Process Optimization-Pyrosection(2-11-20).pdf

- 1. © Confederation of Indian Industry Process Optimization-Pyrosection

- 2. © Confederation of Indian Industry Contents About Preheater system Pressure drop and velocity profile across Preheater Challenges in Pyrosection Concept of minimum air combustion Concept of excess of air Heat loss due to CO Importance of recuperation air Impact of secondary air on Flame Burner pipe centering methodology Challenges in cooler operation

- 3. © Confederation of Indian Industry Contents Cooler efficiency calculations Energy balance across cooler Cooler efficiency curve Function of MFR (Cross Bar) Conada Effect in IKN CFD Study Thermal efficiency Calculations Low NOx burners Latest development in cyclones

- 4. © Confederation of Indian Industry Contents Raw mix & Importance of liquid phase Kiln challenges during petcoke operation Important Case Studies Thumb rules Key points

- 5. © Confederation of Indian Industry Preheater Systems Reduction of losses in Preheater system No of stages – By design Operation of Preheater – Air infiltration Number of stages 4 stages – 725 kcal/kg 5 stages – 700 kcal/kg 6 stages – 685 kcal/kg

- 6. © Confederation of Indian Industry Beauty of PH system .. PH – Basically meant for Heat Recovery 80% in Ducts 20% in Cyclones Why not have a long duct & 1 Cyclone ?

- 7. © Confederation of Indian Industry PH System – Heat Recovery Co-current – Ducts Counter Current – Cyclones (Little !!) Key Attributes Overall – Counter current Stage wise – Co-current Material to next stage – Encounters higher temperature air !! Beauty of PH system ..

- 8. © Confederation of Indian Industry Pre-heaters Latest pre-heaters are designed with high efficiency low pressure drop cyclones and efficient heat transfer Minimum observed pressure drop in PH tower 470 mmwg for 6 stage pre-heater Best observed top stage cyclone efficiency-97% Lowest observed pre-heater exit temperature- 245 0C Minimum observed false air in pre-heater- 5%

- 9. © Confederation of Indian Industry Pressure drop & Velocity profile Across Preheater O2-5% 1 2 3 4 PH FAN 5 6 Calcine r kiln Kiln Feed O2-2.5% Fan Inlet pressure-500 mmwg Temp-923 degree C -161 mmwg-6th Temp-650 degree C -323 mmwg-4th Temp-416 degree C -373 mmwg-2nd Temp-794 degree C -221 mmwg-5th Temp-418 degree C -365 mmwg-3rd Temp-259 degree C -457 mmwg-Top Duct velocity-17 m/s

- 10. © Confederation of Indian Industry How to Calculate pressure Drop across preheater? Pressure drop across 6th stage-5th Stage = (-161)-(-221) = 60 mmwg Similarly for other cyclones 6th -5th=60 mmwg 5th-4th =102 mmwg 4th-3rd = 42 mmwg 3rd -2nd = 8mmwg………………… 2nd-1st=84 mmwg Total pressure drop=296 mmwg+161=457 mmwg Acceptable pressure drop across latest cyclones=50-60 mmwg Some thing wrong- No heat transfer Temp-418 degree C -365 mmwg-3rd Temp-416 degree C -373 mmwg-2nd To be corrected by CFD Study

- 11. © Confederation of Indian Industry How much saving by reducing pressure drop across Preheater? Fan inlet Pressure = -530 mmwg Fan outlet = -45 mmwg Electrical power = 1500 kW Reduction in Pressure drop = 50 mmwg Saving = 50 X1500 (-45)-(-530) = 154 kW Therefore, checking the pressure profiling across the preheater is very important activity.

- 12. © Confederation of Indian Industry Velocity Profile Across Pyro section Riser Duct:-80% heat transfer takes place 15-17 m/sec Down comer duct 15-17 m/s TAD duct 25 m/s Hood & cooler grate 5 m/s Under cooler bull nose 15 m/s Burning zone-9.5 m/s

- 13. © Confederation of Indian Industry High Pre-heater fan power consumption High Pre-heater cyclones pressure drop High specific fuel consumption High Cooler loss Difference in Clinker Quality FEW MAJOR PROBLEMS IN PYRO PROCESS

- 14. © Confederation of Indian Industry PROBLEMS IN PYRO PROCESS 1. High Pre-heater fan power consumption Reasons :- Low Fan efficiency High pre-heater pressure drop High dust recirculation High False entry (excess air)

- 15. © Confederation of Indian Industry PROBLEMS IN PYRO PROCESS 2. High Pre-heater Cyclone Pressure drop Reasons :- Basic design Coating or material accumulation High velocity or flow Cyclone Erection made to suit at site Improper gas distribution

- 16. © Confederation of Indian Industry PROBLEMS IN PYRO PROCESS 3. High Specific fuel consumption Reasons :- Change in quality of fuel Low Cooler efficiency Low heat recuperation 4. High Cooler loss Reasons :- Low heat recuperation

- 17. © Confederation of Indian Industry Parameters Affecting SEC of PH fan Pressure drop across preheater of Fan Depend upon no of stages Best observed value 470 mmwg for 6 stage Fan efficiency Fan design and operating parameters Losses in speed Control • VFD : 98% efficiency • SPRS : 95% efficiency • GRR : 90% efficiency Lowest observed SEC of PH fan : 3.81 kWh/MT clk

- 18. © Confederation of Indian Industry Typical pressure drops - Latest PH with PC 4 Stage – 310 to 360 mmwg 5 Stage – 350 to 400 mmwg 6 Stage – 450 mmwg Low Pressure Drop Cyclones

- 19. © Confederation of Indian Industry Heat Losses in Pre-heater exit gas Factor affecting the Heat loss in PH exit gas PH EXIT GAS VOLUME- Depends upon the gas temp. & false air infiltration • Best observed value : 1.37 Nm3/kg clinker PH EXIT GAS TEMP.- Depends upon the PH heat transfer efficiency • Best observed value : 245 0C Lowest observed heat loss in PH exit gas : 120 kcal/kg clk

- 20. © Confederation of Indian Industry How to calculate minimum air for combustion? Lmin = 1.293 X (32/12 x % C + 16/2 x %H -% O +%S + 32/14 x %N) 1.429 x 21 Lmin = Kg air/kg Fuel How to convert Kg air/kg fuel into Nm3/kg fuel? Dividing by 1.29 kg/Nm3 Sample calculation:- C-85.8% Hydrogen-11% Oxygen:-0.4% Nitrogen:-0.8% Sulphur:-2%

- 21. © Confederation of Indian Industry How to calculate minimum air for combustion? Lmin = 1.293 X (32/12 x 85.8 + 16/2 x 11 -0.4+2+ 32/14 x 0.8) 1.429 x21 Lmin = Kg air/kg Fuel = 13.76 kg air/kg fuel Nm3/fuel = 13.76/1.29 = 10.66 Nm3/kg fuel

- 22. © Confederation of Indian Industry Lmin Values for different types of Coal(kg/1000 kcal) Lignite :- 1.388 Bituminous :- 1.398 Anthracite :- 1.412 Petcoke : 1.407 Diesel : 1.408 Lmin Flow = Lmin x Heat consumption x Production per dayx1000 24 x 1000 Heat Consumption = kcal/kg clinker Production = TPD Lmin Flow = kg/hr

- 23. © Confederation of Indian Industry Excess Air Concept Air requirement for complete combustion process across the pyro section is 10 percent of Lmin . For example :-Pet coke Air Requirement = 1.10 X 1.407 = 1.54 kg air/1000 kcal For anthracite coal:- = 1.41x1.10 = 1.55 Note:-But generally due to Sulphur dilution ,the amount of excess air is increased in the case of pet coke.

- 24. © Confederation of Indian Industry Excess Air Concept

- 25. © Confederation of Indian Industry Standard Values Kiln Inlet :- 2% O2 Calciner Outlet :- 2% O2 Preheater outlet :- 3-4% O2 Preheater Flow :- 1.30-1.50 Nm3/kg Clinker in case of normal coal :- 1.45-1.55 Nm3/kg clinker in case of pet coke Recuperation Air :- 0.75 Nm3/kg Clinker for normal coal :- 0.80 Nm3/kg Clinker for pet coke

- 26. © Confederation of Indian Industry Excess Air Calculation How to find excess air?(approximate & when CO formation is min) = O2 percentage X 100 21 –O2 percentage = (5/21-5) x100 = 31.25% Oxygen :-2% at kiln inlet –Find excess air? = (2/21-2) X100 = 10.52%

- 27. © Confederation of Indian Industry Heat loss due to excess Air

- 28. © Confederation of Indian Industry Numerical No1 Heat Loss due to excess Air Preheater gas flow = 1.30 Nm3/kg clinker Excess air = 10% Then Volume: = 1.10 x 1.30 = 1.43 Nm3/kg clinker = 1.43-1.30 = 0.13 Nm3/kg clinker Preheater gas temp-250 degree C = 0.13x1.42x0.23x250 = 10.60 kcal/kg clinker loss

- 29. © Confederation of Indian Industry Heat loss due to CO formation? C + O2 – CO2 + 8084 kCals/kg of Carbon 2C + O2 – 2 CO + 2430 kCals/kg of Carbon 2H2 + O2 – 2H2O + 28,922 kCals/kg of Hydrogen S + O2 - SO2 + 2,224 kCals/kg of Sulphur Each kilogram of CO formed means a loss of 5654 kCal of heat (8084 – 2430)

- 30. © Confederation of Indian Industry Importance of Recuperation Air Recuperation Air:-Secondary Air + Tertiary Air Secondary Air:- It is the main part of the combustion air (85 – 95% of total air fed). Flame direction is usually affected by the buoyancy of secondary air. Lower temperature of secondary air causes increase in velocity of secondary air as a consequent the mixing of air with coal is in efficient which makes the lengthy flame.

- 31. © Confederation of Indian Industry Which is the correct flame? Flame no1 Flame No2 Flame No3

- 32. © Confederation of Indian Industry Which is the correct flame? Flame no1 Long Flame, unstable coating, high back end temp, low shell temperature Short Intense divergent flame, low back end temp, high shell temperature, poor refractory life, good for burning Flame no2 Flame no3 Convergent flame, low shell temperature, good refractory life, good for burning, stable coating. Flame no3 is the correct one

- 33. © Confederation of Indian Industry Effect of Secondary Air on Flame

- 34. © Confederation of Indian Industry Impact of Secondary Air velocity on flame length Higher the secondary Velocity longer is the flame, hence to increase the flame momentum by increasing primary air velocity at the burner tip as a result the overall heat consumption would be increased.

- 35. © Confederation of Indian Industry Impact of Secondary Air velocity on flame length Q = A XV Q is directly proportional to V as a result Q will be increased and finally affects the heat consumption Higher secondary air velocity that causes the lower the hot air pressure region, therefore, we have to increase the pressure drop at the tip to pull back more secondary air towards the flame. Secondary Air Velocity:-5-6 m/s

- 36. © Confederation of Indian Industry Burner Pipe Centering Position 7,4,1,2& 3 are away from material inside the kiln. Position 9 & 8 are very close to the charge. Only 5 is close to the material as well as with refractory & this position is best because it gives the uniform thermal distribution .

- 37. © Confederation of Indian Industry Burner Pipe Centering Why we are not considering 7,4,1,2,&3 position? These positions are very close to the refractory and it can damage the refractory through burning. some times flame is disturbed Position 8 & 9 is Very close to the material if coal is trapped it has serious negative impact.

- 38. © Confederation of Indian Industry Impact of Primary Air on Fuel Consumption

- 39. © Confederation of Indian Industry Challenges in Cooler Operation Snowmen formation Red river Low Efficiency of Cooler Reason for Snowmen:- Dusty operation of the kiln Fine particles formation Cooling air face more resistance in case of fine particle Kiln overheated Melting condition inside the kiln Change in burner pipe position which affects the cooling zone inside the kiln Raw mix design

- 40. © Confederation of Indian Industry Challenges in Cooler Operation Reason for red river:- Fine dusty clinker Segregation in kiln due to wide range in particle size. Material characteristics , and rotation of kiln Cooler design, air flow distribution Non-uniform clinker bed Operation and maintenance of cooler

- 41. © Confederation of Indian Industry Cooler Efficiency curve

- 42. © Confederation of Indian Industry Cooling Air resistance

- 43. © Confederation of Indian Industry Effect of resistance grates

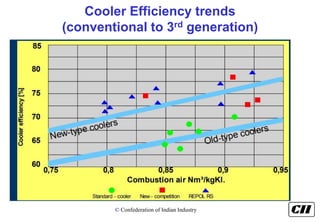

- 44. © Confederation of Indian Industry Cooler Efficiency trends (conventional to 3rd generation)

- 45. © Confederation of Indian Industry Cooler Efficiency Calculations Calculate total input air in kg air /kg clinker. Total Input air= Cooler Vent Air + Recuperation Air(all value on mass basis) ESP Cooler vent Air Recuperation air

- 46. © Confederation of Indian Industry Energy Balance of Cooler 4 COOLER Input heat from clinker Input heat from cooling air Heat losses from clinker SA+TA Cooler Vent Air Radiation & Convection losses

- 47. © Confederation of Indian Industry Cooler Efficiency Calculations Input Heat from clinker = 0.2733 x(Inlet Clinker Temp-Refrence T ) Inlet Clinker temp = 1400 degree C Input heat from clinker = 382.6 kcal/kg clinker Input heat Cooling air = 17.9 kcal/kg clinker(ABC plant) Total input Heat = 400.5 kcal/kg clinker-------- Heat Output Heat through Vent Air = 92.2 kcal/kg clinker----------1 Heat through clinker = 26.9 kcal/kg clinker----------2 Radiation & Convection = 5 kcal/kg clinker---------------3 Heat through Water Spra = 37.7 kcal/kg clinker…………4

- 48. © Confederation of Indian Industry Importance of cooler Efficiency Heat through Secondary & TA = Input Heat-(1+2+3+4) = 400.5-161.80 = 239 kcal/kg clinker Cooler recuperation efficiency = Heat through Secondary & tertiary Air x 100 Input heat from cooler = 60 %

- 49. © Confederation of Indian Industry Important Facts-Cooler The hotter the inlet temperature the hotter the clinker outlet temperature. The hotter the cooling air temperature the hotter the clinker outlet temperature. The longer the air/material contact time the cooler the clinker outlet temperature.

- 50. © Confederation of Indian Industry Latest Generation of Coolers FLS SF cross bar cooler IKN pendulum cooler Claudius Peters ETA (ɳ)cooler CemProTec Revolving Disc Cooler (RDC)

- 51. © Confederation of Indian Industry Major Developments SF Cross Bar Cooler- The 4 Innovative features: Fixed grate line for air distribution Conveying system separate from Cooling system Grate plates with individual regulators for cooling air-Cooling Techniques – Unique Modular design

- 52. © Confederation of Indian Industry Mechanical Flow Regulation (MFR) Classical compartment aeration Each plate equipped with a mechanical flow regulator Pressure drop across perforated plate controls regulator opening Gives constant flow independently of clinker resistance Eliminates need for air beam

- 53. © Confederation of Indian Industry Operation of the (MFR)

- 54. © Confederation of Indian Industry Effect of resistance grates

- 55. © Confederation of Indian Industry Working of MFR

- 56. © Confederation of Indian Industry 11/26/2020 Case Study of Cooler Upgrade with Cross Bar Cooler Parameter Unit Before After Production TPD 3150 3400 Cooler loss Kcal/ Kg Cl 135 98 SPC kWh/MT 5.7 5.17* Clinker temp Deg C 195 98 •Power includes Cooler Fans, cooler drives & HRB

- 57. © Confederation of Indian Industry Hot Air Recirculation +20-25% More heat Waste Heat Recovery Maximised without compromising Recuperation Efficiency

- 58. © Confederation of Indian Industry Waste Heat Recovery with hot air recirculation Mid air / WHR Vent air Secondary + Tertiary air

- 59. © Confederation of Indian Industry IKN Pendulum Cooler Pendulum cooler – IKN Unique features Stationary inlet Coanda nozzle Oscillating frames

- 60. © Confederation of Indian Industry Coanda Nozzles Narrow, inclined and curved slots in transport direction of clinker Narrow sharp jet of air – 40 m/sec (Horizontal) Fines are swept to the clinker bed surface, Coanda nozzles are completely engulfed by the cooling air Fines always on top – Fluidized Coarser pushed mechanically at the bottom No Red river problem

- 61. © Confederation of Indian Industry Oscillating Frames

- 62. © Confederation of Indian Industry Features of IKN Cooler Low Air requirement Specific power consumption < 4 units/ton Lower clinker temperatures < 100C

- 63. © Confederation of Indian Industry Operating results before and after the IKN upgrade Before After Production rate (TPD) 5550 5750 TA Temp (oC) 760 930 Sp. Heat Consumption (kcal/kg clk) 710 690 Power in cooler section (kW/MT clk) 4.47 3.88 Cooler vent air temp (oC) 220 200 Clinker temp (oC) 152 132

- 64. © Confederation of Indian Industry Revolving Disc Cooler (RDC)- 5th Generation Cooler

- 65. © Confederation of Indian Industry Introduced by CemProTec, Germany Operates according to the “revolving disc” principle The travelling grate is replaced by revolving disc Under trial, results are being awaited Revolving Disc Cooler (RDC)- 5th Generation Cooler

- 66. © Confederation of Indian Industry Revolving disc – speed 30 min per round High efficiency- 100% cross flow heat exchange Low cooling air volume and hence exhaust air No clinker spillage- Dust handling & transport system not required 100% transport efficiency Very limited wear & maintenance Revolving Disc Cooler (RDC)- 5th Generation Cooler

- 67. © Confederation of Indian Industry Benefits of Latest Generation High efficiency cooler Better clinker properties Lower exit gas and clinker temperature Lower cooling air requirement Total heat loss of latest generation cooler is less than 110 kcal/kg clk Recuperation efficiency 75-80% Retrofitting of existing conventional cooler with latest generation cooler offers significant potential for electrical and thermal energy saving

- 68. © Confederation of Indian Industry Cooler Vent Fan Typical power consumption 0.5 to 1.0 kW/ton Typical pressure drops required 40 – 50 mmWC Fan design (Head) very important Natural draught available Example 220C, 55 m height

- 69. © Confederation of Indian Industry Cooler vent fan PARAMETERS AFFECTING THE SEC OF COOLER VENT FAN PRESSURE AT FAN INLET- Depends upon the pressure drop in cooler ESP and duct • Best observed value : 40 mmWc EFFICIENCY OF FAN- Depends upon the fan design and operating parameters CHIMNEY EFFECT- Depends upon the chimney height & dia. LOSSES IN SPEED CONTROL- Depends upon the type of control installed Lowest observed SEC of Cooler vent fan : 0.13 kWh/MT clk

- 70. © Confederation of Indian Industry How to choose best cooler System? Minimum specific power consumption of cooler fans and vent fan Cooler fans:-3-3.5 kWh/ton clinker ESP Fans:-0.5-1.0 kWh/ton of clinker Cooler recuperation efficiency should be greater than 70 % Cooler Efficiency:-70-77% Total losses:-110 kcal/kg clinker (Cooler Vent + Radiation+Clinker) Should be good in terms of maintenance point of view also

- 71. © Confederation of Indian Industry Numerical No N1:-A grate cooler with cooler recuperation efficiency of 44% is to be replaced with high efficient cooler of 77% efficiency then calculate the benefit in terms of kcal/kg clinker? Also estimate the benefit in vent losses Present SEC-760 Kcal/kg clinker

- 72. © Confederation of Indian Industry CFD Study & Thermal Efficiency Calculations

- 73. © Confederation of Indian Industry Application of CFD to Improve Efficiency Computational Fluid Dynamics (CFD) • Predicting the fluid flow related problem by solving mathematically, the equations which govern the process. • Numerical calculation method for solving fluid flow problems as possible, in solving practical engineering flow, heat transfer problem

- 74. © Confederation of Indian Industry CFD – Application Areas Cyclone Ducts Electrostatic Precipitators (ESP) Baghouse Raw Mill/ Coal Mill Kiln/ Calciner Gas Conditioning Tower

- 75. © Confederation of Indian Industry Application of CFD to Improve Efficiency CFD study identifies the region offering high pressure drop, improper flow distribution, high velocity region etc. Benefits of CFD study: Reducing the high pressure drop in pre-heater cyclones Reducing the high pressure drop in ducts Improving the cyclone efficiency

- 76. © Confederation of Indian Industry Reasons for High PH Exit Temperature are Improper material distribution High velocity High excess air High return dust (low cyclone efficiency) Heat Transfer Analysis in Riser Duct for Flue gas with Particles elaborates the Temperature Thermal Efficiency Improvement in PH System

- 77. © Confederation of Indian Industry By CFD analysis, the Exit Temperature Can Reduce & Reduction in Heat consumption about 5-20 kcal / kg clinker is possible. By means of Modification in Riser Duct Modification in Spreader Box & Feed Pipe Modification in Cyclones Thermal Efficiency Improvement in PH System

- 78. © Confederation of Indian Industry Velocity Distribution in Calciner Benefits by CFD analysis in the Cal Improvement in coal particle distribution Improvement in flow Distribution of Velocities which improves the combustion Reduces the high concentration of Temperature near the wall. Improvement in residual time of the Particle Overall improvement in calcinations Particle Trajectory in Calciner Thermal Efficiency Improvement in Calciner

- 79. © Confederation of Indian Industry Cyclone Performance Analysis Pre-modified duct

- 80. © Confederation of Indian Industry CFD Analysis PH system Streamlines plot at the inlet duct of III stage cyclone Reduction in Pressure drop up to 20mm WC

- 81. © Confederation of Indian Industry CFD Analysis for PH system Project Completed and analysis report shows pressure drop up to 25mm WC

- 82. © Confederation of Indian Industry Pre-modified Cyclone analysis with duct Modified Cyclone analysis with duct Cyclone Performance Analysis Reduced pressure drop by 60 mm WC(10% reduction in Fan Power). Energy savings 50 KW/h. Payback period less than 4 months.

- 83. © Confederation of Indian Industry Dust loss from Pre-heater system/Improvement of Cyclone Efficiency By CFD study PH & PC Feed 300 tph 75°C Dust loss – 30 tph 275°C Top cyclone eff Design – 96 % Actual – 90 % Equivalent heat loss – 10 kcal /kg

- 84. © Confederation of Indian Industry Dust loss from Pre-heater system / Improvement of Cyclone Efficiency By CFD study Pre-heater dust loss – 10 % Dust goes out at about 275ºC Fresh feed enters at 75ºC Material heat loss alone – 10.0 kcal/kg Top cyclone efficiency increase of 3 % means -3.0 kcal/kg

- 85. © Confederation of Indian Industry Dust loss from Pre-heater system / Improvement of Cyclone Efficiency By CFD study Excellent opportunity CII had discussions with consultants on reducing dust loss thro CFD analysis & retrofit Consultant positive on dust loss reduction without increasing pressure drop Has been successful in several Cement plants

- 86. © Confederation of Indian Industry Improvement of Cyclone Efficiency By CFD study Present Cyclone Efficiency = 90% Design Efficiency = 96% Kiln feed to clinker Factor = 1.6 Fresh Feed enters at temperature 75 degree C Present dust loss = 0.10X1.60 = 0.16 kg material Present heat loss = 0.16x0.23x275 = 10 kcal/kg clinker

- 87. © Confederation of Indian Industry Improvement of Cyclone Efficiency By CFD study Recoverable is 3% Improving in efficiency by CFD study(Considering 93%) = 0.07*1.60 = 0.112 Benefit in dust loss = 0.16-0.112 = 0.048 kg material Heat improvement = 0.048xspecific heat of flue gasesxT Q = 0.048x0.23x(275-0) = 3.03 kcal/kg clinker

- 88. © Confederation of Indian Industry Calculations Thermal cost = RS 1100 Mkcal (Million kilo calorie) Clinker production :- 4500 ton/day; NCV of coal = 7000 kcal/kg coal Overall Heat saving per day = 3x4500x1000 = 13.5 Mkcal per day

- 89. © Confederation of Indian Industry 13.5 Mkcal per day/ In terms of coal = 1.92 ton of coal in a day No of days per annum = 300 = 13.5x300 = (4050) Mkcal - Energy saving per annum = 4050 x 1100 Savings = Rs 44.55 lakhs per annum Investment = 20 lakhs Payback = 20 X12 44.55 = 6 months Calculations

- 90. © Confederation of Indian Industry Dust loss from Pre-heater system/ Improvement of Cyclone Efficiency By CFD study I Step Conducted CFD analysis for top cyclone Implement retrofits to improve efficiency Target efficiency - 93 % Improvement in efficiency – 3 kcal / kg clinker Saving - Rs. 44.50 lakhs Investment - Rs. 20 lakhs Payback - 6 months

- 91. © Confederation of Indian Industry Minimize Heat Loss in Tertiary Air Duct Cooler PC 950oC 840oC Heat Loss •Air infiltration in TA duct •Surface Heat Loss

- 92. © Confederation of Indian Industry TA Duct – Thermograph Images

- 93. © Confederation of Indian Industry TA Duct – Thermograph Images

- 94. © Confederation of Indian Industry Minimize heat loss in TA Duct Air infiltration Atmospheric air entry Reduces Air intake from Cooler Cooler vent – higher temperature Arresting air infiltration Lower ambient air ingress Increases cooler air utilization (at Temp of about 500 Deg C)

- 95. © Confederation of Indian Industry Minimize heat loss in TA duct Surface insulation Hot spots observed > 200 Deg C Significant drop between cooler & PC Radiation loss estimated > 5 kCal/kg Cl Loss due to air infiltration ~ 3 kCal/kg Cl TARGET – 30-40oC drop between cooler exit and PC

- 96. © Confederation of Indian Industry Calculations Present Temperature Drop:- = 950-840 = 110 oC Margin in temperature = 110-40 = 70 oC Considering recuperation air = 0.80 Nm3/kg clinker Total air requirement for calciner = 0.60 x 0.80 = 0.48 Nm3/kg clinker Mass = 0.48 x1.29 = 0.6192 kg air/kg clinker = 0.6192 x 0.25x 70 = 10.836 kcal/kg clinker benefit

- 97. © Confederation of Indian Industry Calculations Thermal cost = Rs 1100 Mkcal (million kilo calorie) Clinker production = Rs 4500 ton/day NCV of coal = 7000 kcal/kg coal Overall Heat saving per day = 10.836x4500x1000 = 48.76 Mkcal per day/ In terms of coal = 6.96 ton of coal in a day

- 98. © Confederation of Indian Industry Calculations No of days per annum:= 300 = 48.76x300 = (14628) Mkcal Energy saving per annum Annual Saving = 14628 x 1100 = Rs 160.90 lakhs per annum Investment = 70 lakhs Payback = 70 X 12 160.96 = 6 months

- 99. © Confederation of Indian Industry Minimize heat loss in TA duct Annual Saving - Rs 160.90 Lakhs Investment - Rs 70.0 Lakhs Payback period - 6 Months

- 100. © Confederation of Indian Industry Reduce PH exit temperature 1 A 1 B 2 3 4 5 1 A 1 B 2 3 4 5 325 oC 293 oC 502 oC 659 oC 815 oC 893 oC 478 oC 650 oC 799 oC 890 oC Standard profile Case stufy plant profile ILC ILC

- 101. © Confederation of Indian Industry Lower Dispersion Box in riser ducts and increase heat transfer PH system – heat transfer Overall – Counter current Each Stage – Co-current Maximum heat transfer in riser ducts Separation of material & air in cyclones Very little heat transfer in cyclones

- 102. © Confederation of Indian Industry Lower Dispersion Box in riser ducts and increase heat transfer Latest approach Locate feed pipe as low as possible Increases heat transfer in riser ducts Lowers PH gas exit temperature Discussions with Suppliers & other Cement Plants Favor this step (Upto 1 m, easy) Implemented in several plants

- 103. © Confederation of Indian Industry

- 104. © Confederation of Indian Industry Present System Kiln String Calciner String Dispersion Box Height Total Riser Height Dispersion Box Height Total Riser Height 5.055 16.932 2.953 14.570 3.0 12.8 2.947 12.392 5.435 12.78 3.335 13.2 2.1 12 3.053 12.918 4.435 13.4 4.7 -

- 105. © Confederation of Indian Industry Good potential to lower the feed point Discussion with supplier before implementation Saving of 10-15oC 2.5 - 3 kCal / kg of clinker, At least Recommended to take up one by one Monitor temp & pressure profiles closely Lower Dispersion Box in riser ducts and increase heat transfer

- 106. © Confederation of Indian Industry Lower Dispersion Box in riser ducts and increase heat transfer Annual Saving - Rs 34.98 Lakhs Investment - Rs 6.0 Lakhs Payback period - 2 Months

- 107. © Confederation of Indian Industry Reduce cold air entry into system Cold air entry in Kiln and Pre-heater system Coal conveying Primary air Coal conveying offers a good potential for energy saving Presently coal conveying air – ~ 16.0 tph Same irrespective of type of coal used Equivalent heat loss with air finally going out at 265°C is – 1.50 kcal/kg

- 108. © Confederation of Indian Industry Reduce cold air entry into system.. Phase density for FK pumps – up to 7 possible Present phase density – 2 to 2.5 Varies depending on the coal used and the fineness Good potential to reduce Install VFD for all four coal conveying blowers Reduce rpm in a phased manner 5 % steps and observe performance Target speed reduction – 20 - 25%

- 109. © Confederation of Indian Industry Reduce cold air entry into system Saving - Rs. 26.61 Lakhs Investment - Rs. 30.0 lakhs Payback - 14 months

- 110. © Confederation of Indian Industry Impact of False Air on fuel & Electrical Consumption O2-5% 1 2 3 4 PH FAN 5 6 Calcine r kiln Kiln Feed O2-2.5% Measuring Points 1) Calciner Outlet 2) Preheater down Comer 3) Fan Inlet Temp-275 degree C Fan Inlet pressure-600 mmwg

- 111. © Confederation of Indian Industry Calculations Preheater Down Comer:-5% Calciner Outlet:-2.5% Apply False Air Formula = (Down Comer oxygen-Calciner outlet) X 100 ( 21-calciner outlet oxygen) = 5-2.5 X 100 21-2.5 = 13.5 % Consider preheater outlet Temperature :- 275 degree C Considering Reduction in false air :- 5% Present Flow: - 1.50 Nm3/kg Clinker

- 112. © Confederation of Indian Industry Impact of False Air on fuel Consumption Mass Flow Rate = 1.50x1.42 = 2.13 kg gases /kg clinker Reduction in mass flow by reducing FA = 0.05x2.13 = 0.1065 kg/kg clinker Heat Loss = 0.1065xspecific heat of flue gasesxTemp difference

- 113. © Confederation of Indian Industry Impact of False Air on fuel Consumption Q = 0.1065x0.23x(275-0) = 6.73 kcal/kg clinker. Thermal cost = RS 1100 Mkcal (million kilo calorie) Clinker production:- = 4500 ton/day NCV of Coal = 7000 kcal/kg coal

- 114. © Confederation of Indian Industry Overall Heat loss per day = 6.73x4500x1000 = 30285000 kcal per day In terms of coal = 4.326 ton of coal in a day No of days per annum: = 300 = 30285000x300 = (9,085) Mkcal - energy saving per annum In terms of Mkcal = (9.085x10^9)/(10^6) = 9.085x(10^3 ) Cost = 9085 x 1100 Saving = Rs 99.93 lakhs per annum Impact of False Air on fuel Consumption

- 115. © Confederation of Indian Industry Impact of False Air on Electrical power Electrical Loss = Percentage of false airX electrical power of fan Electrical power = 1400 kW Power loss = 0.05x1400 = 70 kW Electrical cost = Rs 5 kWh No of days per annum: -300 Annual Saving = 135x300x5x24 = 25.2 lakhs per annum Total Saving = 99.93+25.2 = 125 lakhs

- 116. © Confederation of Indian Industry Impact of False Air on Electrical power Saving - Rs. 125. Lakhs Investment - Rs. 50.0 lakhs Payback - 5 months Pay back = (50/125)x12 = 5 months

- 117. © Confederation of Indian Industry Burners The ultimate objective of a burner is to provide a stable short and intense flame for burning of raw materials to the desired temperature and achieve heat economy More efficient mixing of fuel and air Improvement in entrainment of secondary air

- 118. © Confederation of Indian Industry First Generation Burners(conventional) Advantages Burning traditional Fuels Good Flame Adjustability Good Mixing of the combustion air with the Fuel Disadvantages Generation of high Nitrogen oxides emissions Inability to use market dependent alternate fuels

- 119. © Confederation of Indian Industry Second Generation burner(Multichannel) Duoflex burner:-FLS Pyrojet:-KHD Pillard:-Rotaflam Greco:-Greco

- 120. © Confederation of Indian Industry How to select best burner for the plant operation? Adjustability of the flame shape to suit the kiln operation and type of fuel Operating costs and servicing costs Other Important process parameters Primary air requirement(%) & pressure(effect the energy cons.) Flame momentum Coal conveying air(solid loading ratio) NOX emissions (Low NOX burner) Emission behavior with respect to NOx emissions Flexibility with traditional fuels Flexibility with market-dependent alternative fuels

- 121. © Confederation of Indian Industry NOX Generation Thermal NOX Form in burning zone and reaction takes place at high temperature(1400 degree C) 2N2+O2-2NO +N N+O2-NO+O Higher excess air results high amount of NOX As Input N2 increases due to excess air High residence time in calciner also increase the NOX formation

- 122. © Confederation of Indian Industry NOX Generation Fuel NOX Fuel NOx is formed by the oxidation of nitrogen present in fuel A study has indicated that gas-fired, dry-process kilns typically produce almost three times more NOx than coal- fired, dry-process kilns Fuel NOx predominates NOx generation in the calciner and at lower-temperature combustion sites. Approximately 60% of fuel nitrogen is converted to NOx and is dependent upon available oxygen in the flame and temperature profile

- 123. © Confederation of Indian Industry Low NOx Burners (Latest generation Burners) Parameters FLS –Jet Flex Novaflam KHD Pyrojet Type of Fuel Coal or Pet coke Coal or Pet coke Coal or Pet coke Transport Air volumetric flow for pet coke 2805 m3/hr 2135 Nm3/hr 2165 Nm3/hr Solid loading factor-coal 3.8 4.96 kg coal/Nm3 4.90 kg coal/Nm3 Primary air cons(%) 5-6% 6.5% 4.8% Primary air pressure(mbar) 700 500 Jet-900;swirl-160 Primary air flow 5100 m3/hr. 5500 Nm3/hr Jet-2710m3/hr;swirl:- 1355 m3/hr Burner out put(68 MW) Primary air consumption:- 8-9% in ordinary multichannel burner with low pressure(1500-2500 mmwg).

- 124. © Confederation of Indian Industry Low NOx burner Concept Less primary air means less oxygen and may produce an initial high-temperature, fuel-rich combustion zone, followed by a low-temperature fuel-lean combustion zone. Such a combination is likely to reduce the formation of NOx. Reduce flame turbulence, delay fuel & air mixing and establish fuel rich zones for initial combustion A fuel-rich, oxygen-lean, high temperature combustion zone is created first by reducing the amount of primary air in the primary combustion zone and delaying the combustion of all of the fuel

- 125. © Confederation of Indian Industry NOX reduction-solutions(Primary level) Reducing excess air levels also results in increased productivity per unit of energy; thus, resulting in the indirect reduction of NOx emissions per amount of clinker produced. Improving burnability of kiln feed & thermal efficiency of the system Reduction in heat consumption Installing the low NOX burner Change in the preheater system(hot bottom formation in ILC) Nitrogen content in the fuel Latest developments by technology suppliers

- 126. © Confederation of Indian Industry Case Study No1 Objective Toreduce the primary air percentage by installing pillard Novaflame burner Primary air consumption:-12% Problems:- Frequent build up in the 28th m of the kiln Benefits:- After changing the burner the coating tendencies are reduced and plant team are able to increase the petcoke to 100%.

- 127. © Confederation of Indian Industry Case Study Project Economics:- Energy saving:-2 kcal per kg clinker Total fuel saving:-350 tonnage of coal Cost :-Rs 6500 per ton of coal Total cost saving:-Rs 23 lakhs per annum Investment:-Rs 52 lakhs Payback:-27 months

- 128. © Confederation of Indian Industry Case Study No2 Pyro-Jet Burner was commissioned successfully and Primary Air consumption reduced by 5% thereby Heat consumption reduced by 5 Kcal/ kg clinker

- 129. © Confederation of Indian Industry Latest Developments:-KHD Pyroclon-R Low NOx

- 130. © Confederation of Indian Industry Fuel PYROREDX Reactor Main Calciner ① ② Technology Gasifying reactor between kiln and calciner. Formation of CO by Boudouard reaction. Reduction of NOx. Suppression of fuel NOx formation. PYROCLON® Redox Reactor-For low NOX

- 131. © Confederation of Indian Industry PYROCLON® Redox Reactor-For low NOX

- 132. © Confederation of Indian Industry Redox reactor inlet Gas Composition: CO2 19.4 Vol.% CO 0 Vol.% 100 % Of Calciner Fuel fired in PYROREDOX duct in Kiln Flue gas only, Without any TERTIARY Air admission hence Reducing atmosphere ( Insufficient Combustion air / Starved O2 Condition ) Created In PYROREDOX. Due to reducing atmospheres in PYROREDOX, the CO2 in kiln flue gas react with fuel C which is sub stoichiometric conditions. The sub stoichiometric reaction as follows and it produces CO at the same time CO2 content of flue gas reduces to 8.1 % , hence Conversion of NO into N2 using CO is > 95 % CO2 + C 2 CO Boudouard reaction Working Principle

- 133. © Confederation of Indian Industry Working Principle Redox reactor outlet / Calciner Inlet Gas Composition: CO2 8.1 Vol.% ` CO 21.8 Vol.% The above condition is very favorable for DENOX Reaction using CO as Follows 2CO + 2NO = 2CO2 + N2 Final NOX CONCENTRATION IN CALCINER OUTLET IS < 500 mg/Nm3 @ 10 % O

- 134. © Confederation of Indian Industry Typical pressure drops - Latest PH with PC 4 Stage – 310 to 360 mmwg 5 Stage – 350 to 400 mmwg 6 Stage – 450 mmwg Low Pressure Drop Cyclones

- 135. © Confederation of Indian Industry Latest development in Cyclones by KHD Previous Cyclone Design 55% dip tube ratio Inlet cross section 100% h/w = 1,6 High Efficiency (HE) Cyclone Design for > 60% dip tube ratio New 110% h/w = 2,0 Benefits Based on same capacity Dp saving of 1,5 - 2 mbar per cyclone stage Smaller Cyclone size can be used Less equipment and building expenditure

- 136. © Confederation of Indian Industry New design 6852 HE / 5 25,5 mbar 22,6 mbar 11,1 mbar 7,1 mbar 36,6 mbar 29,7 mbar Cyclone Developments –CASE STUDY Existing design 7950/5 Double Separator: • increased by one size System Cyclones: • reduced by one size • new design of gas inlet • increased dip tupe ratio Reduction building height Approx. 3 % Reduction foot print Approx. 5 % Reduction building volume complete Approx. 10 to 15 %

- 137. © Confederation of Indian Industry CCX Cyclone by FLS 1. Material top feed 2. Rotating spreader (Counter current heat exchange) 3. Integrated heat exchange and separation 4. Light weight lining 5. Central pipe is pointing upwards 6. Exit gas outlet naturally pointing downwards 7. Reduced civil & Structural loads 1 2 5 6 3 4 7

- 138. © Confederation of Indian Industry CCX Cyclone by FLS

- 139. © Confederation of Indian Industry Standard Cyclone HR+ Counter Current Cyclone CCX Gas out Gas In Material In Material Out Gas In Material In Material Out Gas out CCX Cyclone by FLS

- 140. © Confederation of Indian Industry CASE STUDY-European Cement Plant Kiln capacity, clinker Operating at ~ 3300 tpd Production increase (tpd) ~ 200 tpd Pressure drop reduction 40% Recorded gas material temp. difference 50-60°C Fuel savings 8-10 kcal / kg cl Cyclone heat efficiency recorded 1.5 Load on civil structure reduced > 50% Existing top cyclone modified to CCX 6.3m.

- 141. © Confederation of Indian Industry Latest developments in Calciners

- 142. © Confederation of Indian Industry Requirements for Modern Precalciners Stable operation for full decarbonation (60 to 65 % fuel burnt in calciner ) Full combustion of all fuels Maximum alternative fuels (solid and lumpy) Control of emissions (NOx, CO , TOC/VOC )

- 143. © Confederation of Indian Industry FLS In-line calciner Restriction area Mixing zone Splitter gate Splitter gate Reduction zone Kiln riser Raw meal duct Fuel Vmin(ILC) = 6m/s Retention time (ILC) = 3.3s Low Nox Calciners for reduced Nox emissions irrespective of fuel

- 144. © Confederation of Indian Industry FLS Separate Line Calciner - Downdraft 144 Characterizes a special type of burner arrangement and flow path. Flow is down draft. Geometry is designed for instant ignition of combustible. Complete burnout of low volatile fuels high combustion temperatures High material and gas retention time in the calciner

- 145. © Confederation of Indian Industry Developments in KHD Calciner

- 146. © Confederation of Indian Industry PYROCLON® Calciner Technology - Steps of Developments Pyroclon-R LowNOx ILC - staged combustion „The first LowNOx Calciner 1980“ Pyroclon-R LowNOx AF ILC - staged combustion and AF utilisation Pyroclon-R LowNOx „LRF“ Variant for „Low Reactive Fuels“ (e.g. Petcoke)

- 147. © Confederation of Indian Industry PYROCLON® Calciner Technology - Steps of Developments Pyroclon-REDOX ILC with PYROREDOX Pyroclon-R LowNOx Pyroclon-R LowNOx AF Pyroclon-R LowNOx „LRF“

- 148. © Confederation of Indian Industry Raw Mix To achieve the goal of smooth kiln operation it is necessary to know Which parameters in the raw mix influence kiln operation? How and why they influence operation? What can be done about it ?

- 149. © Confederation of Indian Industry Raw Mix design Main Parameters of Raw Mix design Lime Saturation Factor Silica Modulus Alumina Modulus Range:- LSF SM AM

- 150. © Confederation of Indian Industry Raw mix design Software - - - - - - - - - RAWMIX DESIGN - - - - - - - - - LIMESTONE SHALE IRON ORE BAUXITE RAWMEAL MIX % 82.14 14.13 0.94 2.79 100.00 SiO2 3.24 74.98 9.16 9.00 13.59 Al2O3 0.79 8.80 2.00 50.00 3.30 RAWMEAL Fe2O3 0.38 6.20 83.04 14.00 2.36 TARGETS CaO 51.00 0.98 0.06 5.50 42.19 MgO 1.24 0.24 0.41 0.50 1.07 Lime Saturation K2O 0.50 0.30 0.20 0.10 0.46 97.00 Na2O 0.20 0.20 0.10 0.10 0.20 SO3 0.10 0.20 0.07 0.05 0.11 Silica Modulus L.O.I. 42.48 8.00 4.65 21.00 36.65 2.40 TOTAL 99.93 99.90 99.69 100.25 99.93 S.R. 2.40 Alumina Modulus A.R. 1.40 1.40 L.S.F. 97.00 `

- 151. © Confederation of Indian Industry Liquid phase variation by Silica& Alumina Ratio

- 152. © Confederation of Indian Industry Importance of Liquid phase SM decreases as liquid phase increases & vice versa AM also changes as per liquid content in the clinker Significance Clinker granulation Coating (but also formation of rings) Rate of alite formation

- 153. © Confederation of Indian Industry Importance of Liquid phase Typical amount 20 –30 % Dry: ≤ 23 % Normal: 23 – 27 % Wet ≥ 27% Liquid Viscosity: Decreases with increasing temperature Depending on composition and minor elements Reduced by Na2O, CaO, MgO, Fe2O3, MnO Increased by SiO2, Al2O3

- 154. © Confederation of Indian Industry C2S,C3S,C3A & C4AF Formation reactions-1300 degree C

- 155. © Confederation of Indian Industry C2S,C3S,C3A & C4AF Formation reactions-1400 degree C

- 156. © Confederation of Indian Industry Formation of clinker

- 157. © Confederation of Indian Industry Kiln Challenges-Petcoke Grinding problems in coal mill Minimizing the residue is a difficult task(Lower HGI) Low volatile matter Requires high flame momentum in kiln Chances of refractory damage is high due to FM High content of Sulphur Condensation of sulphates in preheater(5th & 6th cyclone) resulting in jamming of process flows , defined as volatile cycle

- 158. © Confederation of Indian Industry Recommendations Use of high flame momentum burner KHD pyrojet, FLS Jet flex ,Novaflam Alkalies(K2O,Na2O),lime for raw meal and SO2 from petcoke Optimize alkali Sulphur ratio Operate the kiln in oxidizing atmosphere with excess of oxygen Excess oxygen:-4%(kiln inlet for petcoke)

- 159. © Confederation of Indian Industry Recommendations Install UT pump and blasters at kiln inlet Reduce filling inside the kiln (12-13%) Increase retention time in the calciner Avoid CO formation by maintaining the residue below 2% on 90 micron. Use Silica Carbide castable at inlet and burner pipes to reduce coating

- 160. © Confederation of Indian Industry Alkali Sulphur ratio Volatile Cycle:- Sulphur to alkali ratio decide the type of coating formed Q = %SO3 / 80 Na2O/62 +(K2O/94)-(Cl/71) Sulphur excess Q>1 = Hard coating Alkali excess Q<1 = Soft coating

- 161. © Confederation of Indian Industry Chemistry To prevent SO2 gas leave from the kiln, it must be combined with alkalies(Na,Ca&K) and form sulphates(Na2SO4,K2SO4) and leave with clinker in the form of sulphates. Sufficient amount of liquid is required for above reactions AM:-1.2 Excess oxygen is required for maintaining oxidizing atmosphere CaO+SO2+1/2 O2 = CaSO4 SO3 in clinker may be maintained in the range:1.5-2%

- 162. © Confederation of Indian Industry Rings Formations

- 163. © Confederation of Indian Industry Important Thumb rules 10% excess air is equivalent to heat loss of 10 kcal/kg clinker False air acceptable range across preheater system is 6-8%, above it only contributes heat losses in the system Kiln inlet O2:-2% -Normal Coal;O2:-4%:-Pet coke Rate of heat transfer increases as the kiln rpm increases the recommended filling inside the kiln of normal coal is 14-15 % and for pet coke is 12- 13%.

- 164. © Confederation of Indian Industry Important Thumb rules It is recommended that to reduce the filling in the case of petcoke due to Sulphur content in it which vaporize in burning zone and increase the tendency of coating formations at 5th and 6th cyclones. Burning zone temperature is directly proportional to square of diameter of raw meal particle,therefore,another way is to optimize the process by controlling the residue of raw meal(15- 16%) on 90 micron

- 165. © Confederation of Indian Industry Important Thumb rules Recommended Cooler grate loading:- Kiln Loading:- Input cooler Air:-1.75 Nm3/kg clinker-Normal Coal :-1.80 Nm3/kg Clinker-petcoke Optimize the cooler vent air by identifying the cooler null point . Heat and mass balance study of pyro section is to be checked by doing mass balance.

- 166. © Confederation of Indian Industry Important Thumb rules Radiation losses contribute 6-8% of total radiation losses Coal conveying pipeline velocity :-25 -26 m/s Recommended Phase density :-3-4 kg coal/kg air-Normal Coal :-4-6 kg coal/kg air-pet coke

- 167. © Confederation of Indian Industry CASE STUDIES

- 168. © Confederation of Indian Industry Case Study No1 Usage of Pyrolytic Oil for Kiln Light up Parameter Unit Pyrolytic Oil Diesel Moisture % 0 0 ASH % 0.025 0 GCV Cal/g 10134 9600 NCV Cal/g 10134 9600 Chloride % 0.23 0.08 Sulfur % 0.69 0.21 Density Kg/m3 0.88 0.83 Flush point Degree C 35 46

- 169. © Confederation of Indian Industry SOP FOR KILN LIGHT UP THROUGH PYROLYTIC OIL Placing of Oil Tanker at safe place( plain & leveled surface) Proper dual Earthling for discharging of static charge of oil tanker. Direct connection to Pump inlet through a T-joint with manual control valve. First firing started with Diesel and after 4Hrs switch to Pyrolytic oil. Diesel firing stopped completely during usage of pyrolytic oil. Separate feeding mechanism provided for Pyro-oil firing. Two pump provided, in case of one pump failure other will start. Oil Flow can be maintained from control valve (MCV1) near pump by checking pressure in installed pressure gauge. Pressure maintained between 6 to 7 bar. In case of fluctuation in pressure gauge, filter was clean up which installed just before pump.

- 170. © Confederation of Indian Industry SOP FOR KILN LIGHT UP THROUGH PYROLYTIC OIL Flow-rate maintained 0.6 KL/Hr. After 36 Hrs. 21.75 KL pyrolytic oil consumed in kiln light up. Recorded the temperature profile hourly. Coal firing started after 9 hours by checking kiln inlet temperature

- 171. © Confederation of Indian Industry Tech. Parameter Value Unit Cost of Diesel 61912 Rs/KL Cost of Pyrolytic Oil 26800 Rs/ KL NCV of Diesel 9600 Kcal/Kg NCV of Py-oil 10134 Kcal/Kg Replacement Ratio 1.05 Net Cash Benefit (NCB) -26800 Rs/ KL Substitute benefit (SB) 65355.8 Rs/KL Gross Added Value (GAV) 38555.8 Rs/KL Benefits

- 172. © Confederation of Indian Industry Case Study No2: De-Swirler Installation in PH Top Cyclone of Kiln-4 Observation : In Kiln-4, PH Fan-2 SPC was high up to 4.42 kWh/T Clk (w/O SPRS Recovery). Problem : While conducting the pressure profile mapping identified top- cyclone pressure-drop was in range of 85-90 mmWG. Solution Adopted : CFD analysis was conducted to identify the regions for excess pressure drop in cyclone & what rectifications can be initiated to reduce this. Modification Done : Based on the recommendations of CFD team, we modified the dip-tube of top cyclone (shown in figure) to reduce the vortex formation without affecting the cyclone collection efficiency.

- 173. © Confederation of Indian Industry Case Study No2: De-Swirler Installation in PH Top Cyclone of Kiln-4 Impact : Pressure drop in the cyclone is now reduced up to 65 mmwg Savings Achieved : Daily Power Savings : 1,050 kWh, Daily Monetary Savings : Rs 3,990 @ Rs 3.8/kWh, Rs 13.00 Lacs / Year Replicability: Cyclones having issues of high pressure drop & maximum operating temperature range of up to 500 Degree Celsius.

- 174. © Confederation of Indian Industry Parameters Unit Before Period After Period Kiln Feed Avg TPH 704 726 Fan Speed 2 RPM 769 766 Load-2 kW 1957 1974 SPC Fan-2 kW/T Clk 4.42 4.32 Avg. Pressure Drop across Top Cyclone- String 3 & 4 mmWg 84 65 De-Swirler Installation in PH Top Cyclone of Kiln-4

- 175. © Confederation of Indian Industry Observations 1. Kiln Shell Temperature : 200 Deg C 2. Average Radiation Loss : 3. Heat Loss in % : 6% Action Taken: 1. To Install Radiation Heat Recovery Panels 2. Generation of 100 Deg C Hot Water 3. Operation of VAM Chiller with Hot Water (1 X 85 TR) 4. Stopping of Conventional Chiller (1 X 85TR) Case Study No3 Kiln Radiation Heat Recovery for AC (VAM Chiller)

- 176. © Confederation of Indian Industry Hot Water to VAM Chiller Kiln Radiation Heat Recovery for AC (VAM Chiller)

- 177. © Confederation of Indian Industry 1. Recovering the Waste Heat from Kiln Shell 2. Operation of VAM Chiller and Stopping Electrical Chiller. 3. Power Saving of 70 KW / Hr. 4. Energy Saving : 1680 Units / Day (5.54 Lakh Units/ Annum) 5. Cost Saving is Rs. 30.25 Lakhs / Annum Kiln Radiation Heat Recovery for AC (VAM Chiller)

- 178. © Confederation of Indian Industry Case Study-4 Cooler Hot Air Recirculation Objective: To Reroute hot air from Line 1 ESP Stack to cooler inlet. This will improve line 1 WHRS AQC 1 Boiler inlet temperature. Benefits: Increase Power Generation of WHRS by 0.3MW Power Savings of 23.76 Lacs Kwh Investment of Rs. 200 Lacs

- 179. © Confederation of Indian Industry Case Study 5 Formation of TAD ramp to increase the oxygen concentration at kiln inlet Problem:- High CO formation at kiln inlet (ILC KILN) Reason:- There was no damper in TAD because whatever the damper the plant team installed worn out within 7-8 months as a consequent CCR operators was not able to pick the kiln due to CO formation

- 180. © Confederation of Indian Industry Formation of TAD ramp to increase the oxygen concentration at kiln inlet Counter Measures:- Installation of ramp inside the TAD which blocks around 40 % area of TAD Optimize the raw mix as per pet coke Optimize the residue on Petcoke(2-3% on 90 micron)

- 181. © Confederation of Indian Industry Benefits Kiln output has been increased from 220 TPH to 300 TPH Smooth kiln operation Benefit in specific heat consumption Total investment:-Rs 1 lakh(castable & labor)

- 182. © Confederation of Indian Industry Case Study No 6 MgO added as Mineralizer through Kiln firing Project Concept Clinkerisation is an energy intensive process and it is influenced to a large extent by the chemistry and mineralogy of the raw materials used. In the burning zone, where the formation of C3S occurs by diffusion reaction between C2S and free lime, the liquid phase plays a very important role. .

- 183. © Confederation of Indian Industry MgO added as Mineralizer through Kiln firing Many of the problems such as dusty clinker formation, inadequate porous or excessive coating formation ,high levels of uncombined lime are attributed to the unfavorable viscosity of the melt phase especially when Sulphur rich fuels are used It is possible to modify the viscosity of the melt phase through use of various additives including alkalis. However, in dry process kilns with suspension preheaters, there are limitations on the use of alkalis.

- 184. © Confederation of Indian Industry MgO added as Mineralizer through Kiln firing Concept & Principle The most compatible and least harmful and yet economical additive is magnesia. It improves the viscosity of the melt phase and therefore aids in the combinability of lime with C2S. As a result of this, the free lime is reduced and the C3S formation is enhanced.

- 185. © Confederation of Indian Industry MgO added as Mineralizer through Kiln firing Execution Methodology Addition of Dolomitic Limestone with the MgO range of 13 - 15 % at the rate of 1 % with respect to Clinker Production of 7000 TPD. Point pile quantity of 3000 Tons was made through LS Crusher/CPP Crusher Crushed material stored in the outside yard and fed to the Coal crusher along with the Coal pile . Fine grinding with PetCoke in Coal Mill then fed to the Kiln Main burner. Reduction in Kiln Primary Fuel and change in raw mix design with Less iron changed

- 186. © Confederation of Indian Industry MgO added as Mineralizer through Kiln firing XRD analysis of clinkers show positive effect of MgO addition

- 187. © Confederation of Indian Industry Benefits The MgO modifies the viscosity of the melt phase and changes the liquid phase composition The effect is seen both in terms of reduction in free lime content and enhancement of C3S contents and its modification to high temperature polymorphic Clinker shown better granulometry and grindability characteristics as the C3S content is increased with concomitant reduction in C2S MgO added as Mineralizer through Kiln firing

- 188. © Confederation of Indian Industry MgO added as Mineralizer through Kiln firing Results:- Project involves No Capex or Opex expenditure. Cost Savings are as follows without any investment : Cost savings due to Power - ₹ 1.59 Crores/Annum Cost savings due to SHC - ₹ 69.33 lacs/Annum Total Cost Savings - ₹ 2.28 Crores/Annum Replication potential:- 100% replication potential in Cement Sector for all Dry process Inline Calciner Kilns

- 189. © Confederation of Indian Industry Key Points SEC of Preheater fan can be reduced by minimizing the pressure drop and optimizing the velocity profile across preheater system by using efficient cyclones (low pressure drop) and avoiding the coating formations at kiln inlet & cyclones(5th & 6th) Optimizing the excess air leads to tremendous potential in thermal energy saving potential Excess air 10% is equivalent to loss of 8-10 kcal per kg clinker Secondary air temperature plays an important role in optimizing the flame length Recommended Velocity:-5 m/s

- 190. © Confederation of Indian Industry Key points Latest generation coolers have the potential to face the challenges of snow men formation and red river in the cooler by installing latest device in the cooler such as MFR (Mechanical flow regulator) and through conada effect. Plant can improve the thermal efficiency of cooler by reducing vent losses and improving the recuperation air temperature by avoiding leakages Recommended parameters 70% efficiency Cooler losses:-110-120 kcal/kg clinker Vent air:-1 Nm3/kg clinker

- 191. © Confederation of Indian Industry Key points CFD study is new era in the field of cement industry through which lots of modification can be done both thermal as well as electrical Improving Cyclone Efficiency through CFD study Reducing the system resistance across ducts &cyclones Latest development in cyclones ,Latest generation burners(Low NOx) and other developments regarding reducing NOX have increased the productivity as well as fulfill the environment norms with output Latest in-house modifications such as TAD ramp and utilization of MgO in kiln are the evidences there is enough potential of improvement in pyro process with low investment

- 192. © Confederation of Indian Industry Annexures

- 193. © Confederation of Indian Industry Annexures

- 194. © Confederation of Indian Industry http://energy.greenbusinesscentre.com/ THANK YOU ! For any queries related to energy efficiency log in @ For latest updates on energy efficiency please visit http://energy.greenbusinesscentre.com/sup/ @CII_GBC cii--godrej-gbc

- 195. © Confederation of Indian Industry