textile bleaching

- 1. TECHNOLOGY OF BLEACHING – 2 By-Hemant yadav Textile processing

- 2. BLEACHING bleaching is a process in which remove the natural colour and give extra whiteness to textile material

- 3. Before bleaching processes :- * Singing * Sizing * Desizing * Scouring

- 4. Topic :- *Impurities in wool *Carbonising processes for raw wool and woolen fabrics *Scouring of wool in loose form * Machines for using scouring of raw wool

- 5. Impurities in wool:- Raw wool contain 40 to 50 % of impurities. It may contain 40 to 50% wool grease. Compared with cotton 0.5 to 1% oil and wax in cotton Wool also contain natural oil and fats dirt etc. wool remove from dead skin . Also contain lime, Which creates difficulties In scouring with soap & soda (soda ash )

- 6. wool fat or grease :- grease is removed in emulsion scouring suint :-suint is water soluble it is removed by washing such wool should be given a treatment with dilute HCL (hydro chloric acid). Impurities ,such as “suint” consist of potassium salt are removed by treating with luke warm water

- 7. Carbonizing process :- Wool carries lot of vegetable matter called “ burrs” . These are removed in worsted industry in loose state while in most carbonizing process is done on piece goods. The process of carbonizing consist in treating wool with mineral acid or acid salt ,drying . The vegetable matter gets tendered being changed into hydrocellulose and is removed by shaking the goods Sulphuric acid of about 9* tw is used and time of absorption is about 2-3 hrs. drying is done at 90*c.take material and wash thoroughly.

- 8. steps of carbonizing process :- Treat material with sulphuric acid (9tw)for 2-3 hrs dry at 90*c Shake in a shaker wash thoroughly with water

- 9. Scouring of wool in loose form:- Due to felting property of wool , scouring of wool in loose state is done. The most common machine is “harro fork”machine ,which machine consist of several compartment each with a pair of sqeezinge roller and having on overhead arrangement with long forks which is given a to and fro motion pussing the loos wool forword loose wool is fed on a lattie belt conveyor after last squeeze much cleaner wool is deliverd on a similar lattice conveyor removal of suint and wool fat along with dirt etc.

- 10. Swing rake machines :- Wool is feed on to a lattice and it is then conveyed through the bowl containing scouring liquor by a series of rakes , Rakes are operated by a crank motion .the machines are constructed with three or four bowls and last one is used for runsing with cold water

- 11. Diagram of swing rake machine :- A -feeding conveyor B -swing rack C -crank D -bowl with perforated flask bottom E –sediment outlet F –output conveyor G –squeeze roller

- 12. (1) The first two bowls are used for scouring (2) Last bowls is used for rinsing with cold water (3) There may be seven to ten rakes per bowl working at a speed of six to fourteen strokes per minute .the wool passes through a pair of squeeze roller between one bowl to other. During its progress through the machine wool moves over a perforated false bottom . This permits the dirt to fall through into the setting compartment each bowl except last is filled with scouring liquor contaning soap and soda and temperature is brought to 35* to 40*C.

- 13. Harrow machines :- It consist of four or five bowls arranged in sequence so that wool passes directly out the machines consist of long through provide with rakes a false bottom and at the exist a pair of squeeze roller the takes have a recipracating movement which makes wool travel forward as wool leaves the excess of soap liquor is squeezed ,wool passes to second bowl ,where it eceiver further scouring in the final through wool rinsed the water

- 14. Diagram of harrow machine :- A –feeding conveyor D –bowl with perforated Flase bottom E –outlet F –out put conveyor G –squeeze roller

- 15. TECHNOLOGY OF BLEACHING -2 POWER POINT PRESENTATION

- 16. DegumDming of raw silk : • Removal of natural gum from raw silk is done in 3stages.

- 17. o To bath 12.15% soap and 7% soda ash is used at about o 50 degree celcious oIn order avoid in entanglement entire natural is wrapped in gunny bag and steel in soap solution oSecond soap bath is used with lesser quantity of soap and soda oThe final soap bath same quantities of soap and soda is taken as in second bath oIn this way silk gum known as sericius is completely removed and degummed

- 18. BOILED OF LEGOUR • The legour obtained after degumming silk containing soap and silk gum is used in all dying operation this boiled of legour being highly colloidal in nature server as a protective colloid to maintain luster of fiber and for trevention of Degums due to friction

- 19. DEGUMMING OF RAW SILK IN BLENDSWITH WOOL OR ACETATE • Acetate usually get affected with strong soap solution at high temperature and hence the following method of degumming raw silk in blend with wool and acetate is successive • By Enzymic action • 20%popping • 40%thaiosulphate • 40%hydrosulphate • Only three gum of above per litre of water used the metrial is worked for two hours at 65 degree celcious

- 20. •

- 21. CONTENT 1. BLEACHING 2. BLEACHING OF NATURAL SILK 3. METHOD OF BLEACHING 4. BLEACHING OF CELLULOSE ACETATE 5. SCOURING OF MAN MADE FIBRE 6. BLEACHING OF MAN MADE FIBRE

- 22. BLEACHING BLEACHING IS A CHEMICAL TREATMENT EMPLOYED FOR THE REMOVAL OF NATURAL COLOURING MATTER FROM THE SUBSTRATE

- 23. BLEACHING OF NATURAL SILK Even after degumming by ordinary method, some yellow pigment of natural silk still remain and this is due to presence of sericine not being completely removed. When the silk gum is completely removed it appears perfectly white and only a treatment with suitable optical whitening agent is sufficient.

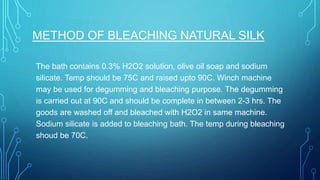

- 24. METHOD OF BLEACHING NATURAL SILK The bath contains 0.3% H2O2 solution, olive oil soap and sodium silicate. Temp should be 75C and raised upto 90C. Winch machine may be used for degumming and bleaching purpose. The degumming is carried out at 90C and should be complete in between 2-3 hrs. The goods are washed off and bleached with H2O2 in same machine. Sodium silicate is added to bleaching bath. The temp during bleaching shoud be 70C.

- 25. BLEACHING OF CELLULOSE ACETATE Cellulose Acetate may be bleached with H2O2. The alkalinity must be adjusted to 9.5 either by addition of sodium silicate or ammonia. The temp must not be allowed to exceed 65C. Time period is an hour.

- 26. SCOURING OF MAN MADE FIBRE Goods(Polyamide) should be scoured to remove any oil applied picked up during weaving and knitting. Scouring is affected in a liqour containing 1-2 g/l of Sodium Tri Phosphate and 1-2 g/l synthetic detergent at a temp 80-90C. Period of 30-45min is sufficient.

- 27. BLEACHING OF MAN MADE FIBRE Bleaching of Polyamide can be done by Paracetic acid. It has all essential properties of H2O2 but does not need an alkali as an activator. It bleaches more effectively between ph 6-7 at which degradation of fibre is less. It effectively removes any discolouration which arises as a result of heat setting under normal condition

- 28. • Peracetic Acid-3lb per 100 gallons • Anhydrous Sodium Pyrophosphate-0.25lb per 100 gallons • Wetting agent-1lb per 100 gallons The pH- of liqour is aadjusted by addition of well diluted Sodium Hydroxide solution. Goods are entered cold and bleaching solution is raised to 80-85C over a period of 30 min and then retained at this temp for further half an hour. After bleaching wash the material with cold water

- 29. SUBMITTED BY Group- VI SATYAM JUGENDRA ASHISH BANSAL SACHIN VIPIN VINOD KUMAR SANGAM KUMAR SACHIN KUMAR

- 30. TECHNOLOGY OF BLEACHING -2 POWERPOINT PRESENTATION

- 31. Topic- •Fluorescent brightening agent •Application of fluorescent brightening agent •Uses of fluorescent

- 32. FLUORESCENT BRIGHTENING AGENT •Compounds with oxidizing or reducing properties are classified as bleaching agent because they decompose the natural colouring. •Bleaching agent also introduce a complementary colour. •The result of this is that distribution of reflected light is more uniform. •Optical brightening agent of fluorescent brightening agent counter the reflection of excello

- 33. APPLICATION OF FLUORESCENT BRIGHTNING AGENT • Optical brightening agent may be applied by either Exhausoion or padding method. Natural fibre require prior bleaching for an acceptable white. The man made fibre are usually softning white • Cellulosic fabric generally required between.0.05 and 0.6 present on the weight of the goods .from a long liqour by exhaustion methods. The goods are entered into a cold liiqour, temperature period of 15 minutes to the optimum for the product which is being used. When required temperature has been reach a further 30 minutes of running will be sufficient for complete exhaustion when padding method are used solution containing between 0.05 to 2 gpl are necessary according to

- 34. USES OF OPTICAL BRIGHTENING AGENT 1.Protein fibres 2.Polyamides 3.Polyester 4.Polyacrylonitriles

- 35. PROTEIN FIBRE •Tinopal, uvitex etc are D.B.A suggest for wool and Silk. They are applied from debarred adjusted to PH between 3and 5 by addition of organic acid. The Liquor is made up with required D B.A, acitic or formic acid is added to Bring pH 3 to 5. Goods are entered and temperature is raised to 40°c during a period of 15 minutes and maintain for another 20 minutes.

- 36. POLYIMIDES • O.B.A suitable for cellulosic can be applied to polyimides but exhausting is inddequate. These are number of optical brightening agent which are used for cellulose are applied to polyamide from a liqour Containing organic acid. • pH of Liqour should be 3.5 to 4 temperature recommended iS 40c to 70°v c • Light fastness is 1 to 2 and washing fastness at 60°c in 0.5% soap solution in 3

- 37. STER They have no affinity for water soluble O.B.A but have affinity for the compounds insoluble in water. Exhaustion is very slow so career it’s reqminute’m/c is required to raise tempeure Liqour is made up wiTh 1 to 2% O.B.A. Material to be treated is entered between 40 and 50°c and Run for 15 minutes at this temperature. What is raise to boil over a period of 30 minutes and boil for further 30 to 60 minutes.

- 38. POLYACRYLONITRILES Mainly cationic O.B.A . Are preferred. They are applied from iiqour Containing 3 to 5 .formic acid to maintain pH 3 to 4 at a temperature between 95o 100°c.

- 39. NATURAL BAST FIBERS 1. BAST FIBER ARE PRODUCED FROM RENEWABLE AGRICULTURE CROPS WITH NO PESTICIDES AND LITTLE ARE NO HERBICIDES. 2. BAST FIBER HAVE BEEN USED FOR THOUSAND OF YEARS BEFORE PETROCHEMICAL FIBERS WHERE DEVELOPED AND PUSHED THEM ASIDE. 3. BAST FIBER CAN REDUCE COST , REDUCE WEIGHT ,REDUCE MANUFACTURING TIME AND IMPROVE SAFETY IN AUTOMOBILES. EUROPEAN AUTOMAKERS HAVE ADOPTED THEM AND ARE EXCEPTED TO USE UP 70000 METRIC TONS OF FIBER BY THE YEAR 2005

- 40. NATURAL RENEWABLE FIBERS BAST FIBERS LEAF FIBERS SEED FIBERS FRUIT FIBER FLAX SISAL COTTON COCONUT HEMP CURAUA KAPOK KENAF BANANA JUTE PINEAPPLE RAMIE

- 41. BLEACHING OF JUTE JUTE IS DIFFICULT TO BLEACH SUITE. IT SURFACE DEGRADATION WHEN TREATED WITH CHLORINE ESPECIALLY IN ALKALINE. THE BEST VARIATION HAVE LITTLE COLOR AND CAN BE DYED WITHOUT BLEACHING JUTE GIVES HARSH FEEL DUE TO LIGNIN. LIGNIN IS REMOVED PARTLY BY TREATMENT WITH CAUSTIC FOR HALF HOUR WITH 18-20% NAOH FOR COMPLETE DELIGNIFICATION. SOME CHLORINE CONTAINING AGENT IS REQUIRED SAME LIKE COTTON

- 42. DISADVANTAGE THIS PROCESS CAUSES HIGH STRENGTH LOSS SCOURING SCOURING OF MATERIAL IS DONE WITH 3% NAOH AT BOILING TEMP. FOR 1 HRS. THEN WASH THE MATERIAL WITH COLD WATER AT ROOM TEMP. AND TREAT WITH ACID TO NEUTRALIZE THE ALKALI

- 43. BLEACHING OF JUTE IS DONE WITH HYDROGEN PEROXIDE. MATERIAL IS TREATED WITH 3% HYDROGEN PEROXIDE 3% SODIUM META SILICATE 2% SODA ASH 10%SOAP FOR 1HRS. HYPOCHLORITE IS NOT RECOMMENDED AS AT CONTAIN CHLORINE WHICH WAY CASES DEGRADATION. HYDROGEN PEROXIDE GIVE HALF BLEACH TO GET PURE WHITE MATERIAL IS AGAIN TREATED WITH ABOVE RECIPE ADDING COLD BLEACH PROCESS Hydrogen peroxide 6% Caustic soda 3% Soda ash 3% Soap 1% Temp RoomTemp ENTER THE MATERIAL IN THIS SOLUTION. PREPARED WITH ABOVE CHEMICALS FOR 24 HRS. WASH WITH HOT WATER AND COLD WATER THIS PROCESS GIVEN FULL WHITENESS

- 44. TOPIC BLEACHING WOOL WITH H2O2 BLEACHING WITH SULPHUR DIOXIDE BLEACHING WITH SODIUM DITHIONITE(SODIUM HYDROSULPHITE)

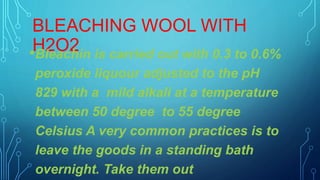

- 45. BLEACHING WOOL WITH H2O2•Bleachin is carried out with 0.3 to 0.6% peroxide liquour adjusted to the pH 829 with a mild alkali at a temperature between 50 degree to 55 degree Celsius A very common practices is to leave the goods in a standing bath overnight. Take them out

- 46. •The traditional method of bleach liqour for wool age as follow •Tetra sodium pyrophosphate 2g/l •E.D.T.A 30%. 1g/l •H2O2 35%. 13m/l •Or H2O2 50%. 9ml/l

- 47. •When bleaching is completed the wool must be rinsed •Thoroughly and treated in a liqour containing 0.5% of •Acetic acid to neutralise alkali

- 48. BLEACHING WITH SULPHUR DIOXIDE •This is the oldest method Wool is bleached by stretching •It over a lattice frame in the cautre of which small pot of •Burning sulphur is placed. •This method gives adequate bleach for lower quality goods

- 49. •It is a cheap method and required only simple equipment •The equipment consists of chamber fitted with rails in which wooden poles can rest . Moistured wool goods are •Hung over there poles and a cost iron pot containing sulphur is placed in the chambers.

- 50. •Sodium sulphite to remove SO2 other wise SO2 May be oxidised to H2SO4 •And cause holes. •A extremely clear white can be obtained by bleaching with H2O2 first and then •By SO2

- 51. BLEACHING WITH SODIUM DITHIONITE (SODIUM HYDROSULPHITE) • It is a stable white powder with strong reducing properties . In first stage pass • SO2 through an aqueous suspension of ZN dust • When treated with formaldehyde a stable additional compound is formed. • When acetic acid is added.it decomposes slowly on warming with the formation of HYDROSULPHITE acid • Wool can be bleached with sodium hydrosulphite or its

- 52. •In practice they do not find much application because they tend to import harsh handle . •They are used as stripping agent to remove dyes when necessary