Capstone Technology Canada - Advanced Process Control Project Lifecycle

- 1. 1 CAPSTONE TECHNOLOGY CANADA Advanced Process Control Solutions

- 2. 2 ABOUT THE COMPANY Senior Application Engineer & Software Developer Capstone Technology Canada (Inc 2002) is an Advanced Control technology and services company focusing on serving Canada’s Oil & Gas industry Over 100 years combined applications experience implementing and supporting APC solutions to multiple process industries Advanced process control engineering, model predictive control, multivariate modeling, real-time optimization Integrator of partner technologies Extensive APC project experience with RMPC, DMC, Connoisseur, and Capstone Control technology Employees located throughout Canada ABOUT THE COMPANY

- 3. CAPSTONE SERVICES AND SOLUTIONS

- 4. OUR APC PHILOSOPHY PROJECT CRITICAL SUCCESS FACTORS 4 APC Project Success Application Design Maintenance and Support Scope Prioritized Based on Business Case/Risk ‘End User’ Engagement & APC Utilization Project Team ** APC technology is proven and mature. Application success depends mainly on implementation.

- 5. WHY CAPSTONE? Success Factor Why CAPSTONE? Project Team • Extensive experience in APC-specific, Oil & Gas-specific applications • Experienced personnel assigned for entire project lifecycle, including site visits • Local project/support engineers ensures responsive support/training for Operations Application Design • Depth of experience enables us to design the optimal solution for your specific application • Multi-platform integration expertise allows for cost effective project delivery • Experience integrating visualization tools with APC systems Maintenance and Support • Long-term support of our applications at Canadian and International clients • Same-day response to service calls by a member of our team with extensive process, control, and systems engineering knowledge. End User Engagement & APC Utilization • Track record of successful implementations resulting from high end user buy-in • Local presence facilitates effective training, support, and adoption of APC applications • APC and information systems support by our experienced team Scope Prioritized Based on Business Case/Risk • Lower project risk through project risk management plan • Demonstrate business value to stakeholders by delivering benefits

- 6. 6 2. Regulatory control & instrumentation improvements 3. APC Dynamic Modelling 4. APC Controller + Property Estimator Design 5. APC Interface Design 6. APC Commissioning 7. Operator & Process Engineer Training 8. System Documentation 1. Evaluate Benefits Project Start APC PROJECT LIFECYCLE 9. Maintenance

- 7. 1. BENEFITS ANALYSIS AND PRELIMINARY DESIGN • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • Primary Benefits – variability reduction and optimizing operating point • Identify control benefits by analyzing process areas • Analyze historical and controlled step test data to estimate variability reduction • Characterize process capability, mechanical and process constraints • Identify instrumentation issues (tuning, loop pairing, etc), best operating practices, modes of operation, feed switches, etc. • Combine the results of the analysis with economic data to estimate benefits Deliverables, Milestones, and Outcomes • Completed analysis of operating environment and initial optimization approach defined • Dynamic control matrix • Business case defined for each in-scope item • Prioritized scope by business value & implementation risk • Input to Phase 2 planning APC Benefits

- 8. 2. REGULATORY CONTROL + INSTRUMENTATION IMPROVEMENTS • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • Re-tune main PID loops (as required) that will interface with APC • Implement any recommended improvements to instrumentation Deliverables, Milestones, and Outcomes • Regulatory control systems are prepared for the APC project

- 9. 3. DYNAMIC MODELING & STEP RESPONSE TESING • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • Develop dynamic control models by fitting models to bump test data • Determine test plan based on the operations analysis performed in Phase 1 and approved by Operations • Include an experienced Board Operator as part of the project team. This individual often has a positive impact on ultimate ‘end user’ support. • Operations is engaged to ensure that the process constraints are respected during the bump tests • Several modeling packages available: Capstone’s own or 3rd party Deliverables, Milestones, and Outcomes • Modelling approaches are defined • Inputs to dynamic control models

- 10. 4. APC CONTROLLER DESIGN • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • Controller matrix is built from models identified during the previous phase • Input/output tag mapping • Initial tuning Deliverables, Milestones, and Outcomes • Map for the control policy has been established

- 11. 4. CONTROLLER DESIGN - CAPSTONE MODEL PREDICTIVE CONTROLLER FEATURES • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • Unlimited MV-CV pairings • Predictive constraint control • Optimization functionality: LP, QP • Linear models may be used to map a non-linear response space through gain, lag and dead-time adaptation (allows for variable model parameters) • Runs on Windows and has detailed server-side interface • Reads/writes OPC • Internal controller tags available for viewing in visualization tools through MPC data series Deliverables, Milestones, and Outcomes • Realize economic objectives for the application design • Fine Tune the control policy to capture benefits

- 12. 4. APC CONTROLLER DEMO • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models

- 13. 4. PROPERTY ESTIMATOR DESIGN - CAPSTONE PROPERTY ESTIMATOR FEATURES • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • Provides a continuous estimate for properties measured infrequently ( e.g. analyzer or lab measurements) • Removes analyzer / lab delay • Multi-input single output 1st order dynamic models; also supports multivariate gain models (PLS) combined with 1st order dynamics • Internal estimator tags available for viewing in visualization tools Deliverables, Milestones, and Outcomes • Provides dead time compensated, continuous measurement(s) corrected by lab feedback, ready for control deployment.

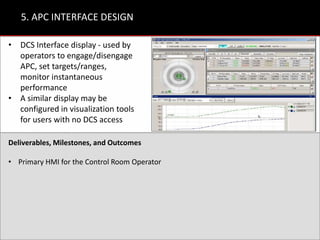

- 14. 5. APC INTERFACE DESIGN • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • DCS Interface display - used by operators to engage/disengage APC, set targets/ranges, monitor instantaneous performance • A similar display may be configured in visualization tools for users with no DCS access Deliverables, Milestones, and Outcomes • Primary HMI for the Control Room Operator

- 15. 6. APC COMMISSIONING • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • Work directly, on-site with Operations to ensure smooth transition to APC control • Control Room Operators embedded in project team and support/participate in communicating commissioning activities to stakeholders • Engage MVs and verify/modify initial tuning • Tune applications to a satisfactory level of performance where they can remain permanently engaged Deliverables, Milestones, and Outcomes • Provide 1-on-1 operator training • Document benefits obtained

- 16. 7. OPERATOR & PROCESS ENGINEER TRAINING • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • 1-on-1 operator training during previous phase • Classroom training sessions for operator group • Operator training focuses on: • process objectives, constraints • engagement/disengagement procedures • how the operator interacts with the interface • Control Room Operators embedded in project team and support/participate in training sessions • Process engineers are trained in detail on controller design and architecture Deliverables, Milestones, and Outcomes • Training curriculum • Training courses

- 17. 8. SYSTEM DOCUMENTATION • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • Create detailed engineering documentation (needed for maintenance of the APC system) Deliverables, Milestones, and Outcomes • Detailed engineering documentation for the following: • Control strategy design • System architecture • DCS interface • Operating procedures

- 18. 9. LONG-TERM MAINTENANCE • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • Long-term performance benefits can be maintained in the absence of significant process changes with monitoring and maintenance • Model predictive control performance may deteriorate over time due to process changes and if the initial models are no longer representative • Typical changes may include: Unit revamps, equipment fouling, new or changed product specifications, instrumentation failures, etc Deliverables, Milestones, and Outcomes • Periodic monitoring program to ensure the performance and benefits are maintained • Automated reports to monitor system performance • Visualization package is often used to calculate, store and display KPIs, some examples: • App uptime • no. of MVs engaged or wound up • Economic benefits • Model mismatch size may be treated as SPC variables in visualization package • Alarms

- 21. 21 APPENDIX

- 22. Deliverables, Milestones, and Outcomes • Regulatory control systems are prepared for the APC project

- 23. PROPERTY ESTIMATOR DESIGN - CAPSTONE PROPERTY ESTIMATOR FEATURES • Process analysis performed in this initial step also used to map out operating space, define unit economics, identify optimum operating points, benchmark process, build initial correlation models between main operating variables, or initial property estimator models • Provides a continuous estimate for properties measured infrequently ( e.g. analyzer or lab measurements) • Removes analyzer / lab delay • Multi-input single output 1st order dynamic models; also supports multivariate gain models (PLS) combined with 1st order dynamics • Internal estimator tags available for viewing in PARCView Deliverables, Milestones, and Outcomes • Provides dead time compensated, continuous measurement(s) corrected by lab feedback, ready for control deployment.

- 24. 24

- 25. 25