Lecture-1- Compressor and its Types.ppt

- 2. COMPRESSOR AND ITS TYPES

- 3. COMPRESSOR Definition It is that part of a jet engine which compresses the ingested air and then, feeds it to combustion chamber. Power absorbing device.

- 4. Q. How a compressor works? Compressor is continuous flow machine which function by imparting kinetic energy to the air by means of a rotary part (rotor blades or impeller), subsequently diffusing the velocity into static pressure rise. WORKING OF A COMPRESSOR

- 5. ROLE OF A COMPRESSOR Compressor in a gas turbine engine is to provide a maximum of high-pressure air. Q. What is the use of high-pressure air? This air is then heated in a combustion chamber and expanded in a turbine.

- 6. Energy released in the combustion chamber is proportional to the mass of the air consumed. Its efficient operation (maximum compression with minimum temperature rise) is the key to high overall engine performance. ROLE OF A COMPRESSOR

- 7. Q. What is the importance of compressor efficiency? The compressor efficiency will determine the power necessary to create the pressure rise and will affect the temperature change in the combustion chamber. Present day compressors have compression ratios over 25:1. Compression ratio. Compressors have efficiencies over 90 percent. Mass flow rate of air up to approximately 350 lbs/s (158.8 kg/s). ROLE OF A COMPRESSOR

- 8. With the addition of a fan, total pressure ratios of more than 25:1 and mass airflows of 1000 lbs/s (453.6 kg/s) have been achieved. AMENDMENTS IN A JET ENGINE

- 9. T-S DIAGRAM

- 10. TYPES OF A COMPRESSOR Q. What are different types of a compressor? There are two types of compressors with respect to airflow:- Centrifugal compressor Axial flow compressor

- 11. CENTRIFUGAL COMPRESSOR The airflow is radial, i.e. the flow of air is outward from the centre of the compressor.

- 12. CENTRIFUGAL COMPRESSOR It is used extensively in the early days of gas turbines. These are limited to the small gas turbine ‘gas generators’ for engine air starters and missile engines. Single Entry Impeller Double Entry Impeller

- 14. AXIAL FLOW COMPRESSOR Compressor in which air flows axially i.e. the flow of air is maintained parallel to the compressor’s shaft. Used in turbofan and turbojet engines.

- 16. COMPARISON OF COMPRESSORS Centrifugal compressors generally need to operate at much higher rpm than axial compressors.

- 18. COMBINATION OF BOTH COMPRESSORS Axial/centrifugal compressor combinations are used extensively in turbo-shaft and turboprop engines.

- 19. FACTORS AFFECTING THE PERFORMANCE Q. What are those factors which affect the performance of a compressor? The principal factors are:- Aerofoil sections, Pitch angles and The length/chord ratios of the blades Clearance between the blade tips and the compressor annulus

- 20. REQUIREMENTS OF A COMPRESSOR Introduction SFC is very important in case of internal combustion engines. The efficiency of a compressor is one of the factors directly influencing the specific fuel consumption (SFC).

- 21. FACTORS AFFECTING THE PERFORMANCE Q. What are those factors which affect the performance of a compressor? The principal factors are:- Aerofoil sections, Pitch angles and The length/chord ratios of the blades Clearance between the blade tips and the compressor annulus

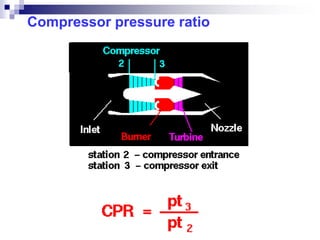

- 22. HIGH PRESSURE RATIO It is the ratio of pressure of the air at the outlet of compressor to the inlet. The thermal efficiency and the work output are both proportional to the compressor pressure ratio. The centrifugal compressor has a maximum pressure ratio of about 4.5:1 for a single stage. Raised to approximately 6:1 by using a two stage, single-entry centrifugal compressor.

- 23. HIGH PRESSURE RATIO For axial compressors, it is a matter of stability and complexity. The current values are 10:1 for single-spool compressors. For multi-spool compressors, the pressure ratio is in excess of 25:1. Higher pressure ratios give higher engine efficiency due to an improved SFC.

- 25. SFC and Pressure Ratio

- 27. High Mass Flow Jet engine air mass flows are becoming much larger. Ram-compression Must be matched with the swallowing capacity of the compressor. For transport aircraft, the required air mass flow at altitude requires large diameter compressors. Larger diameter fans for dual flow engines are required (high by- pass turbofan engines).

- 28. Stable Operation Under all Conditions Both centrifugal and axial compressors are liable to exhibit unstable characteristics under certain operating conditions. The centrifugal type is less likely to stall and surge than the axial. But it is not capable of the high pressure ratios now required. In high pressure ratio axial compressors anti-stall/surge devices are often a design requirement to guard against unstable conditions.

- 29. COMPRESSOR DESIGN Compressor design in most engines is a compromise between high performance over a narrow band of rpm, and moderate performance over a wide band of rpm. Consequently, although it is possible for the compressor to be designed so that very high efficiency is obtained at the highest power. Any deviation from the designed conditions may cause significant changes in the aerodynamic flow leading to a loss of efficiency and unstable conditions within the engine.

- 30. Axial Flow Compressor-Single Spool

- 31. Axial Flow Compressor-Double Spool

- 32. Q. What is a compressor? Q. What are different types of compressors? Q. Which compressor is used in T-37 Aircraft’s engine?

- 33. CENTRIFUGAL COMPRESSOR Definition 1. The airflow is radial, i.e. the flow of air is outward from the centre of the compressor. Explanation 2. (a) Centrifugal force (b) Limited to the small gas turbine (gas generators) for engine air starters and missile engines.

- 34. Purpose 3. To increase the mass flow rate through the engine which results in generation of thrust. Principle of Operation 4. To impart kinetic energy to the airflow and then converts this kinetic energy into pressure energy.

- 35. Main Components 5. (a) Compressor casing (b) Impeller (c) Diffuser

- 37. Compressor Casing 6. (a) Embodies the air inlet guide vanes (IGVS) and outlet ports. (b) Air entering the intake at atmospheric temperature and pressure passes through the fixed intake guide vanes. (c) IGVS direct the air smoothly into the centre of the impeller. (d) Outlet ports direct the air into the combustion chamber.

- 38. Impeller 7. (a) Rotating part (b) Rotated at high speed by the turbine (c) The incoming air smoothly fall at the centre of the impeller. (d) Designed to admit the air without excessive velocity (e) The air is picked up by the rotating guide vanes of the impeller, and centrifugal force causes the air to flow outwards along the vanes to the impeller tip.

- 39. Impeller (e) Air leaves the impeller tip approximately at right angles to its intake direction. (f) Impellers operate at tip speeds of up to 500 meter per second to give high tangential air velocity for conversion to pressure. (g) Impellers are of two types (i) Single entry impeller (ii) Double entry impeller

- 41. Single Entry Impeller 8. Type of an impeller in which air is falling on one side (towards intake). (a) Single Stage (b) Double Stage Advantages 9. (a) The single-sided, single- entry impeller lends itself to efficient ducting. (b) Makes more use of the ram effect at high speeds than does the double-entry arrangement.

- 42. (c) This leads to an increase in the overall diameter of the engine for a given thrust.

- 43. Double Entry Impeller 10. (a) Type of an impeller in which air is falling on both sides of impeller. (b) It can handle a higher mass flow. (c) The airflow to the rear side is reversed in direction.

- 44. (d) Penalties are (i) Relatively inefficient intake ducting. (ii) Preheating imparted to the air by virtue of its reversal on entry.

- 46. Diffuser 11. (a) Used to convert energy of the air leaving the compressor to pressure energy. (b) Formed integral with the compressor casing or be bolted to it. (c) The vane passages are divergent to convert the velocity energy into pressure energy.

- 47. AXIAL FLOW COMPRESSOR Definition 1. Compressor in which air flows axially Purpose 2. Converts kinetic energy into static pressure energy - How it converts? • Rows of rotating blades (rotors) impart kinetic energy to the air • Alternate rows of stationary diffusing vanes (stators), convert the kinetic energy to pressure energy

- 48. Construction 3. Consists of an annular passage Series of small blades of aerofoil section, alternately rotating on a central shaft assembly or fixed to the outer case Each pair of rotor and stator rings is termed a stage

- 49. Typical gas turbine engine may have between 10 and 15 stages on a single spool Divided between multiple spools An additional row of stator blades may be fitted to single spool-engines

- 50. Automatically adjusted to suit prevailing intake conditions Outlet guide vanes straighten the airflow into the combustion stage The cross-sectional area of the annulus is progressively reduced To maintain constant axial velocity with increasing density

- 51. Types 4. (a) Single spool (b) Multi spool

- 52. DOUBLE SPOOL

- 56. COMPRESSOR STALL AND SURGE Introduction A compressor is designed to operate between certain critical limits of rpm, pressure ratio and mass flow. If operation is attempted outside these limits, the flow around the compressor blades breaks down to give violent turbulent flow. When this occurs, the compressor will stall or surge. The greater the number of stages in the compressor more complex will be the situation.

- 57. Stalling of Compressor Rotor Blades These blades (which are like small aero foils) stall in the same way as the wings of an aircraft. Stalling of wing occurs at high angle of attack when the flow separates from the upper surface of wing. Since the pitch of the blades is fixed, this condition is brought about by a change in direction of the relative airflow (V1).

- 58. Stalling of Compressor Rotor Blades A reduction in the axial velocity Va to a value Va1 while the rpm and hence blade speed U remains constant. Increases the angle of attack. If the fall in Va is sufficient, the blade stalling angle will be reached.

- 59. Stalling of Compressor Rotor Blades The fall in Va at constant rpm is associated with a reduction in mass flow from the stable value due to a variety of causes. Generally, when the critical condition is approached due to velocity gradients and local effects, a group of blades will be affected first rather than the complete blade row. A stall cell would be generated. The stall “cell” moves around the blade row. There may be several “cells” which can stall the whole row.

- 60. Compressor Stall at Low Rpm Compressor Acceleration Stall Compressor Stall at High Rpm TYPES OF COMPRESSOR STALL

- 61. Compressor Stall at Low Rpm With a reduction in mass flow rate at low rpm, the angle of attack of the first low pressure stage is greater than that of the high pressure stages. Due to this reason the low pressure stages will first stall. It is not necessary that the succeeding stages will be affected. Stalling of the initial compressor stages may be indicated by an audible rumbling (low or dull) noise and a rise in turbine gas temperature (TGT). In the latter case, a further reduction in mass flow would cause a successive breakdown of the remaining stages.

- 62. Compressor Acceleration Stall On starting or during rapid acceleration from low rpm, there will be increase in mass flow rate of air and additional fuel will be sprayed in the combustion chamber. During combustion, there will be sudden increase in combustion pressure which causes a momentary back pressure. This affects the compressor performance and hence, there will be reduction in the mass flow rate which causes the same effects as described above.

- 63. Compressor Stall at High RPM At high compressor rpm, the angle of attack of all the stages is almost same. If there is sudden reduction in mass flow then a simultaneous breakdown of flow through all the stages is caused. This type of stall is usually initiated by airflow interference at the intake during certain maneuvers or gun firing. The compressor may be un-stalled by throttling fully back, but in some cases it may be necessary to stop the engine.

- 64. COMPRESSOR SURGE In an axial compressor, surging indicates a complete instability of flow through the compressor. Surging is a motion of airflow forwards and backwards through the compressor, which is accompanied by audible indications ranging from soft rumblings to an abrupt explosion and vibration, depending on the degree of severity. Surge is indicated by rapid rise in turbine gas temperature (TGT ) and fluctuation or falling of rpm. Compressor surge causes very severe vibrations and excessive temperatures in the engine. A compressor stall usually leads to a compressor surge.