08 pid.controller

- 1. PID CONTROLLER 19-Apr-17 1 Eng. Mahmoud Hussein RTECS

- 2. The Classical Three-Term Controller PID Controller3 RTECS

- 3. Rationale (Physical Sense) 4 How to determine the control action? based on the error (the difference between the set-point and the actual output value) PID = Proportional + Integral + Derivative Proportional mode reacts to the present error Integral mode reacts to the past history of the error signal Derivative mode reacts to the expected future of the error signal (rate) RTECS

- 4. Block Diagram 5 Gc(s) Controller n sensor noise w load disturbance Gprocess(s) u control y output r reference input, or set-point e sensed error GActuator(s) Actuator Process W(s) Gp (s) 1GcGp (s) N(s) GcGp (s) 1GcGp (s) R(s) GcGp (s) 1GcGp (s) Y (s) RTECS

- 5. Block Diagram 6 PID = Proportional + Integral + Derivative Also known as: Three-term controller Kp Ki ()dt Kd d() dt + P I D e(t) u(t) Kp Ki s Kd s + P I D E(s) U(s) RTECS

- 6. PID Time Domain Representation 7 dtT K dt d t i p dp i de(t) e(t)dt T 1 e(t) de(t)t u(t) K e(t) K e(t)dt K 0 0 p d d i p i K K K K T where T , proportional gain integral gain derivative gain derivative time constantintegral time constant RTECS

- 7. S-Domain Representation 8 KTs s s Tis p Kd d i Kp id i p dpc p 1 E(s) TT s2 T s 1 Kp i d i where T , T K 1 T s K K s Ki G (s) U (s) K Kd sE(s) Ki U(s) K RTECS

- 8. Open loop Response Mass Spring Damper Problem9 RTECS

- 9. Mass Spring Damper Problem 10 Consider the simple mass, spring, and damper system d ms2 ds k 1 F(s) G(s) X (s) mx dx kx f ms2 X (s) dsX (s) kX(s) F(s) RTECS

- 10. Mass Spring Damper Problem 11 1 s2 10s 20 G(s) 1 F(s) ms2 ds k G(s) X (s) m = 1 d = 10 ;% kg ;% N s/m k = 20 ;% N/m F = 1 ;% N step(P) 0 0.5 1 2 2.5 3 s = tf('s'); 0.005 P = 1/(s^2 + 10*s + 20); 0 0.015 0.01 0.02 0.025 0.03 0.035 0.04 0.045 0.05 Step Response 1.5 Time (seconds) Amplitude RTECS

- 11. Step Response Amplitude 0.5 1 1.5 Time (seconds) 2 2.5 3 0 0 0.025 0.02 0.015 0.01 0.005 0.03 0.035 0.045 0.05 System: P Settling time (seconds): 1.59 System: P 0.04 Rise time (seconds): 0.884 Mass Spring Damper Problem Open-Loop Step Response - Matlab 12 DC gain = 1/20 Output = 0.05 Steady state error = 0.95 Rise time = 0.884 s Settling time = 1.59 s RTECS

- 12. Mass Spring Damper Problem Open-Loop Step Response - Simulink13 RTECS

- 13. P-Term14 RTECS

- 14. Rationale (Physical Sense) 15 Intuitively one can deduce that the amount of correction applied to the system should be directly proportional to the error. As the gain increases (Kp), the applied correction to the Process becomes more aggressive RTECS

- 15. Advantages 16 Immediate corrective action Simple to implement RTECS

- 16. Disadvantages 17 It leaves a steady state error in some cases (when the error is zero action is zero steady state error reproduced) High values of proportional gain reduces the stability of the system RTECS

- 17. Steady State Error 18 Gc(s) Controller n sensor noise w load disturbance Gp(s) Plant u control y output r reference input, or set-point e sensed error W(s) Gp (s)GcGp (s)GcGp (s) 1GcGp (s) N(s) 1GcGp (s) R(s) 1GcGp (s) Y(s) RTECS

- 18. Steady State Error 19 R(s) G G (s) K Kdc Kdc Kp dc p p 1s 1 K 1sR(s) c p 1GcGp (s) Y (s) 1s and for a firstorder systemG (s) For a proportional controller Gc (s) Kp RTECS

- 19. Steady State Error 20 This can happenonly if Kp Kdc isinfinite Kp Kdc Required to be1 s 1Kp Kdc lim sG(s) 1 In case R(s) is a unit step,using the final value theorem y() limsG(s)R(s) s0 s0 RTECS

- 20. Mass Spring Damper Problem Proportional Controller - Simulink21 RTECS

- 21. Mass Spring Damper Problem Proportional Controller22 Closed loop transfer function with a proportional controller p p CL K G (s) s2 10s 20 K RTECS

- 22. Proportional Gain Design 23 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 open 0.001 0.01 0.1 1 10 50 100 0.5 1 1.5 -2 0 -1 0 1 2 3 4 5 6 open 0.001 0.01 0.1 1 10 50 100 RTECS

- 23. Proportional Gain Design 24 Increasing the controller gain less sluggish process response steady state error reduced Too large controller gain undesirable degree of oscillation or even unstable response An intermediate value best control result RTECS

- 24. I-Term25 RTECS

- 25. Rationale (Physical Sense) 26 Unlike proportional control, which looks at the present error, integral control looks at past errors it looks at the history of the error signal. if there is a continuous error even if it is a small error, add more control action since the integration of the error signal grows as the signal persists to exist. control action will continue correcting the error until it vanishes RTECS

- 26. Advantages 27 Main advantage is steady state error elimination RTECS

- 27. Disadvantages 28 More oscillatory response & overshoot For a very slow system the error signal will accumulate fast and a large integrator action will be introduced this can cause serious overshoots the system response becomes more oscillatory RTECS

- 28. Integral Gain Design 29 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 open 0.001 0.01 0.1 1 10 50 100 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 -2 0 -1.5 -1 -0.5 0 0.5 1 1.5 2 2.5 3 open 0.001 0.01 0.1 1 10 50 100 RTECS

- 29. PID Time Domain Representation 30 dtT K dt d t i p dp i de(t) e(t)dt T 1 e(t) de(t)t u(t) K e(t) K e(t)dt K 0 0 p d d i p i K K K K T where T , proportional gain integral gain derivative gain derivative time constantintegral time constant RTECS

- 30. Integral Time Constant 31 Integral time constant represents the time needed for the Integral control to have an effect equal to the proportional control Increasing the integral time more conservative (sluggish) process response Average value of error over a wider time slot i p i K K T RTECS

- 31. Integral Time Constant 32 For slow systems with large system time constants use large integral time constant and vice versa Too large integral time Too long time to reach to the set point after load upset or set-point change occurs. Steady state error Theoretically, offset will be eliminated for all values of integral time constant Decreasing the integral time constant response becomes more oscillatory further increase system instability and wind up problems if saturation occurs RTECS

- 32. Disadvantages 33 Integral windup refers to the situation where the integral action continues to integrate (ramp) indefinitely This usually occurs when the controller's output can no longer affect the controlled variable, which in turn can be caused by controller saturation RTECS

- 33. Mass Spring Damper Problem Proportional-Integral Controller34 Closed loop transfer function with a proportional-integral controller ip sK Kps Ki s 10s 20 K GCL (s) 3 2 RTECS

- 34. Mass Spring Damper Problem Proportional-Integral Controller - Simulink RTECS 2015 4/19/2017 35 RTECS

- 35. D-Term36 RTECS

- 36. Rationale (Physical Sense) 37 Expected future of the error signal While the proportional control reacts only to the present error and the integral control reacts to the past history of the error signal the derivative control reacts to the expected future of the error signal. Tendency of the error signal it uses the present and past errors to forecast/ anticipate the future behaviour of the error signal and reacts according to the tendency of the error signal with the appropriate action RTECS

- 37. Rationale (Physical Sense) 38 Avoiding overshoot if the error is decreasing too fast that means that the current control action is very high so it needs to be decreased substantially to avoid overshoots in the system. Braking system derivative action is against other actions like the proportional or the integral actions, so the derivative action acts as a braking system for the response. RTECS

- 38. Derivative Gain Design 39 0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 -20 0 20 40 60 80 100 0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 open 0.001 0.01 0.1 1 10 50 100 0.8 0.9 1 open 0.001 0.01 0.1 1 10 50 100 RTECS

- 39. Advantages 40 Reduces system oscillations Main advantage: reduces system oscillations by braking the response (braking here will not slow the system, it will increase the rise time … On the other hand reducing oscillations will reduce the settling time) RTECS

- 40. Advantages 41 Quick response for abrupt changes enhance the robustness of the PID controller by considering abrupt change of the error. e(t) dpresent (t) future ( t ) d de(t) / dt d e(t) p d d c p d K K where T E(s) G (s) U (s) K T s RTECS

- 41. Disadvantages 42 Amplifies high frequency noise Noise signal : n(t) = a sin(ωt) After derivative part: d/dt( a sin(ωt) )= a ω cos(ω t) The derivative action amplifies noise RTECS

- 42. Derivative Filter 43 Derivative part is not a proper transfer function in addition it amplifies noise signal Derivative filter approximation acts as a derivative for low- frequency signals and as a constant gain for the high frequency signals. RTECS

- 43. PID Time Domain Representation 44 dtT K dt d t i p dp i de(t) e(t)dt T 1 e(t) de(t)t u(t) K e(t) K e(t)dt K 0 0 p d d i p i K K K K T where T , proportional gain integral gain derivative gain derivative time constantintegral time constant RTECS

- 44. Derivative Time Constant Design 45 Increasing the derivative time improved response by reducing the maximum deviation, Settling time and the degree of oscillation. Too large derivative time measurement noise tends to be amplified and the response may be oscillatory. Intermediate value of derivative time is desirable. RTECS

- 45. Derivative Time Constant 46 Effect of increasing derivative gain as the derivative gain increases system becomes more susceptible to noises further increase extreme behaviour RTECS

- 46. Mass Spring Damper Problem Proportional-Derivative Controller47 Closed loop transfer function with a proportional-derivative controller 2 pd pd 10 K s K 20s K s K GCL (s) RTECS

- 47. Mass Spring Damper Problem Proportional-Derivative Controller - Simulink RTECS 2015 4/19/2017 48 RTECS

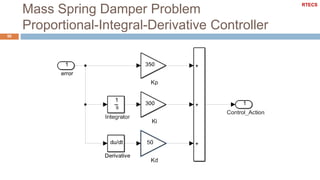

- 48. Mass Spring Damper Problem Proportional-Integral-Derivative Controller 49 Closed loop transfer function with a proportional-integral- derivative controller ipd id p CL 20 s K G (s) s2 Ks3 10 K K s2 K s K RTECS

- 49. Mass Spring Damper Problem Proportional-Integral-Derivative Controller 50 RTECS

- 51. Closed-loop Response 52 Rise time Maximum overshoot Settling time Steady-state error P Decrease Increase Small change Decrease I Decrease Increase Increase Eliminate D Small change Decrease Decrease No Change RTECS

- 52. Controller Effects 53 Proportional controller (P) reduces error responses to disturbances, speeds up the process response but still allows a steady-state error. Integral controller (I) When the controller includes a term proportional to the integral of the error (I), then the steady state error to a constant input is eliminated, although typically at the cost of deterioration in the dynamic response. Derivative controller (D) typically makes the system better damped and more stable. RTECS

- 53. General Tips for Designing a PID Controller 54 Obtain an open-loop response and determine what needs to be improved Add a proportional control to improve the rise time Add an integral control to eliminate the steady-state error Add a derivative control to improve the overshoot Adjust each of Kp, Ki, and Kd until you obtain a desired overall response RTECS

- 54. General Tips for Designing a PID Controller 55 RTECS

- 55. How to Represent PID Controller in Matlab56 RTECS

- 56. Defining a PID Controller Using Transfer 57 Function Command Kp = 1; Ki = 1; Kd = 1; s = tf('s'); C = Kp + Ki/s + Kd*s RTECS MATLAB's PID Controller Kp = 1; Ki = 1; Kd = 1; PID_O = pid(Kp,Ki,Kd) PID_Tf = tf(PID_O)

- 57. Mass Spring Damper Problem Proportional Controller - Matlab58 s = tf('s'); P = 1/(s^2 + 10*s + 20); Kp = 300; C = Kp + Ki/s + Kd*s T = feedback(C*P,1) t = 0:0.01:2; step(T,t) Step Response Amplitude 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 Time (seconds) 2 0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 System: T Peak amplitude: 1.31 Overshoot (%): 40 At time (seconds): 0.18 System: T Settling time (seconds): 0.772 System: T Final value: 0.938 System: T Rise time (seconds): 0.0728 RTECS

- 58. Mass Spring Damper Problem Proportional-Integral Controller - Matlab59 Kp = 30; Ki = 70; C = pid(Kp, Ki) T = feedback(C*P,1) t = 0:0.01:2; step(T,t) Step Response Amplitude 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 Time (seconds) 2 0 0 0.4 0.2 0.6 0.8 1 1.2 1.4 System: T Settling time (seconds): 0.618 System: T Peak amplitude: 1.01 Overshoot (%): 1.26 At time (seconds): 0.81 System: T Rise time (seconds): 0.408 RTECS

- 59. Mass Spring Damper Problem Proportional-Derivative Controller - Matlab60 Kp = 300; Kd = 10; C = pid(Kp,0,Kd) T = feedback(C*P,1) t = 0:0.01:2; step(T,t) Step Response Amplitude 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 Time (seconds) 2 0 0 0.4 0.2 0.6 0.8 1 1.2 1.4 System: T Peak amplitude: 1.08 Overshoot (%): 15.3 At time (seconds): 0.17 System: T Rise time (seconds): 0.0779 System: T Settling time (seconds): 0.29 RTECS

- 60. Mass Spring Damper Problem Proportional-Integral-Derivative Controller61 Kp = 350; Ki = 300; Kd = 50; C = pid(Kp,Ki,Kd) T = feedback(C*P,1); t = 0:0.01:2; step(T,t) Step Response Amplitude 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 Time (seconds) 2 0 0 0.1 0.2 0.3 0.7 0.6 0.5 0.4 0.8 0.9 1 System: T Final value: 1 System: T Settling time (seconds): 0.831 System: T Rise time (seconds): 0.0549 RTECS

- 61. Variations of PID Controller62 RTECS

- 62. Variations of PID Controller 63 P P+D (Lead) Compensation P+I (Lag) Compensation Is generally adequate when plant/process dynamics are essentially of 1st-order P+I+D (Lead-Lag) Compensation Is generally ok if dominant plant dynamics are of 2nd-order RTECS

- 63. PI Controller: The Need 64 In a feedback control system, sensor’s noise is propagated via the controller to the control signal, causing variations in the control signal. The derivative term of the controller amplifies these variations. These variations can be reduced in several ways: Using a measurement low-pass filter Setting the derivative gain to zero, i.e. using PI in stead of PID RTECS

- 64. PI Controller: Transfer Function 65 Ts s i p i Kp i p pc E(s) Tis1 K whereT T s i K 1 K 1 Ki G (s) U (s) K proportional gain integral gain RTECS

- 65. Design Guidelines 66 Liquid level Integrating process Use P or PI controller with high gain D-mode is not suitable since level signal is usually noisy due to the splashing and turbulence of the liquid entering the tank Flow control Use PI controller with intermediate gain No D-mode because of high frequency noise Fast response, no time delay RTECS

- 66. Design Guidelines 67 Temperature Various characteristics with time delay. Use PID or PI controller (D-mode can accelerate the response) RTECS

- 67. PID script 68 RTECS for i=1:length(kgain) if control_type ==1; C=kp(i)+ki/s+kd*s; elseif control_type ==2; C=kp+ki(i)/s+kd*s; elseif control_type ==3; C=kp+ki/s+kd(i)*s; end GF=feedback(C*g,1); if input_type==0; [ytc,ttc]=impulse(GF,t); elseif input_type==1; [ytc,ttc]=step(GF,t); end plot(ttc,ytc,c_gain{i}) end legend('close',num2str(kgain(1)), num2str(kgain(2)),num2str(kgain(3)),... num2str(kgain(4)),num2str(kgain(5))) clc,clear all, close all t_F=10; input_type=1; control_type=3; t=0:.001:t_F; s=tf('s'); g=1/(s^2+10*s+20); G_close=feedback(1*g,1); if input_type==0; [yt,tt]=impulse(G_close,t); elseif input_type==1; [yt,tt]=step(G_close,t); end plot(tt,yt,'-k','linewidth',2),hold on, grid on kgain=[1 5 10 15 20]; c_gain={'--b','--r','--g','--m','--k'}; if control_type ==1; kp=kgain;ki=0;kd=0; elseif control_type ==2; kp=0;ki=kgain;kd=0; elseif control_type ==3; kp=300;ki=0;kd=kgain;end

- 68. Home Work: Cruise Control 69 RTECS

- 69. RTECS

![PID script

68

RTECS

for i=1:length(kgain)

if control_type ==1;

C=kp(i)+ki/s+kd*s;

elseif control_type ==2;

C=kp+ki(i)/s+kd*s;

elseif control_type ==3;

C=kp+ki/s+kd(i)*s; end

GF=feedback(C*g,1);

if input_type==0;

[ytc,ttc]=impulse(GF,t);

elseif input_type==1;

[ytc,ttc]=step(GF,t); end

plot(ttc,ytc,c_gain{i})

end

legend('close',num2str(kgain(1)),

num2str(kgain(2)),num2str(kgain(3)),...

num2str(kgain(4)),num2str(kgain(5)))

clc,clear all, close all

t_F=10; input_type=1; control_type=3;

t=0:.001:t_F;

s=tf('s'); g=1/(s^2+10*s+20);

G_close=feedback(1*g,1);

if input_type==0; [yt,tt]=impulse(G_close,t);

elseif input_type==1; [yt,tt]=step(G_close,t); end

plot(tt,yt,'-k','linewidth',2),hold on, grid on

kgain=[1 5 10 15 20];

c_gain={'--b','--r','--g','--m','--k'};

if control_type ==1;

kp=kgain;ki=0;kd=0;

elseif control_type ==2;

kp=0;ki=kgain;kd=0;

elseif control_type ==3;

kp=300;ki=0;kd=kgain;end](https://image.slidesharecdn.com/08pid-191204155053/85/08-pid-controller-67-320.jpg)