Seshasai

- 2. Crack Propagation behavior is a significant problem in Industries. Aerospace Structures, Pressure Vessels, gas turbine engines and pipe lines in oil and gas industry are examples, Where Failure could lead to damages and loss of life as well. For example Crack found in turbine blade of Aircraft engine and Shutting down of pipe line of process industry leads to not only economical loss it affects other dependent industries. The presence of Crack does not mean structure or component is unsafe, it is necessary to know how long initial crack size take grow at critical size at which component or structure would become fail or unsafe. And also it is necessary to know how crack evolves and its rate of propagation, hence we should be able to estimate service life of a component .Cost involved if in service Component found crack, initiated for numerical methods to predict crack propagation. Not only in above said, crack propagation analysis is required studying effect of surface treatment etc. Until recently Crack Propagation behavior is predicted experimentally, which is time consuming, ever since development of high speed computers and commercially available fem coding, industries using soft ware’s to predict crack propagation. In this project obtained stress intensity factor from ANSYS. And Predicting crack growth prediction. Analysis is carried on component of AERO STRCTURE

- 3. Fracture means the cracking or breaking of a hard object or material. What is fracture? Breaking of Materials High sulphur in material Cold waters Welding instead of riveting Continuity of the structure Applied stress Microcracks

- 4. Factors affecting fracture Thermal expansion Quality of surfacesMagnitude of stress

- 5. Brittle deformation: it occurs (in rocks) when a rock breaks or fractures due to stress. This happens in high pressure but low temperature environments Elastic deformation: An object can bend or flex temporarily and will “ spring back" to its original shape, but at some point it will also fail. Ductile deformation: Any strain is irreversible and the rock deforms readily (Think taffy puller). Often in a single fault all three forms of deformation take place in that order as depth increases. Brittle & Ductile Fracture

- 6. Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture. Fracture mechanics is based on the implicit assumption that there exists a crack in a work component. It is the study of flaws and cracks in materials. Mostly deals with crack growth.

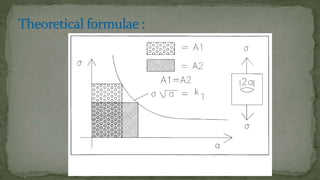

- 7. • Strength of Material approach does not anticipate the presence of a crack or does via concentration factors • Presence of cracks can significantly decrease the structural strength and reliability 𝜎 = 𝐹 𝐴 𝜎 ≫ 𝐹 𝐴

- 8. • Flaw Size (a) is an important parameter in fracture mechanics approach • Fracture Toughness replaces strength of material 𝑲 𝑰𝑪 For Linear-Elastic Fracture Mechanics (LEFM), fracture toughness of a material is determined from “Stress Intensity Factor” For Elastic-Plastic Fracture Mechanics(EPFM), fracture toughness is determined via energy required to grow a crack 𝑱 𝑰𝑪 𝜎 ≫ 𝐹 𝐴 a

- 9. • Probably encountered in any industry dealing with structures – Automotive – Electronics – Healthcare – Aviation – Civil – Nuclear – Defense – Maritime

- 10. • Physically, cracks initiate from; – An imperfection – An already existing crack – A damaged (locally weakened) area • A failure analysis must include; – Stress analysis – Failure criterion

- 11. • A. Griffith (1893-1963) published the results of his studies on brittle fracture • He found the strength of glass depended on the size of microscopic cracks

- 13. Three Modes of Fracture : Mode I denotes a symmetric opening (opening or tension mode) Mode II denotes an antisymmetric separation (In-plane shear mode) Mode III denotes an antisymmetric separation (out-of-plane shear or tearing mode) Crack growth usually takes place in mode I or close to it. The crack “adjusts” itself such that the load is perpendicular to the crack faces.

- 14. The stress intensity factor K is used in fracture mechanics to predict the stress state ("stress intensity") near the tip of a crack caused by a remote load or applied stresses. Stress Intensity Factor is a quantity determined analytically and varies as a function of the crack configuration and the external loads are applied Critical stress intensity factor is independent of the crack geometry and loading and may be regarded as a material constant.

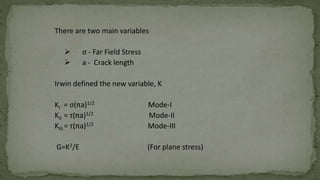

- 15. There are two main variables σ - Far Field Stress a - Crack length Irwin defined the new variable, K KI = σ(πa)1/2 Mode-I KII = τ(πa)1/2 Mode-II KIII = τ(πa)1/2 Mode-III G=K2/E (For plane stress)

- 16. To observer the crack propagation on a rectangular plate of length 2m and breadth 1.6m and considering a crack length of 0.6m Material: - Aluminum Young’s modulus: - 70GPa Poisson’s ration: - 0.3 Density: - 2700 Kg/m^3 Software: - ANSYS 16.0

- 17. PRE PROCESSING: From main menu select Preferences select structural ok

- 18. From the main menu select Pre-processor Element type Add/Edit/Delete Add select solid select 4 node 182 ok.

- 19. Options change K3 into the plane strain ok close.

- 20. Material properties Material models Structural Linear Elastic Isotropic Define EX=70e9 PRXY=0.33 Density= 2700 ok close

- 21. From the main menu select Pre-processor Modeling. Create the key point in the workspace Create Key points In active CS X Y Z 0 0 0 1 0 0 1 0.8 0 0 0.8 0 0.3 0 0

- 22. Click APPLY to all the points and for the last point click OK. Create LINES using the Key points Create Lines Straight Line Select 1-5, 5-2, 2-3, 3-4 & 4-1

- 23. From the main menu select MESHING Meshing Size control Manual sizing Lines Picked lines select the lines 1, 2 & 5 Apply Assign the number of division equal to “4” Again select the lines 3 & 4 Assign the number of division equal “6” and give space ratio as “0.2”.

- 24. Meshing Sizing control Manual size Concentrate key points Give radius R1=0.025 No of element around the circumference = 16 Change node position from no skewed 1/2pt → skewed 1/4pt

- 25. Again go to modeling Modeling Create areas Arbitrary By lines select all five lines ok

- 26. Again go to meshing Meshing mesh areas free select the area ok

- 27. Defining loads Loads define loads apply structural displacement symmetric B.C. with areas select the line first and then area apply Define loads apply structural force/moment on nodes select the nodes on the top side ok Define the direction of the force = “ fy” `And the value of forces = 750 N ok

- 28. SOULTION: Solve → current LS → ok

- 29. POST PROCESSING: From utility menu → plot →nodes

- 30. Defining path General postproc → path operation → define path → by nodes → select the nodes → ok

- 31. From utility menu → work plane → local coordinate system → create local cs → by 3 nodes

- 32. Selecting the three nodes as follows

- 33. General postproc → option for output → change global CS to local CS → local system reference no = 11 → ok

- 34. RESULT: General post processing → nodal calculation → stress intensity factor

- 35. Click OK Hence the stress intensity factor (KI) = 922.00

- 36. Hence the stress intensity factor of the given rectangular plate is (K) 922.00. Hence by using these software the crack propagation is measured.