PPT ON TYPES OF PATTERN

- 1. GANDHINAGAR INSTITUTE OF TECHNOLOGY(012) SUBJECT : Manufacturing Process – 2 (2141908) ALA Topic : Types of Pattern Prepared by : JERIN SIBI (150120119052) Class : 4 – B1(MECHANICAL) Guided by :Professor Hitesh H. Patel

- 2. CONTENTS What is metal casting process? What is pattern? Different types of pattern

- 3. WHAT IS METAL CASTING PROCESS? In metalworking, casting means a process, in which liquid metal is poured into a mold, that contains a hollow cavity of the desired shape, and is then allowed to cool and solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process.

- 4. WHAT IS PATTERN? In casting, a pattern is a replica of the object to be cast, used to prepare the cavity into which molten material will be poured during the casting process. Patterns used in sand casting may be made of wood, metal, plastics or other materials.

- 5. REQIREMENT OF GOOD PATTERN Secure the desired shape and size of the casting. Cheap and readily repairable. Simple in design for ease of manufacture. Light in mass and convenient to handle. Have high strength and long life in order to make as many moulds as required. Retain its dimensions and rigidity during the definite service life. Its surface should be smooth and wear resistant. Able to withstand rough handling.

- 6. DIFFERENT TYPES OF PATTERN Several types of patterns are used in foundries depending on the casting requirements the pattern may conform to one of the following types : Solid piece pattern Segmental pattern Split piece pattern Follow board pattern Match plate pattern Lagged up pattern Cope and drag pattern Multi piece pattern Loose piece pattern Gated patterns Sweep patterns Skelton pattern Shell pattern

- 7. SOLID OR SINGLE PATTERN It is the simplest of all patterns is made in one piece and carries no joints, partition or loose pieces. The pattern is cheap and it is best suited for limited production only. Since its moulding involves a large number of manual operations like gate cutting, providing runner and risers. so, such patterns are used for producing a few large castings for example, stuffing box of steam engine.

- 8. SPLIT OR TWO PIECE PATTERN These patterns are used for intricate casting of usual shapes. They are made in two parts and these two parts of the pattern are joined together with the help of dowel pins. While molding one of the patterns is contained by the drag and other by the cope. For a more complex casting, the pattern may be split in more than two parts.

- 9. MATCH PLATE PATTERN These are used for mass production these patterns find a great favor in machine moulding. A match plate pattern is a split pattern having the cope and drags portions mounted on opposite sides of a plate (usually metallic), called the “match plate” that conforms to the contour of the parting surface. The gates and runners are also mounted on the match plate, so that very little hand work is required. This results in higher productivity.

- 10. COPE AND DRAG PATTERN When very large casting are to be made, the complete pattern becomes too heavy to be handled by a single operator. such pattern is made in two parts which are separately moulded in different moulding boxes. After completion of the moulds, the two boxes are assembled to from the complete cavity. It is similar to two-piece pattern.

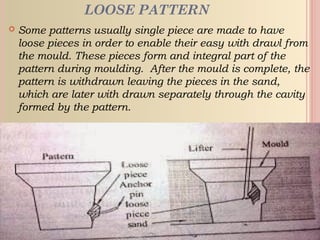

- 11. LOOSE PATTERN Some patterns usually single piece are made to have loose pieces in order to enable their easy with drawl from the mould. These pieces form and integral part of the pattern during moulding. After the mould is complete, the pattern is withdrawn leaving the pieces in the sand, which are later with drawn separately through the cavity formed by the pattern.

- 12. GATED PATTERN They are used in mass production for such castings multi – cavity moulds are prepared i.e., a single sand mould carries a number of cavities patterns and these castings are connected to each other by means of gate formers. Which provides suitable channels or gates in sand for feeding all the cavities. Gated patterns reduce the moulding time somewhat. Because of their higher cost, these patterns are used for producing small castings in mass production systems and on moulding machines.

- 13. SWEEP PATTERN Sweeps can be advantageously used for preparing moulds of large symmetrical castings. This effects a large saving in time, labour and material. A sweep is a section or board (wooden) of proper contour that is rotated about one edge to shape mould cavities having shapes of rotational symmetry. This type of pattern is used when a casting of large size is to be produced in a short time.

- 14. SKELETON PATTERN For large castings having simple geometrical shapes, skeleton patterns are used. Just like sweep patterns, these are simple wooden frames that outline the shape of the part to be cast and are also used as guides by the molder in the hand shaping of the mould. This type of pattern is also used in pit or floor molding process.

- 15. FOLLOW BOARD PATTERN A follow board is a wooden board used for support a pattern during moulding. It acts as a seat for the pattern. In the former case, the follow board is provided with a cavity corresponding to the shape of the pattern in which the pattern is seated for moulding.