑥𝑖 𝑓(X) = 𝑖=1 𝑛 𝑓𝑖 (𝑥𝑖) 𝑔𝑗(X) = 𝑖=1 𝑛 𝑔𝑖𝑗 (𝑥𝑖) ≤ 𝑏𝑗, 𝑗 = 1,2, ⋯ , 𝑚

- 89. 89 Multiobjective Programming Problem • A multiobjective programming problem can be stated as follows: Find X which minimizes f1 (X), f2 (X),…., fk (X) subject to where f1 , f2,…., fk denote the objective functions to be minimized simultaneously. 𝑔𝑗(X) ≤ 0, 𝑗 = 1,2, . . . , 𝑚

- 90. 90 Review of mathematics Concepts from linear algebra: Positive definiteness • Test 1: A matrix A will be positive definite if all its eigenvalues are positive; that is, all the values of that satisfy the determinental equation should be positive. Similarly, the matrix A will be negative definite if its eigenvalues are negative. A − 𝜆I = 0

- 91. 91 Review of mathematics Positive definiteness • Test 2: Another test that can be used to find the positive definiteness of a matrix A of order n involves evaluation of the determinants • The matrix A will be positive definite if and only if all the values A1, A2, A3,An are positive • The matrix A will be negative definite if and only if the sign of Aj is (- 1)j for j=1,2,,n • If some of the Aj are positive and the remaining Aj are zero, the matrix A will be positive semidefinite 𝐴 = 𝑎11 𝐴2 = 𝑎11 𝑎12 𝑎21 𝑎22 𝐴3 = 𝑎11 𝑎12 𝑎13 𝑎21 𝑎22 𝑎23 𝑎31 𝑎32 𝑎33 𝐴3 = 𝑎11 𝑎12 𝑎13 ⋯ 𝑎1𝑛 𝑎21 𝑎22 𝑎23 ⋯ 𝑎2𝑛 𝑎31 𝑎32 𝑎33 ⋯ 𝑎3𝑛 ⋮ 𝑎𝑛1 𝑎𝑛2 𝑎𝑛3 ⋯ 𝑎𝑛𝑛

- 92. 92 Review of mathematics Negative definiteness • Equivalently, a matrix is negative-definite if all its eigenvalues are negative • It is positive-semidefinite if all its eigenvalues are all greater than or equal to zero • It is negative-semidefinite if all its eigenvalues are all less than or equal to zero

- 93. 93 Concepts from linear algebra: Nonsingular matrix: The determinant of the matrix is not zero. Rank: The rank of a matrix A is the order of the largest nonsingular square submatrix of A, that is, the largest submatrix with a determinant other than zero. Review of Mathematics

- 94. 94 Review of mathematics Solutions of a linear problem Minimize f(x)=cTx Subject to g(x): Ax=b Side constraints: x ≥0 • The existence of a solution to this problem depends on the rows of A. • If the rows of A are linearly independent, then there is a unique solution to the system of equations. • If det(A) is zero, that is, matrix A is singular, there are either no solutions or infinite solutions.

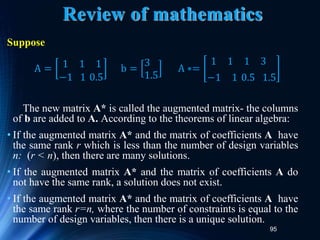

- 95. 95 Review of mathematics Suppose The new matrix A* is called the augmented matrix- the columns of b are added to A. According to the theorems of linear algebra: • If the augmented matrix A* and the matrix of coefficients A have the same rank r which is less than the number of design variables n: (r < n), then there are many solutions. • If the augmented matrix A* and the matrix of coefficients A do not have the same rank, a solution does not exist. • If the augmented matrix A* and the matrix of coefficients A have the same rank r=n, where the number of constraints is equal to the number of design variables, then there is a unique solution. A = 1 1 1 −1 1 0.5 b = 3 1.5 A ∗= 1 1 1 3 −1 1 0.5 1.5

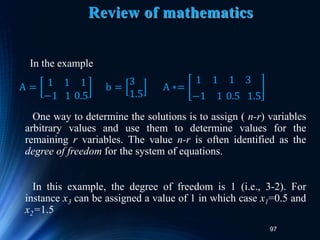

- 96. 96 Review of mathematics In the example The largest square submatrix is a 2 x 2 matrix (since m = 2 and m < n). Taking the submatrix which includes the first two columns of A, the determinant has a value of 2 and therefore is nonsingular. Thus the rank of A is 2 (r = 2). The same columns appear in A* making its rank also 2. Since r < n, infinitely many solutions exist. A = 1 1 1 −1 1 0.5 b = 3 1.5 A ∗= 1 1 1 3 −1 1 0.5 1.5

- 97. 97 Review of mathematics In the example One way to determine the solutions is to assign ( n-r) variables arbitrary values and use them to determine values for the remaining r variables. The value n-r is often identified as the degree of freedom for the system of equations. In this example, the degree of freedom is 1 (i.e., 3-2). For instance x3 can be assigned a value of 1 in which case x1=0.5 and x2=1.5 A = 1 1 1 −1 1 0.5 b = 3 1.5 A ∗= 1 1 1 3 −1 1 0.5 1.5

- 98. 98 Homework What is the solution of the system given below? Hint: Determine the rank of the matrix of the coefficients and the augmented matrix. 𝑔1: 𝑥1 + 𝑥2 = 2 𝑔2: −𝑥1 + 𝑥2 = 1 𝑔3: 𝑥1 + 2𝑥2 = 1