Practical Programmable Logic Controllers (PLCs) for Automation and Process Control

- 1. Practical Programmable Logic Controllers (PLCs) for Automation and Process Control Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 2. Objectives In this chapter, we will learn the following: • Introduction to the PLC • Basic block diagram of the PLC • Size of the PLC system • Components of the PLC system • PLC and process interaction • Number system and codes Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 3. Introduction to the PLC “PLC” means “Programmable Logic Controller”. The word “Programmable” differentiates it from the conventional hard-wired relay logic. It can be easily programmed or changed as per the application’s requirement. The PLC also surpassed the hazard of changing the wiring. The PLC as a unit consists of a processor to execute the control action on the field data provided by input and output modules. In a programming device, the PLC control logic is first developed and then transferred to the PLC. Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 4. What can a PLC do? • It can perform relay-switching tasks. • It can conduct counting, calculation and comparison of analog process values. • It offers flexibility to modify the control logic, whenever required, in the shortest time. • It responds to the changes in process parameters within fraction of seconds. • It improves the overall control system reliability. • It is cost effective for controlling complex systems. • Trouble-shooting becomes simpler and faster. • An operator can easily interact with the process with the help of the HMI (Human-Machine Interface) computer. Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

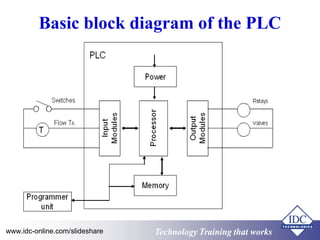

- 5. Basic block diagram of the PLC Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 6. Size of the PLC system PLCs are classified on basis of their sizes: • A small system is one with less than 500 analog and digital I/Os. • A medium system has I/Os ranging from 500 to 5,000. • A system with over 5,000 I/Os is considered large. Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

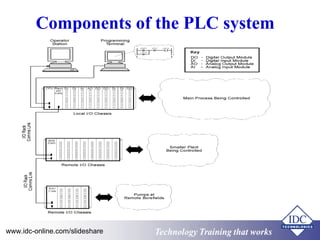

- 7. Components of the PLC system Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

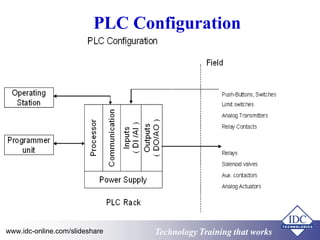

- 8. PLC Configuration Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 9. CPU or processor The main processor (Central Processing Unit or CPU) is a microprocessor-based system that executes the control program after reading the status of field inputs and then sends commands to field outputs. It is easy to perform arithmetic functions, manipulate data and calculate Boolean logic. The PLC’s memory contains the manufacturer’s operating system and housekeeping functions. It also has program written by the user and data stored by the user related to the process or equipment being controlled. Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 10. I/O section The I/O section consists of a rack and individual I/O modules, which are plugged into the rack and a DC power supply. A standard approach is to connect to the main processor rack with communication cables to a series of other I/O racks. I/O modules act as “Real Data Interface” between field and PLC CPU. The PLC knows the real status of field devices, and controls the field devices by means of to the relevant I/O cards. Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 11. Programming device A CPU card can be connected with a programming device through a communication link via a programming port on the CPU. Thus, it is possible to transfer programs from the programming device to the CPU, monitor the CPU’s program online and make necessary changes in the CPU’s program. Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 12. Operating station • An operating station is commonly used to provide an "Operating Window" to the process. It is usually a separate device (generally a PC), loaded with HMI (Human Machine Software). • This operating station can change any process set point, observe all process parameters, process alarms, etc. Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 13. PLC and process interaction The field devices or field data are broadly classified as follows: • Digital or discrete or on/off type field devices • Analog or continuous type field devices Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

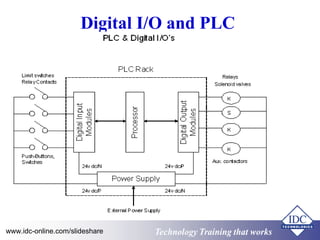

- 14. Digital I/O and PLC Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 15. Digital I/O and PLC • Discrete or digital inputs are the most common types of field inputs. Selector switches, pushbuttons, limit switches, temperature switches, level switches, flow switches, etc., are common examples. All types of switches that permit digital contact are included in this class. • Depending on the field device contacts, they are normally connected to 110VAC, 230V AC and, 24VDC types of digital input cards installed in PLC rack. Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

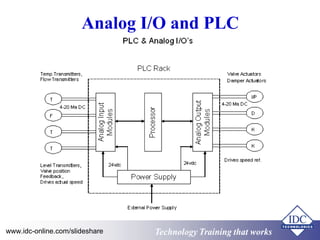

- 16. Analog I/O and PLC Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 17. Analog I/O and PLC • Analog or continuous devices are generally used for getting feedback of the process parameter control. For example, temperature transducers (RTDs, thermocouples), level, pressure, flow, etc., transmitters. • Depending on field transducer devices, they are normally connected to 0-20 or 4-20 mA DC, 0-10VDC, RTDs, thermocouples, etc., type of analog input card, installed in the PLC rack. • Analog output actuators, commonly used in the field, include continuous actuators, I/P converter for valves, reference for drives, etc. Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 18. Number systems and codes The commonly used number systems can be listed as: • Decimal number system • Binary number system • Octal number system • Hexadecimal (Hex) number system Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 19. Number systems and codes The following definitions / terms are commonly encountered: • Bit: A single binary digit that can have either value 0 or 1. • Base: This denotes the total number of digits used by the number system. • LSB (Least Significant Bit): This is the bit that represents the smallest value. • MSB (Most Significant Bit): This is the bit that represents the largest value. • Byte: A group of 8 bits. • Nibble: A group of 4 bits. • Word: A group of 16 bits Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

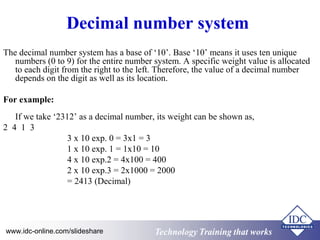

- 20. Decimal number system The decimal number system has a base of ‘10’. Base ‘10’ means it uses ten unique numbers (0 to 9) for the entire number system. A specific weight value is allocated to each digit from the right to the left. Therefore, the value of a decimal number depends on the digit as well as its location. For example: If we take ‘2312’ as a decimal number, its weight can be shown as, 2 4 1 3 3 x 10 exp. 0 = 3x1 = 3 1 x 10 exp. 1 = 1x10 = 10 4 x 10 exp.2 = 4x100 = 400 2 x 10 exp.3 = 2x1000 = 2000 = 2413 (Decimal) Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

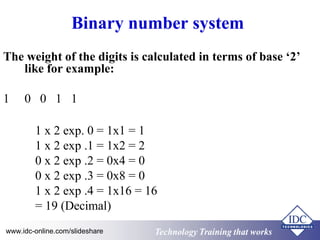

- 21. Binary number system The weight of the digits is calculated in terms of base ‘2’ like for example: 1 0 0 1 1 1 x 2 exp. 0 = 1x1 = 1 1 x 2 exp .1 = 1x2 = 2 0 x 2 exp .2 = 0x4 = 0 0 x 2 exp .3 = 0x8 = 0 1 x 2 exp .4 = 1x16 = 16 = 19 (Decimal) Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 22. Octal number system The binary system uses eight digits – from zero (0) to seven (7) to represent all the numbers. For example, the octal number 24 is represented as, 2 4 4 x 8 exp.0 = 4x1 = 4 2 x 8 exp.1 = 2x8 = 16 = 20 (Decimal) Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

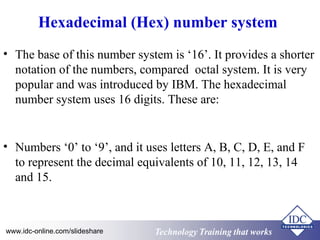

- 23. Hexadecimal (Hex) number system • The base of this number system is ‘16’. It provides a shorter notation of the numbers, compared octal system. It is very popular and was introduced by IBM. The hexadecimal number system uses 16 digits. These are: • Numbers ‘0’ to ‘9’, and it uses letters A, B, C, D, E, and F to represent the decimal equivalents of 10, 11, 12, 13, 14 and 15. Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

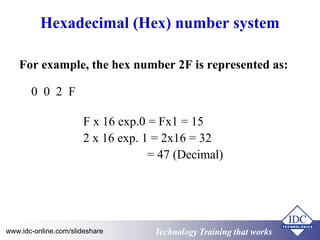

- 24. Hexadecimal (Hex) number system For example, the hex number 2F is represented as: 0 0 2 F F x 16 exp.0 = Fx1 = 15 2 x 16 exp. 1 = 2x16 = 32 = 47 (Decimal) Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 25. BCD (Binary Coded Decimal) • Binary coded decimal uses binary numbers in coded format to represent the decimal numbers (unlike the normal way; discussed in the earlier section). • It is also called as 8421 BCD code. It basically employs four binary bits, with the weights 1, 2, 4 and 8 assigned to it. Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss

- 26. DO YOU WANT TO KNOW MORE? If you are interested in further training or information, please visit: http://idc-online.com/slideshare Technology www.idc-online.com/slideshare Technology TTrraaiinniinngg tthhaatt Wwoorrkkss