Week 8_DTM_CH9_Replineshment in a Multi-echelon Channel Environment

- 1. PART III: INVENTORY MANAGEMENT IN THE SUPPLY CHAIN ENVIRONMENT Replenishment in A Multi-echelon Channel Environment (Ch. 9) Distribution and Transportation Management Friday 21 October 2016 21 October 2016, BSc – IBN Didik Siswantoyo, BSc Fin., MSc IFM Lecturer in Financial Management, Distribution and Transportation Management

- 2. Objectives § Review of how multi-echelon distribution demand and supply inventories are managed § Understand the channel “push” and “pull” methods of replenishment management. § Describe the application of statistical replenishment in a multi-echelon channel. § Focus on the theory and processing logic of Distribution Required Planning. § Analyse how DRP uses time-phased demand and supply input to generate output information that is used by the inventory planner to guide resupply order action. § Discuss the impact of the DRP priority plan on financial capital planning, transportation capacity requirements, warehouse space requirements, and labour and equipment capabilities. 2Distribution and Transportation Management (Ch. 9) Friday 21 October 2016

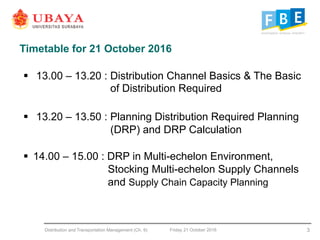

- 3. Timetable for 21 October 2016 § 13.00 – 13.20 : Distribution Channel Basics & The Basic of Distribution Required § 13.20 – 13.50 : Planning Distribution Required Planning (DRP) and DRP Calculation § 14.00 – 15.00 : DRP in Multi-echelon Environment, Stocking Multi-echelon Supply Channels and Supply Chain Capacity Planning 3Distribution and Transportation Management (Ch. 9) Friday 21 October 2016

- 4. Contents (1/2) § Distribution Channel Basics – Coupled Deployment (Push) and Independent Deployment (Pull) Systems – Which to choose: Order Points or Distribution Required Planning (DRP) § The Basics of DRP – Intro. to the DRP Grid, DRP Order Policies and Safety Stock § The DRP Calculation – Basic Data Elements, Bucketless DRP, and – DRP Regeneration Frequency § DRP in Multi-echelon Environment – DRP Planning Process 4Distribution and Transportation Management (Ch. 9) Friday 21 October 2016

- 5. Contents (2/2) § Stocking Multi-echelon Supply Channels – Bullwhip Effect – Adjusting Channel Imbalance § Supply Chain Capacity Planning – Financial Estimating – Transportation Planning § Summing up 5Distribution and Transportation Management (Ch. 3) Friday 21 October 2016

- 6. Distribution Channel Basics § Product and Information Flows 6Distribution and Transportation Management (Ch. 3) Source: Ross (2015) Fig. 1: Distribution Channel Flows 9 Friday 21 October 2016

- 7. Distribution Channel Basics § Coupled and Independent Deployment Systems 1/3 7Distribution and Transportation Management (Ch. 9) Source: Ross (2015) Fig. 2: Push and Pull Systems Friday 21 October 2016

- 8. Distribution Channel Basics § Coupled and Independent Deployment Systems 2/3 8Distribution and Transportation Management (Ch. 9) Source: Ross (2015) Fig. 3: Coupled Deployment “Push” System The Key Success factor in the Push System Friday 21 October 2016

- 9. Distribution Channel Basics § Coupled and Independent Deployment Systems 3/3 9Distribution and Transportation Management (Ch. 9) Source: Ross (2015) Fig. 3: EXAMPLE of Coupled Deployment “Push” System Inventory Planners quantify the total amount of goods to be distributed Friday 21 October 2016

- 10. Distribution Channel Basics 10Distribution and Transportation Management (Ch. 9) Table 2: Allocation sample of Coupled Deployment “Push” System Friday 21 October 2016

- 11. Distribution Channel Basics 11Distribution and Transportation Management (Ch. 9) Table 3: Advantages of Push System (1/2) Performance Measurement Enables corporate planners to leverage the total inventory & historical demand to meet shipment goals while minimizing the cost. The measurement is dependent on how well the whole channel is meeting corporate sales and asset management targets. Central Planning Can create a single inventory plan for the ongoing ordering and deployment of channel inventory. Can determine global channel inventories and remove the normal supply point stock redundancies caused by inaccuracies in local replenishment decision making. Cost Reductions By centralizing inventory planning and deployment, companies can reduce the total working capital necessary to stock the supply channel. operating costs are reduced by economies attained in transportation and purchasing. Safety Stock Control is a characteristic feature of inventories subject to independent demand, a “push” system enables planners to centralize safety stocks at the central facility. By eliminating unnecessary safety stocks carried at each channel location, “push” systems reduce total inventory costs while maintaining high channel serviceability. Friday 21 October 2016

- 12. Distribution Channel Basics 12Distribution and Transportation Management (Ch. 9) Table 4: Drawbacks of Push System (2/2) Performance Measurement branch management’s role migrates from a focus on detailed inventory replenishment management to ensuring transmission of accurate stock status and sales usage information to the channel’s central planning functions. Central Planning requires a professionally trained central planning staff that can work with aggregate data and demand forecasting techniques. Cost Reductions requires changes in operational roles. Safety Stock Control inventory accuracy and timely transaction record posting normally requires a computer system that combines the historical demand resident at each channel location Source: Siswantoyo based upon Ross, 2015 Friday 21 October 2016

- 13. Independent Deployment “ Pull “ Systems (1/5) § How does the Pull System Flow works? 13Distribution and Transportation Management (Ch.9) Source: Ross (2015) Fig. 4: Pull System Flow Friday 21 October 2016

- 14. Independent Deployment “ Pull “ Systems (2/5) § Each facility in the distribution channel is responsible for inventory reordering based on demand requirements, determining the replenishment and then ordering the requested products from the supplying location. § The branch warehouse specifies the order timing, nature of items to be ordered, quantify the resupply orders and consignment demands. § Distribution centers (DCs) receive a sequence of resupply orders by due date from their branches and attempt to fill and ship them according to some priority rule, usually first-come first-serve. § Facilities have a choice of selecting either statistical order point or distribution requirements planning (DRP) or a combination of both as their ordering system. § Normally, executing a pull system requires the presence of an enterprise resources planning (ERP) system shared by all facilities in the channel network § Finally, the DC acquires its replenishment inventory directly from the manufacturer or the supplier. 14Distribution and Transportation Management (Ch. 9) Friday 21 October 2016

- 15. Independent Deployment “ Pull “ Systems (3/5) Fig. 5: Example of how the Pull System Flow works 15Distribution and Transportation Management (Ch.9) Source: Ross (2015) Fig. 4: Pull System Flow 12 3 Friday 21 October 2016

- 16. Independent Deployment “ Pull “ Systems (4/5) 16Distribution and Transportation Management (Ch. 9) Table 5: Advantages of Pull System Planning Simplicity The systems are easy to operate because each facility is responsible for inventory planning No centralize planning DC is needed, No process of aggregating demand and developing allocation plans are needed. Turnover The inventory costs at the warehouse level will decline, because they only bear the right amount of products based upon the demand. Less risky because it turn the inventory faster than in the push system. Overhead Cost Reduction is a characteristic feature of inventories subject to independent demand, a “push” system enables planners to centralize safety stocks at the central facility. Use of Replenishment and DRP Ordering Methods Reorder Point (ROP) and DRP computer system logic provide excellent tools to operate pull systems, because both systems enable local warehouse to determine the actual timing and quantities of replenishment orders. This methods connect the correlated facilities when the resupply orders arrive through bill of distribution (BOD) Friday 21 October 2016

- 17. Independent Deployment “ Pull “ Systems (5/5) 17Distribution and Transportation Management (Ch. 9) Table 6: Drawback of Pull System Possibly safety stock at multiple echelons in the channel, because each location in the network is responsible for their own service levels overall inventory carrying costs and deficiencies in information flows, particularly in a supply chain driven by statistical replenishment techniques. Supplying warehouses are usually unaware of branch requirements until the resupply order arrives. Friday 21 October 2016

- 18. How to Deal With the Deficiency of Pull Systems? (1/2) 18Distribution and Transportation Management (Ch. 9) § Periodic Review System Operationally, branch warehouse inventories are reviewed periodically and resupply orders generated with sufficient quantities necessary to restore channel-wide stocks to a targeted level. § Double Reorder Point Each branch’s inventory has its reorder point set by calculating the normal reorder point plus the average demand during the central warehouse’s procurement, transportation, and production lead time. § Base Stock System Requires each location in the channel to maintain a base level of inventory determined as the facility’s statistically computed demand plus stock at all upstream warehouses. The inventory position (IP) at each level is indicated by the following formula: IP = ES + RO Where, IP = Inventory Position, ES = Echelon Stock, RO = Replenishment Order Friday 21 October 2016

- 19. How to Deal With the Pull Systems Deficiency? (2/2) 19Distribution and Transportation Management (Ch. 9) § Base Stock System For example: Branch facility A is resupplied from warehouse 1. For a given item, branch facility A stocks 100 units and warehouse 1 stocks 300 units. There are also 50 units in transit to branch facility A, and warehouse 1 has an unfilled replenishment order from the supplier for 100 units. Finally, branch facility A has a customer order backlog of 125 units. Then, warehouse 1’s inventory position is: IP = ES + RO IP = (100 + 300 + 50 - 125) + 100 IP = 425 units Friday 21 October 2016

- 20. Which one to Chose: Reorder Point or DRP? § Depending on how inventory moves through the multi-echelon channel and the level of control required by management. 2.1. Finished goods are purchased from suppliers and then transported through the various channel echelons until they reach the end-use customer. 2.2. Items originate at an internal company production plant. 20Distribution and Transportation Management (Ch.9) ROP or DRP 1. the length and homogeneity of the lead time 2. how items enter the supply chain Friday 21 October 2016

- 21. ROP Mechanics in a Multi-echelon Supply Channel Fig. 6: Purchased Finished Good 21Distribution and Transportation Management (Ch.9) Source: Ross (2015) Friday 21 October 2016

- 22. How does the ROP works in a multi-echelon environment? Fig. 7: ROP Channel Management 22Distribution and Transportation Management (Ch.9) Source: Ross (2015) Supply Facilities (i.e. W1, W2, W3) Regional Supply Facility ROP is best suited for goods that are not self-manufactured by the firm. It focuses only on short lead-time reorder points. Friday 21 October 2016

- 23. DRP Mechanics in a Multi-echelon Supply Channel (1/3) § Distribution Requirements Planning (DRP) • Used if the finished goods are supplied from production plants or made-to- order products supplied by the suppliers, exclusively for long-lead time items. § How to manage a complex circumstance under DRP? • Production planners often must manage significant processing and purchasing lead times before finished goods are made and shipped through the supply channel. • Production planners uses the material requirements planning (MRP) system to purchase the components and make the products (the cumulative lead time) and to offset the lead-time. 23Distribution and Transportation Management (Ch.9) Friday 21 October 2016

- 24. DRP Mechanics in a Multi-echelon Supply Channel (2/3) Fig 8: DRP Manufactured Finished Product Flow 24Distribution and Transportation Management (Ch.9) Source: Ross (2015) Friday 21 October 2016

- 25. DRP Mechanics in a Multi-echelon Supply Channel (3/3) 25Distribution and Transportation Management (Ch.9) Source: Ross (2015) § Planners employ the DRP by means of using the time-phased order point (TPOP) to meet the plan of supply and demand requirements Table 7: DRP Manufactured Finished Product Flow Friday 21 October 2016

- 26. The Basic Concepts of DRP (1/5) 26Distribution and Transportation Management (Ch.9) Table 8: Concepts of DRP Grip 1. Time Periods Inventory based on Daily, Weekly, and/or Monthly. 2. Gross Requirements (GR) Define the total demand placed on an item, literally based on forecasts 3. DRP in Transit Receipts (TR) Define the total quantity of released replenishment orders for an item due within a specific time period. 4. Projected Available Balance (PAB) provides the planner visibility to current and projected on-hand quantities in all periods constituting the planning horizon. PAB = (IBn-1 + TRn) – GRn 5. Net Requirements It indicates in which time periods the gross requirements (demand) exceed the available inventory supply (i.e. result has to be negative). 6. DRP Planned Order Receipt The order is considered as “planned” because it has not been released into an actual order and placed at the supply source. 7. DRP Planned Order Release The date a DRP planned order is to be released is calculated by subtracting the item’s replenishment lead time from the planned order receipt date. § The DRP time-phased format is designed to assist the inventory planner to visualize the interaction between supply and demand as they appear in the planning horizon. Friday 21 October 2016

- 27. The Basic Concepts of DRP (2/5) 27Distribution and Transportation Management (Ch.9) Source: Ross (2015) § Table 9: PAB Calculation PAB = (IBn-1 + TRn) – GRn Friday 21 October 2016

- 28. The Basic Concepts of DRP (3/5) 28Distribution and Transportation Management (Ch.9) Source: Ross (2015) § Table 10: Net Requirement Calculation NRn = PABn Friday 21 October 2016

- 29. The Basic Concepts of DRP (4/5) 29Distribution and Transportation Management (Ch.9) Source: Ross (2015) § Table 11: DRP Planned Order Receipt DRP POR = PAB + NR Friday 21 October 2016

- 30. The Basic Concepts of DRP (5/5) 30Distribution and Transportation Management (Ch.9) Source: Ross (2015) § Table 12: DRP Planned Order Release Friday 21 October 2016

- 31. DRP Order Policies and Safety Stock 31Distribution and Transportation Management (Ch.9) § The Implementation of order policies is to compute the order lot size based upon the requirements. And the most common policies in the DRP System are: § Discrete (lot-for-lot). This order policy recommends a resupply quantity that matches exactly each item’s net requirements by due date. § Fixed period requirements. In this technique, the system calculates the replenishment quantity based on a simple rule of ordering n period’s supply. § Discrete above the standard lot size. Often an item is resupplied in quantities of a certain lot size because of discounting, minimum quantity lot sizes, or shipping purposes. This order policy requires the user to set the required lot-size quantity in the item’s master record. § Incremental above the standard lot size. This order policy is based on two values entered in the item master record: the lot size and an incremental quantity that is added to the lot size when the net requirement is greater than the lot size. § Multiples of a standard lot size. When using this order policy, the system will attempt to satisfy the net requirement with the item’s replenishment lot size § Min/max order quantity. Requirements occur during the DRP planned order generation for an item with a min/max order policy, the suggested DRP planned resupply order cannot be less than the preset minimum nor greater than the preset maximum. § Lot costing models. The final order policy model is based on some form of lot size that, like the EOQ, seeks to minimize the sum of inventory carrying costs. Friday 21 October 2016

- 32. Safety Stock (1/5) 32Distribution and Transportation Management (Ch.9) § The use of safety stock plays an important role in distribution inventory planning. § Based on APICS dictionary, Safety Stock defines as “a quantity of stock planned to be in inventory to protect against fluctuations in demand or supply.” § Safety stock acts as a buffer to probabilistic variability, decoupling demand from stocked inventories thereby sheltering inventory from the threat of stock out. § The safety stock quantity is normally based on a company decision to support a targeted customer service percentage. The higher the targeted service percentage, the higher the safety stock. Friday 21 October 2016

- 33. Safety Stock (2/5 33Distribution and Transportation Management (Ch.9) § Exercise: DRP Without Safety Stock Item K-2000-10 is replenished through DRP. The item takes 3 days to be delivered from the supplying distribution center. The order quantity is in lot sizes of 200 units. There is an opening balance of 275 units on hand. Demand occurs in the form of gross requirements through the planning horizon. When the DRP computer processor is run, the following results are evident in the DRP grid detailed: Source: Ross (2015) Table13: DRP Without Safety Stock Recalculation Friday 21 October 2016

- 34. Safety Stock (3/5) 34Distribution and Transportation Management (Ch.9) § Exercise: DRP Safety Stock Violation The projected available balance (PAB) in periods 3, 4, 7, and 10 have ending balances that fall below the 75 safety stock units and clearly constitute a safety stock violation. Source: Ross (2015) Table 14: DRP Safety Stock Violation Friday 21 October 2016

- 35. Safety Stock (4/5) 35Distribution and Transportation Management (Ch.9) § How to eliminate the Safety Stock violations along the Period? ª Add the safety stock into the DRP calculation, then DRP will generate the initiated quantity sufficiently. Source: Ross (2015) Table 15: DRP Safety Stock Recalculation PABn = (IBn-1 + TRn +PORn) - GRn Friday 21 October 2016

- 36. The DRP Calculation 36Distribution and Transportation Management (Ch.9) § The generation of planned orders to cover all future item net requirements is the cornerstone of the DRP planning process. § The calculation is based upon the following basic data elements: 1. The DRP process is generated by using the data input from the following sources: 2. Length of the planning horizon 3. Size of the planning buckets 4. Item forecasts by due date 5. Open customer orders by item by due date 6. Beginning on-hand quantities by item 7. Open purchase, interbranch, and postponement orders by item by due date 8. Replenishment lead times by item 9. Safety stock by item 10. Order policy code by item 11. Supply sources based on the bill of distribution (BOD) § Once the DRP calculation is complete, the inventory planners can obtain output information (i.e. Exception reporting, Planned orders, Action messages and Pegged requirements) which then utilised to guide resupply order action. Friday 21 October 2016

- 37. Bucketless DRP 37Distribution and Transportation Management (Ch.9) § The time bucket format is merely a convenient way to aggregate demand and supply data for viewing purposes. § Most commercial DRP systems provide a bucketless display, permitting the planner to see the orders in ascending or descending order by actual due dates and quantities along with a running PAB total. Table 16: Bucketless DRP Display Source: Ross (2015) Friday 21 October 2016

- 38. 38Distribution and Transportation Management (Ch.9) Source: Ross (2015) Source: Ross (2015) Friday 21 October 2016

- 39. DRP in A Multi-echelon Environment 39Distribution and Transportation Management (Ch.9) § The channel consists of three distribution centres (DCs) that are supplied from a single production plant. Item KL-2000-10 is produced at the production plant. § The three DCs pull the item from the production plant based on the DRP planned resupply order generation. § This step could be performed by the planners at each DC or globally from a central location. § Replenishment orders are received only from the production plant. § The resulting DRP grids use the statement of customer orders and forecasts for the item to populate the gross requirements row for each DC. § Resupply orders in the process of being shipped are visible in the DRP in transit receipts row § Finally, the DRP processor uses the replenishment order quantities, lead times, and current on hand inventories to calculate the projected available inventory, net requirements, and planned order rows for item KL-2000-10 at each DC. § The DRP planned orders from the DC are then placed by the DRP system directly into the gross requirements of the “parent” production plant. Friday 21 October 2016

- 40. DRP Planning Process (1/3) 40Distribution and Transportation Management (Ch.9) § The objectives of DRP are the creation of an inventory replenishment plan that optimizes targeted customer service levels while minimizing channel inventory costs. § In developing the DRP plan, inventory planners consider questions such as the following: 1. Is the planning data for each DRP planned item accurate and up-to-date? 2. Have BODs been created that accurately reflect the structure of the distribution channel? 3. Are on-hand balances being updated accurately and on a timely basis? 4. Are open customer and purchase order due dates and quantities accurate? 5. Have replenishment order policies been accurately defined? 6. Do product replenishment lead times reflect current delivery realities? 7. Have safety stocks been calculated correctly? 8. Have DRP regeneration and planning procedures been formalized? § The schedule of planned order releases defines the scope of replenishment order action to be performed by the planner (see. Figure 10) Friday 21 October 2016

- 41. DRP Planning Process (2/3) 41Distribution and Transportation Management (Ch.9) Source: Ross (2015) Fig 9: DRP Planning Process Friday 21 October 2016

- 42. DRP Planning Process (3/3) 42Distribution and Transportation Management (Ch.9) Friday 21 October 2016 § The schedule of planned order releases defines the scope of replenishment order action to be performed by the planner. § Most commercial DRP systems provide online displays and output reports advising planners of required order release and reschedule activities. § The final step in the DRP planning process is the calculation and review of the logistics capacities necessary to deliver the schedule of resupply planned orders. § Logistics capacities are composed of four elements: inventory investment, transportation, warehouse space, and labor and equipment. Source: Ross (2015) Table 17: DRP Order Action

- 43. Stocking Multi-echelon Supply channels 43Distribution ad Transportation Management (Ch.9) § An important problem facing planners is determining which items are to be stocked at each warehouse and in what quantities. § Solving this basic multi- echelon problem is often perceived as consolidating inventories into fewer stocking locations in order to reduce total inventory costs. § Bullwhip Effect “An extreme change in the supply position upstream in a supply chain generated by a small change in demand downstream in the supply chain.” § It occurs if a small variation in customer demand ripples back up the supply chain in successively wider peaks and troughs, such as: – Lack of collaboration and information sharing: – Demand forecast updating: A critical feature of the bullwhip effect is the nature of the forecasts generated in the channel. – Order batching – Price fluctuations and promotions – Rationing and shortage gaming Friday 21 October 2016

- 44. Stocking Multi-echelon Supply channels 44Distribution and Transportation Management (Ch.9) Friday 21, October 2016

- 45. Stocking Multi-echelon Supply channels 45Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 § How to Cope With Bullwhip Effect (Chopra and Meindl, 2007)? 1. Aligning of channel goals and profitability • Achieving synchronization of goals and profitability requires channel members to develop strategies that ensure profitability and risk are shared equally by all channel nodes 2. Improved information accuracy • A variety of computerized applications provide planners with increased visibility to supply chain disruptions and improve the accuracy of available information (e.g. point of sales, EDI, CPFR.) 3. Improved operational performance • Reducing replenishment lead times and lot sizes will significantly assist in decreasing demand uncertainty during the replenishment process (e.g. EDI, Cross-docking, etc.). 4. Designing pricing strategies to stabilize orders • to move from lot-size to volume-based quantity discounts • to restrict or eliminate promotions and to establish standardized prices with the goal of linking prices directly to customer sales 5. Building strategic partnership and trust • action-oriented levers : includes information sharing, changing incentives, operational improvements, and stabilizing of pricing • relationship-oriented levers : involves the construction of cooperation and trust within the supply chain by detailing the benefits to each party, identifying operational roles and decision rights for each channel member, establishing effective contracts, and designing effective conflict-resolution mechanisms.

- 46. Selective Stocking 46Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 § What does selective stocking mean, is the objective of this method and how to maximise the existing warehouse space, and finally how to determine stocking levels? – A simple concept to stock channel locations. – To allow supply chain planners to maximise the available warehouse space in the channel. – The maximisation can be done through determining which items are to be stocked at what channel level based upon the items classification. – Supply channel planners are suggested to compute the trade-off costs of lowering channel carrying costs towards increases to other logistics costs and customer service.

- 47. The Square-Root Rule (1/3) 47Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 § This technique assists planners to calculate the advantage gained through a channel inventory consolidation strategy. § To decrease the total channel costs assuming that the greater the number of channel locations, the greater will be the cost of inventory needed to maintain targeted customer service levels. § Equation for Square-Root Rule, CI = SI √n Where; CI = Cost of Channel Inventory of an item if the entire network stock is centralised at “ n “ number of stocking locations. SI = The Amount of inventory stocked at “ n “ distribution locations n = The number of stocking points in the channel.

- 48. How Does The Square-Root Rule Work? (2/3) 48Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 § If a planner wanted to determine the cost of carrying an item in multiple channel distribution points. § The first step is to determine the total average inventory value for stocking the item in a single warehouse. § The next step is calculating the square root of each additional location beyond one. § The final step is multiplying the square root value associated with a determined number of warehouses by the base average inventory value of stocking the item in a single warehouse.

- 49. How Does The Square-Root Rule Work? (3/3) 49Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 § The square-root law could be used to find the inverse of the above problem. § In the scenario, the distribution channel contains US$20,554.80 in inventory, stored in 10 facilities. § The goal is to find out what the total cost would be if the channel is reduced from 10 to 3 facilities The square-root rule assumes several conditions if it is to provide meaningful data. 1. Interbranch transfers rarely occur. 2. The lead times do not vary and thus inbound transportation is not greatly impacted by centralization. 3. Customer service targets are constant regardless of the number of facilities. 4. Customer demand at each facility is normally distributed.

- 50. Adjusting Channel Imbalances (1/3) 50Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 § There are two conventional ways to cope with the imbalance of inventory quantities: 1. Least-Cost Redistribution: to restore channel imbalances at the least cost. Price – Delivery Matrix Delivery Cost Solution

- 51. Adjusting Channel Imbalances (2/3) 51Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 2. “Fair Share” Allocation : to provide branch locations with equal run-out replenishment resupply that should be sufficient to prevent stock out during the lead time until supplier receipts arrive at the warehouse.

- 52. Adjusting Channel Imbalances (3/3) 52Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 2. “Fair Share” Allocation : to provide branch locations with equal run-out replenishment resupply that should be sufficient to prevent stock out during the lead time until supplier receipts arrive at the warehouse. DS = 200 + (30 + 37 + 33) : (8 + 10 + 12) DS = 10 days Ab = ((10 – (30/8)) x 8) Ab = 50 units The Drawback is that it does not consider differences in performance cycle times, EOQs, or safety stock requirements, and is, therefore, limited in its ability to manage multi-echelon channel systems.

- 53. Supply Chain Facility Planning 53Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 1. Financial Estimating: to assist planners to provide sufficient capital to fund the replenishment plan. The advantage of using DRP in developing inventory asset planning asf: 1. Ease of planning: DRP provides planners with projected costs over the planning horizon by product family and by total warehouse. 2. Accuracy: DRP provides planners with an accurate calculation of projected inventory costs driven by estimated forecast demand. The more accurate the forecast, the more accurate the financial projection. 3. Simulation: By inputting alternate forecasts into the system, DRP provides planners with the ability to simulate product level, individual warehouse, and aggregate channel costs 4. Productivity: DRP permits planners to make the right inventory decisions so that targeted customer service levels are met while reducing inventory costs.

- 54. Supply Chain Facility Planning 54Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 2. Transportation Planning: To allow planners to control the transportation costs effectively towards the uncertain future shipping requirements. There are four key areas to be closely paid attention by planners: 1. The transportation planner has the critical information necessary to schedule cost- effective transportation and loading. 2. Through the use of simulation, planners have the ability to see the effect of different forecast plans and provide essential input into selecting the optimal forecast that minimizes total transportation cost. 3. The aggregate shipping schedule assists in planning other critical logistics components (i.e. freight budgets, negotiate freight rates, and justify the acquisition of additional equipment such as trucks, trailers, and rail, cars). 4. The shipping plan represents what the firm is planning to ship. This information can be used by other business functions, such as accounting and sales, in their planning processes.

- 55. Sum-up (1/2) 55Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 § Inventory management in a multi-echelon channel environment is determined by the structure and objectives of a firm’s distribution channel. § There are basically two ways to replenish inventory in a distribution channel: push or pull. § The decision to choose one of the techniques depends on how inventory moves through the channel and the level of control required by managers. § In a “push” system, all channel resupply activities are conducted by the supplying facilities. Channel resupply is performed first by aggregating the demand requirements from all lower echelon stocking points, forecasting methods applied, and then replenishment inventory is pushed back down the channel using some form of allocation algorithm. § In a “pull” system each downstream facility maintains its own inventory system and determines the timing and quantity of replenishment from designated upstream channel supply points. When a “pull” system strategy is chosen, inventory managers can choose from two possible techniques: reorder point (ROP) or distribution requirements planning (DRP). § A ROP technique is mostly chosen by channels that only stock finished goods acquired from outside suppliers.

- 56. Sum-up (2/2) 56Distribution and Transportation Management (Ch.9) Friday, 21 October 2016 § A key factor to note in the selection of the ROP technique is the relative shortness (expressed in days) of the replenishment lead times separating each channel facility § The decision to use DRP is purely one of lead time. Unlike the short lead times characteristic of a ROP supply channel, DRP is best used to manage the much longer production lead times required by production plants at the beginning of the supply chain. § DRP works well with the time-phased manufacturing resources planning (MRP) systems used by producers to plan inventories. § The DRP computer system retrieves key input from such data source files as forecast, open customer order, open replenishment order, on-hand balance, supplier lead times, order policy codes, and safety stock. § A significant advantage of DRP is also found in the ability of planners to use the DRP output to maintain the balance between demand requirements and supply chain resource capacities. § Distribution planners can use the DRP-generated schedule to identify and remove capacity constraints in channel inventory deployment by providing visibility to possible constraints in capital, the work force, equipment, and space availability. § Achieving these goals requires that supply chain planners possess information systems that provide a schedule of priority requirements that are translated quickly and accurately into detailed capacity planning elements.

- 57. 57Distribution and Transportation Management (Ch.9) That was Replenishment in a Multi-echelon Channel Environment (Ch. 9) See you again next week! Friday 21 October 2016