Limit state of serviceability

- 2. WORKING STRESS METHOD: Structure is designed assuming that it is in working condition, it uses permissible stresses and factors of safety for design. LIMIT STATE METHOD: Structures are designed with this method assuming that the structure has reached its limit state. The object of design is based on the concept that the structure should not become unserviceable in its lifetime for the use for which it is intended. LIMIT STATE METHOD

- 3. Concerned with functioning of structure or structural members under normal use, or comfort of people or appearance of the construction works

- 5. Concrete should be able to perform satisfactorily in anticipated exposure conditions during its service life. Durability is mainly affected by: 1. Permeability of concrete 2. Environment 3. Cover to embedded steel 4. Type and quality of constituent material 5. Cement content and water cement ratio 6. Workmanship; for full compaction and curing 7. Shape and size of member

- 6. 1) PERMEABILITY: Low permeability is achieved by having adequate cement content, sufficiently low water cement ratio, complete compaction and adequate curing. 2) ENVIRONMENT: General environment to which concrete will be subjected to is classified in 5 levels of severity i. e. mild, moderate, severe, very severe & extreme.

- 7. 3) COVER TO CONCRETE: #cls.26.4 • For longitudinal reinforcing bars in column nominal cover should not be less than 40mm or the dia. of such bar. For columns with dimensions less than 200mm a cover of 25mm may be used. • For footings minimum cover shall be 50mm.

- 8. 4) CONSTITUENT MATERIAL: #cls.8.2.5 Deleterious constituents such as chlorides and sulphates should not exceed limits

- 9. 5) CEMENT CONTENT & WATER CEMENT RATIO : OPC in excess of 450 kg/m3 should not be used unless special consideration in design has been given to the risk of cracking.

- 10. 6) COMPACTION AND CURING: • Adequate compaction without segregation should be ensured. • Overworking the surface and addition of water/cement should be avoided. • Curing is essential to reduce permeability of concrete . • #cls.13.5 provides for moist curing which should be done for atleast 7 days for OPC and minimum 10 days(extendable to 14) for other types of blended cements.

- 11. 7) SHAPE AND SIZE OF MEMBER: • Design of exposed structures should promote good drainage of water. • For structures subjected to partial hydrostatic pressure life can be lengthened by providing extra cover to steel, chamfering the corners or using circular cross sections.

- 13. 1) OVERTURNING: #cls.20.1 Restoring moment shall not be less than 1.2(max. overturning moment due to characteristic DL) +1.4(max. overturning moment due to characteristic IL) *in cases where only DL provides restoring moment, 0.9(characteristic DL) shall b considered. The anchorages provided for overhanging members shoulrd be such that static equilibrium is maintained.

- 14. 2) SLIDING: The structure should have a factor of not less than 0.4 against sliding. 3)VARIATION IN DEAD LOAD: probable variation in dead load during construction, repair etc should be taken into account. 4)MOMENT CONNECTIONS: For designing framework of building, adequate moment connections or system of bracing should be provided to transmit horizontal forces to the foundation. 5)LATERAL SWAY: Lateral sway at the top of building should not exceed H/500. *H is total height of building.

- 16. . Fire resistance of concrete depends on member size, cover to reinforcement and type of aggregate.

- 18. A structural element when designed for design load should not undergo excessive deflection. Causes for short term deflection are: 1. Magnitude and distribution of live load 2. Span and type of end restraints 3. Cross sectional properties and % of steel. 4. Stress in reinforcement 5. Amount and extent of cracking

- 19. Causes of long term deflection are: 1. Humidity and temperature conditions at the time of curing of concrete. 2. Age of concrete at the time of loading 3. Other factors influencing shrinkage and creep: type and size of aggregate, water cement ratio, size of member, presence of compression reinforcement etc.

- 20. The total deflection due to all loads should not exceed span/250 for slabs, beams and other horizontal members. The deflection should not exceed span/350 or 20 mm whichever is less for these members, after the construction of partitions and finishes etc, in order to avoid damage to them.

- 21. IS 456 cls.23.2.1 recommends that if span/effective depth ratio are kept below the following( for span less than 10m) then vertical deflection will not be excessive. For simply supported and continuous span over 10m the ratio must be multiplied by a factor F given as: 10/span in metres. For cantilevers over 10m in length, actual deflection has to be calculated and checked with the provisions of LSM for deflection. TYPE OF SUPPORT RECTANGULAR SECTIONS CANTILEVER 7 SIMPLY SUPPORTED 20 CONTINUOUS 26

- 23. * For flanged beams the values for rectangular section need to be multiplied by reduction factor which is worked out from the graph below:

- 25. EXPOSURE INTENSITY CRACK WIDTH MODERATE EXPOSURE Limited to 0.2mm SEVERE EXPOSURE Limited to 0.1mm AGGRESSIVE EXPOSURE Not more than 0.004mm Cracks develop when tensile strength of concrete is exceeded. Cracks are an eyesore, affect strength of structure & exposes reinforcement making it vulnerable to corrosion. As per cls.35.3.2 the crack width at the surface of concrete should not exceed 0.3mm for the sake of appearance.

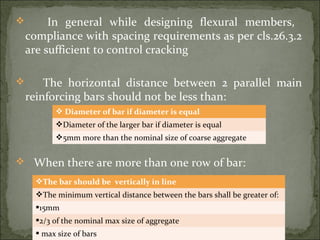

- 26. In general while designing flexural members, compliance with spacing requirements as per cls.26.3.2 are sufficient to control cracking The horizontal distance between 2 parallel main reinforcing bars should not be less than: When there are more than one row of bar: Diameter of bar if diameter is equal Diameter of the larger bar if diameter is equal 5mm more than the nominal size of coarse aggregate The bar should be vertically in line The minimum vertical distance between the bars shall be greater of: 15mm 2/3 of the nominal max size of aggregate max size of bars

- 27. If greater spacing is required crack width has to be checked as per formula mentioned in Annexure F of IS 456

- 29. SLENDER BEAMS Those beams in which breadth of compression face is small as compared with its depth and thus the compression side has a tendency to buckle. #cls 23.3 TYPE OF BEAM CLEAR DISTANCE BETWEEN LATERAL SUPPORTS OR FROM FREE END TO FIXED END SIMPLY SUPPORTED OR CONTINUOUS BEAM <60b OR <250b2/d (whichever is less) CANTILEVER BEAM <25b OR < 100b2/d (whichever is less)

- 31. Vibrations may be caused by machines with rotating parts, electric overhead cranes, wind or earthquake loads or simply by intense repair work in a structure. These vibrations lead to cracks in the structural elements overtime not to mention disturbance to the inhabitants, rendering the structure unserviceable. Code is silent but research is needed on this topic.

- 32. PRESENTED BY: ADITI SHARMA SAURABH SOOD CHARUL SHARMA