Two Component System:Binary Eutectic Phase Diagram

- 1. CHAPTER 2(CONTD.) Lead (Pb)-Tin(Sn) Phase Diagram Development of microstructure in eutectic alloys Problems on Eutectic Phase Diagram Practice Problems MTE/III SEMESTER/MSE/MTE 2101 1

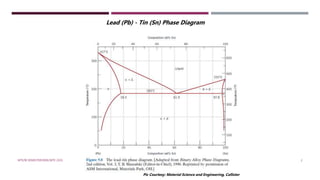

- 2. MTE/III SEMESTER/MSE/MTE 2101 2 Pic Courtesy: Material Science and Engineering, Callister Lead (Pb) - Tin (Sn) Phase Diagram

- 3. DEVELOPMENT OF MICROSTRUCTURE IN EUTECTIC ALLOYS Case 1: Cooling curve and micro-structure development for eutectic alloy that passes mainly through terminal solid solution Consider an alloy of composition C₁ as it is slowly cooled from a temperature within the liquid-phase region, say, 350°C; this corresponds to moving down the dashed vertical line ww´ in the figure. The alloy remains totally liquid and of composition C₁ until we cross the liquidus line at approximately 330°C at which time the solid phase begins to form. While passing through this narrow phase region, solidification takes place in similar manner as Cu-Ni system. The resulting alloy is polycrystalline with a uniform composition of C₁, and no subsequent changes will occur. (point c)MTE/III SEMESTER/MSE/MTE 2101 3 Pic Courtesy: Material Science and Engineering, Callister

- 4. Case 2: Cooling curve and micro-structure development for eutectic alloy that passes through terminal solid solution without formation of eutectic solid Let us examine an alloy of composition as it is cooled along the vertical line xx´. Down to the intersection of xx´ and the solvus line, changes that occur are similar to the previous case, as we pass through the corresponding phase regions (d,e,f). Upon crossing the solvus line, the α solid solubility is exceeded, which results in the formation of small – β particles. With continued cooling, these particles will grow in size because the mass fraction of the phase β increases slightly with decreasing temperature. MTE/III SEMESTER/MSE/MTE 2101 4Pic Courtesy: Material Science and Engineering, Callister

- 5. Case 3: Cooling curve and micro-structure development for eutectic alloy that passes through eutectic-point Consider an alloy having this composition that is cooled from a temperature within the liquid-phase region (e.g., 250C) down the vertical line yy´. As the temperature is lowered, no changes occur until we reach the eutectic temperature, 183°C. Upon crossing the eutectic isotherm, the liquid transforms to the two α and β phases. This transformation is represented by the reaction: MTE/III SEMESTER/MSE/MTE 2101 5

- 6. Case 4: Cooling curve and micro-structure development for eutectic alloy that passes through hypo-eutectic region Consider, for example, the composition C₄ which lies to the left of the eutectic; as the temperature is lowered, we move down the line zz´ beginning at point j. The microstructural development between points j and l is similar to that for the second case. As the temperature is lowered to just below the eutectic, the liquid phase, which is of the eutectic composition, will transform to the eutectic (i.e., alternating α,β and lamellae). MTE/III SEMESTER/MSE/MTE 2101 6

- 7. PROBLEMS ON EUTECTIC PHASE DIAGRAM Determination of Phases Present and Computation of Phase Compositions For a 40 wt% Sn–60 wt% Pb alloy at 150° C (300°F): (a) What phase(s) is (are) present? (b) What is (are) the composition(s) of the phase(s)? Refer: Example Problem 9.2; Material Science and Engineering, Callister. MTE/III SEMESTER/MSE/MTE 2101 7

- 8. Relative Phase Amount Determinations—Mass and Volume Fractions For the lead–tin alloy in Example Problem 9.2, calculate the relative amount of each phase present in terms of : (a) mass fraction, and (b) volume fraction. At 150°C, take the densities of Pb and Sn to be 11.23 and 7.24 g/cm³, respectively. MTE/III SEMESTER/MSE/MTE 2101 8

- 9. Practice Problem 1: A lead–tin alloy of composition 30 wt% Sn–70 wt% Pb is slowly heated from a temperature of 150°C. (a) At what temperature does the first liquid phase form? (b) What is the composition of this liquid phase? (c) At what temperature does complete melting of the alloy occur? (d) What is the composition of the last solid remaining prior to complete melting? MTE/III SEMESTER/MSE/MTE 2101 9 (Refer Exercise Problem 9.11; Material Science and Engineering, Callister)

- 10. Practice Problem 2: A 65 wt% Ni–35 wt% Cu alloy is heated to a temperature within the α+liquid-phase region. If the composition of the phase is 70 wt% Ni, determine: (a) The temperature of the alloy (b) The composition of the liquid phase (c) The mass fractions of both phases MTE/III SEMESTER/MSE/MTE 2101 10 (Refer Exercise Problem 9.17; Material Science and Engineering, Callister)