Module 7 design concepts in ic engine.ppt

- 1. NEW DESIGN CONCEPTS IN I.C. ENGINE • Lean Burn S.I. Engine • Alternative Fuel Engine • Adiabatic Diesel Engine

- 2. NEW DESIGN CONCEPTS IN I.C. ENGINE (Contd.) • Turbocharged and Turbocharged After Cooled Engines • Multi-valve Engines • Variable Valve Timing Engines

- 3. NEW DESIGN CONCEPTS IN I.C. ENGINE (Contd.) • Surface Ignition Diesel Engine • Stratified Charge Engine • Homogeneous Charge Compression Ignition Engine

- 8. • In a stratified charge engine, the fuel is injected into the cylinder just before ignition. This allows for higher compression ratios without "knock," and leaner air/fuel mixtures than in conventional internal combustion engines.

- 10. • A stratified charge engine concentrates a rich mixture near the spark plug (air-fuel ratio is less than 14:1) and lean mixture (at air-fuel ratios of 50:1or greater) throughout into the cylinder. • It uses a direct-injection system like the Diesel, with its ability to be run at high compressions. • However, like Otto it relies on gasoline’s ability to mix quickly and burn cleanly in order to avoid the poor combustion found in diesel.

- 11. ADVANTAGES As very rich mixture near spark plug that ignites easily and burns smoothly. As the combustion proceeds, it meets a very lean area (often only air) where it cools rapidly and the harmful Nox never has a chance to form. The additional oxygen in the lean charge also combines with any CO to form CO2, which is less harmful. Hence allows for the elimination of the catalytic converter

- 12. Limitations They have significantly higher HC at medium load and NOx emissions at very high load. With increasing load, the injected volume of fuel must increase. The area around the spark plug with rich mixture becomes larger. It tried to increase the velocity and swirl of the intake charge in keeping the rich and lean mixtures separated.

- 13. Need for Stratification 1.Ultra-lean air-fuel mixtures. 2.Overall higher fuel economy. 3.Gain in thermal efficiency. 4.Increased compression ratio. 5.Lower the temperature at which the fuel is sprayed ,this leads to a reduction in fuel consumption. 6.Decreases heat losses. 7.Decreasing the overall emissions.

- 14. HCCI

- 15. HCCI-Advantages • Lean combustion returns 15 percent increase in fuel efficiency over a conventional spark ignition engine. • Cleaner combustion and lower emissions (especially NOx) than a conventional spark ignition engine. • Compatible with gasoline as well as E85 (ethanol) fuel. • Fuel is burned quicker and at lower temperatures, reducing heat energy loss compared to a conventional spark engine. • Throttleless induction system eliminates frictional pumping losses incurred in traditional (throttle body) spark engines.

- 16. Disadvantages • High cylinder pressures require stronger (and more expensive) engine construction. • More limited power range than a conventional spark engine. • The many phases of combustion characteristics are difficult (and more expensive) to control.

- 17. Low Heat Rejection (LHR) Engines • Also called as adiabatic engines, introduced in 1980s • Principle: About 1/3rd of fuel energy is lost as heat to coolant. Insulating the cylinder walls using a Thermal Barrier Coating (TBC) reduces thermal losses. • Theoretically it should improve the power output • In practice, the energy recovered is lost via exhaust due to the higher temperature of the products of combustion, no much surge in BP. However, energy of exhaust can be harnessed by turbocharging/compounding. • Using TBC, 10% reduction in coolant loss, corresponding increase in exhaust loss. MEE 3004 - IC Engines 30% Brake Power 30% Coolant 35% Exhaust Gas 5% Friction Energy Supplied (Combustion) 100% Heat Engine QSupplied QRejected W

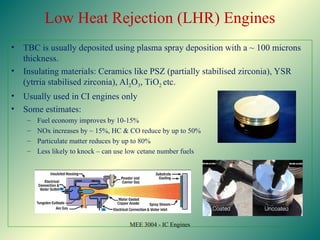

- 18. Low Heat Rejection (LHR) Engines • TBC is usually deposited using plasma spray deposition with a ~ 100 microns thickness. • Insulating materials: Ceramics like PSZ (partially stabilised zirconia), YSR (ytrria stabilised zirconia), Al2O3, TiO2 etc. • Usually used in CI engines only • Some estimates: – Fuel economy improves by 10-15% – NOx increases by ~ 15%, HC & CO reduce by up to 50% – Particulate matter reduces by up to 80% – Less likely to knock – can use low cetane number fuels MEE 3004 - IC Engines

- 19. Lean Burn Engines • In use since 1984, Toyota introduced the first Lean burn combustion control engine and it is named as (Toyota Total Clean – Lean ) TTC-L engine. • Principle: Leaner mixtures provide better efficiency (closer to air standard, low temperature, hence less heat loss), lower emissions (complete combustion) • Can operate at equivalence ratios as low as 0.3 with direct injection (GDI) • Benefits – BSFC is 5 – 25% lower, HC emissions up to 80% less – Less chance of knocking – can use high CR – better efficiency – Using fuel injection, Carburetion can be eliminated – Fuel flexibility • Drawbacks: – Difficult to ignite – need more intense spark (can be overcome by stratification, as in GDI) – Too lean can cause misfire, flame quenching, HC formation – Low burning velocity, less power • Sometimes spark plug is located in a pre-chamber with relatively rich mixture for easy ignition, flame consumes lean mixture in main chamber • Can’t operate with three way catalytic converter – require special system (e.g. SCR) for NOx reduction MEE 3004 - IC Engines

- 20. RCCI Reactivity Controlled Compression ignition

- 21. RCCI

- 24. Performance and Emissions • Performance comparable with that of diesel • Lower emissions at low load especially low Nox. • At higher load the Nox emissions are higher.

- 25. Disadvantages The many phases of combustion characteristics are difficult (and more expensive) to control.

- 61. HEV-HYBRID ELECTRIC VEHICLE A vehicle that has two or more energy conversion technologies combined with one or more energy storage units, electricity and fuel. • Electricity means that a battery is used to store the energy, and that an electromotor will be used as traction motor. • Fuel means that a tank is required, and that an Internal Combustion Engine is used to generate mechanical power, or that a fuel cell will be used to convert fuel to electrical energy. In the latter case, traction will be performed by the electromotor only. In the first case, the vehicle will have both an engine and a motor.

- 62. Why HEV? • Maximize fuel economy • Minimize fuel emissions • Minimize propulsion system cost to keep affordable • Maintain acceptable performance with a reasonable cost • Reduce the conventional car weight

- 63. HEV- Advantages • Regenerative Braking • Reduction in engine and vehicle weight • Fuel efficiency is increased • Emissions are decreased • Cut emissions of global warming pollutants by 1/3 or 1/2 • Reduce the dependency on fossil fuels

- 65. Components of a Hybrid Electric Vehicle • Battery (auxiliary) • DC/DC converter • Electric generator • Electric traction motor • Exhaust system • Fuel filler • Fuel tank • Internal combustion engine • Power electronics controller • Thermal system (cooling. • Traction battery pack • Transmission

- 66. Plug in Hybrid Electric vehicle

- 67. Components of a Plug-in Hybrid electric car • Battery (auxiliary) • Charge port • DC/DC converter • Electric generator: • Electric traction motor • Exhaust system: • Fuel filler • Fuel tank (gasoline) • Internal combustion engine • Onboard charger • Power electronics controller • Thermal system (cooling) • Traction battery pack • Transmission

- 68. Hybrid Vehicle Vs Plug-In HybridVehicle • Size • Cost • Electric battery • plug-in hybrid's electric battery can be recharged at home or a public charging station • full hybrid car recharges its electric battery using its gas-powered engine.

- 69. Electric Vehicle

- 70. Components of a Electric vehicle • Battery (all-electric auxiliary) • Charge port • DC/DC converter • Electric traction motor • Onboard charger • Power electronics controller • Thermal system (cooling) • Traction battery pack • Transmission

- 71. Drive train of HEV • Electric Motors/Controllers • Electric Energy Storage systems • Hybrid power units • Transmission

- 72. • Basic Components – An Armature or Rotor – A Commutator – Brushes – An Axle – Field Magnet – DC Power Supply Electric Motors/Controllers

- 73. Electric Motors/Controllers Advanced electronics allows the motor to act as a generator Draws energy to accelerate and regenerates the battery when slowing down Motor uses magnets and magnetism to create motion

- 74. Electric Energy Storage Systems • Batteries: Lithium Ion and Nickel-metal hydride batteries • Ultra capacitors • Flywheels

- 75. Energy Storage: Ultracapacitors Store energy as an electric charge in a polarized liquid layer between an ionically electrolyte and conducting electrode Primarily used for acceleration, climbing hills and regenerative braking

- 76. Energy Storage: Flywheel Store kinetic energy within a rapidly spinning wheel Complex, heavy, and large Contains no acid or hazardous material Not affected by temperature Delivers a smooth flow of power

- 77. Regenerative Braking When the driver apply brakes, the motor becomes a generator and the kinetic energy generates electricity stored into the battery The Toyota Prius uses about 30% of the heat lost kinetic energy from braking

- 78. Hybrid Power Units 4 Types: Compression Ignition Direct Injection Engines (CIDI) Spark Ignition Engines Gas Turbines Fuel Cells

- 79. Hybrid Power Units: CIDI • Most promising power unit • Achieves combustion through compressions without the use of a spark plug • High pressure injection of the fuel into the combustion chamber • Throttle and heat losses travels into the combustion chamber increasing thermal efficiency

- 80. Hybrid Power Units: Spark Ignition Engine • Runs on Otto cycle • Uses a homogeneous air-fuel mixture before entering the combustion chamber • When the combustion chamber is compressed, the spark plug is ignited • Controlled by limiting the amount of air allowed into the engine

- 81. Hybrid Power Units: Gas Turbines Runs on a Brayton cycle A compressor raises the pressure and temperature of the inlet air. Air is moved to the burner and fuel is injected and combusted to raise the air temperature. Power is produced when the heated pressure mixture is expanded and cooled through the turbine.

- 82. Hybrid Power Units: Fuel Cells Generate electricity through an electrochemical reaction combining hydrogen with ambient air Pure hydrogen or any fossil fuel produced is used as hydrogen-rich gas Water vapor is emitted

- 83. Transmission systems Continuous Variable Transmission (CVT) Automated shifted transmission Manual transmission Traditional automatic transmission with torque converter

- 86. Series Configuration Small fuel-burning engine that directly drives an alternator to generate electricity Electricity is stored in the battery or sent the to electric motor When the batteries are drained to a certain level, the engine turns on and recharges the battery

- 87. Series Hybrid Vehicle • In a series hybrid system, the combustion engine drives an electric generator (usually a three-phase alternator plus rectifier) instead of directly driving the wheels. The electric motor is the only means of providing power to the wheels. The generator both charges a battery and powers an electric motor that moves the vehicle. When large amounts of power are required, the motor draws electricity from both the batteries and the generator.

- 88. Advantages of series hybrid vehicles: • There is no mechanical link between the combustion engine and the wheels. The engine-generator group can be located everywhere. • There are no conventional mechanical transmission elements (gearbox, transmission shafts). Separate electric wheel motors can be implemented easily. • The combustion engine can operate in a narrow rpm range (its most efficient range), even as the vehicle changes speed. • Series hybrids are relatively the most efficient during stop-and- go city driving.

- 89. Limitations of series hybrid vehicles: • The ICE, the generator and the electric motor are dimensioned to handle the full power of the vehicle. Therefore, the total weight, cost and size of the power train can be excessive. • The power from the combustion engine has to run through both the generator and electric motor. During long-distance highway driving, the total efficiency is inferior to a conventional transmission, due to the several energy conversions

- 90. PARALLEL HYBRID

- 91. PARALLEL HYBRID

- 92. Parallel Configuration Two power paths Hybrid power unit or electric propulsion system or both can power the wheels For long trips the engine is used For hills, acceleration, and high power scenarios the electric motor is used

- 93. PARALLEL HYBRID • Most designs combine a large electrical generator and a motor into one unit, often located between the combustion engine and the transmission, replacing both the conventional starter motor and the alternator. • The battery can be recharged during regenerative braking, and during cruising (when the ICE power is higher than the required power for propulsion). • As there is a fixed mechanical link between the wheels and the motor (no clutch), the battery cannot be charged when the car isn’t moving.

- 94. Advantages of parallel hybrid vehicles: • Total efficiency is higher during cruising and long- distance highway driving. • Large flexibility to switch between electric and ICE power • Compared to series hybrids, the electromotor can be designed less powerful than the ICE, as it is assisting traction. Only one electrical motor/generator is required.

- 95. Drawbacks of parallel hybrid vehicles: • Rather complicated system. • The ICE doesn’t operate in a narrow or constant RPM range, thus efficiency drops at low rotation speed. • As the ICE is not decoupled from the wheels, the battery cannot be charged at standstill.

- 96. Series- parallel Hybrid vehicle

- 97. Hybrid cars Toyota Prius Honda Insight

- 98. Toyota Prius Honda Insight Electric Motor/Generator/Po wer Storage Output 273.6V (228 cells @ 1.2V) 144V (120 cells @ 1.2V) Battery Type Nickel-Metal Hydride Nickel Metal Hydride Power Output 33kW @ 5600rpm 10kW @ 3000rpm Transmission ECVT CVT Mileage City/Highway 52/45 61/68 Gasoline Engine Horsepower @ rpm 51.45kW @ 4500rpm 49.24 kW @ 5700rpm Emission Rating SULEV ULEV

- 99. HEV - Challenges • Energy storage devices with high power-to- energy ratios • Frequent shut down and start up of the HEV • Reduce the size, weight, and cost • Higher efficiency in the conversion of fuel to useful power • Advanced configurations for the propulsion system components

- 100. FCV • A fuel cell vehicle (FCV) or fuel cell electric vehicle (FCEV) is a type of electric vehicle which uses a fuel cell, instead of a battery, or in combination with a battery or super capacitor, to power its on-board electric motor.

- 101. • Fuel cells in vehicles generate electricity to power the motor, generally using oxygen from the air and compressed hydrogen. Most fuel cell vehicles are classified as Zero emission vehicles that emit only water and heat.

- 102. • As compared with internal combustion vehicles, hydrogen vehicles centralize pollutants at the site of the hydrogen production, where hydrogen is typically derived from reformed natural gas. Transporting and storing hydrogen may also create pollutants

- 103. Hydrogen

- 110. Toyota Mirai

- 111. Honda Clarity fuel cell

- 112. Hyundai Nexo

- 113. Challenges Accurate techniques to determine battery state of charge Develop abuse-tolerant batteries Recyclability

- 114. Batteries Nickel-Metal Hydride Lithium Ion Current Uses Computer and Medical equipment Laptops and Cell phones Life Cycle Much larger than lead acid batteries Low Current contribution Used successfully in low production of HEVs Challenges High Cost High self-discharge Heat generation Control losses of hydrogen Low cell efficiency Life cycle Cell and battery safety Acceptable cost Miscellaneous Reasonable specific energy and power Components are recyclable Abuse-tolerant High specific energy and power High energy efficiency Good high-temperature performance Low self-discharge Recyclable parts

- 117. Components • Solar Arrays • Power trackers • Batteries • Motor & Controller

- 118. Solar Array: Collects the energy from the sun and converts it to usable Electrical Energy

- 120. Power tracker: The power trackers Convert the solar array voltage to system voltage.

- 121. Power Trackers to batteries

- 122. Batteries to motor

- 123. Motor to wheels

- 124. Solar cell • A solar cell converts solar energy to electric energy. Photons in sunlight provide the energy that moves electrons from one layer of semi conducting metallic wafer to another. The movement of electrons creates a current. • Solar cells are devices which convert solar energy directly into electric energy. The most common solar cells function by the photovoltaic effect. Photo means light and voltaic reference to a Italian electricity pioneer alessandro volta.

- 125. • A solar cell is a sandwich of n-type silicon (blue) and p-type silicon (red). It generates electricity by using sunlight to make electrons hop across the junction between the different flavors of silicon: • When sunlight shines on the cell, photons (light particles) bombard the upper surface. • The photons (yellow blobs) carry their energy down through the cell. • The photons give up their energy to electrons (green blobs) in the lower, p- type layer. • The electrons use this energy to jump across the barrier into the upper, n-type layer and escape out into the circuit. • Flowing around the circuit, the electrons make the lamp light up.

- 126. • The power produced by the solar array varies depending on the weather, the sun’s position in the sky, and the solar array itself. On a bright, sunny day at noon, a good solar array will produce well over 1000 watts. The power from the array is used either to power the electric motor or stored in the battery pack for use.

- 127. Power Trackers • Power trackers condition the electric power from the solar array to maximize the power and deliver it either to the batteries for the storage or the motor controller for propulsion. • The power trackers are of light weight and reach efficiencies of around 95%.

- 128. Power Trackers

- 129. Electric Motor • It is the most important part of the car. It should work with optimal power and high efficiency. An electric motor is the one which converts electric energy into mechanical energy by the interactions of the magnetic fields and current carrying conductors.

- 130. Speed controller • The purpose of the motor speed controller is to take a signal representing the demanded speed, and to drive a motor at that speed. The controller may record the speed of the motor.

- 131. THANK YOU

Editor's Notes

- #19: Toyota, Honda, Mitsubishi