Circuit Board Layout Techniques - www.circuitsinc.tk

- 1. Circuit Board Layout Techniques by Awanish Raj CircuitsInc.tk

- 2. Introduction Analog circuitry must be partitioned in its own section of the board, using special layout techniques.. The common design mistakes of digital circuitry cannot be corrected by the cut and jumper method for analog circuitry.

- 3. Noise sources Conducted Emissions — noise that the analog circuitry generates through its connections to other circuits. Negligible for low power circuits. Radiated Emissions — noise that the analog circuitry generates, or transmits, through the air. Negligible for low frequency operations. Conducted Susceptibility — noise from external circuitry that is conducted into the analog circuit through its connections to other circuits. Analog circuitry must be connected to the ―outside world‖ by at least a ground connection, a power connection, an input, and an output. Noise can be conducted into the circuit through all of these paths, as well as any others that are present.

- 4. Noise sources (continued) Radiated Susceptibility — noise that is received through the air (or transmitted into the analog circuitry) from external sources. Analog circuitry, in many cases, resides on a PCB that may have high-speed digital logic including DSP chips. High-speed clocks and switching digital signals create considerable radio frequency interference (RFI). Other sources of radiated noise are endless: the switching power supply in a digital system, cellular telephones, broadcast radio and TV, fluorescent lighting, nearby PCs, lightning in thunderstorms, and so on. Even if the analog circuitry is primarily audio in frequency, RFI may produce noticeable noise in the output.

- 5. PCB material GRADE DESIGNATION MATERIAL/COMMENTS FR–1 Paper/phenolic: room temperature punchable, poor moisture resistance. FR–2 Paper/phenolic: suitable for single-sided PCB consumer equipment, good moisture resistance. FR–3 Paper/epoxy: designed for balance of good mechanical and electrical characteristics. FR–4 Glass cloth/epoxy: excellent mechanical and electrical properties. FR–5 Glass cloth/epoxy: high strength at elevated temperatures, self-extinguishing. G10 Glass cloth/epoxy: high insulation resistance, highest bond strength of glass laminates, high humidity resistance. G11 Glass cloth/epoxy: high flexural strength retention at high temperature, extreme resistance to solvents

- 6. PCB material (continued) Do not use FR–1. FR–4 is commonly used in industrial-quality equipment, while FR–2 is used in high-volume consumer applications. These two board materials appear to be industry standards.

- 7. Layers of PCB Single-Sided Very simple consumer electronics are sometimes fabricated on single-sided PCBs, keeping the raw board material inexpensive (FR–1 or FR–2) with thin copper cladding. This technique is only recommended for low-frequency circuitry. This type of design is extremely susceptible to radiated noise. Resistance in the power leads of the device must be taken into account, as well as resistance between the return for the inputs and the load. Both the input and load must return somewhere. If these are at different potentials due to trace resistance, there can be problems.

- 8. Layers of PCB (continued) Double-Sided There are some double-sided FR–2 boards, they are more commonly fabricated with FR–4 material. The increased strength of FR–4 material supports vias better. Crossing traces on different layers is not recommended for analog circuitry. Wherever possible, the bottom layer should be devoted to a ground plane, and all other signals routed on the top layer.

- 9. Layers of PCB (continued) Multi-layered Critical designs call for multi-layer boards. Some of the reasons are : Better routing for power as well as ground connections. If the power is also on a plane, it is available to all points in the circuit simply by adding vias. Other layers are available for signal routing, making routing easier. There will be distributed capacitance between the power and ground planes, reducing high frequency noise. Other reasons which may not be intuitive: Better EMI/RFI rejection. When a conductor is placed close to a parallel conductive surface, most of the high frequency currents will return directly under the conductor, flowing in the opposite direction. This transmission line type setup is relatively immune to radiated noise. Reduced overall project cost for small production runs. Although multi-layer boards are more expensive to manufacture, EMI/RFI requirements from the FCC or other agencies may require expensive testing of the design.

- 10. Layers of PCB (continued) It is far better to take advantage of the distributed capacitance between the power and ground plane by making them internal. Another advantage of placing the planes internally is that the signal traces are available for probing and modification on the top and bottom layers. Anyone who has had to change connections on buried traces will appreciate this feature. For more than four layers, it is a general rule to shield higher speed signals between the ground and power planes, and route slower signals on the outer layers.

- 11. Ground plane - Benefits Ground is frequently the most common connection in the circuit. Having it continuous on the bottom layer usually makes the most sense for circuit routing. It increases mechanical strength of the board. It lowers the impedance of all ground connections in the circuit, which reduces undesirable conducted noise. It adds a distributed capacitance to every net in the circuit — helping to suppress radiated noise. It acts a shield to radiated noise coming from underneath the board.

- 12. Grounding - Rules Good grounding is a system-level design consideration. It should be planned into the product from the first conceptual design reviews. The Most Important Rule: Keep Grounds Separate Separate grounding for analog and digital portions of circuitry is one of the simplest and most effective methods of noise suppression. One or more layers on multi-layer PCBs are usually devoted to ground planes. More clarification in later slides. Ground and power planes are at the same ac potential, due to decoupling capacitors and distributed capacitance. Therefore, it is important to isolate the power planes as well.

- 13. Grounding – Rules (continued) Do not overlap digital and analog planes. Place analog power coincident with analog ground, and digital power coincident with digital ground. If any portion of analog and digital planes overlap, the distributed capacitance between the overlapping portions will couple high-speed digital noise into the analog circuitry.

- 14. Grounding – Rules (continued) Separate grounds does not mean that the grounds are electrically separate in the system. They have to be common at some point, preferably a single, low-impedance point. All returns should be connected together at a single point, which is system ground. At some point, this will be the chassis. It is important to avoid ground loops by multiple connections to the chassis.

- 15. Grounding – Rules (continued) It is important to keep digital signals away from analog portions of the circuit. It makes little sense to isolate planes, keep analog traces short, and place passive components carefully if there are high-speed digital traces running right next to the sensitive analog traces. Digital signals must be routed around analog circuitry, and not overlap analog ground and power planes. It is a good idea to locate analog circuitry as close as possible to the I/O connections of the board. Digital designers, used to high current ICs, will be tempted to make a 50-mil trace run several inches to the analog circuitry thinking that reducing the resistance in the trace will help get rid of noise. What they have actually done is create a long, skinny capacitor that couples noise from digital ground and power planes into the op amp, making the problem worse!

- 16. A Good Example Three separate and isolated ground/power planes are employed: one for power, one for digital, and one for analog. High-frequency conducted noise on the power lines is limited by inductors (chokes). The designer has even located low frequency analog circuitry close to low speed digital, keeping high frequency digital and analog physically apart on the board.

- 17. Combining analog and digital signals The pin names analog ground and digital ground refer to internal connections in the IC, not the plane to which they should be connected. Both should connect to the analog ground plane. Be sure to properly decouple the logic supply for the converter to analog ground. One might suspect that the digital portions of the converter would make circuit performance worse by coupling digital switching noise onto the analog ground and power plane. Converter designers realize this, and design digital portions without a lot of output power to minimize switching transients

- 18. Unexpected PCB Passive Components Trace Antennas One basic type of antenna is the whip, or straight conductor. This antenna works because a straight conductor has parasitic inductance, and therefore can concentrate flux from external sources. The impedance of any straight conductor has a resistive and an inductive component. Another major type of antenna is the loop. The inductance of a straight conductor is dramatically increased by bending it into partial or complete loops. Increased inductance lowers the frequency at which the conductor couples radiated signals into the circuit.

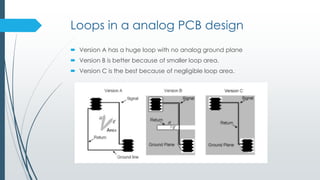

- 19. Loops in a analog PCB design Version A has a huge loop with no analog ground plane Version B is better because of smaller loop area. Version C is the best because of negligible loop area.

- 20. Unexpected PCB Passive Components (continued) Trace reflections When a PCB trace turns a corner at a 90 degree angle, a reflection can occur. This is primarily due to the change of width of the trace. At the apex of the turn, the trace width is increased to 1.414 times its width. This upsets the transmission line characteristics, especially the distributed capacitance and self–inductance of the trace — resulting in the reflection.

- 21. Unexpected PCB Passive Components (continued) Trace-to-Plane Capacitors PCB traces, being composed of foil, form capacitance with other traces that they cross on other layers. For two traces crossing each other on adjacent planes, this is seldom a problem. Coincident traces (those that occupy the same routing on different layers), form a long, skinny capacitor

- 22. Unexpected PCB Passive Components (continued) Trace-to-Trace Capacitors and Inductors PCB traces are not infinitely thin. They have some finite thickness, as defined by the ounce parameter of the copper clad foil. The higher the number of ounces, the thicker the copper. If two traces run side-by-side, then there will be capacitive and inductive coupling between them.

- 23. Unexpected PCB Passive Components (continued) Inductive Vias Whenever routing constraints force a via (connection between layers of a PCB, a parasitic inductor is also formed.

- 24. Summary General Think of the PCB as a component of the design. Know and understand the types of noise the circuit will be subjected to. Prototype the circuit. Board Structure Use a high-quality board material such as FR–4. Multi-layer boards are as much as 20-dB better than double-sided boards. Use separate, non overlapping ground and power planes. Place power and ground planes to the interior of the board instead of exterior.

- 25. Summary (continued) Components Be aware of frequency limitations of traces and other passive components. Avoid vertical mounting of through-hole passive components in high-speed circuits. Use surface mount for high-speed analog circuitry. Keep traces as short as possible. Use narrow traces if long traces are required. Terminate unused op amp sections properly.

- 26. Summary (continued) Routing Keep analog circuitry close to the power connector of the board. Never route digital traces through analog sections of the board, or vice versa. Make sure that traces to the inverting input of the op amp are short. Make sure that traces to the inverting and noninverting inputs of the op amp do not parallel each other for any significant length. It is better to avoid vias, but the self-inductance of vias is small enough that a few should cause few problems. Do not use right angle traces, use curves if at all possible.

- 27. Summary (continued) Bypass Use the correct type of capacitor to reject the conducted frequency range. Use tantalum capacitors at power input connectors for filtering power supply ripple. Use ceramic capacitors at power input connectors for high frequency conducted noise. Use ceramic capacitors at the power connections of every op amp IC package. More than one capacitor may be necessary to cover different frequency ranges. Change the capacitor to a smaller value — not larger — if oscillation occurs. Add series inductors or resistors for stubborn cases. Bypass analog power only to analog return, never to digital return.

- 28. References: Excerpts from TI SLOA089 Op Amps for Everyone Literature Number: SLOD006A Analog Dialog 30th Anniversary Issue, Analog Devices, Ask the Applications Engineer–10, James Bryant High-Speed Operational Amplifier Layout Made Easy, Texas Instruments, Andy Hahn, SLOA046 Visit www.circuitsinc.tk and get your PCB designed for free!