POLYMERS

- 1. POLYMERS By Mr. H.P.Varade Assistant Professor Sanjivani College of Engineering, Kopargaon, District-Ahmednagar

- 2. What is a polymer? • A long molecule made up from lots of small molecules called monomers.

- 3. Polymers Very Large molecules structures chain-like in nature. Poly mer many repeat unit Adapted from Fig. 14.2, Callister 7e. C C C C C C HHHHHH HHHHHH Polyethylene (PE) ClCl Cl C C C C C C HHH HHHHHH Polyvinyl chloride (PVC) HH HHH H Polypropylene (PP) C C C C C C CH3 HH CH3CH3 H repeat unit repeat unit repeat unit

- 4. Polymer Composition Most polymers are hydrocarbons – i.e. made up of H and C • Saturated hydrocarbons – Each carbon bonded to four other atoms CnH2n+2 C C H H H H H H

- 5. Definition of Polymer • A polymer ( Greek poly-, "many" + -mer, "part") is a large molecule, or macromolecule, composed of many repeated subunits. • Due to their broad range of properties,both synthetic and natural polymers play essential and ubiquitous roles in everyday life. • Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. • Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. • Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, viscoelasticity, and a tendency to form glasses and semicrystalline structures rather than crystals.

- 6. Common Examples of Polymers • Polymers are of two types: naturally occurring and synthetic or man made. • Natural polymeric materials such as hemp, shellac, amber, wool, silk, and natural rubber have been used for centuries. A variety of other natural polymers exist, such as cellulose, which is the main constituent of wood and paper. • The list of synthetic polymers, roughly in order of worldwide demand, includes polyethylene, polypropylene, polystyrene, polyvinyl chloride, synthetic rubber, phenol formaldehyde resin (or Bakelite), neoprene, nylon, polyacrylonitrile, PVB, silicone, and many more. More than 330 million tons of these polymers are made every year (2015).

- 7. • Most commonly, the continuously linked backbone of a polymer used for the preparation of plastics consists mainly of carbon atoms. • A simple example is polyethylene ('polythene' in British English), whose repeating unit is based on ethylene monomer. • Many other structures do exist; for example, elements such as silicon form familiar materials such as silicones, examples being Silly Putty and waterproof plumbing sealant. • Oxygen is also commonly present in polymer backbones, such as those of polyethylene glycol, polysaccharides (in glycosidic bonds), and DNA (in phosphodiester bonds)

- 8. 8 Chemistry and Structure of Polyethylene •Polyethylene is a long-chain hydrocarbon. •Top figure shows repeat unit and chain structures. •Other figure shows zigzag backbone structure. Tetrahedral arrangement of C-H

- 9. Chapter 4 - 9 Polymers – Molecular Shape Molecular Shape (or Conformation) – chain bending and twisting are possible by rotation of carbon atoms around their chain bonds – note: not necessary to break chain bonds to alter molecular shape Adapted from Fig. 4.5, Callister & Rethwisch 3e. – C-C bonds are typically 109° (tetrahedral, sp3 carbon)

- 10. Molecular structure of Polymers- Physical properties of polymers depend not only on their molecular weight/shape, but also on the difference in the chain structure. Four main structures • Linear polymers • Branched polymers • Crosslinked polymers • Network polymers

- 11. polymers in which the mer units are connected end- to-end along the whole length of the chain These types of polymers are often quite flexible • Van der waal’s forces and H-bonding are the two main types of interactions between chains • Some examples – polyethylene, teflon, PVC, polypropylene 1.Linear polymers

- 12. 2.Branched polymers • Polymer chains can be like branches: • Or the fibers may aligned parallel, as in fibers and some plastic sheets. • This leads to inability of chains to pack very closely together • These branches are usually a result of side-reactions during the polymerization of the main chain

- 13. 3.Crosslinked polymers • Molecular structure – adjacent chains attached via covalent bonds • Carried out during polymerization or by a non-reversible reaction after synthesis (referred to as crosslinking) • Materials often behave very differently from linear polymers • Many “rubbery” polymers are crosslinked to modify their mechanical properties; in that case it is often called vulcanization • Generally, amorphous polymers are weak and cross-linking adds strength: vulcanized rubber is polyisoprene with sulphur cross-links:

- 14. 4.Network polymers – polymers that are “trifunctional” instead of bifunctional – There are three points on the mer that can react – This leads to three-dimensional connectivity of the polymer backbone • Highly crosslinked polymers can also be classified as network polymers • Examples: epoxies, phenol-formaldehyde polymers

- 15. 2 • Covalent chain configurations and strength: Direction of increasing strength Adapted from Fig. 14.7, Callister 6e. POLYMER MICROSTRUCTURE

- 16. Polymerization:- Process of forming polymer. Linear Polymer:- Polymer which is obtained by simply adding monomers together to form long chain. Copolymer:- Polymer which is obtained by different types of monomers. Degree of Polymerization, DP :- It is ratio of molecular weight of polymer to molecular weight of single monomer.

- 17. Types of polymers:- 1.Thermoplastics • No cross links between chains. • Weak attractive forces between chains broken by warming. • Change shape - can be remoulded. • Weak forces reform in new shape when cold. • E.g. Polyethylene ,PVC, Polystyrene

- 18. 2.Thermosets • Extensive cross-linking formed by covalent bonds. • Bonds prevent chains moving relative to each other. • E.g. Epoxies ,Phenolics

- 19. 3 • Thermoplastics: --little cross linking --ductile --soften with heating --polyethylene polypropylene polycarbonate polystyrene • Thermosets: --large cross linking (10 to 50% of mers) --hard and brittle --do NOT soften with heating --vulcanized rubber, epoxies, polyester resin, phenolic resin Callister, Fig. 16.9 T Molecular weight Tg Tmmobile liquid viscous liquid rubber tough plastic partially crystalline solid crystalline solid Thermoplastic vs Thermoset

- 20. 2020 Types of polymerization 1.Addition (Chain) Polymerization – Initiation – Propagation – Termination

- 21. Some Common Addition Polymers

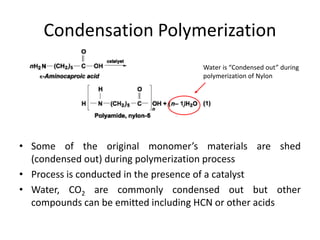

- 23. Condensation Polymerization • Some of the original monomer’s materials are shed (condensed out) during polymerization process • Process is conducted in the presence of a catalyst • Water, CO2 are commonly condensed out but other compounds can be emitted including HCN or other acids Water is “Condensed out” during polymerization of Nylon

- 25. Polymer Processing 1. Molding: • Compression and transfer molding – Applicable for thermoplastics or thermosets

- 26. 2. Injection molding: Polymer is melted in chamber & then the molten polymer is forced under pressure into the die – thermoplastic & some thermosets – High speed production

- 28. 3. Extrusion: An extruder is a device that uses a large screw and heating coils to melt a polymer, compress it, & force it into a mold.

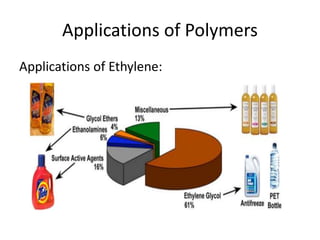

- 29. Applications of Polymers Applications of Ethylene:

- 30. • Applications of Ethylene:

- 31. REFERENCES • Callister & Rethwisch, Materials Science and Engineering: An Introduction-John Wiley and Sons • www.wikipedia.org