5758.ppt

- 1. REACTOR DESIGN AND PHYSIOLOGY TRANSPORT / Mass transfer, aeration and agitation: OVERVIEW : 1. Concepts of mass transfer through different phases using oxygen as an example. 2. Oxygen demand and respiration 3. Factors influencing mass transfer through gasliquid interfaces 4. Kla - measurement, factors influencing. 5. Agitation, mixing patterns 6. Impeller design, fluid dynamics 7. Relationship of viscosity and agitation 8. Power input 9. Scale-up

- 2. 5. Reactor design and physiology 5.1. Mass transfer and phases: 5.1.1 different phases present -introduction 5.1.2. Mass transfer and respiration 5.1.3. Factors affecting oxygen demand 5.1.4. Factors influencing oxygen supply 5.1.4. (a) process factors 5.1.4. (b) transfer through an interface (kla) 5.1.4. (c) determination of kla; 5.1.4. (d) factors affecting bubble size 5.1.4. (e) gas hold-up : 5.1.4. (f) economics of oxygen transfer Lecture Overview

- 3. Introduction • The oxygen demand of an industrial process is generally satisfied by aeration and agitation • Productivity is limited by oxygen availability and therefore it is important to the factors that affect a fermenters efficiency in supplying O2 • This lecture considers the O2 requirement, quantification of O2 transfer and factors influencing the transfer of O2 into solution

- 4. 5.1. MASS TRANSFER and PHASES 5.1.1 Different phases present -Introduction Fundamental concept in fermentation technology is transfer of materials (e.g nutrients, products, gases etc.) through different phases (e.g gas into a liquid). Major problem associated with provision of oxygen to the cell - is a rate limiting step and thus serves as a model system to understand mass transfer. The rate of oxygen transfer = driving force / resistance. E.g resistance to mass transfer from medium to mo`s are complex and may arise from; Diffusion from bulk gas to gas/liquid interface Solution of gas in liquid interface Diffusion of dissolved gas to bulk of liquid Transport of dissolved gas to regions of cell Diffusion through stagnant region of liquid surrounding the cell Diffusion into cell Consumption by organism (depends on growth/respiration kinetics)

- 5. The following diagram serves to illustrate the different phases and material that are relevant in general transport processes associated with fermentation technology; Dispersed gases Dissolved nutrients Solid and Immiscible liquid nutrients Floc Cells Products in water MASS TRANSFER

- 6. Phases present in bioreaction/bioreactor Non aqueous phase Aqueous phase Solid phase (Reactants / products) Dissolved reactants / products Reaction Gas (O2, CO2, CH4 etc) Cells Liquids (e.g oils) Sugars Organelles Solid (e.g particles of substrate) Minerals Enzymes Enzymes ......... 1 2 .......... 1 = reactant supply and utilisation 2 = product removal and formation

- 7. • One of the most critical factors in the operation of a fermenter is the provision of adequate gas exchange. •The majority of fermentation processes are aerobic • Oxygen is the most important gaseous substrate for microbial metabolism, and carbon dioxide is the most important gaseous metabolic product. • For oxygen to be transferred from a air bubble to an individual microbe, several independent partial resistance’s must be overcome Mass Transfer

- 8. 1) The bulk gas phase in the bubble 2) The gas-liquid interphase 3) The liquid film around the bubble 4) The bulk liquid culture medium 5) The liquid film around the microbial cells 6) The cell-liquid interphase 7) The intracellular oxygen transfer resistance 1 2 3 4 5 6 7 Gas bubble Liquid film Microbial cell Oxygen Mass Transfer Steps

- 9. The Oxygen requirements of industrial fermentations • Oxygen demand dependant on convertion of Carbon (C) to biomass • Stoichiometry of conversion of oxygen, carbon and nitrogen into biomass has been elucidated • Use these relationships to predict the oxygen demand for a fermentation • Darlington (1964) expressed composition of 100g of dry yeast C 3.92 H 6.5 O 1.94

- 10. O2 Requirements 6.67CH2O + 2.1O2 = C 3.92 H 6.5 O 1.94 + 2.75CO2 + 3.42H2O 7.14CH2 + 6.135O2 = C 3.92 H 6.5 O 1.94 + 3.22CO2 + 3.89H2O where CH2 = hydrocarbon CH2O = carbohydrate From the above equations to produce 100g of yeast from hydrocarbon requires three times the amount of oxygen than from carbohydrate

- 11. (b) OXYGEN CONC. vs RESPIRATION RATE (growth rate) • The effect of dissolved oxygen on the specific uptake rate (i.e respiration or growth) is described by; • Michaelis Menton or Monod type relationship Respiration rate (QO2) = QO2 max . O2 conc / ( Ks + O2 conc) or = max. C/ (Ks + C) where C = oxygen conc. QO2 = mmoles of oxygen consumed per gram of dry weight

- 12. Dissolved Oxygen Concentration QO2 Ccritical Effect of dissolved O2 concentration on the QO2 of a microorganism Specific O2 uptake increases with increase in dissolved O2 levels to a certain point Ccrit

- 13. Critical dissolved oxygen levels for a range of microorganisms Organism Temperature Critical dissolved oC Oxygen concentration (mmoles dm -3) Azotobacter sp. 30 0.018 E. coli 37 0.008 Saccharomyces sp. 30 0.004 Penicillium chrysogenum 24 0.022 Azotobacter vinelandii is a large, obligately aerobic soil bacterium which has one of the highest respiratory rates known among living organisms

- 14. Critical dissolved oxygen levels • To maximise biomass production you must satisfy the organisms specific oxygen demand by maintaining the dissolved O2 levels above Ccrit • Cells become metabolically disturbed if the level drops below Ccrit • In some cases metabolic disturbance may be advantageous • Or high dissolved O2 levels may promote product formation • Amino acid biosynthesis by Brevibacterium flavum • Cephalosporium synthesis by Cephalosporium sp.

- 15. 5.1.3. FACTORS AFFECTING OXYGEN DEMAND Rate of cell respiration Type of respiration (aerobic vs anaerobic) Type of substrate (glucose vs methane) Type of environment (e.g pH, temp etc.) Surface area/ volume ratio large vs small cells (bacteria v mammalian cells) hyphae, clumps, flocs, pellets etc. Nature of surface area (type of capsule etc)

- 17. Size of sparger gas bubble Gas composition, volume & velocity Design of Impeller size, no. of blades rotational speed Baffles width, number 5.1.4. FACTORS INFLUENCING OXYGEN SUPPLY Foam/antifoam Temperature Type of liquid Height/width ratio ‘’Hold up’’ 5.1.4 (a) Process factors

- 18. 5.1.4(b) Transfer through an interface (Kla) Ci = O2 conc at interface CL = O2 conc in liquid Pg = Partial pressure of gas Pi = Partial pressure at interface Bubble Gas Liquid of Gas film film Pg Pi (1/k2) Ci (1/k4) (1/k1) (1/k3) CL Bulk Liquid

- 19. Overall mass transfer is (Whitman theory) dC/dt = kg (Pg - Pi) = KL (Ci - CL) (Driving force) (Resistance) Note kg = 1/k1 + 1/k2, KL = 1/k3 + 1/k4 Use conc rather than partial pressure (measure?) dC/dt = KL (Csat - CL) ......assume that Csat substitutes for Ci (measure?) This is per unit interface! Overall then dC/dt = KLa( Csat - CL)

- 20. 5.1.4. (c) Determination of KLa • Determination of KLa in a fermenter is important in to establish its aeration efficiency and quantify effects of operating variables on oxygen supply • Used to compare fermenters before scale up or scale down • A number of different methods are available

- 21. 5.1.4.(c) Determination of KLa (1) The Sulphite oxidation technique Measures the rate of conversion of a 0.5m solution of sodium sulphite to sodium sulphate in the presence of a copper or cobalt catalyst Na2SO3 + 1/2 O2 Na2SO4 Oxidation of sulphite is equivalent to the oxygen-transfer rate Disadvantages i) slow, ii) effected by surface active agents iii) Rheology of soln not like media Cu++ or Co++

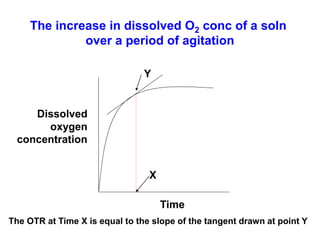

- 22. 5.1.4.(c) Determination of KLa (2) Gassing out techniques • Estimation of KLa by gassing out involves measuring the increase in dissolved O2 of a solution during aeration and agitation • The OTR will decrease with the period of aeration as CL approaches CSAT due to resultant decrease in driving force (CSAT - CL) • The OTR at any one time will be equal to the slope of the tangent to the curve of dissolved O2 conc against time of aeration

- 23. The increase in dissolved O2 conc of a soln over a period of agitation X Y Time Dissolved oxygen concentration The OTR at Time X is equal to the slope of the tangent drawn at point Y

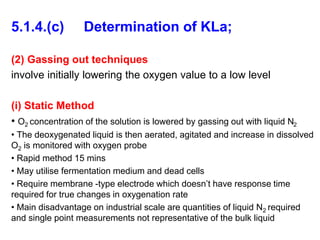

- 24. 5.1.4.(c) Determination of KLa; (2) Gassing out techniques involve initially lowering the oxygen value to a low level (i) Static Method • O2 concentration of the solution is lowered by gassing out with liquid N2 • The deoxygenated liquid is then aerated, agitated and increase in dissolved O2 is monitored with oxygen probe • Rapid method 15 mins • May utilise fermentation medium and dead cells • Require membrane -type electrode which doesn’t have response time required for true changes in oxygenation rate • Main disadvantage on industrial scale are quantities of liquid N2 required and single point measurements not representative of the bulk liquid

- 25. 5.1.4.(c) Determination of KLa (ii) Dynamic Method; • Involves measuring oxygen levels in growing culture in the fementer • Utilises the growing culture to reduce O2 levels • Correction factors must be used • Slope of AB is a measure of the respiration rate • BC is observed increase in dissolved oxygen is the difference between transfer of oxygen into solution and uptake by the culture

- 26. X B A C Time Dissolved oxygen concentration Dynamic gassing out for the determination of Kla values. Aeration terminated at point A and recommenced at point B Slope AB gives RX (Respiration rate) Slope BC gives dC/dt

- 27. Dynamic Method Expressed as the equation dC/dt = Kla (Csat - CL) - RX R = respiration rate (mmoles of O2 g-1 biomass h-1), X = concentration of biomass Turn off air supply, monitor dissolved O2 dC/dt = - RX ... thus the slope of the trace gives RX Resume aeration and monitor, Supply term can be calculated (from slope + substitute calculated value of RX) dC/dt = KLa (Csat - CL) - RX (slope BC) (solve) (Literature) (Observe) (slope AB)

- 28. Dynamic Method Advantages • Can determine KLa during an actual fermentation • Rapid technique • Can use a dissolved oxygen probe of the membrane type Limitations • Limited range of dissolved oxygen levels can be studied • Must not allow oxygen levels to fall below Ccrit • Difficult to apply technique during a fermentation with a high oxygen demand • Relies on measurements taken at one point

- 29. 5.1.4.(d) FACTORS AFFECTING BUBBLE SIZE (a) Influence of gas velocity on bubble formation: .. .. :: ::: .. ... :: :: .. . . low medium high Very little backmixing backmixing slug flow slow medium fast

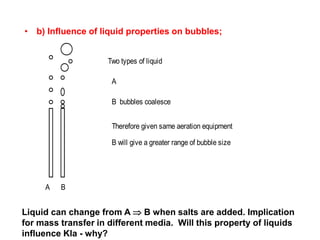

- 30. • b) Influence of liquid properties on bubbles; Two types of liquid A B bubbles coalesce A B Therefore given same aeration equipment B will give a greater range of bubble size Liquid can change from A B when salts are added. Implication for mass transfer in different media. Will this property of liquids influence Kla - why?

- 31. 5.1.4.(e) GAS HOLD-UP Represents air volume retained in the liquid Vh = V - V0 Where Vh = hold-up volume, V = vol. of gassed liquid, V0 = vol of ungassed liquid. No air Air Difference in volume represents hold-up volume That is the amount of gas retained in the liquid

- 32. Correlations exist that relate hold-up to power input , for example, (P/V)0.4 . Vb 0.5 P/V = power input per unit vol ungassed liquid, V b = linear velocity of air bubble (ascending velocity). Ascending velocity of bubble (Vb): V b = FH l /H 0 V Where H0 = hold-up of bubble, F = aeration rate, Hl = liquid depth, V = liquid volume.

- 33. How does height (h) of a reactor vary with radius (r) when volume (v) is kept constant? volume of a cylinder is v = r 2 h Let us fix the volume as 1 then h = 1/ r 2 If r = 1 then h = 1/ r = 2 then h = 1/4 r = 3 then h = 1/9 Therefore as the radius increases the height (or path length) decreases as the square of the radius

- 34. 5.1.4.(f) ECONOMICS OF OXYGEN TRANSFER Fermentation e.g Penicillin - high KLa Waste treatment - economy Kla . Csat = maximum rate at which oxygen can be dissolved Economy and capacity related through power input per unit volume (P/V) ECONOMY = KLa. Csat / (P/V)

- 35. The balance between OXYGEN DEMAND and SUPPLY Must consider how processes may be designed such that O2 uptake rate of the culture does not exceed the oxygen transfer rate of the fermentor. Uptake rate = QO2.X QO2 = O2 uptake rate, X = Biomass dC/dt = KLa(Csat - CL ) = supply rate Dissolved O2 conc. should not fall below the critical dissolved O2 conc. (Ccrit) A fermentation will have a max Kla dictated by operating conditions thus it is the demand that often has to be adjusted. Achieved by Control of biomass conc. Control of specific O2 uptake rate Combination of both