Prop basics(n)

- 1. PROPORTIONAL VALVES - BASIC PRINCIPLES Copyright © Eaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UK

- 2. BASIC SYSTEM 1) Consider a simple hydraulic system consisting of a reservoir (A), electric drive motor (B), pump (C), relief valve (D), filter (E), flow control valve (F), directional control valve (G) and cylinder (H). 1) Consider a simple hydraulic system consisting of a reservoir (A), electric drive motor (B), pump (C), relief valve (D), filter (E), flow control valve (F), directional control valve (G) and cylinder (H). 2) Movement of the cylinder is controlled by the flow control valve (which determines the speed of movement) and the directional control valve (which determines which way the cylinder moves). 2) Movement of the cylinder is controlled by the flow control valve (which determines the speed of movement) and the directional control valve (which determines which way the cylinder moves). AA BBCC DD EE FF HH GG

- 3. BASIC SYSTEM When the solenoid valve is energised, the cylinder piston will extend or retract at a speed determined by the flow control valve. The solenoid valve itself therefore has no control over the cylinder speed. When the solenoid valve is energised, the cylinder piston will extend or retract at a speed determined by the flow control valve. The solenoid valve itself therefore has no control over the cylinder speed.

- 4. BASIC SYSTEM A three position solenoid valve can: - extend the cylinder A three position solenoid valve can: - extend the cylinder

- 5. BASIC SYSTEM A three position solenoid valve can: - extend the cylinder - retract the cylinder A three position solenoid valve can: - extend the cylinder - retract the cylinder

- 6. BASIC SYSTEM A three position solenoid valve can: - extend the cylinder - retract the cylinder - stop the cylinder A three position solenoid valve can: - extend the cylinder - retract the cylinder - stop the cylinder

- 7. The solenoid valve is therefore acting much like a switch in an electrical circuit. In one position the light is switched off... The solenoid valve is therefore acting much like a switch in an electrical circuit. In one position the light is switched off...

- 8. ... and in the other position it is switched on but there are no intermediate states. ... and in the other position it is switched on but there are no intermediate states.

- 9. However, another type of switch can be used for controlling a light bulb known as a dimmer switch. However, another type of switch can be used for controlling a light bulb known as a dimmer switch.

- 10. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb.

- 11. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb.

- 12. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb.

- 13. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb.

- 14. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb.

- 15. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb.

- 16. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb.

- 17. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb. In this case, the switch can be turned to any position between fully off and fully on to vary the brightness of the bulb.

- 18. BASIC SYSTEM 2) The valve spool can now be moved not just to one of three discrete positions but anywhere in between. The direction of the spool movement away from the central position still determines which way the cylinder moves but the amount of spool movement also controls the speed of the piston. 2) The valve spool can now be moved not just to one of three discrete positions but anywhere in between. The direction of the spool movement away from the central position still determines which way the cylinder moves but the amount of spool movement also controls the speed of the piston. 1) A proportional directional valve can be thought of as the dimmer switch equivalent of an electrical switch. 1) A proportional directional valve can be thought of as the dimmer switch equivalent of an electrical switch.

- 19. BASIC SYSTEM So in effect the proportional directional valve is acting as both a directional valve and a flow control valve. So in effect the proportional directional valve is acting as both a directional valve and a flow control valve.

- 20. SWITCHING SOLENOID VALVE A conventional solenoid valve can be thought of as a simple switching valve. It is controlled by some form of electrical device which simply switches the electrical current on or off. A conventional solenoid valve can be thought of as a simple switching valve. It is controlled by some form of electrical device which simply switches the electrical current on or off.

- 21. SWITCHING SOLENOID VALVE A conventional solenoid valve can be thought of as a simple switching valve. It is controlled by some form of electrical device which simply switches the electrical current on or off. A conventional solenoid valve can be thought of as a simple switching valve. It is controlled by some form of electrical device which simply switches the electrical current on or off.

- 22. SWITCHING SOLENOID VALVE A conventional solenoid valve can be thought of as a simple switching valve. It is controlled by some form of electrical device which simply switches the electrical current on or off. A conventional solenoid valve can be thought of as a simple switching valve. It is controlled by some form of electrical device which simply switches the electrical current on or off.

- 23. PROPORTIONAL VALVE A proportional directional valve however will be controlled by an electrical device more like a dimmer switch. A proportional directional valve however will be controlled by an electrical device more like a dimmer switch.

- 24. PROPORTIONAL VALVE By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled. By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled.

- 25. PROPORTIONAL VALVE By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled. By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled.

- 26. PROPORTIONAL VALVE By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled. By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled.

- 27. PROPORTIONAL VALVE By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled. By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled.

- 28. PROPORTIONAL VALVE By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled. By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled.

- 29. PROPORTIONAL VALVE By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled. By varying the current to either solenoid, the amount of spool movement can be varied and hence the amount of flow through the valve can be controlled.

- 30. PROPORTIONAL SOLENOID So unlike a conventional solenoid valve, the electrical current flowing through the coil of a proportional valve needs to be regulated not just switched on or off. The construction of a proportional solenoid is however similar to that of an on/off solenoid. The solenoid consists of: - a coil (A) - a frame (B) - an armature (C) - a pole piece (D) - a push-pin (E) The armature is enclosed in a core tube (F) and the whole assembly is often fully encapsulated in a plastic resin material (G). So unlike a conventional solenoid valve, the electrical current flowing through the coil of a proportional valve needs to be regulated not just switched on or off. The construction of a proportional solenoid is however similar to that of an on/off solenoid. The solenoid consists of: - a coil (A) - a frame (B) - an armature (C) - a pole piece (D) - a push-pin (E) The armature is enclosed in a core tube (F) and the whole assembly is often fully encapsulated in a plastic resin material (G). AA BB CC DDFF GG EE

- 31. PROPORTIONAL SOLENOID When a voltage is applied to the coil connections, an electrical current will flow through the coil. When a voltage is applied to the coil connections, an electrical current will flow through the coil.

- 32. PROPORTIONAL SOLENOID 1) In turn, the electrical current creates a magnetic field which is concentrated in the metal frame, pole piece and armature. 1) In turn, the electrical current creates a magnetic field which is concentrated in the metal frame, pole piece and armature. 2) There is however a gap in the magnetic circuit between the pole piece and armature so a force is created which acts to close this gap and complete the magnetic circuit. 2) There is however a gap in the magnetic circuit between the pole piece and armature so a force is created which acts to close this gap and complete the magnetic circuit.

- 33. PROPORTIONAL SOLENOID 1) The push-pin connects the solenoid to the valve spool and normally moves the spool against a spring. 1) The push-pin connects the solenoid to the valve spool and normally moves the spool against a spring. 2) The force created by the solenoid is determined by the strength of the magnetic field which itself is proportional to the current flowing through the coil. 2) The force created by the solenoid is determined by the strength of the magnetic field which itself is proportional to the current flowing through the coil.

- 34. PROPORTIONAL SOLENOID Increasing the coil current will increase the solenoid force and hence move the spool a greater amount against the spring. Increasing the coil current will increase the solenoid force and hence move the spool a greater amount against the spring.

- 35. PROPORTIONAL SOLENOID Increasing the coil current will increase the solenoid force and hence move the spool a greater amount against the spring. Increasing the coil current will increase the solenoid force and hence move the spool a greater amount against the spring.

- 36. PROPORTIONAL SOLENOID Increasing the coil current will increase the solenoid force and hence move the spool a greater amount against the spring. Increasing the coil current will increase the solenoid force and hence move the spool a greater amount against the spring.

- 37. F I F I PROPORTIONAL SOLENOID The solenoid is designed so that the relationship between the solenoid force (F) and the coil current (I) is a linear one. This means that the solenoid force depends only on the coil current. The solenoid is designed so that the relationship between the solenoid force (F) and the coil current (I) is a linear one. This means that the solenoid force depends only on the coil current.

- 38. SWITCHING SOLENOID SPOOL A further difference between a switching solenoid valve and a proportional valve is in the design of the spool. A further difference between a switching solenoid valve and a proportional valve is in the design of the spool.

- 39. S S Q Q SWITCHING SOLENOID SPOOL 1) With a switching valve, the spool is designed to achieve minimum pressure drop when the valve is energised. 1) With a switching valve, the spool is designed to achieve minimum pressure drop when the valve is energised. 2) Which would mean that to control low flow rates, the amount of spool opening required would be very small and difficult to control. 2) Which would mean that to control low flow rates, the amount of spool opening required would be very small and difficult to control.

- 40. S S Q PROPORTIONAL SPOOL 1) A proportional valve spool therefore has wider lands with notches cut into the edges. 1) A proportional valve spool therefore has wider lands with notches cut into the edges.

- 41. S S Q PROPORTIONAL SPOOL 1) A proportional valve spool therefore has wider lands with notches cut into the edges. 1) A proportional valve spool therefore has wider lands with notches cut into the edges. 2) So although the maximum flow through the valve may be reduced (compared to a switching valve) low flows in particular are more easily controlled and the opening of the valve is more gradual. 2) So although the maximum flow through the valve may be reduced (compared to a switching valve) low flows in particular are more easily controlled and the opening of the valve is more gradual.

- 42. S S Q PROPORTIONAL SPOOL Depending upon the maximum flow to be controlled, different spools can be fitted to a particular valve which have different shape, size or number of spool notches. Depending upon the maximum flow to be controlled, different spools can be fitted to a particular valve which have different shape, size or number of spool notches.

- 43. DIRECT ACTING PROPORTIONAL RELIEF VALVE 1) Proportional valves can also be used to control pressure. In this case a proportional solenoid is used to push a poppet against a seat via a spring. The greater the solenoid force the greater the pressure required to push the poppet off its seat and open the valve. 1) Proportional valves can also be used to control pressure. In this case a proportional solenoid is used to push a poppet against a seat via a spring. The greater the solenoid force the greater the pressure required to push the poppet off its seat and open the valve.

- 44. DIRECT ACTING PROPORTIONAL RELIEF VALVE 2) This provides a direct acting relief valve function but like most such valves, it is only possible to pass small flow rates through the valve. 2) This provides a direct acting relief valve function but like most such valves, it is only possible to pass small flow rates through the valve. 1) Proportional valves can also be used to control pressure. In this case a proportional solenoid is used to push a poppet against a seat via a spring. The greater the solenoid force the greater the pressure required to push the poppet off its seat and open the valve. 1) Proportional valves can also be used to control pressure. In this case a proportional solenoid is used to push a poppet against a seat via a spring. The greater the solenoid force the greater the pressure required to push the poppet off its seat and open the valve.

- 45. TWO-STAGE PROPORTIONAL RELIEF VALVE To control higher flow rates, the proportional direct acting relief valve can be used as the pilot stage of a two- stage relief (or reducing valve). To control higher flow rates, the proportional direct acting relief valve can be used as the pilot stage of a two- stage relief (or reducing valve).

- 46. TWO-STAGE PROPORTIONAL RELIEF VALVE To control higher flow rates, the proportional direct acting relief valve can be used as the pilot stage of a two- stage relief (or reducing valve). To control higher flow rates, the proportional direct acting relief valve can be used as the pilot stage of a two- stage relief (or reducing valve).

- 47. BENEFITS OF PROPORTIONAL SYSTEMS

- 48. REMOTE CONTROL - CONVENTIONAL SYSTEM In order to adjust the speed of an actuator in a conventional system, the flow control valve has to be mounted in a convenient or accessible position. This may often mean running high pressure hydraulic pipes to and from an operator’s desk. In order to adjust the speed of an actuator in a conventional system, the flow control valve has to be mounted in a convenient or accessible position. This may often mean running high pressure hydraulic pipes to and from an operator’s desk.

- 49. REMOTE CONTROL - PROPORTIONAL SYSTEM With a proportional system however, where control valve adjustment is electronic, only low-power electrical cables need to be connected between the operator’s desk and the valve. With a proportional system however, where control valve adjustment is electronic, only low-power electrical cables need to be connected between the operator’s desk and the valve.

- 50. PLC REMOTE CONTROL - PROPORTIONAL SYSTEM More commonly these days, machine control is carried out by a digital electronic controller. Here again, the ability to control proportional valves electronically provides a simple interface between the hydraulic system and the electronic controller. More commonly these days, machine control is carried out by a digital electronic controller. Here again, the ability to control proportional valves electronically provides a simple interface between the hydraulic system and the electronic controller.

- 51. PROPORTIONAL PRESSURE CONTROL The use of proportional directional and pressure control valves means that all hydraulic functions of a machine (movement and force) can be controlled electronically. The use of proportional directional and pressure control valves means that all hydraulic functions of a machine (movement and force) can be controlled electronically.

- 52. SOLENOID VALVE RESPONSE TIME A further benefit of proportional valves is the ability to electronically control the speed of operation of the valve. A further benefit of proportional valves is the ability to electronically control the speed of operation of the valve.

- 53. 0.015 S SOLENOID VALVE RESPONSE TIME Depending upon its size and voltage supply, a conventional switching solenoid valve will have an energisation response time of approximately 15 milli-seconds. Depending upon its size and voltage supply, a conventional switching solenoid valve will have an energisation response time of approximately 15 milli-seconds.

- 54. 0.040 S SOLENOID VALVE RESPONSE TIME The de-energisation response time will be only slightly slower (typically around 25 ms) since the return spring produces less force than the solenoid . The de-energisation response time will be only slightly slower (typically around 25 ms) since the return spring produces less force than the solenoid .

- 55. S PROPORTIONAL VALVE RESPONSE TIME The speed of movement of a proportional valve spool however can be determined by the electronic signal fed to the valve solenoid. By gradually increasing or decreasing the the signal (known as ramping), it is possible to achieve energisation and de-energisation response times of several seconds. The speed of movement of a proportional valve spool however can be determined by the electronic signal fed to the valve solenoid. By gradually increasing or decreasing the the signal (known as ramping), it is possible to achieve energisation and de-energisation response times of several seconds.

- 56. 1.000 S PROPORTIONAL VALVE RESPONSE TIME The speed of movement of a proportional valve spool however can be determined by the electronic signal fed to the valve solenoid. By gradually increasing or decreasing the the signal (known as ramping), it is possible to achieve energisation and de-energisation response times of several seconds. The speed of movement of a proportional valve spool however can be determined by the electronic signal fed to the valve solenoid. By gradually increasing or decreasing the the signal (known as ramping), it is possible to achieve energisation and de-energisation response times of several seconds.

- 57. 2.000 S PROPORTIONAL VALVE RESPONSE TIME The speed of movement of a proportional valve spool however can be determined by the electronic signal fed to the valve solenoid. By gradually increasing or decreasing the the signal (known as ramping), it is possible to achieve energisation and de-energisation response times of several seconds. The speed of movement of a proportional valve spool however can be determined by the electronic signal fed to the valve solenoid. By gradually increasing or decreasing the the signal (known as ramping), it is possible to achieve energisation and de-energisation response times of several seconds.

- 58. 3.000 S PROPORTIONAL VALVE RESPONSE TIME The speed of movement of a proportional valve spool however can be determined by the electronic signal fed to the valve solenoid. By gradually increasing or decreasing the the signal (known as ramping), it is possible to achieve energisation and de-energisation response times of several seconds. The speed of movement of a proportional valve spool however can be determined by the electronic signal fed to the valve solenoid. By gradually increasing or decreasing the the signal (known as ramping), it is possible to achieve energisation and de-energisation response times of several seconds.

- 59. LIFT EXAMPLE - CONVENTIONAL SYSTEM The reason why it is useful to be able to control the speed of spool movement of a valve is to reduce shock in a system. This is achieved by controlling the acceleration and deceleration of the actuator. Suppose, for example, that the simple hydraulic system described earlier is used to operate a passenger lift in a hotel. The reason why it is useful to be able to control the speed of spool movement of a valve is to reduce shock in a system. This is achieved by controlling the acceleration and deceleration of the actuator. Suppose, for example, that the simple hydraulic system described earlier is used to operate a passenger lift in a hotel.

- 60. LIFT EXAMPLE - CONVENTIONAL SYSTEM When the solenoid valve is energised to lower the lift, the valve spool will move across very rapidly. This means that the cylinder will accelerate very quickly up to its maximum speed (determined by the setting of flow control valve F). This sudden starting of the lift provides a very uncomfortable ride for its occupants. When the solenoid valve is energised to lower the lift, the valve spool will move across very rapidly. This means that the cylinder will accelerate very quickly up to its maximum speed (determined by the setting of flow control valve F). This sudden starting of the lift provides a very uncomfortable ride for its occupants. FF

- 61. LIFT EXAMPLE - CONVENTIONAL SYSTEM Similarly, when the lift reaches its destination, the solenoid valve will shut off very rapidly causing a sudden stopping of the lift and again a very uncomfortable situation for the occupants. In real hydraulic systems, the shocks generated by sudden starting and stopping of actuators create high peak pressures which are one of the principle causes of fluid leakage. Similarly, when the lift reaches its destination, the solenoid valve will shut off very rapidly causing a sudden stopping of the lift and again a very uncomfortable situation for the occupants. In real hydraulic systems, the shocks generated by sudden starting and stopping of actuators create high peak pressures which are one of the principle causes of fluid leakage.

- 62. LIFT EXAMPLE - PROPORTIONAL SYSTEM If the solenoid valve and flow control valve are replaced with a proportional valve then not only can the speed of the lift be adjusted electronically, but also its stopping and starting can be controlled. If the solenoid valve and flow control valve are replaced with a proportional valve then not only can the speed of the lift be adjusted electronically, but also its stopping and starting can be controlled.

- 63. LIFT EXAMPLE - PROPORTIONAL SYSTEM The proportional valve can be opened sufficiently slowly to provide a smooth acceleration of the lift up to its maximum speed. The proportional valve can be opened sufficiently slowly to provide a smooth acceleration of the lift up to its maximum speed.

- 64. LIFT EXAMPLE - PROPORTIONAL SYSTEM And likewise the deceleration can be controlled by slowing down the speed of spool movement back to the centre condition. And likewise the deceleration can be controlled by slowing down the speed of spool movement back to the centre condition.

- 65. timeDistance MOTION CONTROL In general therefore, proportional valves are capable of providing full motion control in terms of: In general therefore, proportional valves are capable of providing full motion control in terms of:

- 66. time Acceleration Distance MOTION CONTROL 1. A smooth and controlled acceleration of an actuator up to its maximum speed. 1. A smooth and controlled acceleration of an actuator up to its maximum speed.

- 67. time Acceleration Velocity Distance MOTION CONTROL 2. Control of the actuator velocity and if necessary maintaining it constant with varying loads. 2. Control of the actuator velocity and if necessary maintaining it constant with varying loads.

- 68. time Acceleration Deceleration Velocity Distance MOTION CONTROL 3. A smooth deceleration with minimal pressure peaks.3. A smooth deceleration with minimal pressure peaks.

- 69. time Position Acceleration Deceleration Velocity Distance MOTION CONTROL 4. By using suitable sensing devices, the proportional valve can also be used to control the actuator stopping position to high levels of accuracy. 4. By using suitable sensing devices, the proportional valve can also be used to control the actuator stopping position to high levels of accuracy.

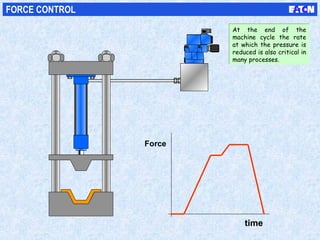

- 70. time Force FORCE CONTROL Proportional valves can also be used to control the force output from an actuator (for example in press or plastic injection moulding applications) by controlling the pressure applied to the actuator. Proportional valves can also be used to control the force output from an actuator (for example in press or plastic injection moulding applications) by controlling the pressure applied to the actuator.

- 71. time Force FORCE CONTROL In such cases it is often necessary to control not only the maximum actuator pressure but also the rate at which the pressure is applied or removed. In such cases it is often necessary to control not only the maximum actuator pressure but also the rate at which the pressure is applied or removed.

- 72. time Force FORCE CONTROL In fact the machine cycle may consist of a series of ramps and holding periods all of which can be achieved with just the one proportional valve. In fact the machine cycle may consist of a series of ramps and holding periods all of which can be achieved with just the one proportional valve.

- 73. time Force FORCE CONTROL At the end of the machine cycle the rate at which the pressure is reduced is also critical in many processes. At the end of the machine cycle the rate at which the pressure is reduced is also critical in many processes.

- 74. FORCE CONTROL Motion and force control can thus be achieved using proportional valves, and in some cases the same valve can be used for both motion and force control. This is usually referred to as ‘PQ’ control ie. the control of both pressure (P) and flow (Q). Furthermore, all of these control functions can be achieved using electronic inputs to the valve thus providing a simple interface to the machine controller. Motion and force control can thus be achieved using proportional valves, and in some cases the same valve can be used for both motion and force control. This is usually referred to as ‘PQ’ control ie. the control of both pressure (P) and flow (Q). Furthermore, all of these control functions can be achieved using electronic inputs to the valve thus providing a simple interface to the machine controller.

- 76. VALVE INPUT SIGNAL As described earlier, the electrical current to the solenoid of a proportional valve needs to be regulated and not just simply switched on or off as is the case with a conventional valve. As described earlier, the electrical current to the solenoid of a proportional valve needs to be regulated and not just simply switched on or off as is the case with a conventional valve.

- 77. VALVE INPUT SIGNAL In theory, this could be achieved by using a dimmer switch type component (ie. a variable resistor). Practical problems such as heat generation and drift however mean that such a device would not normally be used except for the very simplest applications. In theory, this could be achieved by using a dimmer switch type component (ie. a variable resistor). Practical problems such as heat generation and drift however mean that such a device would not normally be used except for the very simplest applications.

- 78. 24 V DC PROPORTIONAL VALVE AMPLIFIER Normally, the current flowing through the proportional solenoid will be controlled by some form of electronic amplifier. The amplifier itself will require a power supply (usually 12 or 24 VDC) and a command input signal. Normally, the current flowing through the proportional solenoid will be controlled by some form of electronic amplifier. The amplifier itself will require a power supply (usually 12 or 24 VDC) and a command input signal.

- 79. 24 V DC PROPORTIONAL VALVE AMPLIFIER The output of the amplifier (electrical current) is controlled by the input signal so with zero input the output current is also zero. The output of the amplifier (electrical current) is controlled by the input signal so with zero input the output current is also zero.

- 80. 24 V DC PROPORTIONAL VALVE AMPLIFIER Increasing the input signal to the amplifier results in a corresponding increase in output current to the valve solenoid. Increasing the input signal to the amplifier results in a corresponding increase in output current to the valve solenoid.

- 81. 24 V DC PROPORTIONAL VALVE AMPLIFIER Increasing the input signal to the amplifier results in a corresponding increase in output current to the valve solenoid. Increasing the input signal to the amplifier results in a corresponding increase in output current to the valve solenoid.

- 82. 24 V DC PROPORTIONAL VALVE AMPLIFIER Increasing the input signal to the amplifier results in a corresponding increase in output current to the valve solenoid. Increasing the input signal to the amplifier results in a corresponding increase in output current to the valve solenoid.

- 83. 24 V DC PROPORTIONAL VALVE AMPLIFIER The relatively large current required to drive the valve solenoid (typically 2 to 3 amps) is provided by the power supply so the current required from the input signal device is very small (normally just a few milli-amps). The input control device can therefore be a simple potentiometer. The relatively large current required to drive the valve solenoid (typically 2 to 3 amps) is provided by the power supply so the current required from the input signal device is very small (normally just a few milli-amps). The input control device can therefore be a simple potentiometer.

- 84. 24 V DC PROPORTIONAL VALVE AMPLIFIER In mobile applications the input device could by a joystick type potentiometer. In mobile applications the input device could by a joystick type potentiometer.

- 85. 24 V DC PROPORTIONAL VALVE AMPLIFIER In an increasing number of applications however, the input signal is generated by the machine controller itself (eg. a PLC - Programmable Logic Controller). This can then be fed directly to the valve amplifier to generate the appropriate output. In an increasing number of applications however, the input signal is generated by the machine controller itself (eg. a PLC - Programmable Logic Controller). This can then be fed directly to the valve amplifier to generate the appropriate output.

- 86. VALVE TYPES

- 87. NON-FEEDBACK VALVE Different types of proportional valves with differing levels of performance are available to meet the requirements of a wide range of applications. The simplest type of proportional directional valve balances the solenoid force against a spring compression force in order to position the spool within the valve body. Different types of proportional valves with differing levels of performance are available to meet the requirements of a wide range of applications. The simplest type of proportional directional valve balances the solenoid force against a spring compression force in order to position the spool within the valve body.

- 88. NON-FEEDBACK VALVE An input signal to the amplifier produces a corresponding output current to the valve solenoid. This current creates a force on the valve spool thus moving it across until the compression of the spring balances the solenoid force. A small input signal thus creates a small opening of the valve. An input signal to the amplifier produces a corresponding output current to the valve solenoid. This current creates a force on the valve spool thus moving it across until the compression of the spring balances the solenoid force. A small input signal thus creates a small opening of the valve.

- 89. NON-FEEDBACK VALVE Increasing the input signal gradually opens up the valve and allows more flow to pass through... Increasing the input signal gradually opens up the valve and allows more flow to pass through...

- 90. NON-FEEDBACK VALVE ... until the valve is wide open and passing maximum flow.... until the valve is wide open and passing maximum flow.

- 91. NON-FEEDBACK VALVE 1) For any input signal therefore, the spool is positioned by balancing solenoid force against spring force. In practice however, other forces also act on the spool. Flow forces in particular are generated when flow passes through the valve and these will act with the spring to oppose the solenoid force and thus reduce the amount of spool opening. 1) For any input signal therefore, the spool is positioned by balancing solenoid force against spring force. In practice however, other forces also act on the spool. Flow forces in particular are generated when flow passes through the valve and these will act with the spring to oppose the solenoid force and thus reduce the amount of spool opening.

- 92. NON-FEEDBACK VALVE 1) For any input signal therefore, the spool is positioned by balancing solenoid force against spring force. In practice however, other forces also act on the spool. Flow forces in particular are generated when flow passes through the valve and these will act with the spring to oppose the solenoid force and thus reduce the amount of spool opening. 1) For any input signal therefore, the spool is positioned by balancing solenoid force against spring force. In practice however, other forces also act on the spool. Flow forces in particular are generated when flow passes through the valve and these will act with the spring to oppose the solenoid force and thus reduce the amount of spool opening. 2) This simple type of valve will therefore have limitations both on the maximum flow rate it can pass and also with its performance in terms of accurate positioning of the valve spool. 2) This simple type of valve will therefore have limitations both on the maximum flow rate it can pass and also with its performance in terms of accurate positioning of the valve spool.

- 93. FEEDBACK VALVE Valve performance can be increased by adding a spool position sensor to the valve. This sensor provides an electronic feedback signal to the amplifier and thus allows the spool to be positioned much more accurately. Valve performance can be increased by adding a spool position sensor to the valve. This sensor provides an electronic feedback signal to the amplifier and thus allows the spool to be positioned much more accurately.

- 94. FEEDBACK VALVE Increasing the input signal to the amplifier gradually opens the valve flow path. Increasing the input signal to the amplifier gradually opens the valve flow path.

- 95. FEEDBACK VALVE Increasing the input signal to the amplifier gradually opens the valve flow path. Increasing the input signal to the amplifier gradually opens the valve flow path.

- 96. FEEDBACK VALVE As before, flow forces will build up to oppose the solenoid force and attempt to reduce the spool opening. Any reduction in opening is now detected by the spool sensor however and results in an increased output current from the amplifier and an increased force from the solenoid to counteract the flow forces. As before, flow forces will build up to oppose the solenoid force and attempt to reduce the spool opening. Any reduction in opening is now detected by the spool sensor however and results in an increased output current from the amplifier and an increased force from the solenoid to counteract the flow forces.

- 97. FEEDBACK VALVE 1) As the pressure drop and flow rate through the valve increase further, ultimately the flow forces will overcome the solenoid force and act to reduce the valve opening as with the simple valve but this will now occur at a significantly greater flow rate than before. For a given size therefore, a feedback type valve will pass a greater flow than the equivalent non- feedback valve and the spool positioning will be more accurate. 1) As the pressure drop and flow rate through the valve increase further, ultimately the flow forces will overcome the solenoid force and act to reduce the valve opening as with the simple valve but this will now occur at a significantly greater flow rate than before. For a given size therefore, a feedback type valve will pass a greater flow than the equivalent non- feedback valve and the spool positioning will be more accurate. 2) The penalty for the improved performance however is a higher cost valve and the fact that the amplifier needs to be dedicated to the type of valve it is controlling (as opposed to a multi-purpose amplifier used on the non-feedback valve). 2) The penalty for the improved performance however is a higher cost valve and the fact that the amplifier needs to be dedicated to the type of valve it is controlling (as opposed to a multi-purpose amplifier used on the non-feedback valve).

- 98. HIGH PERFORMANCE VALVE Where very high performance is required (such as for closed loop position or pressure control), a second type of feedback valve can be used. In this case the spool is accurately matched to a sleeve fitted into the valve body. Also, the spool is moved by a single solenoid rather than two. The normal working centre condition is achieved by energising the solenoid sufficiently to move the spool half-way along its stroke. Where very high performance is required (such as for closed loop position or pressure control), a second type of feedback valve can be used. In this case the spool is accurately matched to a sleeve fitted into the valve body. Also, the spool is moved by a single solenoid rather than two. The normal working centre condition is achieved by energising the solenoid sufficiently to move the spool half-way along its stroke.

- 99. HIGH PERFORMANCE VALVE Movement one side of centre is achieved by increasing the solenoid force (current). Movement one side of centre is achieved by increasing the solenoid force (current).

- 100. HIGH PERFORMANCE VALVE And movement the other side of centre by reducing the solenoid force. And movement the other side of centre by reducing the solenoid force.

- 101. HIGH PERFORMANCE VALVE This type of construction provides a very fast acting, high performance valve but again with the penalty of increased cost. The application requirements will therefore dictate which type of valve is most suited. This type of construction provides a very fast acting, high performance valve but again with the penalty of increased cost. The application requirements will therefore dictate which type of valve is most suited.

- 102. TWO-STAGE SOLENOID VALVE When higher flow rates need to be controlled, a two- stage valve becomes the most practical solution (rather than fitting larger and larger solenoids). As with direct acting valves, a two-stage proportional valve has many similarities with its equivalent switching valve, but there are also significant differences. When higher flow rates need to be controlled, a two- stage valve becomes the most practical solution (rather than fitting larger and larger solenoids). As with direct acting valves, a two-stage proportional valve has many similarities with its equivalent switching valve, but there are also significant differences.

- 103. TWO-STAGE PROPORTIONAL VALVE Firstly, the main spool is modified to incorporate the spool metering notches as on the direct acting valves. This provides a more controlled opening and closing of the valve flow path. Firstly, the main spool is modified to incorporate the spool metering notches as on the direct acting valves. This provides a more controlled opening and closing of the valve flow path.

- 104. TWO-STAGE PROPORTIONAL VALVE Secondly, the pilot stage is modified so that the solenoid current varies the pressure created in the ports leading to either end of the main spool. Effectively, the pilot stage operates as two proportional pressure reducing valves. Secondly, the pilot stage is modified so that the solenoid current varies the pressure created in the ports leading to either end of the main spool. Effectively, the pilot stage operates as two proportional pressure reducing valves.

- 105. TWO-STAGE PROPORTIONAL VALVE Thirdly, the main spool springs are replaced with just one spring. This means that the same spring is compressed whichever side of centre the main spool is moved thus avoiding the need for two accurately matched springs. Thirdly, the main spool springs are replaced with just one spring. This means that the same spring is compressed whichever side of centre the main spool is moved thus avoiding the need for two accurately matched springs.

- 106. TWO-STAGE VALVE (NON-FEEDBACK) Finally, a pressure reducing module is sometimes fitted between the main stage and pilot stage to reduce the pilot pressure when operating at high system pressures (typically greater than 200 bar). Finally, a pressure reducing module is sometimes fitted between the main stage and pilot stage to reduce the pilot pressure when operating at high system pressures (typically greater than 200 bar).

- 107. TWO-STAGE VALVE (NON-FEEDBACK) Energising one of the pilot stage solenoids creates a pressure in one main spool end-chamber proportional to the solenoid current. This pressure pushes the main spool across until the main spring compression force balances the pilot pressure force. Energising one of the pilot stage solenoids creates a pressure in one main spool end-chamber proportional to the solenoid current. This pressure pushes the main spool across until the main spring compression force balances the pilot pressure force.

- 108. TWO-STAGE VALVE (NON-FEEDBACK) Energising the opposite solenoid moves the main spool in the other direction but still compresses the same main centering spring. Energising the opposite solenoid moves the main spool in the other direction but still compresses the same main centering spring.

- 109. TWO-STAGE VALVE (SINGLE FEEDBACK) When an increased level of performance is required, a spool position sensor can be fitted to the main spool and a single solenoid pilot stage used. As before however, this will increase the cost of the valve and require a dedicated amplifier. When an increased level of performance is required, a spool position sensor can be fitted to the main spool and a single solenoid pilot stage used. As before however, this will increase the cost of the valve and require a dedicated amplifier.

- 110. TWO-STAGE VALVE (DOUBLE FEEDBACK) For more demanding applications, spool position sensors can be fitted to both the main spool and the pilot spool to achieve a high dynamic performance from the valve. As with direct acting valves therefore, two- stage proportional valves are available with three levels of performance to meet the requirements of different applications. For more demanding applications, spool position sensors can be fitted to both the main spool and the pilot spool to achieve a high dynamic performance from the valve. As with direct acting valves therefore, two- stage proportional valves are available with three levels of performance to meet the requirements of different applications.

- 111. PROPORTIONAL VALVES - BASIC PRINCIPLES Copyright © Eaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UK

Editor's Notes

- #3: NOTES

- #4: NOTES

- #5: NOTES

- #6: NOTES

- #7: NOTES

- #19: NOTES

- #20: NOTES

- #21: NOTES

- #22: NOTES

- #23: NOTES

- #24: NOTES

- #25: NOTES

- #26: NOTES

- #27: NOTES

- #28: NOTES

- #29: NOTES

- #30: NOTES

- #49: NOTES

- #50: NOTES

- #51: NOTES

- #52: NOTES

- #53: NOTES

- #54: NOTES

- #55: NOTES

- #56: NOTES

- #57: NOTES

- #58: NOTES

- #59: NOTES

- #77: NOTES

- #78: NOTES

- #88: NOTES

- #89: NOTES

- #90: NOTES

- #91: NOTES

- #92: NOTES

- #93: NOTES

- #94: NOTES

- #95: NOTES

- #96: NOTES

- #97: NOTES

- #98: NOTES

- #99: NOTES

- #100: NOTES

- #101: NOTES

- #102: NOTES