2016 asl hitachi

- 2. ASL History (1995-2005) Dragline Swing Automation Shovel/Excavator Automation Rockbreaker/Shiploader LHD Automation (Caterpillar) Longwall Automation (CESRE)Explosive Loading (ORICA)

- 3. A world in which humans and autonomous systems are able to seamlessly, reliably and safely collaborate. ASL Vision 2005 45 40 15

- 5. Persistent Robotics • Autonomous Unmanned Helicopters • Smart Skies (with Boeing) • ResQu • Ground Vehicles • Hot Metal Carrier (with RioTinto) • Autonomous Science Rover Information Driven Manufacturing • Dependable hardware and software, • Precise control, robust state estimation • Obstacle avoidance, autonomous planning, • Health monitoring, reasoning and decision making • Power and energy management • Advanced Engineering

- 6. Bespoke Robotics 1. Task Based Design • Confined space inspection 2. Reconfigurable • Anyleg / Anywheel 3. Extreme Locomotion • Hexapod platform Information Driven Manufacturing • Real-time proprioceptive • Machine learning • Energetics based gait switching • Stabilisation in unstructured terrain • Ground cover classification • Rapid Prototyping to high TRL

- 7. Reality Capture (Situational Awareness) 1. Lidar, Vision, Thermal • Zebedee • Heatwave • Hovermap 2. Hyper spectral 3. Gas and RF • Plant Mapping Information Driven Manufacturing • Simultaneous Localisation and Mapping (SLAM) • Data Fusion and Registration • Compressive Sensing • Design lead engineering (Product development)

- 8. Reality Display (Human Machine Interface) 1. Augmented Reality • ReMote Tele-Maintanence 2. Augmented Virtuality • 3P Learning - Endeavour tour 3. Panomersive Video streaming • National Museum Tele-presense Information Driven Manufacturing • Wearable technology • Immersive technology • Human Factors / Ethics

- 9. Pervasive Sensing (Monitoring and Tracking) • Longevity • Springbrook with Fleck • Scale • Digital Homestead • Sense-T with PACP • Mobility • Batmon with Camazotz • Passive • People Tracking • Smart Homes Information Driven Manufacturing • Delay tolerant networking • Energy Management, Radio Diversity • Mobile Analytics, distributed processing • Spatiotemporal Modelling

- 10. Connected Sensing (Internet of Things) 1. Sensor Data Models and Management • SenseT / SenseDB 2. Interoperability • OpenIoT / BIoTope 3. Security and Trust • AU2EU 4. Collaboration • Industrial Internet Consortium Information Driven Manufacturing

- 11. Problem 1: The Mixed Traffic Problem • 20 years ago automation was driven by safety • Lead to the automation of specialized vehicles • Equal performance of a human driver • Forced to isolate the machines • This impacted the existing workflow (Maintenance, exploration) Increase Safety Change in Workflow Loss in Productivity

- 12. Solution 1: Global Situational Awareness 1. Technology that allows humans and robots to interact safety and productively 2. To do this we need to provide fail-safe people detection 3. No such technology exists 4. Put intelligence into the environment rather than the machine 5. Detect absence rather than presence 6. Autonomous safety.

- 13. Robotics in the IoT Landscape

- 15. Problem 2: Interoperability • 10 years ago, investment was driven by labor force availability and productivity • We were able to automate a rock-breaker, but it does not exceed the performance of the human operator • Productivity gains can only be realized if we integrate the upstream and downstream processes Fleet Management Rock Breaker Processing

- 16. Unified User Interface 3DCMM Communications Infrastructure Digital Model Exploration MinePlanning Drilling Excavation Blasting Haulage RockBreaking Processing Train ShipLoading Process Surveying Analysis Infrastructure Maintenance LogisticsSupport Framework of Standards Remote Operations Solution 2: Common Mine Model Vendors

- 18. Software systems in Manufacturing I Manufacturing – “A Glass Half Full”

- 19. Trends in Future Manufacturing •New Workflows •New Business Models •New Enterprises •New Processes •New Materials •New Production •Mass Customization •Maximize Flexibility •Mass Production •Minimize Waste Lean Agile SmartAdvanced Great Expectations Digital Immersion MoreFrom Less

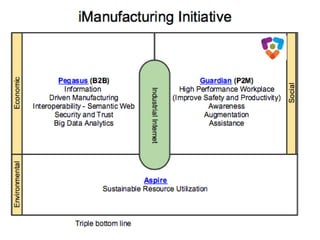

- 20. Manufacturing Terminology Industrial Internet (GE) Industry 4.0 (Germany) Network Enabled Manufacturing (Boeing) Smart Manufacturing (Rockwell)

- 22. Lightweight Technologies HMI ICT Perception Robotics Mobile Tele-presence Lightweight Robotics Mirror Worlding Social Networking Sensing in Unstructured Dynamic Environments Field Robotics Dependability Robustness Military/Mining Collective Intelligence Cloud ServicesBig Data Internetofthings Cheap sensor, processors and actuation Consumer Devices Immersive Interfaces Gaming AdditiveManufacturing Intuitive interfaces Mobile Devices Ubiquitous Connectivity Locationbasedservice Technology/Trendsto DevelopAssistiveRobotics

- 23. Virtual Factory – Executive Layer • Simulation of factory and the world around it. • Interactive and collaborative user interface • Decision support (simulated scenarios) Digital Factory – Strategic Layer • Live (Real-time) digital model of factory • Fully Integrated across the production cycle - Data Fusion • Optimization of production based upon demands Smart Factory – Tactical Layer • Smarter sensing and actuation around each process • Reconfigurable / Adaptive / Responsive processes • Improved situational awareness - QA/QC External Forces Demands Demands Demands Data Intelligence Layered Architecture CRM Customer Relationship Management PLM Product LifeCycle Management SCM Supply Chain Management ERP Enterprise Resource Planning MES Manufacturing Execution System SCADA

- 24. Connected Architecture CRM PLM SCM ERP MES SCADA CRM PLM SCM ERP MES SCADA CRM PLM SCM ERP MES SCADA

- 25. subcontracting process Engineer at company A defines product specification in in- house ERP A raises purchase order and generates further specifications in ERP A Engineer at company B retypes specification in in- house ERP B ERP A ERP B Engineer at company B retypes specification in in- house ERP C ERP C Status Quo

- 27. Presentation title | Presenter name27 |

- 28. Pegasus • Bespoke solution are not scalable. • Previously required installation of software on-site. • Too expensive for SME. • The cloud can provide off-load the software • But still have a problem with inter-connections. Solution • Objects with relationships to other objects across strata exist. • Management by Semantic Web • Deliver information flows to the supply chain to allow secure, fit for purpose, interoperability across various platforms and processes

- 29. Human Services Client data Supply chain events Supplier data ICT Automation, IoT, Robotics Factory events Factory data End to end data Material, Products and Processes Product data Process data Supply chain management Assistive technologies Design, customisation Direction of data flow Nodes Sustainable manufacturingRelationship Management Informatics Workforce skills What are the information flows At the nodes, we need Informatics

- 30. Guardian Angel • Monitors environment • Tracks people and assets • Make work safer for humans Guardian Mentor • Worker augmentation • Provides skills and training • Make work easier for human Guardian Helper • Provides physical assistance • Robotic co-workers • Works with humans Guardian Worker • Provides remote assistance • Tele-operated robotics • Work for humans High Performance Workplace Augmentation • Collaboration • Interface • Observatory Assistive • Navigation • Manipulation • Cooperation Awareness • Monitoring • Modeling • Management Social Science Human Factors Informatics Communications Sensors Robotics Engineering Investment Innovation Impact Worker Centric: Increase productivity, safety and adaptability of future workforce through virtual and assistive automation technologies • Low-cost, from purchasing price and installation costs, to reprogramming and maintenance costs • Easy to use, without the need of technical expertise to deploy, operate and reconfigure the systems • Support mass customisation, ideal for small runs of multiple types of products

- 31. Guardian – Mobile Industrial Internet CSIRO – Digital Productivity Flagship

- 32. Objectives. • Enhances the productivity and safety of the industrial workplace. This is achieved with the development and integration of a number of situational awareness, decision support and assistive technologies. Key Research Challenges • Large scale Integration across heterogeneous systems • Managing and predicting risk Partners • Boeing, GE • Woodside, Chevron • IIC, ROS Industrial • IMCRC, ASC Guardian Facility: High Performance Workplace

- 33. Guardian Facilities at QCAT Guardian Managed Work Zone Manufacturing Work Zone Situational Wall Remote Management

- 34. Operations in a dynamic industrial environment • Seamless Connections / Exchange between • Workshop (Tactical) & The Control Room (Executive)

- 35. Thankyou 35 |

- 36. What the world is saying • GE estimates that the IOT could add $10-15 trillion to the global GDP over the next 20 years • Gartner estimates digitization of business and life will replace 1 in 3 knowledge workers by 2020 • McKInsey Global estimates an annual economic impact of $2.7 trillion to $6.2 trillion by 2025 • Impacts in healthcare, infrastructure, public sector safety & services & in the environment • The Industrial Internet has also attracted increasing levels of venture capital, with an estimated $1.5 billion in 2014.8 Unlike in other technology sectors, VC funding for the Industrial Internet comes primarily from large corporate venture funds, such as GE Ventures, Siemens Venture Capital, Cisco Investments, Qualcomm Ventures and Intel Capital. CSIRO – Digital Productivity Flagship - BCG - Confidential

- 37. World Economic Forum (2015)

- 38. Industry Consultation 38 | • Industry Interviews • 5 locations in Australia • 70 high performing manufacturing companies • Cross-section through all areas of manufacturing • Manufacturing companies (in general) do not: • have digital strategies • understand business models enabled by digital • know how to take advantage of IoT • Others countries • Germany: 80 % of value chains digitised by 2020

- 39. Roadblocks 1. Understanding the Impact of Disruptive Technologies 2. Insufficient Absorptive Capacity of Companies 3. Fragile/Sparse Industrial Ecosystem (in Australia) 4. Challenges Bridging the Valley of Death 5. Differenced in Culture / Communication 6. Managing the Technology Hype 7. Other Issues

- 40. Dealing with Disruptive Technologies A disruptive innovation is an innovation that helps create a new market and value network, and eventually disrupts an existing market and value network (over a few years or decades), displacing an earlier technology.

- 41. Bridging the Valley of Death Technology Push Technology Pull Technology Facilities

- 42. Managing the Technology Hype What makes money What people are interested in What we do research on

- 43. Absorptive Capacity The ability to recognize the value of new information: • Assimilation – Very poor collaboration between companies and research institutes • Transformation – Companies are not willing to change or understand • Exploitation – Changing business models

- 44. • Need to use common language • Project proposals • Companies like Waterfall • Researchers like Agile Communication

- 45. Other Issues • Geography • Not invented here – Remote workforce • Not sold here – Only look at ROI for local market • Culture • Collaborative – Open Innovation • Competitive – Closed Innovation • Licensing • Non-excusive • Exclusive • IP Ownership?

- 46. Presentation title | Presenter name46 |

- 48. i3Hub Vision “Australia will become a leading market and supplier of Industrial Internet Technology. Australian companies will participate in global inter-company value chains and networks, and vertical integration of flexible (manufacturing) systems. It will also facilitate digital end-to-end engineering across the entire value chain (iManufacturing).”

- 49. i3Hub Mission To inspire and transform Australian businesses, CSIRO will create a connected innovation marketplace where our customers and partners will collaborate and experience what is possible today and what are the potential futures associated with the industrial internet. Engagements • Industrial Internet Consortium • ROS Industrial (Robotic Operation Systems) • OpenIoT and AU2EU (security and trust) • IMCRC – Innovative Manufacturing CRC • AMGC – Advanced Manufacturing Growth Centre's

- 50. i3Hub Strategy i3Hub will be an independent, not-for-profit industrial internet innovation hub with the objective to improve Australia’s global competitiveness by inspiring and transforming Australian businesses through the use of the industrial internet. i3Hub will connect CSIRO, government, industry, academia, tech providers and early stage companies to create a national presence for Australian businesses to participate in the global industrial internet ecosystem

- 51. i3Hub Activities

- 52. i3Hub Think: The Network MVP: Capability Discovery Across Network

- 53. Think - Partner Business Model INVESTOR/ACCELERATOR TIER I TECH PROVIDER TIER II/III TECH PROVIDER RESEARCH PROVIDER Offer • Precuration of companies • Pipeline of opportunities • Boilerplate agreements • Beauty parade • Home for cohort graduates • Ability to incubate companies • Industrial internet specific (incubator for II tech) • Exposure • Uptake • demos@scale • Opportunity to build other demos • Opportunity pipeline • Access to network • Access to tier II tech providers • Access to govt orgs and policy • Access to research providers • Exposure • Uptake • demos@scale • Opportunity to build other demos • Opportunity pipeline • Access to network • Access to tier II tech providers • Access to govt orgs and policy • Access to research providers • Access to complementary tier II/III providers • Hackathons • Community • Capability • Exposure/uptake • Opportunity pipeline • Facilities • Job/project board • Student/postdoc market place • Access to industry experts • Customers Ask • “just be partners” • Business mentoring • Selection guaranteed to be incubated for 12 months • Demo kit • Demo scenarios • “Biz Spark Programme” • Access to IP • Access to Experts • Contribution to outreach (sponshorship) • Demo kit • Demo scenarios • “Biz Spark Programme” • Access to IP • Access to Experts • Contribution to outreach (sponshorship) • Access to capability/talent (students. Staff) • IP exposure/contribution • Participation in and sponsorship of outreach • Access to facilities • Customers (ARC linkage) Presentation title | Presenter name53 |

- 54. Think – Partner Business Model FED STATE & LOCAL GOVERNMENT TAFE GROWTH CENTRES (IM)CRC Offer • Better commercialisation/mar ket validation • Metrics on involvements • International participation in IoT • Access to pipeline • Thought leadership/policy advice • Trusted advisor • Leverage investments • Whole of system focus for CSIRO • Demos • Access to experts • Access to facilities • Exposure • Access to exports • Curriculum development assistance • Researcher in TAFE • Placement board • Skilling/training teams • Virtual access to regional TAFE • Funnel companies to Growth Centre • Capability Discovery i3 Hub • Exposure • Funnel companies to IMCRC • Capability Discovery i3 Hub • ARC Linkage Grants • Portal Links • Exposure Ask • I3 Hub Funding/in kind • Shaping policy • Promotion (Local /int) • Policy experts • Relationship manager • Participation • Students • Some sponsorship for out reach events • In-Kind for outreach • Funnel companies to i3 Hub • Capability discovery Growth Centre • Shared outreach events • In-Kind for outreach • Funnel companies to i3 Hub • Capability discovery IMCRC • ARC linkage grants • Portal links • Shared outreach events • Program 4 tools Presentation title | Presenter name54 |

- 55. i3Hub Play – Connected Facilities QCAT Guardian Perth (Oil Gas) Lindfield Sydney Clayton Lab22 • Connect Research Facilities as Nodes to the Hub • Invite external facilities to provide Nodes to the Hub • Provide expertise & training at each Node • Develop Common Specification of Infrastructure • Tele-Presence between and within Nodes – Mobile Technology / Wearable Technology • Situational Awareness – Tracking / 3D Mapping / State, Modeling and Risk • Capability Discovery – Communications / Networking • Outcomes • Better factory visibility • Better supply chain visibility • Better HSE outcomes • Better resource management

- 56. i3Hub Underlying Principle • Industrial Internet technologies typically address five business scenarios, independent of sector or particular activity. These are: 1. connecting supply chains 2. enabling proactive maintenance 3. enabling better factory/plant/refinery/rig automation and/or integration 4. better factory/plant/refinery/rig visibility 5. improved safety without an impact on productivity • The i3Hub will aim to develop demonstrators for each of these scenarios with the emphasis on the manufacturing process. • Open to other facilities – national and international.

- 57. i3Hub will • Be a showcase where CSIRO customers and partners can experience and trial existing Guardian and IoT technologies and; • Serve as an innovation lab where customers and CSIRO partners co-develop, co-test and co-evaluate new technology and; • Assist companies with business model innovation around these technologies and in particular help them understand how to create new service-based revenue streams. • Be part of our business as usual. • It will not only demonstrate what ‘could be’, but what ‘is’. • It will provide confidence to our customers that our research is applied and lead by their interests • It will research HSE/social dimension of technology

- 58. i3Hub Business Project objectives • Develop business models that allow a wide variety of stakeholders (technology consumers/providers, investors, government agencies, research providers etc to participate in the hub) Key research challenges • Developing a network of startups, SMEs, technology providers, investors, government entities, research providers to increase uptake and adoption of the industrial internet in Australia • Develop appropriate business models for participation • Get startups “investment ready”

- 59. i3Hub Do – Co-Create FREE SUBSCRIPTION PROJECT BASED CO-INVEST WITH OPERATIONS JOINT VENTURE SPIN OFF Free + Subscription + Project Based + Co-Invest + Subscription + • Product Manager • Seminars • Workshops • Verticals not capability focussed • Portal • Community • Affiliation • Matchmaki ng • Data sheets • Networks • CSIRO rents at other facilities & lets out space • Visibility • Mtg rooms • Infrastructure • IP access • Office & lab infrastructure at CSIRO • Access to investors/sectors • Deals • Co-location with CSIRO (ADDRESS) • CSIRO researchers in project • Set dates/ timeframe • License rights to members’ BIP • Fast start legal • License rights to FIP • Ausindustry networks • Commercialisati on mentoring • Insurance • Intro to PE or VC/pitch sessions • Strategic partnership • Steering committee • Access to members’ IP • Beneficial ownership rights to FIP • Multiyear • Major projects to programme • Board oversight & governance • Mgmnt team • Investment advisory cttee • Shared license royalties • Sustainable bus models • Sustainable bus dev capability • CSIRO infrastructure • Subsidised rent • Pipeline of early stage IP • Access to early stage researchers & interns • CSIRO showcase of spin-offs • CSIRO equity /shareholder • CSIRO second/ support for key staff • Research capability • OEM • Clarity around IP portfolio Presentation title | Presenter name59 |

- 60. Relationships CRC OREMETS GC • High Value products • Information Driven Man • Business Transformation • Key Enabling Technologies i3Hub •Industrial Internet Innovation HUB IMCRC •Innovative Manufacturing CRC AMGC •Advanced Manufacturing Growth Centre Companies Projects

- 61. LASC Presentation title | Presenter name61 |

- 62. LISCA Presentation title | Presenter name62 |

- 63. www.csiro.au Elliot Duff Research Director Autonomous Systems Program Thankyou 63 |