7 qc tools

- 1. 7 QC TOOLS 1. Flow Chart 2. Check Sheet 3. Histogram 4. Pareto 5. Cause & Effect Diagram 6. Scatter Plot 7. Control Chart

- 2. 1. Flow Chart 2. Check Sheet 3. Histogram 4. Pareto 5. Cause & Effect Diagram 6. Scatter Plot 7. Control Chart

- 3. Flow Charts: The benefits of flowcharts are as follows: Communication: Flowcharts are better way of communicating the flow of a system to all concerned. Effective analysis: With the help of flowchart, problem can be analyzed in more effective way. Proper documentation: Program flowcharts serve as a good process documentation, which is needed for various purposes. Identifying errors: By breaking the process down into its constituent steps, flowcharts can be useful in identifying where errors are likely to be found in the system • Flowcharts are pictorial representations of a process.

- 4. 1. Flow Chart 2. Check Sheet 3. Histogram 4. Pareto 5. Cause & Effect Diagram 6. Scatter Plot 7. Control Chart

- 5. What is a check sheet ? The Check Sheet is a data-gathering and interpretation tool A Check Sheet is used for: distinguishing between fact and opinion gathering data about how often a problem is occurring gathering data about the type of problem occurring The most straight forward check sheet is simply to make a list of items that you expect will appear in a process and to mark a check beside each item when it does appear. This type of data collection can be used for almost anything, from checking off the occurrence of particular types of defects to the counting of expected items (e.g., the number of times the telephone rings before being answered).

- 6. Example of Check Sheet: (continuous data use) No.___________741 PRODUCTION CHECK SHEET Product Name_________________________________Alternator Pulley Date_________________________________12- 02- 02 Usage________________________________________Pulley Bolt Torque Factory_______________________________Church Street Specification__________________________________2.2 +/- .5 Section Name__________________________SI Line No. of Inspections______________________________185 Data Collector__________________________Sam The Man Total Number__________________________________185 Group Name___________________________ Lot Number___________________________________1631 Remarks:_____________________________ Dimensions 1.5 1.6 1.7 1.8 1.9 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3.0 3.1 3.2 40 35 SpecLSL SpecUSL 30 25 20 15 X XXXX XX X XXXXX XX 10 XXX XXXXX XXXXX XXXXX XX XXXXX XXXXX XXXXX XXX 5 XX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXX X 0 X XX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XXXXX XX X TOTAL FREQUENCY 1 2 7 13 10 16 19 17 12 16 20 17 13 8 5 6 2 1

- 7. 1. Flow Chart 2. Check Sheet 3. Histogram 4. Pareto 5. Cause & Effect Diagram 6. Scatter Plot 7. Control Chart

- 8. • The purpose of a Histogram is to take the data that is collected from a process and then display it graphically to view how the distribution of the data, centers itself around the mean, or main specification. From the data, the histogram will graphically show: The center of the data. The spread of the data. Any data skew ness (slant, bias or run at an angle). The presence of outliers (product outside the specification range). The presence of multiple modes (or peaks) within the data.

- 9. Calculations needed… Mean The average of all the values. Minimum The smallest value. Maximum The biggest value. Std Dev An expression of how widely spread the values are around the mean. Class Width The x-axis distance between the left and right edges of each bar in the histogram. Number of Classes The number of bars (including zero height bars) in the histograms.

- 11. The standard normal distribution, with its zero skewness and zero kurtosis The standard normal distribution, with its zero skewness and zero kurtosis Example: Histogram

- 12. A truncated curve, with the peak at or near the edge while trailing gently off to the other side, often means that part of the distribution has been removed through screening, 100% inspection, or review. These efforts are usually costly and make good candidates for improvement efforts A double-peaked curve often means that the data actually reflects two distinct processes with different centers. You will need to distinguish between the two processes to get a clear view of what is really happening in either individual process Example: Histogram

- 13. Outliers in a histogram – bars that are removed from the others by at least the width of one bar – sometimes indicate that perhaps a separate process is included. It may also indicate that special causes of variation are present in the process and should be investigated A plateau-like curve often means that the process is ill-defined to those doing the work, which leaves everyone on their own. Since everyone handles the process differently, there are many different measurements with none standing out. The solution here is to clearly define an efficient process Example: Histogram

- 14. 1. Flow Chart 2. Check Sheet 3. Histogram 4. Pareto 5. Cause & Effect Diagram 6. Scatter Plot 7. Control Chart

- 15. • Pareto chart • The Pareto chart is a specialized version of a histogram that ranks the categories in the chart from most frequent to least frequent. A Pareto Chart is useful for non-numeric data, such as "cause", "type", or "classification". This tool helps to prioritize where action and process changes should be focused. If one is trying to take action based upon causes of accidents or events, it is generally most helpful to focus efforts on the most frequent causes. Going after an "easy" yet infrequent cause will probably not reap benefits. What Questions The Pareto Chart Answers What are the largest issues facing our team or business? What 20% of sources are causing 80% of the problems (80/20 Rule)? Where should we focus our efforts to achieve the greatest improvements?

- 16. Build a Pareto chart Sort your data in descending order by frequency of occurrence Delay Due To Frequency % Cumulative % Tool Change 31 36 36 No Raw material 26 30 66 No Steam Pressure 15 17 83 Power failure 9 10 93 others 6 7 100 87 Create Percentage and Cumulative Percentage columns, as shown above.

- 18. 1. Flow Chart 2. Check Sheet 3. Histogram 4. Pareto 5. Cause & Effect Diagram 6. Scatter Plot 7. Control Chart

- 19. Cause & Effect Diagram The cause and effect diagram is used to explore all the potential or real causes (or inputs) that result in a single effect (or output). Causes are arranged according to their level of importance or detail. Causes in a cause & effect diagram are frequently arranged into four major categories. While these categories can be anything, you will often see: Manpower, Methods, Materials, and Machinery (recommended for manufacturing) equipment, policies, procedures, and people (recommended for administration and service).

- 20. Example MAN MACHINE METHOD MATERIAL ATMOSPHERE Lack of operator Skill. Lack of knowledge H E efficiency Bypass blower efficiency Quality of ICW. Speed of R/C Fan. Proper sealing Of I/C flange & Base flange Servo flapper Opening of bypass Water servo opening Stacking rule Start bypass gas Tempr. Cooling water temp. cooling water flow. EXCESS BYPASS COOLING TIME.Quality of degd. coils Coil chemistry Climatic effect ICW quality

- 21. 1. Flow Chart 2. Check Sheet 3. Histogram 4. Pareto 5. Cause & Effect Diagram 6. Scatter Plot 7. Control Chart

- 22. Example of scatter plot Study Hours Test Score 3 80 5 90 2 75 6 80 7 90 1 50 2 65 7 85 1 40 7 100 The data displayed on the graph resembles a line rising from left to right. Since the slope of the line is positive, there is a positive correlation between the two sets of data. This means that according to this set of data, the longer one studies, the better grade he will get in examination.

- 23. Types of scatter plots Scatter Plot: No Relationship Scatter Plot: Strong Linear (positive correlation) Relationship

- 24. Scatter Plot: Strong Linear (negative correlation) Relationship Scatter Plot: Exact Linear (positive correlation) Relationship Types of scatter plots

- 25. Scatter Plot: Outlier Types of scatter plots

- 26. 1. Flow Chart 2. Check Sheet 3. Histogram 4. Pareto 5. Cause & Effect Diagram 6. Scatter Plot 7. Control Chart

- 27. All control charts have three basic components: •a centerline, usually the mathematical average of all the samples plotted. •upper and lower statistical control limits that define the constraints of common cause variations. •performance data plotted over time.

- 28. Elements of Typical Control Chart 1. Horizontal axis for sample number 2. Vertical axis for sample statistics e.g. mean, range, standard deviation of sample. 3. Target Line 4. Upper control line 5. Upper warning line 6. Lower control line 7. Lower warning line 8. Plotting of sample statistics 9. Line connecting the plotted statistics

- 29. Elements of Typical Control Chart 1 2 3 4 5 Sample Number Upper control line Target Lower control line Upper warning line Lower warning line SampleStatistics

- 30. Types of control chart

- 31. Types of Control Chart We have two main types of control charts. One for variable data and the other for attribute data. Since now world-wide, the current operating level is ‘number of parts defective per million parts produced’, aptly described as ‘PPM’; control charts for ‘attribute data’ has no meaning. The reason being that the sample size for maintaining control chart at the ‘PPM’ level, is very large, perhaps equal to lot size, that means 100% inspection.

- 32. Most Commonly Used Variable Control Charts Following are the most commonly used variable control charts: To track the accuracy of the process - Mean control chart or x-bar chart To track the precision of the process - Range control chart

- 33. Most Common Type of Control Chart for Variable Data Variable Control Chart For tracking Accuracy For tracking Precision Mean control chart Range control chart

- 34. Concepts behind control charts

- 35. Case When Process Mean is at Target 43 48 49 50 51 52 5344 45 46 47 Target Process Mean Chances of getting a reading beyond U & L is almost nil 42 U L - 3 s +3 s U - L = 6 s

- 36. Case - Small Shift of the Process Mean 43 48 49 50 51 52 5344 45 46 47 Target Process Mean Chances of getting a reading outside U is small Small shift in process 42 Shaded area shows the probability of getting a reading beyond U UL U-L = 6 s

- 37. Process Mean Case - Large Shift of the Process Mean 43 48 49 50 51 52 5344 45 46 47 Target Chances of getting a reading outside U is large Large shift in process 42 Shaded area shows the probability of getting a reading beyond U UL U-L = 6 s

- 38. Summary of Effect of Process Shift When there is no shift in the process nearly all the observations fall within -3 s and + 3 s. When there is small shift in the mean of process some observations fall outside original -3 s and +3 s zone. Chances of an observation falling outside original -3 s and + 3 s zone increases with the increase in the shift of process mean.

- 39. Our Conclusion from Normal Distribution When an observation falls within original +3 s and -3 s zone of mean of a process, we conclude that there is no shift in the mean of process. This is so because falling of an observation between these limits is a chance. When an observation falls beyond original +3 s and -3 s zone of process mean, we conclude that there is shift in location of the process

- 40. If the process output follows these rules, the process is said to be stable or in control with only common causes of variation present. If it fails to follow these rules, it may be out of control with special causes of variation present. These special causes must be found and corrected. Interpreting Control Chart

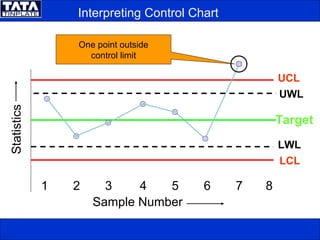

- 41. Interpreting Control Chart A single point above or below the control limits. Probability of a point falling outside the control limit is less than 0.14%. This pattern may indicate: - a special cause of variation from a material, equipment, method, operator etc. - mismeasurement of a part or parts. - miscalculated or misplotted data point.

- 42. Interpreting Control Chart UCL 1 2 3 4 5 6 7 8 Sample Number Statistics UWL LCL Target LWL One point outside control limit

- 43. Interpreting Control Chart Seven consecutive points are falling on one side of the centre line. Probability of a point falling above or below the centre line is 50-50. The probability of seven consecutive points falling on one side of the centre line is 0.78% ( 1 in 128) This pattern indicates a shift in the process output from changes in the equipment, methods, or material or shift in the measurement system.

- 44. Interpreting Control Chart UCLUCL 1 2 3 4 5 6 7 8 Sample Number Statistics UWLUWL LCLLCL TargetTarget LWLLWL Seven consecutive points on one side of the centre line

- 45. Interpreting Control Chart Two consecutive points fall between warning limit and corresponding control limit. In a normal distribution, the probability of two consecutive points falling between warning limit and corresponding control limit is 0.05% (1 in 2000). This could be due to large shift in the process, equipment, material, method or measurement system.

- 46. Interpreting Control Chart UCL 1 2 3 4 5 6 7 8 Sample Number Statistics UWL LCL Target LWL Two consecutive points between warning limit and corresponding control limit

- 47. Interpreting Control Chart Two points out of three consecutive points fall between warning limit and corresponding control limit. This could be due to large shift in the process, equipment, material, method or measurement system.

- 48. UCLUCL 1 2 3 4 5 6 7 8 Sample Number Statistics UWLUWL LCLLCL TargetTarget LWLLWL Two points out of three consecutive points between warning limit and corresponding control limit Interpreting Control Chart

- 49. A trend of seven points in a row upward or downward demonstrates nonrandomness. This happens when - Gradual deterioration or wear in equipment. - Improvement or deterioration in technique. - Operator fatigue. Interpreting Control Chart

- 50. UCL 1 2 3 4 5 6 7 8 Sample Number Statistics UWL LCL Target LWL Seven consecutive points having upward trend Interpreting Control Chart

- 51. UCLUCL 1 2 3 4 5 6 7 8 Sample Number Statistics UWL LCLLCL Target LWL Seven consecutive points having downward trend Interpreting Control Chart