Construction management sample drawing file

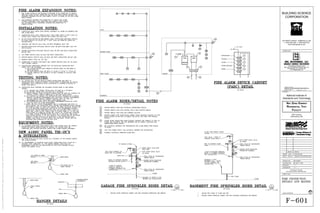

- 1. NationalInstituteofStandardsandTechnology NISTCampus Gaithersburg,MD NetZeroEnergyResidentialTestFacility DRAWINGLIST ARCHITECTURAL FIREPROTECTION DESIGN CRITERIA, ABBREVIATIONS, & GEN. STRUCTURAL NOTES ARCHITECTURAL SITE PLAN ARCHITECTURAL SITE PLAN DETAILS FOUNDATION PLAN BASEMENT PLAN FIRST FLOOR FRAMING PLAN FIRST FLOOR PLAN FIRST FLOOR KEY PLAN & WALL FRAMING ELEVATIONS SCREEN PORCH & GARAGE KEY PLANS & WALL FRAMING ELEVS. SECOND FLOOR & LOWER ATTIC FRAMING PLAN SECOND FLOOR PLAN SECOND FLOOR KEY PLAN & WALL FRAMING ELEVATIONS ATTIC FRAMING PLAN ROOF FRAMING PLAN ROOF PLAN LOWER ROOF OVERHANG FRAMING PLAN UPPER ROOF OVERHANG FRAMING PLAN FIRST AND SECOND FLOOR REFLECTED CEILING PLANS A-001 A-101 A-101A A-102 A-103 A-104 A-105 A-106 A-107 A-108 A-109 A-110 A-111 A-112 A-113 A-114 A-115 A-121 F-001 FIRE PROTECTION GENERAL NOTES, LEGEND, AND ABBREVIATIONS F-101 F-102 F-103 F-104 BASEMENT FLOOR PLAN FIRST FLOOR PLAN SECOND FLOOR PLAN ATTIC FLOOR PLAN A F-601 FIRE PROTECTION DETAILS AND MATRIX S PLUMBING BASEMENT FLOOR PLAN - PLUMBING FIRST FLOOR PLAN - PLUMBING SECOND FLOOR PLAN - PLUMBING ATTIC FLOOR PLAN - PLUMBING P-101 P-102 P-103 P-104 o PLUMBING DETAILS P-501 PROJECTDESCRIPTION PLUMBING RISERS AND SCHEDULES P-601 A-201 A-202 A-203 A-204 A-205 A-206 A-207 EXTERIOR ELEVATIONS EXTERIOR ELEVATIONS EXTERIOR ELEVATIONS INTERIOR ELEVATIONS INTERIOR ELEVATIONS INTERIOR ELEVATIONS INTERIOR ELEVATIONS These plans describe an energy efficient net zero single family home to be built in Gaithersburg, MD. The home has four bedrooms, three full baths and a full basement.The drawing set and specifications were developed by Building Science Corporation with support from the Department of Energy's Building America Program. The home will be registered under USGBC's LEED for Homes program and will target Platinum Certification. During project planning and construction, all efforts should be made to meet the goals of this project. MECHANICAL MECHANICAL LEGEND, SCHEDULES & DETAILS MECHANICAL SITE PLAN M-001 M-002 BUILDING CODE M-101 M-102 M-103 M-104 M-105 M-106 BASEMENT FLOOR PLAN - HVAC FIRST FLOOR PLAN - HVAC FIRST FLOOR PLAN GARAGE - HVAC SECOND FLOOR PLAN - HVAC ATTIC FLOOR PLAN - HVAC BASEMENT FLOOR PLAN - RADIANT FLOOR HEAT BUILDING SECTION BUILDING SECTION BUILDING SECTION BUILDING SECTION GARAGE, BREEZEWAY & SCREEN PORCH SECTIONS A-301 A-302 A-303 A-304 A-305 These plans are submitted under the 2009 Edition of the International Residential Code For One-and Two-Family Dwellings. SQUARE FOOTAGES - Area calculations according to ANSI Z765-2003 A-401 A-402 WALL SECTIONS & DETAILS WALL SECTIONS MECHANICAL DETAILS MECHANICAL DETAILS M-501 M-502 1,518 sq. ft. 1,518 sq. ft. 1,191 sq. ft. Basement First Floor Second Floor REQUIRED CONSTRUCTION SEQUENCE - PART A REQUIRED CONSTRUCTION SEQUENCE - PART B REQUIRED CONSTRUCTION SEQUENCE - PART C ADVANCED FRAMING DETAILS WINDOW DETAILS & INSTALLATION SEQUENCE DOOR DETAILS & INSTALLATION SEQUENCE ENCLOSURE PENETRATION DETAILS & SEQUENCES FOUNDATION DETAILS HORIZONTAL DETAILS VERTICAL DETAILS ROOF DETAILS A-501A A-501B A-501C A-502 A-503 A-504 A-505 A-506 A-507 A-508 A-509 MECHANICAL SCHEDULES M-601 ELECTRICAL PROJECTTEAM ELECTRICAL LEGEND, ABBREVIATIONS, SYMBOLS & LIGHTING FIXTURE SCHEDULE E-001 CLIENT MEP ENGINEER EBL Engineers, LLC 8005 Harford Road Baltimore, MD 21234 Contact: Ed Hubner (410) 668-8000 ehubner@eblengineers.com SPECIFICATIONS CONSULTANT Kalin Associates 1121 Washington Street Newton, MA 02465 Contact: Mark Kalin (617) 964-5477 mkalin@kalinassociates.com National Institute of Standards and Technology 100 Bureau Drive Gaithersburg, MD 20899 Contact: Hunter Fanney (301)975-5900 hunter.fanney@nist.gov BASEMENT FLOOR PLAN - ELECTRICAL FIRST FLOOR PLAN - LIGHTING FIRST FLOOR PLAN - POWER SECOND FLOOR PLAN - LIGHTING & POWER ATTIC FLOOR PLAN - ELECTRICAL E-101 E-102 E-103 E-104 E-105 A-601 A-602 A-603 WINDOW & DOOR SCHEDULES & TYPES INTERIOR FINISH SCHEDULE PENETRATION SCHEDULE ELECTRICAL RISER DIAGRAM ELECTRICAL DETAILS E-501 E-502 A-701 A-702 FIRST FLOOR OPEN WEB FLOOR TRUSS TYPE ELEVATIONS SECOND FLOOR OPEN WEB FLOOR TRUSS TYPE ELEVATIONS ARCHITECT LEED for HOMES PROVIDER CONSTRUCTION MANAGER ELECTRICAL PANEL SCHEDULES E-601 Building Science Corporation 30 Forest Street Somerville, MA 02143 Contact: Betsy Pettit (978)589-5100 betsy@buildingscience.com Everyday Green 1877 Ingleside Terrace NW Washington, DC 20010 Contact: Andrea Foss (202)213-6984 andrea@everydaygreen.com Jacobs Engineering Group, Inc. Contact: AHIBIldlSa^Sa U.S. Department of Energy Research Toward Zero Energy Homes BuildingScienceCorporation 30ForestStreet Somerville,MA02143 978.589.5100 Contact:BetsyPettit betsy@buildingscience.com CONSTRUCTIONDOCUMENTS 31MARCH2010ISSUEDFORCONSTRUCTION U.S. DEPARTMENT OF EnergyEfficiency& RenewableEnergy ENERGY COPYRIGHT (C) 2009 BUILDING SCIENCE CORPORATION

- 2. DESIGNCRITERIA GENERALSTRUCTURALNOTES BUILDINGSCIENCE CORPORATION 1. ALL CONSTRUCTION SHALL BE IN ACCORDANCE WITH THESE PLANS, THE INTERNATIONAL RESIDENTIAL CODE (IRC 2009), TRUSS MANUFACTURER SHOP DRAWINGS, AND THE MATERIAL MANUFACTURERS' INSTALLATION INSTRUCTIONS. STRUCTURAL DESIGN CRITERIA DESIGN ITEM CRITERIA CODE REFERENCE GROUND SNOW LOAD 30 PSF — SEE NOTE 1 IRC 2009 FIG R301.2(5), ASCE 7 FIG 7-1 2. WHERE CONFLICTING INFORMATION EXISTS BETWEEN THESE PLANS AND OTHER REFERENCED REQUIREMENTS, THE MORE STRINGENT REQUIREMENT SHALL APPLY UNLESS OTHERWISE APPROVED BY THE DESIGN PROFESSIONAL RESPONSIBLE FOR THESE PLANS. BASIC WIND SPEED 90 MPH (GUST) IRC 2003, FIG R301.2(4) ASCE 7, FIG 6-1C WIND EXPOSURE C IRC 2003, SEC R301.2.1.4 ASCE 7, Sect 6.5.6 3. THE CONTRACTOR IS RESPONSIBLE TO IDENTIFY AND RESOLVE ALL CONFLICTS AND DISCREPANCIES PRIOR TO AND DURING CONSTRUCTION AND FACILITATE PROPER CONSTRUCTION AS INTENDED BY THESE PLANS. WIND BORNE DEBRIS REGION NO IRC 2009 Sect. R301.2.1.2 ASCE 7, Sect. 6.5.9 MAPPED SEISMIC HAZARD Ss = 0.16g S1 = 0.05g ASCE 7, CH 11 &CH 22 4. CONTRACTOR SHALL BE RESPONSIBLE FOR PROVIDING ADEQUATE STRUCTURAL SUPPORT OF CONSTRUCTION LOADS DURING ALL PHASES OF CONSTRUCTION INCLUDING, BUT NOT LIMITED TO, FOUNDATION BACKFILL, BRACING OF WALL FRAMING TO RESIST CONSTRUCTION FLOOR LOADS AND LATERAL BUILDING LOADING, BRACING OF TRUSSES DURING INSTALLATION AND SUBSEQUENT CONSTRUCTION LOADING, AND OTHER CONDITIONS AS DICTATED BY THE CONTRACTOR’S CONSTRUCTION PRACTICE. 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com SEISMIC SITE CLASS D (firm soil assumed) (Fa = 1.6; Fv = 2.4) ASCE 7, Sect. 11.4.2 SEISMIC DESIGN SPECTRAL ACCELERATION PARAMETERS SDS = 2/3(1.6)(0.16g) = 0.17g SD1 = 2/3(2.4)(0.05g) = 0.08g ASCE 7, Sect. 11.4 SEISMIC DESIGN CATEGORY B CONSULTANT: (IRC DWELLINGS EXEMPT) ASCE 7, Sect. 11.6 5. CONTRACTOR SHALL COMPLY WITH THE MOST CURRENT CONSTRUCTION SAFETY REGULATIONS OF OSHA. IRC 2009, FIG R301.2(2) LIVE LOADS IRC 2009, TABLE R301.4 ASCE TABLE 4-1 FLOORS & DECKS FLOORS (BEDROOM AREAS) ATTIC WITH STORAGE ATTIC W/O STORAGE ROOF 40 PSF 30 PSF 20 PSF 10 PSF 20 PSF - SEE NOTE 2 6. ALL CONSTRUCTION SHALL BE PERFORMED IN A GOOD, WORKMANLIKE MANNER FOLLOWING ACCEPTED CONSTRUCTION PRACTICES AND TOLERANCES. DEFECTIVE OR DAMAGED MATERIALS SHALL NOT BE USED AND SHALL BE REPLACED. DEAD LOADS Main house roof/ceiling dead load is 20 psf to account for solar panels and non-standard framing. FLOOR ROOF WALL 10 PSF 15 PSF (20 PSF main house) 8 PSF ENCLOSURETHERMALENVELOPECRITERIA r n FROST DEPTH 30 INCHES Based on local practice AIR-FREEZING INDEX 350 deg. F-DAYS ASCE 32-01, IRC FIG. R403.3(2) COMPONENT R-VALUE U-VALUE SOIL BEARING VALUE (ASD) 3,000 PSF-SEE NOTE 3 Based on preliminary information for soils report provided by NIST consultant (otherwise use presumptive value per IRC Table 401.4.1) FRAMED WALLS R-45 ROOF R-72 L J WINDOWS U-0.19 LATERAL SOIL LOAD 45 PCF Backfill Soil Class I or II required per IRC 2009 Table R404.1.2(4) and Table 405.1 PROJECT: BASEMENT WALLS R-23 NationalInstituteof StandardsandTechnology BASEMENT FLOOR R-10 CONVENTIONAL LIGHT-FRAME CONSTRUCTION REQUIREMENTS SEE CODE REFERENCE IRC 2009, CH 3, 4, 5, 6, 8 IBC 2009, CH 18 AND SEC 2308 NOTES: NetZeroEnergy ResidentialTest Facility 1. UNIFORM ROOF SNOW LOAD (23 PSF) SHALL BE USED ONLY WITH LOAD COMBINATIONS INVOLVING MORE LOAD EFFECTS THAN DEAD PLUS SNOW. GROUND SNOW LOAD SHALL BE USED FOR DESIGN OF ROOF FRAMING AND WHEN CHECKING D+S LOAD COMBINATION. DRIFT SNOW LOAD OF 54 PSF SHALL BE USED FOR LOWER ROOFS. ROOF LIVE LOADS SHALL BE USED FOR THE DESIGN OF ROOF ELEMENTS ONLY. THESE LOADS ARE INTENDED TO ADDRESS MAINTENANCE, ACCESS, AND TEMPORARY CONSTRUCTION LOADS AND ARE NOT INTENDED FOR USE IN COMBINATION WITH OTHER LOAD EFFECTS. MINIMUM 2,700 PSF SOIL BEARING VALUE REQUIRED FOR 36”X36” BASEMENT COLUMN FOOTINGS; MINIMUM 1,500 PSF SOIL BEARING VALUE REQUIRED FOR CONTINUOUS FOUNDATION WALLS. 2. NIST Campus Gaithersburg, MD 3. U.S. Department of Energy Research Toward Zero Energy Homes ABBREVIATIONS U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY A.F.F. ABOVE FINISHED FLOOR B.O. BOTTOM OF BTW BETWEEN C/L CENTER LINE CLR. CLEAR ELEVATION EL. ELEVATION ELEV. MARK DATE DESCRIPTION EQ. EQUAL ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION GWB GYPSUM WALLBOARD PROJECT NO: NIST NZERTF HEAT RECOVERY VENTILATOR HRV A-PLOT-SPEC-NZERTF CAD DWG FILE: HVAC HEATING VENTILATING AND AIR CONDITIONING CG DRAWN BY: INSUL INSULATION CHECKED BY: BP LSL LAMINATED STRAND LUMBER COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION MIN. MINIMUM SHEET TITLE: O.C. ON CENTER DESIGNCRITERIA, ABBREVIATIONS& GEN.STRUCTURAL NOTES PCF POUNDS PER CUBIC FOOT PHOTOVOLTAIC PV T&G TONGUE & GROOVE T.O. TOP OF TYPICAL TYP. I W/ WITH o SCALE AS NOTED z WD. WOOD W/O WITHOUT A-001

- 3. GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. FOR PROPERTY LINE, LIMIT OF DISTURBANCE, GRADING CHANGES, LANDSCAPING, AND LOCATION OF BUILDING ON SITE, SEE SITE/CIVIL DRAWINGS. STEPS DOWN TO GRADE (2 RISERS) DRIP EDGE DRAINAGE SYSTEM UNDER PATIO, SEE 5/A-101A PATIO WITH CONCRETE PAVER UNIT AND VENEER STONE EDGE , SEE 4/A-101A 3'-0" WIDE PEASTONE BED WITH DRIP EDGE DRAINAGE SYSTEM, TYP. SEE 2/A-101A OUTDOOR AIR-HANDLER UNIT 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com i i TRANSFORMERS I :L: FUTURE OUTDOOR AIR-HANDLER UNIT CONSULTANT: T OUTDOOR AIR-HANDLER UNIT r n FUTURE OUTDOOR AIR-HANDLER UNIT MAX.y4" GRADE INCREASE FROM SIDEWALK TO BREEZEWAY SLAB 3'-0" WIDE PEASTONE BED, TYP. SEE 1/A-101A CONCRETE PAVERS L J PROJECT: NationalInstituteof StandardsandTechnology MAX.y4" GRADE INCREASE FROM SIDEWALK TO PORCH SLAB prn' ' NetZeroEnergy ResidentialTest Facility WALKWAY WITH SLOPE <1:20 3'-0" WIDE CONCRETE WALKWAY WITH 6" CONCRETE PAVER EDGE EACH SIDE, TYP. SEE 3/A-101 A, SIM. NIST Campus Gaithersburg, MD U.S. Department of Energy Research Toward Zero Energy Homes U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY CONCRETE DRIVEWAY WALKWAY WITH SLOPE <1:20 EXISTING TREE TO BE REMOVED, TYP. 05/07/10 UPDATED MARK DATE DESCRIPTION ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION PROJECT NO: NIST NZERTF A-PLOT-PLAN-NZERTF CAD DWG FILE: DRAWN BY: HW CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: ARCHITECTURAL SITEPLAN 3'-0" WIDE CONCRETE WALKWAY WITH 6" CONCRETE PAVER EDGE EACH SIDE, TYP. SEE 3/A-101A SCALE AS NOTED / A-101 ARCHITECTURALSITEPLAN SCALE: 1:10

- 4. GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION PATIO CONCRETE PAVERS (SET IN SAND WITH CRUSHED STONE SUBBASE) 5’—0 >> PE "7Ta TT ] <7 A A <7. I <7 4 -4 /: STONE BED, DEPTH BASED ON GRADE AND DEPTH NEEDED TO CONNECT TO DRAIN JH l A JH J I L, b. o k- ^43' p( p( j 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com A - b FILTER FABRIC > [£> EPDM MEMBRANE ATTACHED TO BUILDING WALL, WRAPPED AROUND PIPE AND EXTENDED UP TO EDGE OF FILTER FABRIC 4 * CONSULTANT: 6" PERFORATED PIPE CONNECTED TO NON-PERFORATED PIPE DRAINING TO DAYLIGHT (SEE SITE/CIVIL DRAWINGS) FREE DRAINING BACKFILL: UNIFIED SOIL CLASSIFICATION SYSTEM TYPE GW, GP, SW, OR SP DRIPEDGEDRAINAGEUNDERPATIO 5 SCALE: 3/4" = 1-0" r n t-fJh 3" DEEP, 3-0" WIDE PEASTONE BED WITH BLACK STEEL EDGING OR OTHER PERMEABLE MATERIAL CONCRETE PAVER UNIT WITH MIN. SOLAR REFLECTANCE INDEX (SRI) OF 29; SET IN SAND SLOPE GRADE AWAY FROM FOUNDATION (5% MIN SLOPE) Pk L J PLANTING SOIL STONE VENEER CAP (COLORING AND TEXTURE TO MATCH GARAGE FACADE STONE) ~ y PROJECT: NationalInstituteof StandardsandTechnology n ^~l FILTER FABRIC 3“i t- </. •- <7 o< >o a c> a C: C: C: C: o 3'-0" WIDE STONE BED, DEPTH BASED ON GRADE AND DEPTH NEEDED TO CONNECT TO DRAIN 4 8"-14" STONE VENEER (COLORING, SHAPE AND TEXTURE TO MATCH GARAGE FACADE STONE) >3 3 3 3 3 3 3 >^< $< i=ni=ni=ni=ni=ni=rn=rrtern= 4 o< )0( )0( )0( )0( >o 3 a :: C: C: C: b =■ <j NetZeroEnergy Residential Test Facility A EPDM MEMBRANE ATTACHED TO BUILDING WALL, WRAPPED AROUND PIPE AND EXTENDED UP TO EDGE OF FILTER FABRIC 6" PERFORATED PIPE, CONNECTED TO NON-PERFORATED PIPE DRAINING TO DAYLIGHT (SEE SITE/CIVIL DRAWINGS) FREE DRAINING BACKFILL: UNIFIED SOIL CLASSIFICATION SYSTEM TYPE GW, GP, SW, OR SP J j 4 t 1 4'-6" OF CRUSHED STONE (CR) 4 '> 8" CONCRETE WALL WITH WEEPHOLES AND SEAT FOR STONE VENEER tE A NIST Campus Gaithersburg, MD <i J SOIL SUBGRADE (COMPACTED) U.S. Department of Energy Research Toward Zero Energy Homes l=l l l=l l l=l 11 l l l l l l l l l l PEASTONEBEDWITHDRIPEDGEDRAINAGE SCALE: 3/4" = 1-0" U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY PATIOEDGE SCALE: 1" = 1'-0" 05/07/10 CONCRETE CURB (AT DRIVEWAY) UPDATED MARK DATE DESCRIPTION 3" DEEP, 3-0" WIDE PEASTONE BED WITH BLACK STEEL EDGING OR OTHER PERMEABLE MATERIAL 6" CONCRETE PAVER EDGE PATTERN (BOTH SIDES) ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION SLOPE GRADE AWAY FROM FOUNDATION (5% MIN SLOPE) PROJECT NO: NIST NZERTF WALKWAY: CONCRETE WITH MIN. SOLAR REFLECTANCE INDEX (SRI) OF 29 A-PLOT-PLAN-NZERTF CAD DWG FILE: PLANTING SOIL T DRAWN BY: HW ♦ ♦ o< o>< o>< o>< o>< o>< o>< o 9L ■:> ■:> ■:> ■:> ■:> ■:> v; t> ♦ ♦ H CHECKED BY: BP ao< o o< o< o< o< o in FILTER FABRIC DROUGHT-TOLERANT TURF b COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION o o o o o o o o 6 3’-0" WIDE STONE BED, DEPTH BASED ON GRADE AND ADJACENT STONE BEDS b - — b SHEET TITLE: DRIVEWAY: CONCRETE WITH MIN. SOLAR REFLECTANCE INDEX (SRI) OF 29 FILTER FABRIC it. ARCHITECTURAL SITEPLAN DETAILS 4 * NOTE: SEE SITE/CIVIL DRAWINGS AND SPECIFICATIONS FOR CONSTRUCTION DETAILS ♦ FREE DRAINING BACKFILL: UNIFIED SOIL CLASSIFICATION SYSTEM TYPE GW, GP, SW, OR SP I o SCALE AS NOTED z A-101A PAVINGPLAN PEASTONEBEDW/ODRIPEDGEDRAINAGE SCALE: 1" = r-0' SCALE: 3/4" = 1'-0"

- 5. 10" SONO TUBE FOOTINGS FOR BREEZEWAY COLUMNS, PROVIDE 3 #4 REINFORCING, TYP. - DRAIN A1 BASE OF WINDOW WELL (CONNECTED TO BASEMENT SUMP) | v ft 4ft J I T * F -V ■ r n n ©f it m S6 n CONDENSATE DRAIN THROUGH-WALL CONDUITS FOR HEADER PIPES FOR VERTICAL GROUND LOOP SYSTEM o -V LU Q "si- § S1 THROUGH-WALL CONDUITS FOR HEADER PIPES FOR HORIZONTAL GROUND LOOP SYSTEM § 5 5 o O l V-7 o D CO CO LU CO 4" PERFORATED VENT BEDDED IN STONE WITH "L" CONNECTION TO 4" RISER SOIL GAS VENT THROUGH ROOF; SEE 4/A-506 SOIL GAS VENT c: § CM o LJ -V S5 WINDOWSILL___zk 'EL. -7-1" V T.O. 4" CONCRETE SLAB EMBEDDED HYDRONIC TUBING W1.4 x W1.4 WELDED WIRE MESH AT MID-DEPTH 6 MIL POLYETHYLENE 2" XPS RIGID INSULATION 4" STONE PAD (NO FINES) FILTER FABRIC UNDISTURBED NATIVE SOIL IJJ F3 Q. O SANITARY DRAIN THROUGH SLAB > 4" PVC PIPE THROUGH BOTTOM OF FOOTING, TYP; SEE 1/A-506 o CM / O I CONDENSATE DRAIN O I I S6 be CT> CO MINIMUM 4" DIAM. STANDARD STEEL PIPE O CM CM O THROUGH-STEM WALL CONDUITS FOR FUTURE HIGH VELOCITY HVAC AIR TO AIR OUTDOOR UNIT (SEE GENERAL SHEET NOTE #7) CO on CO COLUMN (RATED FOR MIN. 22,230 LB. LOAD) O o F10 3-0" X 3-0" X 1'-4" CONCRETE FOOTING TYP. =T W/ (4) #5 EACH WAY, 4'-6' FLOOR DRAIN 6K" W x 16y2" D BEAM POCKET, 1 SEE 2/A-506 TYP. o S2 S6 -CJ------- ----- CJ------- ------CJ------ ------|—r^—a- ------ ©©5 D O' LSL BEAM ABOVE S3 S3 COLUMN ISOLATION CONTROL JOINT, TYP. _____ 12-4 3/4" ____ -------- CONDENSATE DRAIN it- 6%" W x 16/4" D BEAM POCKET; SEE 2/A-506 12-4 3/4" 9-6 1/2" -- CONDENSATE DRAIN I THROUGH-STEM WALL CONDUITS FOR C ENTRAL AIR TO AIR OUTDOOR UNIT 7^ COLUMN AND FOOTING DETAIL, TYP; SEE 3/A-506 4> T.O. FOUNDATION EL. +0,-0" T.O. FOUNDATION S EL. -r-2 ±^F 9-4" II CD CD F9 THROUGH-STEM WALL CONDUITS FOR FUTURE AIR TO AIR OUTDOOR UNIT 8" CONCRETE SLAB THIS SECTION (UNDER BASE OF BASEMENT STAIR) FLOOR DRAIN CD i O S6 O O CONDENSATE DRAIN SUMP PUMP: SUMP PUMP CROCK TO HAVE AIR-TIGHT LID OR CLOSURE F10 T.O. SLAB 9 CONNECTION TO STORM DRAIN WITH CHECK 7ALVE S4 4’-6" ~Z-9" EL. -9-11 1/ 7^ 7L B -v o F7 THROUGH-WALL CONDUITS FOR HEADER PIPES FOR SLINKY LOOP SYSTEM o fUl SUMP THROUGH-WALL CONDUIT FOR DOMESTIC AND SPRINKLER WATER CM F12 - GAS CD F11 CONNECTION K ?’ 9s oo CN CM F4 ftft F13 --- CM - CONDENSATE - DRAIN F8 1—1 Hff B =Hi/d Jr CO JO" F8 F2 ftftl ftr O :—r-fp CM -i.i i—i Ett nt ftttr A ft) C/L 2’-6" -,± y- THROUGH-STEM WALL CONDUIT FOR SUMP DISCHARGE CO 10" SONO TUBE FOOTINGS FOR LO BOTTOM OF FOUNDATION WALL DETAIL, TYP; SEE 1/A-506 o I 4" DIAM. PERFORATED PERIMETER DRAIN PIPE TYP; SEE 1/A-506 o -v F.1 -v n 13’-5" T.O. PORCH FDN WALL 4 r- EL. HY-2 3/8 CD CO THROUGH-WALL INSTRUMENTATION CONDUIT TO GARAGE SLAB (3'-0" ABOVE BASEMENT SLAB) - THROUGH-WALL PENETRATION FOR INVERTER DISCONNECT UTILITY THROUGH-WALL PENETRATION FOR COMMUNICATION AND FIRE SAFETY THROUGH-WALL PENETRATION FOR FIRE DEPARTMENT CONNECTION THROUGH-WALL CONDUIT FOR UNMETERED ELECTRICAL WIRING SLAB (3-0" ABOVE BASEMENT SLAB) st- CD CD C/L C/L © © C/L £JL F1 7E 10"B © / 9 T.O. GARAGE FOUNDATION =F EL. -0-5' T.O. GARAGE FOUNDATION AT FRONT OPENINGS EL. -2-8" * SLAB ON GRADE ABOVE * T.O. GARAGE FOUNDATION AT SOUTH DOOR EL. -2-1 3/4 4-2 1/4' CM i Is- i oo FRONT PORCH COLUMNS, PROVIDE 3 #4 REINFORCING, TYP. © © © A.1 C/L C/L C/L C/L , , 5 1/2l' 11'-7' 11’-11" ir-7' 5 1/2" 7L 7L "7 ^ 7 ~ TH|ROUGH-WALL CONDUIT FOR ELECTRICAL WIRING FROM HOUSE METER 6" CONCRETE GARAGE FOUNDATION W^LL, TYP 2-0" CONCRETE FOOTING, TYP 7-0 11 THROUGH-WALL INSTRUMENTATION CONDUIT TO GARAGE to 1 CO -V o I 5 6 6.1 2 3 4.1 1 4 7 86-0" ■7 ~ ■7 ~ 26-0' 16’-0" 36-0' 8-0' -7 ~ y- y- y- y- 4" 2-0" CONCRETE FOOTING, TYP 7^ foundAtion wall 6" CONCRETE PORCH , TYP CO o CM 1 Ob 00 1 Ob CO o CN F E E.1 CO 00 CO C.1 c k I s CD 1 S2 10" CONCRETE FOUNDATION WALL, TYP. 2-0" CONCRETE FOOTING, TYP. 9-4 M FOUNDATIONPLAN SCALE: 1/4" = 1'-0" o S6 S6 F5 .u CD 1 LO O 1 CM O 1 Ob GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. BASEMENT FOUNDATION WALL TO HAVE (1) #4 HORIZONTAL REINFORCEMENT W/ MATCHING CORNER BAR AT TOP AND (1) AT EACH MIDDLE THIRD, AND (1) #4 VERTICAL REINFORCEMENT AT 48" O.C. LOCATED WITH 1-1/4" CONCRETE COVER MEASURED FROM THE INSIDE FACE OF THE FOUNDATION WALL. 2. LOCATE 4" CONNECTION PIPE THROUGH BASE OF FOOTING WITHIN 5’ OF EVERY CORNER AND EVERY 15’ MAX ALONG LENGTH OF WALL SEGMENT WITH MIN OF 1 PER WALL SEGMENT. 3. LOCATE CONDENSATE DRAINS BASED ON LAYOUT OF MECHANICAL EQUIPMENT 4. SEE A-506 FOR FOUNDATION DETAILS. SEE A-603 FOR PENETRATION SCHEDULE. 5. 6. EL. +0-0" IN THE ARCHITECTURAL DRAWINGS CORRESPONDS TO 461.30' IN THE SITE/CIVIL DRAWINGS 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com IF THE HIGH VELOCITY HVAC OPTION IS NOT AWARDED, THE PENETRATION FOR THE CONDUITS WILL NOT BE PROVIDED. 7. CONSULTANT: OSHEETKEYNOTES r n L j PROJECT: PENETRATIONKEY NationalInstituteof StandardsandTechnology S1. SOIL GAS VENT S2. FLOOR DRAIN NetZeroEnergy Residential Test Facility S3. STEEL PIPE COLUMN S4. SUMP PUMP S5. SEWER CONNECTION S6. CONDENSATE DRAIN F1. VERTICAL GROUND LOOP SYSTEM NIST Campus Gaithersburg, MD F2. SLINKY LOOP SYSTEM F3. HORIZONTAL. GROUND. LOOP SYSTEM U.S. Department of Energy Research Toward Zero Energy Homes F4. SUMP PUMP OUTLET F5. INSTRUMENTATION CONDUIT F6. GAS CONNECTION F7. WATER CONNECTION U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY F8. ELECTRICITY CONNECTION AIR-TO-AIR OUTDOOR UNIT CONNECTION F9. F10. FUTURE AIR-TO-AIR OUTDOOR UNIT CONNECTION F11. COMMUNICATION/FIRE SAFTEY CONNECTION INVERTER UTILITY DISCONNECT CONNECTION F12. 07/27/10 UPDATED F13. FIRE DEPARTMENT CONNECTION 06/29/10 UPDATED MARK DATE DESCRIPTION ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION PROJECT NO: NIST NZERTF A-PLOT-PLAN-NZERTF CAD DWG FILE: CG DRAWN BY: CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: FOUNDATIONPLAN i o SCALE AS NOTED z A-102 = C/L OF BEAM POCKET CO CM o

- 6. SANITARY DRAIN UTILITY SHAFT OPENING ABOVE r L J PREFABRICATED WINDOW WELL WITH EGRESS LADDER; SEE 6/A-506 i FLOOR DRAIN; CONNECT TO SOIL PIPE 6-0" HIGH PLYWOOD PANEL WITH 2x4 STUD BACKING CONDENSATE DRAIN; CONNECT TO SUMP ZQ '0[ 4. 4 SOIL GAS VENT 3-9' I CONDENSATE DRAIN; CONNECT TO SUMP O- FLOOR DRAIN; CONNECT TO SOIL PIPE <D CONDENSATE DRAIN; CONNECT TO SUMP o □ SUMP CONDENSATE DRAIN; CONNECT TO SUMP -v cc < LU 12'-2‘ 5 1/2" O CM CO I ABOVE 5 6 6.1 3 4.1 4 7 PATIO ABOVE SLAB ON GRADE ABOVE GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. BASEMENT AREA TO OUTSIDE FACE OF FOUNDATION WALL: 1,518 SQ. FT. SEE A-602 FOR FINISH SCHEDULE. 2. F.1 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com CONSULTANT: F OSHEETKEYNOTES 1. PROVIDE BLOCKING IN WALL TO SUPPORT FUTURE STAIR LIFT. BLOCKING SHOULD EXTEND UP TO A HEIGHT OF 3’-0" ABOVE STAIR TREADS. r n STAIR FROM BASEMENT TO FIRST FLOOR TO HAVE 16 RISERS AT 6-2/3", 15 TREADS AT 10" WITH y4" NOSING. 2. L J PROJECT: NationalInstituteof StandardsandTechnology NetZeroEnergy ResidentialTest Facility D NIST Campus Gaithersburg, MD U.S. Department of Energy Research Toward Zero Energy Homes U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY B A MARK DATE DESCRIPTION ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION PROJECT NO: NIST NZERTF A.1 A-PLOT-PLAN-NZERTF CAD DWG FILE: CG DRAWN BY: CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: BASEMENTPLAN o SCALE AS NOTED A-103 2 1 F E © © E.1 SLAB ON GRADE ABOVE WALKWAY ABOVE © C.1 c A BASEMENTPLAN SCALE: 1/4" = 1'-0" UP 3-9 M n © © © © EGRESS WINDOW

- 7. BLOCKING BETWEEN JOISTS UNDER PARTITIONS PARALLEL TO BUT BETWEEN JOISTS, TYPICAL 1-1/4" x 14" LSL RIM JOIST ATTACHED TO FOUNDATION THROUGH 2" XPS INSULATION 2" XPS INSULATION ON FOUNDATION SHELF, TYPICAL 1-3/4" x 14" ENGINEERED WOOD BLOCKING BETWEEN RIM JOIST AND WEB JOIST, 4'-0" O.C., TYPICAL 3t- CD CD 2 5 6 6.1 7 F.1 8-0’ 7L o 2'-0" 2'-0" 2'-0" v- —> — —> — F -v 1-1/4" x 14" LSL RIM JOIST ATTACHED TO FOUNDATION THROUGH 2" XPS INSULATION / 14" DEEP OPEN WEB FLOOR TRUSS TYPE "A" AT 24" O.C. WITH T & G FLOOR SHEATHING; SEE A-701 ,A-702 FOR TRUSS TYPES o o CM 14" DEEP OPEN WEB FLOOR TRUSS TYPE "A" AT 24" O.C. WITH T & G FLOOR SHEATHING; SEE A-701 ,A-702 FOR TRUSS TYPES BEAM BELOW - LSL 5-1/4" x 16" 1.55E 2'-0" 2'-0" 2'-0" 7^ 7^ 7^ CD CO CO D ■V 1-1/4" x 14" LSL RIM JOIST ATTACHED TO FOUNDATION THROUGH 2" XPS INSULATION CD CD 14" DEEP OPEN WEB FLOOR TRUSS TYPE "C" AT 24" O.C. WITH l" T & G FLOOR SHEATHING; SEE A-701, A-702 FOR TRUSS TYPES B A A.1 3 4.1 4 44'-0" 36-0' 14" DEEP OPEN WEB FLOOR TRUSS TYPE "A1" AT 24" O.C. WITH g" T & G FLOOR SHEATHING; SEE A-701,A-702 FOR TRUSS TYPES 2x4 TREATED SILL PLATE 2x6 TREATED PLATE ON FOUNDATION SHELF n o : LL □ CO D= □ ! u 11 <£> <£> <i> <i> <£> <D O m ■»c o i CN 1 F E E.1 C.1 C 14" DEEP OPEN WEB FLOOR TRUSS TYPE "B" AT 24" O.C. WITH T & G FLOOR SHEATHING; SEE A-701,A-702 FOR TRUSS TYPES 1-%" x 14" LSL HEADER AT STAIR OPENING / 7 /■ 1-1/4" x 14" LSL RIM JOIST ATTACHED TO FOUNDATION THROUGH 2" XPS INSULATION A -r BLOCKING BETWEEN JOISTS UNDER PARTITIONS PARALLEL TO BUT BETWEEN JOISTS, TYPICAL 14" DEEP OPEN WEB FLOOR TRUSS TYPE "D" AT 24" O.C. WITH §" T & G FLOOR SHEATHING; SEE A-701,A-702 FOR TRUSS TYPES 2’-0" 2’-0" 2’-0" 7^ 7^ 7^ 7^ FIRSTFLOORFRAMINGPLAN SCALE: 1/4" = 1'-0" 1-3/4" x 14" LSL HEADER AT STAIR OPENING DASHED LINES INDICATE STUD WALLS ABOVE 12-5 1/2' 3-10' CD CN GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. CONTRACTOR TO VERIFY ENGINEERED WOOD PRODUCT (EWP) MEMBER SIZES WITH EWP SUPPLIER. EWP CONNECTIONS TO FOLLOW EWP SUPPLIER INSTRUCTIONS. 2. 3. LIMIT THE OVERALL ESTIMATED WASTE FACTOR ON THE FRAMING ORDER TO 10% OR LESS. PROVIDE ENGINEERED WOOD BLOCKING BETWEEN JOISTS UNDER PARTITIONS PARALLEL TO, BUT BETWEEN, JOISTS; COORDINATE LOCATION OF BLOCKING WITH MECHANICAL DUCTWORK. 4. SEE A-701 AND A-702 FOR OPEN WEB FLOOR JOIST TYPES; OPEN WEB FLOOR JOISTS TO BE CONSTRUCTED USING FSC-CERTIFIED WOOD; OPEN WEB FLOOR JOISTS TO BE ENGINEERED BY TRUSS SUPPLIER TO MEET LOCAL CODE. 5. 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com 6. GENERAL STRUCTURAL FRAMING CONNECTIONS: LSL CEILING JOISTS TO FLOOR HEADERS: USP THD179 ENGINEERED WOOD JOIST HANGER; DOUBLE LSL FLOOR HEADER TO TRIMMER: USP HD 410 DOUBLE HANGER. CONSULTANT: STRUCTURAL FRAMING CONNECTIONS FOR CENTER BEARING WALL (TO RESIST ROOF UPLIFT): RAFTER TO RIDGE BOARD: USP AC7 ANGLE BRACKET WITH 4 10d NAILS EACH LEG 7. RAFTER TO STUD IN ATTIC BEARING WALL: USP LTW12 WITH R 10d NAILS EACH END STUD IN ATTIC BEARING WALL TO CEILING JOIST: USP LTW12 WITH 4 10d NAILS EACH END CEILING JOIST TO STUD IN SECOND FLOOR BEARING WALL: USP RT10 WITH 4 8d NAILS EACH END (USE USP LTW12 AT CONNECTIONS TO WALL HEADERS) r n STUD TO SOLE PLATE IN SECOND FLOOR BEARING WALL: (2) USP S01 CLIP ANCHORS SOLE PLATE TO FLOOR DECK: (2) #8x3" WOOD SCREWS AT 12" O.C. ATTIC FLUSH-FRAMED BEAM TO WALL STUDS AT ENDS OF BEAM: USP LTW12 WITH 6 10d NAILS EACH END OF STRAP; PROVIDE CONTINUOUS LOAD PATH DOWN TO BASEMENT BEAM USING SIMILAR SIZED STRAPS AT ALL FRAMING JOINTS. L J PROJECT: NationalInstituteof StandardsandTechnology OSHEETKEYNOTES NetZeroEnergy ResidentialTest Facility END OF FLOOR JOIST TO BE FULL BEARING ON BEAM BELOW. 1. 2-2x6 BLOCKS IN FLOOR BELOW JACK STUDS TO TRANSFER LOAD TO BEAM BELOW WHERE JACKS STUDS ARE NOT ALIGNED WITH FLOOR JOIST. 2. NIST Campus Gaithersburg, MD U.S. Department of Energy Research Toward Zero Energy Homes U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY MARK DATE DESCRIPTION ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION PROJECT NO: NIST NZERTF A-PLOT-PLAN-NZERTF CAD DWG FILE: CG DRAWN BY: CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: FIRSTFLOOR FRAMINGPLAN o SCALE AS NOTED A-104 C/LOF BEAM

- 8. cr sri p{(2 A lj o 5-0" CLEAR 11" x UP 11ii 11 ii 7^ <2 ■V ATTIC ACCESS ABOVE - 1 o CO GARAGE CONCRETE STAIR AND LANDING J 1 CO CJ l J ■V 8" CM L_ + -H 18 I J CO CM -2/A-294- i i i LO LO WINDOW WELL LO 28'-1 1/2 3ji i 375" ii d- "7 CO 8/A-204 I CO SEAT 6/A-204 -v o CONDUIT THROUGH WALL TO FUTURE MULTI-SPLIT OUTDOOR UNIT - r □ SOI. GAS ----- VENT —3/|lTH #1 4/A-|204 'd- o CM I < CM OO DINING ROOM / X o i CM LO i < i a LO O ■I Ol Ol m- > ■f] i <s> N) a> 12 co o -i^ > i CO ro o = O - o ACCESS PANEL ABOVE 4^ LO 2 r 4 CM I I CO CO < CD = o U o ©, ©54. 4-4^ --2-7 1/4' 3’-1" 4’-3 1/4 M 11-10" 1 ■7 <2 -7 -7 /CCESS PANEL ABOVE <25 15 O co 3/A-207 11--1 1/4' 3-1" 3-11 3/4' 8-1 ,'-10 1/2; I 5 1/2’ ■ii 1 iL BEARING WALL MUDROOM 5 1/2 11 5 1/2" CL © I S> O CM 4- CM -CO ■V DOWN CO CLOSE 5 T UTILITY co o CO I II CM CLOSET 5 1/2 11 1 1/2 HI 11/A-204 CT> I 1/A-205 ® i CD m 1 1 CO < "nJ- 4i T o 12" 4'-9"/y5 1/2 11 2-3 1/2" 3’-10 4’-11 1/2" 2-1 1/2 11 9-10 1/2 M ~ 7 ~ h' t- -7 !©, ENTRY HALL - ol CO CO CO > > I Q t LO ro LU ro o o o CM LIVING ROOM 5 1/2" 4-2 M cn 1 1 ACCESS PANEL ABOVE -h < co CD m ; S ; <2 < CO o CO I LO - <2 ■7-^r O OFFICE / OPTIONAL BEDROOM 4 ■f^r S) CO o LU 7/A-205 M—JP- CD ■ DO Tf a: o o < < CT> o I LU 11'-6 1/2" 9'- 11 8-0" 12'-1 ID f 4 <L (- JJ 10 <2 1 T o l LO 13 f ) 3B CL l 4 SEE 2/A-507, TY 6" M CL SEE 1/A-507, TYP. ,'-7- CL CL CL CL CONCRETE SLAB W/ BROOM FINISH: SLOPE SLAB 1/4":12 AWAY FROM HOUSE FRONT PORCH 11 CO I CO 1 II -7 lAT UNDERGROUND CONDUIT BETWEEN GARAGE AND BASEMENT 1 SLOPE GARAGE SLAB 4" :12" 4" SLAB ON GRADE; SEE 1/A-305 SEE 4&5/A-507, TYP. 3-4 M 5-10" 8-10" 8-10" 30-8 1/8 n 5-10 n 3-4 n 4 -2 3/411 7^- 7^- 7— 7— 7— 7 e CL CL CL CL L T1’-7' 1T- TT" 1Y-T xw -71- 7L 0 "7 O (2 ■-11 ■ 5-91/4 n f l -sJ- CO -V O CM O I CD CM O W/D 5 1/2" Oio Kl CO 1 CO LU O O 00 ^ >IS ^4I CH, CM LIFT <<p (11) -| 25-1 UNDERGROUND CONDUIT BETWEE^ GARAGE AND BASEMENT 1^ SEE 3&7/A-507, TYP. co f ) <2 CD 1 LD CL CL 14-5 1/2' 5-9 1/4' 2’-9 1/4' 8-7 3/4' 8-7 3/4' 9-6 3/4' 6’-4 1/2' 3-9 1/4' 4’-2 3/4' 7— 7— 7L 7 ~ 7L 7L 7 ~ 7L 7 ~ 4" 7^" 13-5' 8" 7— 7— -V - CONCRETE PAVERS WITH 8" CONCRETE WALL EDGE; STONE VENEER ON TOP AND SID E OF CONCRETE WALL; SEE 4/A101A CONCRETE SLAB W/ BROOM FINISH: SLOPE TO FLOOR DRAIN DOWN FLOOR DRAIN; CONNECT TO ROOF DRIP EDGE DRAINAGE SYSTEM PATIO -n > o o IM> o o o CONDUIT THROUGH WALL FOR FUTURE GAS WATER HEATER SUPPLY/EXHAUST SCREEN PORCH cn CONCRETE PAD FOR OUTDOOR UNIT FOR GARAGE HEAT PUMP 19 SEE 3/A-507 5/A-205 CL CL CL CL l 2' -v 26-0' 16’-0" 2-0' 32-0' 2’-0" 8-0' 5 6 6.1 2 3 4.1 4 7 86’-0" 8' 3-0' 8" 5'-10" CD I f^- o CM V B B o 11" -V BREEZEWAY O. © CD CONCRETE WITH BROOM FINISH B B 11" CM f^- 1 CD LO 1 F.1 F -V D CD 1 CO CO CONDUIT THROUGH WALL FOR FUTURE GAS FURNACE SUPPLY/EXHAUST O o 1 CO B -V o I CM A CO I LO A.1 O 00 1 1 o CD CM CM 1 LO O 1 CO O <2 CD 1 O Z <2 CD CD 1 7— 7— 5'-9 1/4’ 7— F E E.1 CD 00 CO C.1 c A 8-10 1/4" 11'-4 1/2' 7^- FIRSTFLOORPLAN SCALE: 1/4" = 1'-0" GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. FIRST FLOOR AREA TO OUTSIDE FACE OF STUD WALL: 1,518 SQ. FT. 2. DIMENSIONS ARE TO FACE OF STUD UNLESS OTHERWISE NOTED. INTERIOR PARTITIONS FRAMED WITH 2x4 WOOD STUDS UNLESS OTHERWISE NOTED. 3. 4. INTERIOR BEARING WALLS FRAMED WITH 2x6 WOOD STUDS UNLESS OTHERWISE NOTED. 5. INTERIOR DOORS TO BE CENTERED BETWEEN THE NEAREST WALL PERPENDICULAR ON EACH SIDE OF THE DOOR UNLESS OTHERWISE NOTED. 6. SEE A-602 FOR FINISH SCHEDULE REFER TO POCKET DOOR FRAME KIT INSTALLATION INSTRUCTIONS TO DETERMINE ROUGH OPENING OF POCKET DOOR. 7. 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com CONSULTANT: OSHEETKEYNOTES PROVIDE BLOCKING IN WALL TO SUPPORT FUTURE STAIR LIFT. BLOCKING SHOULD EXTEND UP TO A HEIGHT OF 3’-0" ABOVE STAIR TREADS. 1. 2. STAIR FROM FIRST TO SECOND FLOOR TO HAVE 16 RISERS AT 7%", 10" TREADS WITH % NOSING. 3. CASED OPENING, 7-6" FINISHED HEIGHT CASED OPENING, 6-8" FINISHED HEIGHT DROPPED CEILING, 7-9" FINISHED HEIGHT 4. r n 5. 18" x 18" ACCESS PANEL ABOVE DOOR FOR ACCESS TO FCU-2 UNIT. 6. CONCRETE GARAGE STAIR TO HAVE 4 RISERS AT 6y2", 11" TREADS. 7. 8. GARAGE ATTIC ACCESS PANEL TO FIT WITHIN ROOF TRUSSES; SEE A-112 ROOF FRAMING PLAN FOR LOCATION AND SIZE. PANEL TO BE FASTENED FROM BELOW AND REMOVABLE WITHOUT REMOVING PANEL TRIM. ACCESS PANEL TO BE INSULATED. CELLULOSE ATTIC INSULATION SHALL BE HELD BACK FROM ACCESS OPENING. L J PROJECT: NationalInstituteof StandardsandTechnology 9. SIZE OF CONCRETE PAD TO BE SPECIFIED BY MANUFACTURER OF AIR-TO-AIR OUTDOOR UNIT, 10. LOCATION OF FUTURE OUTDOOR AIR-TO-AIR UNIT. NetZeroEnergy ResidentialTest Facility 11. DO NOT SLOPE SLAB IN THIS AREA; THICKEN SLAB UNDER CHAIR LIFT IF SPECIFIED BY MANUFACTURER OF LIFT. ODOORKEY NIST Campus Gaithersburg, MD 1. 1 ’-8" x 6’-8" LH U.S. Department of Energy Research Toward Zero Energy Homes 2. (2) 1-10" x 6-8" 3. 2-4" x 6-8" LH 4. 2-4" x 6-8" RH 2-4" x 6'-8" POCKET 5. U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY 6. 2-6" x 6'-8" RH 7. 2'-6" x 6'-8" LH 8. 2'-8" x 6'-8" LH 9. 2'-8" x 6'-8" RH 10. 3'-0" X 6'-8" LH 11. 3'-0" x 6'-8" RH 07/27/10 UPDATED 3'-0" x 6-8" POCKET 12. 06/29/10 UPDATED 13. 3'-0" x 7'-0" RH W/12" SIDELITES MARK DATE DESCRIPTION 14. 3'-0" x 7'-0" LH ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION 15. 3'-0" x 7'-0" RH PROJECT NO: NIST NZERTF 16. 9'-0" x 8-0" OVERHEAD A-PLOT-PLAN-NZERTF CAD DWG FILE: 17. (2) 4'-6" x 8'-0' CG DRAWN BY: 18. 6'-0" x 6'-8" (1) LH PANEL, (1) FIXED PANEL CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION 19. 3'-0" x 6-8" RH SHEET TITLE: FIRSTFLOORPLAN i o SCALE AS NOTED z A-105 u ACTIVE DOOR © (= = = = =!= I PASSIVE DOOR 9'-0"

- 9. O'-O M O'-O" GENERALSHEETNOTES BLOCKING TO SUPPORT HANGER FOR SCREEN PORCH END BEAM O'-O M BUILDINGSCIENCE CORPORATION 36'-0' 34'-6 3/4M 17'-3 1/4" '-8 1/4ii 8'-5 1/2ii 5'-11 1/4" 27'-1" 1. REAR WALL FRAMING ELEVATIONS DRAWN AS SEEN FROM INTERIOR; INTERIOR BEARING WALL FRAMING ELEVATION DRAWN AS SEEN FROM THE FRONT; ALL OTHER ELEVATIONS DRAWN AS SEEN FROM EXTERIOR -7^ 4 7 36'-0" 35'-8ii 25'-3 1/2" 10'-8" 14'-7 1/4 2'-6 1/4" 36'-0" 31-10 3/4' 22-1" ii 3-0 3/4' 8-5 1/2" -7^ -7^ 7 “ 36-0" 30-10" 25'-3 1/2" 14'-1 3/4" 2'-1" 2'-0' 2'-0" 2'-0' 7^ "7 ~ Y- 77© 9'-1 1/4" 8'-4 3/4" 4'-6 3/4" 3'-4M 13'-4" z^~ zz zziz ft 7^|ft ~7 Z7 4 7 ,Z TT TYPICAL WALL HEIGHT = 9'-1". 2. ^r ^4 X 3! 3.5" x 5.5" 1.3 = LSL HEADEF 3. TYPICAL FIRST FLOOR WINDOW FRAMING HEAD HEIGHT = 7'-6 3/4". (2) 1.75" x 11.25" LSL 1.55E HEADER (2) 1.75" x 11.25" LSL 1.55E HEADER / 3.5" x 5.5" LSL 1.3E HEADER 3.5" x 5.5" LSL 1.3E HEADER 3.5" x 7.25" LSL 1.3E HEADER ^7 3.5" x 9.25” LSL 1.3E HEADER (2)1.75” x 11.25” LSL 1.55E HEADER 3-10" / / CT> WINDOW AND EXTERIOR DOOR FRAMING OPENING DIMENSIONS TO BE ADJUSTED PER MANUFACTURER SELECTION AS FOLLOWS: 4. CM 3'-2" l E > CM C C&co I E - © —? ! I 6'-4 1/2ii "mI- A V- -AS. 1/2' ©- 4-7 M 3-1 8'-1" 2-5' 2'-5' I -A -A - © -© ©- 7< ' A -A © LO ±5 i A. FRAMING WIDTH FOR DOORS AND WINDOWS: INCREASE THE MANUFACTURER'S SPECIFIED ROUGH OPENING WIDTH BY ADDING V2" TO EACH SIDE. B. FRAMING HEIGHT FOR WINDOWS: INCREASE THE MANUFACTURER'S SPECIFIED ROUGH OPENING HEIGHT BY ADDING V2" TO THE TOP AND 1" TO THE BOTTOM. C: FRAMING HEIGHT FOR DOORS: INCREASE THE MANUFACTURER'S SPECIFIED ROUGH OPENING HEIGHT BY ADDING 1/2" TO THE TOP. FRAMING STUDS TO BE FSC-CERTIFIED LUMBER. CNJ / CD / / CN CN / CN © © © / 18 <D CD CD N- / CD / / CD CD / / c & ■v -V 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com KT TK S S S KTT TT TT TT TT TTK SS S KTT TTK S E KT TK S S KT C C TK S KT C TK S S KT TK S E E S KT TK S E IB1 H7 H6 CONSULTANT: 5. 1 ■A ©------- LU CN O LIMIT THE OVERALL ESTIMATED WASTE FACTOR ON THE FRAMING ORDER TO 10% OR LESS.' 6. CN O CD H7 cn i / STRUCTURAL SHEATHING CONNECTIONS (TO RESIST ROOF UPLIFT): 7. CO CN T £ CO 5-7" o ny W CD -©—V LAP SHEATHING ON RAFTER RIM BOARD: MINIMUM 8d NAILS AT 3" O.C. m O CN DO O i X < OO o HORIZONTAL SHEATHING EDGES AT BLOCKING OR FRAMING: MINIMUM 8d NAILS AT 3" O.C. / (a cn / HORIZONTAL SHEATHING EDGES BELOW SECOND FLOOR: MINIMUM 8d NAILS AT 6" O.C. / CN r i CD LO <> cn i OSHEETKEYNOTES X CN □ CN / < if) Ol i if) 4^ / LO / CO 00 J- if) LO i 7 oo X o / CN < i < CO o L J / CN CN PROJECT: if) CD CD i / / CD CD NationalInstituteof StandardsandTechnology in / U ./ M. 7 LU / 00 00 H6 CN hJ 7'-3" NetZeroEnergy ResidentialTest Facility 2 o t x X a> > * n * 7i o 00 00 2'-7" nni ^ pm PE y n CN © 7!- / CN O IB1 CD / CO if) CO "si- l o U t in NIST Campus Gaithersburg, MD / if) CN / if) 00 CN NO CD i ^1" o CO X if) oo t / Ol NO U.S. Department of Energy Research Toward Zero Energy Homes (n i NO / X NO if) if) 2'-7" V, o / t if) CD Is- i U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy co LO ENERGY S> i o 7s LO N- O i > oo LU -V T NO / 5'-7" o t; T 00 00 if) y OsJ ^ ::=nLU O i i if) CO -N -N OO CD X 4^ A © CO LU m 'I T— T 7 H2 x H1 MARK DATE DESCRIPTION O'-O" O'-O' BLOCKING TO SUPPORT HANGER FOR FRONT PORCH END BEAM BLOCKING TO SUPPORT HANGER FOR FRONT PORCH END BEAM ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION 36’-0' 34-4 1/2" 28-6 1/2 M 21'-2 3/4" 10'-10 1/2" 5'-0 1/2M 8'-5 1/2M 5'-11 1/4" 7L PROJECT NO: NIST NZERTF 36'-0" 30'-11 1/2' 25-1 1/2 M 14’-9 1/4" 7-5 1/2 M r-7 1/5M 8-5 1/2" 2-6 1/4" 7^ 7 = A-PLOT-PLAN-NZERTF CAD DWG FILE: 2-0 M 2-0 M 2-0" 1?*- 7^ DRAWN BY: HW ^7 rz Tz 4 CHECKED BY: BP / -4© -4© '-Z, COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION 3.5” x 5.5” 1.3 = LSL HEADEF 3.5” x 5.5" 1.3 = LSL HEADEF 3.5" x 5.5" 1.3 = LSL HEADEF 3.5" x 5.5" 1.3 = LSL HEADEF 3.5" x 5.5" 1.3 = LSL HEADEF / 3.5" x 7.25" LSL 1.3E HEADER 6-2 1/2" / / 2x4 STUD FOR STRUCTURAL SHEATHING ATTACHMENT, TYPICAL / / SHEET TITLE: 3-2" 3-2 ii 3-2" 3-2 M 3-2 ii -© -© © © © © z' z! ! 3-3 1/2" N- N- i— i— - © 00 / / 1 FIRSTFLOORKEY PLAN&WALL FRAMING ELEVATIONS A A A A A LO LO LO LO LO LO 00 / / CN / i h- / / 13© / ±<Z ns / / / s s m m c c £ E KTC TK S KT C C TK S KT SS SS TK S KT C C TK S KT C TK E E S KT C TK S E 3 3/8" 1/2" 4'x8' PLYWOOD STRUCTURAL SHEATHING, TYPICAL i cz o SCALE AS NOTED H1 H2 z A-106 FIRSTFLOORKEYPLAN&WALLFRAMINGELEVATIONS SCALE: 1/4" = 1'-0 H

- 10. 21 '-11 1/4 7'-5 3/4" 26-0" ii — 12'-4 1/4" 4'-0 3/4’ 26'-0' 2'-0ii 2'-0ii 7^ TFFF fTF' 7F 4 I 22* X 5-8 1/4 ii CD L ■f: I A CO .2^, .2^, .2^, o V 7 7 o /I o w 2X4 STUD FOR STRUCTURAL SHEATHING ATTACHMENT, TYPICAL ho 3.5" x 5.5" L5fL 1.3E HEADER J Z -t* NO 3.5" x 9.25" LSL 1.3E HEADER f o col * 3'-2' 9-4" <> ' Tl v- 00 TCl T r^ Ul 6-9 1/2 M I A LO f^ © 00 ,s]- oo 00 CD CD Ol 7 i 00 CD s A 4^ * 4 5 00 FOUNDATION WALL, TYPICAL 4^ K ’ TK S S S KT C TK S m A-----A / CO r-3 1/21 oo l_ l_ l G1 GENERALSHEETNOTES 1. REAR WALL FRAMING ELEVATIONS DRAWN AS SEEN FROM INTERIOR; ALL OTHER ELEVATIONS DRAWN AS SEEN FROM EXTERIOR TYPICAL GARAGE WALL HEIGHT = 9-4". 2. 3. TYPICAL GARAGE WINDOW FRAMING HEAD HEIGHT= 6’-10y2" ABOVE TOP OF GARAGE FOUNDATION WALL. 4. WINDOW AND EXTERIOR DOOR FRAMING OPENING DIMENSIONS TO BE ADJUSTED PER MANUFACTURER SELECTION AS FOLLOWS: A. FRAMING WIDTH FOR DOORS AND WINDOWS: INCREASE THE MANUFACTURER'S SPECIFIED ROUGH OPENING BY ADDING y2" TO EACH SIDE. B. FRAMING HEIGHT FOR WINDOWS: INCREASE THE MANUFACTURER'S SPECIFIED ROUGH OPENING HEIGHT BY ADDING y2" TO THE TOP AND 1" TO THE BOTTOM. C. FRAMING HEIGHT FOR DOORS: INCREASE THE MANUFACTURER'S ROUGH OPENING HEIGHT BY ADDING Vi' TO THE TOP. FRAMING STUDS TO BE FSC-CERTIFIED LUMBER. 5. 6. LIMIT THE OVERALL ESTIMATED WASTE FACTOR ON THE FRAMING ORDER TO 10% OR LESS. STRUCTURAL SHEATHING CONNECTIONS ON GARAGE (FOR BRACING): 7. FASTEN PLYWOOD SHEATHING ON WEST WALL WITH MINIMUM 8d NAILS AT 3" O.C. OSHEETKEYNOTES O'-O" 13'-5' 12-9 3/4' 8-9 3/4" 3-10 3/4' 7L 9-6 1/4" 4-7 1/4' 13-5' 7 1/4" i1- 3.5” x 9.25" LSL 1.3E BEAM -V SC (2) 2X6 POST (2) 2X6 POST 00 LO CO CO 3-3 1/2’ 4-2 1/2’ 3-3 1/2’ 7 - CO -7' ' CO X I CM —V ES K C C K K C C K K C SP2 SP2 H ft 4 o O J CM 5-8 1/4" Jo o o v- I o t o I I o> A o c/) CL "D * Q_ 3? Cf.) co C/) 1 O CO CM CO / I I LO / o o I LO X -2,- o 3T o A CO o o JJ HI T > o> O'-O" 21'-11 1/4" 7'-5 15/16" 26'-0" 26'-0' 18'-6 1/4" 4'-0 3/4" 7L 2'-0" 2'-0' ~? ~ ~? ~ ~? ~ xA 7^7 FTF' ~FF F7 22. 2^. ^2. ^2. ^2. X ft FT 7F A x / 3.5" X 5.5" LSL 1.3E HEADER 3.5" X 5.5" LSL 1.3E headef: 3'-2' -=f 3'-2" -?: ’A ■ A 7^7 O) f^- LO I A A / LO CM : = 4 5 I c CO I KT TK S S S S S S KT C TK S E J l_ G3 GARAGEKEYPLAN&WALLFRAMINGELEVATIONS SCREENPORCHKEYPLAN&WALLFRAMINGELEVATIONS SCALE: 1/4" = 1'-0" SCALE: 1/4" = 1’-0’ BUILDINGSCIENCE CORPORATION 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com CONSULTANT: r n L j PROJECT: NationalInstituteof StandardsandTechnology NetZeroEnergy Residential Test Facility NIST Campus Gaithersburg, MD U.S. Department of Energy Research Toward Zero Energy Homes U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY MARK DATE DESCRIPTION ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION PROJECT NO: NIST NZERTF A-PLOT-PLAN-NZERTF CAD DWG FILE: DRAWN BY: HW CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: SCREENPORCH& GARAGEKEY PLANS&WALL FRAMINGELEVS. o SCALE AS NOTED A-107 ~I G2 00 I I CO v|KS 0 E S s s S K S w s s s E 5SZ / / / CM / / / / 3'-3 1/2 2L*. 2Li 2L*. ^2 2^. ^2 2^. 2^. ^2 ^2 2^. ^2 2^. ■PI 77 FF©- rr T r-6 1/2” 4 F r-6 1/2" 9'-10 3/4” 23'-1" 13'-2 1/4” 23'-1" O'-O' G2 r o o CO ACTIVE DOOR o CD J J L L ^PASSIVE DOOR X B , II . II fxxr XT i G4 ,o-,o 21'-5 3/4" 10-8 1/4" l-£Z 12'-4 3/4" 1’-7 1/4" r-p 1/2 1 1'-6 1/2 F L2 FF- IK * SINGLE 2x6 HEADER SINGLE 2x6 HEADER l L-.6 I--,6 CT W- w- l CM CM 16 16 / K CD O) w E IX I k s k I I k i I i i i i i i -r G4

- 11. 2'-0' 2'-0" 2'-0" 7^ 2x4 VERTICAL WOOD STUD BLOCKING X 14" LSL RIM JOIST 1 '-5 1/2 ii 9-1 o 1 T F O i 00 WX14" LSL RIM JOIST 2'-0' 36-0 M 2'-0" 5 6 6.1 4.1 7 8'-0' 7L 7^ F.1 [] 2'-0" 2'-0" 2'-0" 7^ 7 ~ -7<- [] t—r F 2x4 VERTICAL WOOD STUD BLOCKING ALONG RAKE END RIM JOIST BETWEEN SILL PLATE AND FLOOR SHEATHING 14" DEEP OPEN WEB FLOOR TRUSS TYPE "E" AT 24" O.C. WITH T & G FLOOR SHEATHING; SEE A-701 ,A-702 FOR TRUSS TYPES 14" DEEP OPEN WEB FLOOR TRUSS TYPE "E" AT 24" O.C. WITH T & G FLOOR SHEATHING; SEE A-701 ,A-702 FOR TRUSS TYPES m m m O o CN m 14" DEEP OPEN WEB FLOOR TRUSS TYPE "E1" AT 24" O.C. WITH T & G FLOOR SHEATHING; SEE A-701, A-702 FOR TRUSS TYPES WX14" LSL RIM (jOIST iy4"X1iy4" LSL RIM JOIST CD CO CO D 2x4 VERTICAL WOOD STUD BLOCKING ALONG RAKE END RIM JOIST BETWEEN SILL PLATE AND GABLE WALL BOTTOM PLATE 1%" x 11 y4" LSL ENGINEERED ATTIC JOISTS AT 24" O.C. tr o CO CO c/3 LU O — 14" DEEP OPEN WEB FLOOR TRUSS TYPE "G" AT 24" O.C. WITH g" T & G FLOOR SHEATHING; SEE A-701, A-702 FOR TRUSS TYPES iy4"X 11-1/4" LSL RIM JOIST B 2'-0" 2'-0" o CN A 1)4" X 14" LSL RIM JOIST A.1 2 3 1 4 2'-0' 2'-0' ■7 ~ F =i E =i BLOCKING BETWEEN JOISTS UNDER PARITIONS ALIGNED WITH BUT BETWEEN JOISTS, TYPICAL J I / E.1 o WfF =3 <D C.1 CO CO DASHED LINES INDICATE STUD WALLS ABOVE CN O CO 1 iy4"X14" LSL RIM JOIST c 2x4 VERTICAL WOOD STUD BLOCKING ALONG RAKE END RIM JOIST BETWEEN SILL PLATE AND FLOOR SHEATHING I 14" DEEP OPEN WEB FLOOR TRUSS TYPE "F" AT 24" O.C. WITH T & G FLOOR SHEATHING; SEE A-701,A-702 FOR TRUSS TYPES 7 - A 2'-0' 2'-0' -7 ~ 7 ~ iy4- SECONDFLOOR&LOWERATTICFRAMINGPLAN SCALE: 1/4" = 1'-0" JC O CL C/3 co 5 LU g o O LU <-ea GENERALSHEETNOTES 1. CONTRACTOR TO VERIFY ENGINEERED WOOD PRODUCT (EWP) MEMBER SIZES WITH EWP SUPPLIER. BUILDINGSCIENCE CORPORATION 2. EWP CONNECTIONS TO FOLLOW EWP SUPPLIER INSTRUCTIONS. 3. LIMIT THE OVERALL ESTIMATED WASTE FACTOR ON THE FRAMING ORDER TO 10% OR LESS. PROVIDE ENGINEERED WOOD BLOCKING BETWEEN JOISTS UNDER PARTITIONS PARALLEL TO, BUT BETWEEN, JOISTS; COORDINATE LOCATION OF BLOCKING WITH MECHANICAL DUCTWORK. 4. SEE A-701 AND A-702 FOR OPEN WEB FLOOR JOIST TYPES; OPEN WEB FLOOR JOISTS TO BE CONSTRUCTED USING FSC-CERTIFIED WOOD; OPEN WEB FLOOR JOISTS TO BE ENGINEERED BY TRUSS SUPPLIER TO MEET LOCAL CODE. 5 6. GENERAL STRUCTURAL FRAMING CONNECTIONS: 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com LSL CEILING JOISTS TO FLOOR HEADERS: USP THD179 ENGINEERED WOOD JOIST HANGER; DOUBLE LSL FLOOR HEADER TO TRIMMER: USP HD 410 DOUBLE HANGER. CONSULTANT: STRUCTURAL FRAMING CONNECTIONS FOR CENTER BEARING WALL (TO RESIST ROOF UPLIFT): 7. RAFTER TO RIDGE BOARD: USP AC7 ANGLE BRACKET WITH 4 10d NAILS EACH LEG RAFTER TO STUD IN ATTIC BEARING WALL: USP LTW12 WITH R 10d NAILS EACH END STUD IN ATTIC BEARING WALL TO CEILING JOIST: USP LTW12 WITH 4 10d NAILS EACH END CEILING JOIST TO STUD IN SECOND FLOOR BEARING WALL: USP RT10 WITH 4 8d NAILS EACH END (USE USP LTW12 AT CONNECTIONS TO WALL HEADERS) r n STUD TO SOLE PLATE IN SECOND FLOOR BEARING WALL: (2) USP S01 CLIP ANCHORS SOLE PLATE TO FLOOR DECK: (2) #8x3" WOOD SCREWS AT 12" O.C. ATTIC FLUSH-FRAMED BEAM TO WALL STUDS AT ENDS OF BEAM: USP LTW12 WITH 6 10d NAILS EACH END OF STRAP; PROVIDE CONTINUOUS LOAD PATH DOWN TO BASEMENT BEAM USING SIMILAR SIZED STRAPS AT ALL FRAMING JOINTS. L J PROJECT: NationalInstituteof StandardsandTechnology OSHEETKEYNOTES NetZeroEnergy ResidentialTest Facility 1. END OF FLOOR JOIST TO BE FULL BEARING ON BEARING WALL BELOW. 2. FOR SIZE AND LOCATION OF HEADERS IN THE BEARING WALL BELOW, SEE A-108, WALL IB1. NIST Campus Gaithersburg, MD U.S. Department of Energy Research Toward Zero Energy Homes U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY MARK DATE DESCRIPTION ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION PROJECT NO: NIST NZERTF A-PLOT-PLAN-NZERTF CAD DWG FILE: CG DRAWN BY: CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: SECONDFLOOR LOWERATTIC FRAMINGPLAN & o SCALE AS NOTED A-108 : 0 T I 0 i n LU Tr o < 3-10 1/2" m x IT C/3 L 0 X 00 .0 CN 18'-1 1/4" ACCtSS FROM BELOW -'j 1 I O 0 IWCT ^ r - t I > F 14'-: O I n i h o 0 ACCESS FROM BELOW

- 12. CO -V 01^5'-: 3“T 2' 14'-6 1/2" 4 ->H‘- o> © h- 05 > i MASTER BEDROOM 5iA-206 CO CO ro o 3-5" 6-8 1/2" to 3]a-2(|)6 z 03 & 7^ o :^/2 < FLOOR ACCESS o LO F CO o o 1 CLOSET i i 3 1/2' o] tol i- a -v CD SOIL GAS VENT ^ 5 1/2" o CN CM © 0/A-206S- < Gk CO N- §/A-206 3-6 6-3’ LO ft CO CM © © BATH #2 oo <D /(TTIC ACCESS W)/ PULLDOWN $T^IR 5 1^2" 3-9' LU 2/A-205 CLOSET © HALL l'-3 1 9-1" 4'-0 1/2" 2' 3 1/2' 5'-9' r ^-7- 7^ 7^ I © -BOWN- O 5 1/2" 5 1/2' ®* 0, . . 5 1/2' ; f~~? ; ■ ~ © CL. CD / FLOOR ACCESS BEARING WALL ± <TJ 5 1/2" BEARING WALL FLOOR ACCESS 7-11 1/2' , 2-9" 3 1/2' 10-8 1/2" -*7 OPEN TO lJ BELOW > lJ O ^1 CLOSET CM BEDROOM 2 BEDROOM 3 CJ S) LA] MASTER BATH r;W A u a A CM co o I o CM CN 00 00 -V CO I 00 LO CO 10-8 1/2' 10-8 1/2" 9-1 5 6 6.1 4.1 7 36'-0' 7^ 8'-2‘ 12-9 1/2" 6-7 1/2' 2’-0" 4'-5' 7^ <- 7^ 7^ 7^ f" tL OL dL 2-0 M 8-10" 8-10 M 2-0 7-2" 7’-2' 7L 7" 7L 7 ~ ____I CL 0L dL A F.1 F D B A A.1 3 4 2-0’ -7^- 1L V o o u 2 1 F r i E - E.1 II GARAGE ATTIC ACCES HATCH I I --l-L- T C.1 C A SECONDFLOORPLAN SCALE: 1/4" = 1-0" -v CO I CM -V r^ i 05 INSTRUMENTATION CONDUIT BETWEEN GARAGE ATTIC AND 2ND FLOOR FRAMING CM i CO GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. SECOND FLOOR AREA TO OUTSIDE FACE OF STUD WALL: 1,191 SQ. FT. 2. DIMENSIONS ARE TO FACE OF STUD UNLESS OTHERWISE NOTED. INTERIOR PARTITIONS FRAMED WITH 2x4 WOOD STUDS UNLESS OTHERWISE NOTED. 3. 4. INTERIOR BEARING WALLS FRAMED WITH 2x6 WOOD STUDS UNLESS OTHERWISE NOTED. 5. INTERIOR DOORS TO BE CENTERED BETWEEN THE NEAREST WALL PERPENDICULAR ON EACH SIDE OF THE DOOR UNLESS OTHERWISE NOTED. 6. FLOOR ACCESS PANELS FIT WITHIN FRAMING MEMBERS; SEE FRAMING PLAN. PANELS TO BE COVERED WITH FINISH FLOORING. SEE 8/A-508. 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com SEE A-602 FOR FINISH SCHEDULE. 7. 8. REFER TO POCKET DOOR FRAME KIT INSTALLATION INSTRUCTIONS TO DETERMINE ROUGH OPENING FOR POCKET DOOR. CONSULTANT: OSHEETKEYNOTES 1. INSTRUMENTATION CONDUIT FROM GARAGE ATTIC (THROUGH BREEZEWAY) TO ENTER WALL THROUGH RIM JOIST (IN 2ND FLOOR FRAMING). PENETRATION "E10", SEE A-603 FOR PENETRATION SCHEDULE. r n 2. AIR RETURN FOR FCU-1 LOCATED IN WALL ABOVE DOOR L J PROJECT: NationalInstituteof StandardsandTechnology NetZeroEnergy Residential Test Facility oDOORKEY NIST Campus Gaithersburg, MD 1. 1 ’-8" x 6’-8" LH 2. (2) T-10" x 6’-8" 3. 2-4" x 6-8" LH U.S. Department of Energy Research Toward Zero Energy Homes 4. 2-4" x 6-8" RH 2-4" x 6-8" POCKET 5. 6. 2-6" x 6-8" RH U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy 7. 2-6" x 6-8" LH ENERGY 8. 2-8" x 6-8" LH 9. 2'-8" x 6-8" RH 10. 3'-0" X 6'-8" LH 11. 3'-0" x 6'-8" RH 3'-0" x 6'-8" POCKET 12. 13. 3-0" x 7'-0" RH W/12" SIDELITES 14. 3'-0" x 7'-0" LH MARK DATE DESCRIPTION 15. 3'-0" x 7'-0" RH ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION 16. 9'-0" x 8-0" OVERHEAD 17. (2) 4'-6" x 8-0' PROJECT NO: NIST NZERTF A-PLOT-PLAN-NZERTF CAD DWG FILE: 18. 6'-0" x 6'-8" (1) LH PANEL, (1) FIXED PANEL CG DRAWN BY: 19. 3-0" x 6-8" RH CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: SECOND FLOOR PLAN i o SCALE AS NOTED z A-109 O O CN CM © H LU = H 4© z-.e § 7 LJ CO 10'-8” 4'-6 1/2" 6-10 1/2' © o ■v 1/A-206 2/A-206 co 6 SHELVES CM To 4 F 4 ..8-6 I, -6©P 2-7' 6-10 1/2' ir-2" © 4 o L ? rv rvj o LO CM 4- 4

- 13. GENERALSHEETNOTES O'-O" REAR WALL FRAMING ELEVATIONS DRAWN AS SEEN FROM INTERIOR; INTERIOR BEARING WALL FRAMING ELEVATION DRAWN AS SEEN FROM THE FRONT; ALL OTHER ELEVATIONS DRAWN AS SEEN FROM EXTERIOR 1. O'-O’ BUILDINGSCIENCE CORPORATION 32'-0" 26'-6" 12'-11 6-3 1/2" 7 “ 36'-0' 34-0 1/4’ 28'-11 3/4" 25'-5" 22'-6 1/2' 12-9 3/4’ 4-10 1/4' 32'-0" 9-2" 2'-6 1/2' 2T-2" 7 7 “ 36'-0' 31-3 3/4" 25-11 1/4" 22’-9 1/2' 13-5 1/2" 9-9 1/4' 2'-1 3/4' 2'-0" 7^ 2 IK IK 2. TYPICAL WALL HEIGHT = 9'-1". 3.5" x 11.25" LSL 1.3E BEAM (FLUSH FRAMED) 3. TYPICAL SECOND FLOOR WINDOW FRAMING HEAD HEIGHT = 7'-7 1/2". s m / / / -----------“r= o ' 5" LSL ADER = 3.5" x 5.5" LSL 1.3E HEADER 3.5" x 5.5" LSL 1.3E HEADER 3.5" x li 1.3E F o / V 4. WINDOW AND EXTERIOR DOOR FRAMING OPENING DIMENSIONS TO BE ADJUSTED PER MANUFACTURER SELECTION AS FOLLOWS: / 2 17) 00 CM CD CD / 5.5" x 3.5' 5.5" x 3.5" LSL. 1.3E HEADER (FLATWISE) 2'-9 1/2" 5.5"): 3.5" LSL 1.3E HEADER (FLAT/VISE) 5.5" x 3.5' 5.5" x 3.5" LSL 1.3E HEADER (FLATWISE) I I 2" I" 5' CN OJ G G LSL 1.3E LSL 1.3E HEADER (FLA'"WISE) 2'-C| 1/2" / / CO <- 7" HEADER (FLATWISE) Z—X—V 71 is A. FRAMING WIDTH FOR DOORS AND WINDOWS: INCREASE THE MANUFACTURER'S SPECIFIED ROUGH OPENING WIDTH BY ADDING V2" TO EACH SIDE. B. FRAMING HEIGHT FOR WINDOWS: INCREASE THE MANUFACTURER'S SPECIFIED ROUGH OPENING HEIGHT BY ADDING©’ TO THE TOP AND 1" TO THE BOTTOM. C: FRAMING HEIGHT FOR DOORS: INCREASE THE MANUFACTURER'S SPECIFIED ROUGH OPENING HEIGHT BY ADDING 1/2" TO THE TOP. FRAMING STUDS TO BE FSC-CERTIFIED LUMBER. o 3'-6 3'-@*' E E CO I / / / / o CT> 1/2' 2'-4 1/2" 2'-5 1/2' 7 ! 2'-5 9'-1" "2 7 © V © -A y v 7 " 7 " © fc© © © Ss® CM T 7 2 r / 1 x 7 CM CM CM co V L L X X 7“ CT> 05 O) CT> CT> 00 X X X X X X X -t* CD CD CD CD CD V. m © X. © © © © 2 M X. UK 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com 2 2 2 2 2 2 2 2 2 c tR 2 2 2 SKT 2 2 2 C Tk Xr E KT TK S TK TK KT TKS SS KT TK S S TK TK E S KT C S KT C TK S : 2 2 + CO C/D 7 CO :22r 2 IB2 2 .© H12 CO T X4 £ o i £ LO 2 2 , 2'-5" oc 5. 7 ! ' LU O CONSULTANT: D ^4 o Q CO X© LU o ,7 V 6. LIMIT THE OVERALL ESTIMATED WASTE FACTOR ON THE FRAMING ORDER TO 10% OR LESS.' CO 77 V CM 7 2 2 7T CP vr 7 X 2 7 CM 5'-4" i 7. STRUCTURAL SHEATHING CONNECTIONS (TO RESIST ROOF UPLIFT): I H12 CM fO O I *7 CD i CD 1 LAP SHEATHING ON RAFTER RIM BOARD: MINIMUM 8d NAILS AT 3" O.C. o "x CO CO ro ro 00 X 2 2 V 2 00 ■> © <© 12 © HORIZONTAL SHEATHING EDGES AT BLOCKING OR FRAMING: MINIMUM 8d NAILS AT 3" O.C. fO C 1" X CD 00 I 2 vn HORIZONTAL SHEATHING EDGES BELOW SECOND FLOOR: MINIMUM 8d NAILS AT 6" O.C. W 7 CO 5-7" CO o k CM O CM S GO /x > ro I r n OSHEETKEYNOTES Z 2 r ©. 2 2-5" 2 2 -7T © 1 9'-1" 2”’ Q o I 0) V CM 7 V CO rv x I £ ro v m m X X' D L J m O m m 73 w © CO CO CO co PROJECT: CO (J) CJ) NationalInstituteof StandardsandTechnology CO CO 77 CD CD 1 1 00 00 CO CO CO 77T NetZeroEnergy ResidentialTest Facility X X JOT non L CO 00 CO CD ©—©—"a O -m o IB2 ro o ■V <n X X ur O o CD NIST Campus Gaithersburg, MD co V 1 © —V <0- 7^ CD CO 00 CO T 5 U.S. Department of Energy Research Toward Zero Energy Homes CN CO CM I CO TT’' o CO CO 40 U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy 9'-1" ENERGY co V 2 CCL ' f 9'-1 7 — 7— z: 7 7 m Mil------ ran m—n X I__ ____I GO GO ■xj H9 o r^- MARK DATE DESCRIPTION X ro O'-O' ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION PROJECT NO: NIST NZERTF 32’-0" 28’-5 1/2" 17'-9 3/4" 10'-9 1/2' 7— A-PLOT-PLAN-NZERTF CAD DWG FILE: 32-0" 21’-2 1/2' 14'-2 1/4" 3'-6 1/2' T7- 1/2" 4'x8' PLYWOOD STRUCTURAL SHEATHING, TYPICAL 7— DRAWN BY: HW 2'-0" / ZL 2 CHECKED BY: BP TO 4. CO / ^ X ^ X COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION / / ^£1. 2X. ^£l. X CO- / © M 3.5" x 7.25" LSL 1.3E HEADER 3.5" X 5.5" LS L 1.3E HEADER 3.5" x 7.25" LSL 1.3E HEADER / SHEET TITLE: o CO 1" 3'-4 1/2' r 7' 7' 00 / © © -© © ~! CO 1 1 SECONDFLOOR KEYPLAN&WALL FRAMING ELEVATIONS O LO IO LO / / B B B B B CO 00 / 2x4 STUD FOR STRUCTURAl SHEATHING ATTACHMENT, TYPICAL CO ro / © k CO 00 ^v vr X o CO 2 2 2 © x © 2 © 2 J© 2 2 2 2 CO 2 2 2 2 2 c tT x- X X X S KT C C SKT TKS KT C c: c C TJ S ©L 4^ 2 co -m -----V 1 co 2 CL O SCALE AS NOTED H9 z 2------V SECONDFLOORKEYPLAN&WALLFRAMINGELEVATIONS A-110 SCALE: 1/4" = 1'-0"

- 14. DOUBLE JOIST © 1 © CONTINUOUS 3-1/2" x 11-1/4" LSL 1.3E FLUSH FRAMED HEADER CO J DOUBLE JOIST -v UTIL n SHAFT .-v CN 2 t ■It r-: 1/4’ 7'-1 1/4’ 4'-6" DOUBLE JOIST 2 © 5 6 6.1 4.1 7 32-0' 2-0" 7^ 7^ F.1 ATTIC JOIST ADJACENT TO ROOF RAFTER, TYPICAL x 11-1/4" RIM LSL BOARD 2'-0' 2'-0' 2'-0' 2-0" ,2’-1 1/2" 7L 7" 7" 7^ F -v 2x4 VERTICAL WD STUD BLOCKING ALONG RAKE END RIM JOIST BETWEEN TOP PLATE OF WALL BELOW AND BOTTOM PLATE OF GABLE WALL 1)4" x 11)4" LSL RIM JOIST o o CN BLOCKING AT 2'-0" O.C. if / 2x6 VERTICAL WD STUD GABLE WALL (BALLOON FRAME) ON TOP PLATE AT 2ND FLOOR FRAMING D J 2 x 6 WD STUD 24 O.C. BEARING WALL CONTINUES TO ROOF RAFTERS ABOVE i CD CO 2x4 VERTICAL WD STUD BLOCKING ALONG RAKE END RIM JOIST BETWEEN TOP PLATE OF WALL BELOW AND BOTTOM PLATE OF GABLE WALL i B = A A.1 2 3 1 4 2'-0' -7^- ■7 ~ 1-1/4’ / 1 -10 1/2’ 2'-0 2'-0' 7L 7 ~ F 2x4 VERTICAL WD STUD BLOCKING ALONG RAKE END RIM JOIST BETWEEN TOP PLATE OF WALL BELOW AND BOTTOM PLATE OF GABLE WALL E iy4"X1iy4" LSL RIM JOIST BLOCKING AT 2’-0” O.C. © E.1 rl 2x6 VERTICAL WD STUD GABLE WALL (BALLOON FRAME) ON TOP PLATE AT 2ND FLOOR FRAMING C.1 7 ~ ar w hr C 2x4 VERTICAL WD STUD BLOCKING ALONG RAKE END RIM JOIST BETWEEN TOP PLATE OF WALL BELOW AND BOTTOM PLATE OF GABLE WALL A 1-1/4" x 11-1/4” LSL RIM BOARD ATTICFRAMINGPLAN SCALE: 1/4” = 1’-0" GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. CONTRACTOR TO VERIFY ENGINEERED WOOD PRODUCT (EWP) MEMBER SIZES WITH EWP SUPPLIER. 2. EWP CONNECTIONS TO FOLLOW EWP SUPPLIER INSTRUCTIONS. 3. LIMIT THE OVERALL ESTIMATED WASTE FACTOR ON THE FRAMING ORDER TO 10% OR LESS. GENERAL STRUCTURAL FRAMING CONNECTIONS: 4. LSL CEILING JOISTS TO FLOOR HEADERS: USP THD179 ENGINEERED WOOD JOIST HANGER; DOUBLE LSL FLOOR HEADER TO TRIMMER: USP HD 410 DOUBLE HANGER. 5. STRUCTURAL FRAMING CONNECTIONS FOR CENTER BEARING WALL (TO RESIST ROOF UPLIFT): RAFTER TO RIDGE BOARD: USP AC7 ANGLE BRACKET WITH 4 10d NAILS EACH LEG 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com RAFTER TO STUD IN ATTIC BEARING WALL: USP LTW12 WITH R 10d NAILS EACH END STUD IN ATTIC BEARING WALL TO CEILING JOIST: USP LTW12 WITH 4 10d NAILS EACH END CONSULTANT: CEILING JOIST TO STUD IN SECOND FLOOR BEARING WALL: USP RT10 WITH 4 8d NAILS EACH END (USE USP LTW12 AT CONNECTIONS TO WALL HEADERS) STUD TO SOLE PLATE IN SECOND FLOOR BEARING WALL: (2) USP S01 CLIP ANCHORS SOLE PLATE TO FLOOR DECK: (2) #8x3” WOOD SCREWS AT 12” O.C. ATTIC FLUSH-FRAMED BEAM TO WALL STUDS AT ENDS OF BEAM: USP LTW12 WITH 6 10d NAILS EACH END OF STRAP; PROVIDE CONTINUOUS LOAD PATH DOWN TO BASEMENT BEAM USING SIMILAR SIZED STRAPS AT ALL FRAMING JOINTS. r n QSHEETKEYNOTES FOR LOCATION OF FLUSH FRAMED HEADER AND SUPPORT, SEE A-110, WALL IB2 1. L J PROJECT: 2. FOR SIZE AND LOCATION OF HEADERS IN THE BEARING WALL BELOW SEE A-110, WALL IB2. NationalInstituteof StandardsandTechnology NetZeroEnergy ResidentialTest Facility NIST Campus Gaithersburg, MD U.S. Department of Energy Research Toward Zero Energy Homes U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY MARK DATE DESCRIPTION ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION PROJECT NO: NIST NZERTF A-PLOT-PLAN-NZERTF CAD DWG FILE: CG DRAWN BY: CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: ATTIC FRAMING PLAN o SCALE AS NOTED A-111 1 3 / 4 " X11 y 4 " LSL ENGINEERED CEILING JOISTS AT 24” O.C. 1%" X 11K" LSL ENGINEERED CEILING JOISTS AT 24” O.C.

- 15. 4:12 SLOPED ROOF RAFTER / BEARING WALL (2 x 6 @ 24 " O.C.) EXTENDED TO SUPPORT ROOF RAFTERS 4:12 SLOPED ROOF RAFTER 9.67:12 SLOPED LEDGER BOARD 1-1/4" x 11%" IISL RIM BOARD 2-0 2-0 2-0 7L 9.67:12 SLOPED LEDGER BOARD 4:12 SLOPED ROOF RAFTER WOOD BLOCKING BETWEEN TRUSSES 2x6 RAFTER PLATE ON Vs FLOOR SHEATHING 2x6 RAFTER PLATE ON Vs FLOOR SHEATHING F 9.67:12 SLOPED LEDGER BOARD o o CM FRAMING MEMBERS FOR ONE-STORY ROOM BELOW 2x6 RAFTER P .ATE 2'-0" 2 x 12 RIM BOARD 2'-0" D 2x14 RIDGE BOARD CD CD 2x6 RAFTER P.ATE ON CEILING JOISTS WOOD BLOCKING BETWEEN UPPER RAFTERS B O CM A 2x12 RIM BOARD FRAMING MEMBERS FOR ONE-STORY ROOM BELOW 2x6 RAFTER PLATE ON Vs" FLOOR S HEATHING A.1 5 6 6.1 7 2'-°" 8'-0' F.1 o o ATTIC ACCESS o CO it: 4:12 SLOPED ROOF RAFTER 4.1 32'-0' 1-1/4" x 1iy4" LSL RIM BOARD 2 3 1 4 26-0' 2-0" , 7L 2x6 RAFTER PLATE ON Vs" FLOOR SHEATHING 2-0' 2'-0' 2'-0' * —? ~ F 2'-0' 2'-0' -7— E Jr E.1 o CM C.1 c A ROOFFRAMINGPLAN SCALE: 1/4" = 1'-0" ?s: 9.67:12 SLOPED LEDGER BOARD GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. CONTRACTOR TO VERIFY ENGINEERED WOOD PRODUCT (EWP) MEMBER SIZES WITH EWP SUPPLIER. EWP CONNECTIONS TO FOLLOW EWP SUPPLIER INSTRUCTIONS. 2. 3. LIMIT THE OVERALL ESTIMATED WASTE FACTOR ON THE FRAMING ORDER TO 10% OR LESS. 4. SAWN LUMBER RAFTERS AND BLOCKING TO BE FSC CERTIFIED. 5. GENERAL STRUCTURAL FRAMING CONNECTIONS: LSL CEILING JOISTS TO FLOOR HEADERS: USP THD179 ENGINEERED WOOD JOIST HANGER; DOUBLE LSL FLOOR HEADER TO TRIMMER: USP HD 410 DOUBLE HANGER. 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com 6. SEE A-305 FOR GARAGE ROOF TRUSS TYPES; TRUSSES TO BE CONSTRUCTED USING FSC-CERTIFIED WOOD; ROOF TRUSSES TO BE ENGINEERED BY TRUSS SUPPLIER TO MEET LOCAL CODE. 7. STRUCTURAL FRAMING CONNECTIONS FOR CENTER BEARING WALL (TO RESIST ROOF UPLIFT): CONSULTANT: RAFTER TO RIDGE BOARD: USP AC7 ANGLE BRACKET WITH 4 10d NAILS EACH LEG RAFTER TO STUD IN ATTIC BEARING WALL: USP LTW12 WITH R 10d NAILS EACH END STUD IN ATTIC BEARING WALL TO CEILING JOIST: USP LTW12 WITH 4 10d NAILS EACH END CEILING JOIST TO STUD IN SECOND FLOOR BEARING WALL: USP RT10 WITH 4 8d NAILS EACH END (USE USP LTW12 AT CONNECTIONS TO WALL HEADERS) r n STUD TO SOLE PLATE IN SECOND FLOOR BEARING WALL: (2) USP S01 CLIP ANCHORS SOLE PLATE TO FLOOR DECK: (2) #8x3" WOOD SCREWS AT 12" O.C. ATTIC FLUSH-FRAMED BEAM TO WALL STUDS AT ENDS OF BEAM: USP LTW12 WITH 6 10d NAILS EACH END OF STRAP; PROVIDE CONTINUOUS LOAD PATH DOWN TO BASEMENT BEAM USING SIMILAR SIZED STRAPS AT ALL FRAMING JOINTS. L J PROJECT: NationalInstituteof StandardsandTechnology NetZeroEnergy ResidentialTest Facility OSHEETKEYNOTES NIST Campus Gaithersburg, MD U.S. Department of Energy Research Toward Zero Energy Homes U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY MARK DATE DESCRIPTION ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION PROJECT NO: NIST NZERTF A-PLOT-PLAN-NZERTF CAD DWG FILE: CG DRAWN BY: CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: ROOF FRAMING PLAN o SCALE AS NOTED A-112 1%" X 1 V/s LSL ENGINEERED ROOF RAFTERS AT 24" O.C. WITH 4" PLYWOOD SHEATHING WITH H-CLIPS Q 7) < O m m O Q cr 1 1%" x 1 V/s" LSL ENGINEERED ROOF RAFTERS AT 24' | O.C. WITH 4" PLYWOOD SHEATHING WITH H-CLIPS cn 4^ X 2X12 COMMON RAFTERS AT 24" O.C.; 1/2" PLYWOOD SHEATHING WITH H-CLIPS 2x4 ROOF TRUSSES AT 24" O.C. W/ USP RT10 W/ 3 8-d NAILS EACH END ON EACH TRUSS; 5/8" PLYWOOD SHEATHING WITH H-CLIPS T 1 I

- 16. GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. ROOF PENETRATIONS TO BE LOCATED SO AS TO AVOID POSSIBILITY OF SHADING PHOTOVOLTAIC ARRAY. AT HOUSE, CONTINUOUS FULLY-ADHERED PEEL AND STICK ROOFING MEMBRANE TO BE APPLIED SHINGLE STYLE OVER ENTIRE ROOF INCLUDING OVERHANGS AT EAVES AND RAKES AND OVER PORCHES AND BREEZEWAY. 2. 5 6 6.1 2 3 4.1 1 4 7 3. AT HOUSE, CONTINUOUS FULLY-ADHERED PEEL AND STICK ROOFING MEMBRANE TO BE EXTENDED MIN. 12" UP PLYWOOD WALL SHEATHING AT ALL ROOF-WALL INTERSECTIONS EXCEPT WHERE PORCH OR BREEZEWAY ROOF MEETS WALL. 32'-0' 2-0' 2'-0" 8-0’ 7^ 7^ 7 ~ 7 ~ 7 ~ 4. AT HOUSE, ADDITIONAL STRIP OF FULLY-ADHERED PEEL AND STICK ROOFING MEMBRANE TO BE APPLIED AT ALL ROOF-WALL INTERSECTIONS EXTENDING MIN. 12" OVER ROOF MEMBRANE AND 12" UP FACE OF WALL INSULATING SHEATHING. F.1 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com AT GARAGE, CONTINUOUS FULLY-ADHERED PEEL AND STICK ROOFING MEMBRANCE TO BE APPLIED TO 4:12 SECTION OF ROOF AND AT EAVE OF 9.67:12 SLOPE EXTENDING A MIN. OF 36" FROM THE EXTERIOR WALL TOWARDS THE RIDGE. 5. Cl CONSULTANT: o o SEE A-603 FOR PENETRATION SCHEDULE. 6. LINE OF CLADDING BELOW F F Jr OSHEETKEYNOTES LINE OF STUD WALLS BELOW r n I LINE OF CLADDING BELOW E <D CD 1 LINE OF STUD WALLS BELOW O) CM CM T” " CD CM | R1 R2 o CJ> o o 0 CM L J CM PROJECT: SOIL GAS VENT PENETRATIONKEY E.1 NationalInstituteof StandardsandTechnology ^r PLUMBING STACK VENT R1. PLUMBING STACK VENT CM R2. SOIL GAS VENT VERTICAL RACK PV PANEL MOUNTING SYSTEM, TYP CONDUIT FOR PV ARRAY CONDUIT FOR PV ARRAY NetZeroEnergy ResidentialTest Facility R3. PV CONDUIT o CM CONDUIT FOR PV ARRAY CM CM - CD D r O R3 R3 O R3 CT> T C.1 7 ROW x 6 COLUMN PV ARRAY CD NIST Campus Gaithersburg, MD o> CM U.S. Department of Energy Research Toward Zero Energy Homes CM CM CD ^r CM 3 CD L J CD OJ C ct> U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy CD ENERGY I*- I (D C7) <75 CM B Jr 1 o LINE OF STUD WALLS iBELOW CM A A -V 06/29/10 UPDATED LINE OF CLADDING BELOW MARK DATE DESCRIPTION CM CM r n co ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION ID PROJECT NO: NIST NZERTF A.1 i "V A-PLOT-PLAN-NZERTF CAD DWG FILE: SOLAR HOT WATER PANELS CG DRAWN BY: 1 1 CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: ROOFPLAN ROOFPLAN o SCALE AS NOTED 1 SCALE: 1/4" = 1’-0" A-113

- 17. GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. LIMIT THE OVERALL ESTIMATED WASTE FACTOR ON THE FRAMING ORDER TO 10% OR LESS 2. STRUCTURAL FRAMING CONNECTIONS FOR 2x4 ROOF OVERHANG OUTRIGGERS (TO RESIST WIND UPLIFT): (1) #10 x 5" WOOD SCREW THROUGH 2x4 INTO RAFTER RIM BOARD; (1) #10 x 5" WOOD SCREW THROUGH 2x4 INTO RAFTER, 4" FROM END OF 2x4. STRUCTURAL FRAMING CONNECTIONS FOR FRONT PORCH ROOF TO RESIST WIND UPLIFT: 5 6 6.1 2 3 4.1 1 4 7 3. 15'-5" 7^ RAFTER LEDGER TO WALL STUDS: (2) %" LAG SCREWS AT 24" O.C. (MINIMUM PENETRATION INTO STUD OF 2"); 1'-0" 13'-5" r-o’ ----;L 7!------------ 7 ~ ■V r-o1 CEILING JOIST LEDGER TO WALL STUDS: (1) %' LAG SCREW AT 24" O.C. (MINIMUM PENETRATION INTO STUD OF 2"); 2X4 FASCIA NAIL ER F.1 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com 3.5" x 9.25" LSL 1.3E BEAM 1-3/4" x 9.25" LSL 1.3E BELOW RAFTER TO LEDGER: USP AC7 ANGLE BRACKET; 1-3/4" x 9.255" LSL. 1.3E BELOW CEILING JOIST TO LEDGER: 4 16d TOE-NAILS OR USE USP A3 ANGLE BRACKET. o CONSULTANT: STRUCTURAL FRAMING CONNECTIONS FOR BREEZEWAY: 24'-1 4. 2X12 RAFTERS AT 24" O.C.; ROOF SHEATHING WITH H-CLIPS; 2x6 CEILING JOISTS BELOW AT 24" O.C. iL USE TIE STRAP AT EACH RAFTER TO TIE RAFTERS TO CEILING JOISTS. 22-9' 1'-4" 2X12 LEDGER INSTALLED ON TOP OF WALL RIGID INSULATION 7' o 5. STRUCTURAL FRAMING CONNECTIONS FOR FRONT PORCH AND BREEZEWAY COLUMNS (TO RESIST WIND UPLIFT): <j> L CM Zl z N F F BEAM TO STRUCTURAL COLUMN AND COLUMN BASE TO SONOTUBE CONNECTION TO FOLLOW COLUMN SUPPLIER'S INSTRUCTIONS; UPLIFT LOAD IS 800 LBS NOMINAL. -v U t w ___I J i i 2X4 FASCIA NAILER 2X4 OUTLOOK AT 24" O.C. INSTALLED ON TOP OF ROOF SHEATHING WITHIN ROOF RIGID INSULATION, TYP. 2X6 FASTENED BACK --------- — -----------T0-2X8 LEDGER, TYP. 6. STRUCTURAL FRAMING CONNECTIONS FOR SCREEN PORCH ROOF (TO RESIST WIND UPLIFT AND FOR BRACING): / r i i :i 2X LEDGER ON TCP OF ROOF RIGID INSULATION FASTEN 2x LEDGER AT SLOPE-CUT ENDS OF RAFTERS TO WALL STUDS AT 24" O.C. USING (2) %" LAG SCREWS, TOP AND BOTTOM, PENETRATING MINIMUM 2-1/2" INTO STUDS ALONG LENGTH OF LEDGER; E m L 2X8 LEDGER INSTALLED ON TOP OF WALL RIGID INSULATION 2X4 FASCIA NAIL ER A-/ 2X4 OUTLOOK ON TOP OF ROOF SHEATHING WITHIN ROOF RIGID INSULATION, TYP. 24" O.C. INSTALLED 15'-0" FASTEN PORCH ROOF SHEATHING TO LEDGER USING 8d COMMON NAILS AT 3" O.C. "7 ~ 4'-0' 7'-0' 4-0' 7 ~ -7<- -7<- 7 ~ L J 2x FRAMING MEMBERS TO BE FSC-CERTIFIED. 7. 2X4 LEDGER INSTALLED ON TOP OF ROOF SHEATHING -v PROJECT: (2)1.75" x 9.25 LSL 1.55E BEAM oo i m. H m E.1 J -V NationalInstituteof StandardsandTechnology ;l i m 2X4 FASCIA NAIL ER OSHEETKEYNOTES CNJ 1 I uJ l±l J 2X4 OUTLOOK AT 24" O.C. INSTALLED ON TOP OF ROOF SHEATHING WITHIN ROOF RIGID INSULATION, TYP. —u o 2X12 RAFTERS AT 24" O.C. ; §" ROOF SHEATHING WITH H-CLIPS; 2x6 CEILING JOISTS BELOW AT 24" O.C. 1. CONCEALED HANGER SCREWED THROUGH INSULATION TO BLOCKING IN HOUSE WALL NetZeroEnergy ResidentialTest Facility LO -V CNJ ■ 2x12 RIDGE BOARD (2)1.75" x 9.25 LSL 1.55E BEAM "1 CM J fry n T3 A ll O D r j- — L i m m C.1 "V m 3 m 00 NIST Campus Gaithersburg, MD ■ STRUCTURAL COLUMN, TYP. 2X4 FASCIA NAILER m U.S. Department of Energy Research Toward Zero Energy Homes m m CO ■'vf CD CNJ r c I J' L T U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY 2X4 FASCIA NAILER S) 2X4 OUTLOOK AT 24" O.C. INSTALLED ON TOP OF ROOF SHEATHING WITHIN ROOF RIGID INSULATION, TYP. 2X4 LEDGER INSTALLED ON TOP OF ROOF SHEATHING 1 r B ■V HATCH INDICATES EXTENT OF MAIN HOUSE FRAMING CD II It r n r i r <N A A -V 2X LEDGER ON TOP OF ROOF RIGID INSULATION 2X10 LEDGER INSTALLED ON TOP OF WALL RIGID INSULATION 1 -3/4" x 9.25 LSL 1,3E BELOW STRUCTURAL COLUMN, TYP. / <D 1 MARK DATE DESCRIPTION 2X4 FASCIA NAILER 2XLEDGER ON TOP OF ROOF RIGID INSULATIO 2X12 RAFTERS AT 24" O.C. ; §" ROOF SHEATHING WITH H-CLIPS; 2x6 CEILING JOISTS BELOW AT 24" O.C. K ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION CNJ LD O CD (2)1.75" x 9.25 LSL 1.55E BEAM (2)1.75" x 9.25 LSL 1.55E BEAM (2)1.75" x 9.25 LSL 1.55E BEAM l PROJECT NO: NIST NZERTF z. ii! A.1 -v A-PLOT-PLAN-NZERTF CAD DWG FILE: 2X4 FASCIA NAILER (2) 1-3/4" x 9.25" L 1.3E BELOW 3L 00 CG DRAWN BY: -v -N- CHECKED BY: BP , 2'-0' 1'-(» 1/2" 2'-0" , 1'-6 1/2' 7 ~ V- v- COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION ir-11" 11'-7' 11 ’-7' 7 — v- 7 7 — 7 ~ 1-9 1/2' -9 1/2' 1 SHEET TITLE: 6-8' 1'-4" 7 ~ / y- LOWERROOF OVERHANG FRAMINGPLAN 38-8' 8-0' 7 — 7 I LOWERROOFOVERHANGFRAMINGPLAN o SCALE AS NOTED z 1 SCALE: 1/4" = 1'-0" A-114

- 18. GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. LIMIT THE OVERALL ESTIMATED WASTE FACTOR ON THE FRAMING ORDER TO 10% OR LESS 2. STRUCTURAL FRAMING CONNECTIONS FOR 2x4 ROOF OVERHANG OUTRIGGERS (TO RESIST WIND UPLIFT): (1) #10 x 5" WOOD SCREW THROUGH 2x4 INTO RAFTER RIM BOARD; (1) #10 x 5" WOOD SCREW THROUGH 2x4 INTO RAFTER, 4" FROM END OF 2x4. 2x FRAMING MEMBERS TO BE FSC-CERTIFIED. 5 6 6.1 2 3 4.1 1 4 7 3. F.1 f" 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com CONSULTANT: 34-8' 1-4" , 2-0 28’-0’ ■ 2-0" r-4" 7^ 7^ 7 “ “V LO CM Irtt CM F F -V OSHEETKEYNOTES ii— i o o CM CM -V r n i r i E f * L J L PROJECT: E.1 in n NationalInstituteof StandardsandTechnology r-: v; X i .J, pi CO CM CO NetZeroEnergy ResidentialTest Facility CO -T]- CM CO CO CO D I jj- C.1 NIST Campus Gaithersburg, MD 4f U.S. Department of Energy Research Toward Zero Energy Homes -j| •*r & 2X4 FASCIA NAILER, TYP. c I_ 2X4 OUTLOOK AT 24" O.C. INSTALLED ON TOP OF ROOF SHEATHING WITHIN ROOF RIGID INSULATION, TYP. U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY ■M- 2X4 INSTALLED ON TOP OF ROOF SHEATHING, TYP. r,J ± -zs i HATCH INDICATES EXTENT OF MAIN HOUSE FRAMING B t I O O I I CM CM I A A -V -V I U CM CM MARK DATE DESCRIPTION ■v ■V ■V ■V ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION 1’-4" 2-0 28’-0' 2’-0" 1’-4" -7^- 7 34-8' PROJECT NO: NIST NZERTF A.1 A-PLOT-PLAN-NZERTF CAD DWG FILE: CG DRAWN BY: CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: UPPERROOF OVERHANG FRAMINGPLAN i UPPERROOFOVERHANGFRAMINGPLAN o SCALE AS NOTED z 1 SCALE: 1/4" = 1'-0" A-115

- 19. FIRSTFLOORREFLECTEDCEILINGPLAN SCALE: 1/4"= 1'-0 ii r -i i HT i EQ. EQ. O -7 + CO LU ■7 ■ I -V CM CM ,S4 0 LU 2'-8 11 0 0 LU LU IEI -v EQ. EQ. a LU 2'-0' 2'-0' :S4 -v 7L 7^ 7L ■^7 EQ. EQ. CO -p - CM SLOPED CEILING CO I O a LU R4; LU r-6 1/2" 7 ^ a LU I I I 7, EQ. EQ. O -7 0 ACCESS - ATTIC PULL DOWN STAIR LU LU EQ. EQ. MR4 + ~A a o 2-0 M2'K LU U iV I I II UJ !r 1'-1 3/4’ 1'-1 3/4’ -- 3'-6 1/4' CM 4-4" 1 CM LO O 1/2 M CO f a 0 CO CO LU LU Kl EQ. EQ. EQ. EQ. 7L 7L "7 -v -v -v EQ. EQ. 7L - ^ “7 5> CM a o (J) LU LU CD I__ SECONDFLOORREFLECTEDCEILINGPLAN SCALE: 1/4" = 1'-0" SLOPED CEILING 10 1/2 11 CM CM CO o I CM CO ;R3 5-11 1/4’ 11-1 M 5-11 1/4’ 10 1/2" CM CM O CO I I CO CM ■r ’c &-8" A.F.F. 7’-6" A.F.F. GENERALSHEETNOTES BUILDINGSCIENCE CORPORATION 1. CEILING ELEMENTS SHOWN FOR LOCATION ONLY; SEE E-001 FOR LIGHT FIXTURE SCHEDULE; SEE M-001 FOR DUCTWORK LEGEND. REFER TO MECHANICAL AND ELECTRICAL DRAWINGS FOR FIXTURE AND GRILLE SPECIFICATIONS. 2. ALL CEILING HEIGHTS AT 9’-0" A.F.F., UNLESS OTHERWISE NOTED. 3. SEE SPRINKLER PLAN FOR SPRINKLER HEAD LOCATIONS. DIMENSIONS ARE TO FACE OF STUD AND CENTER OF CEILING ELEMENT. 4. SITE-BUILT ACCESS PANELS FIT WITHIN FRAMING MEMBERS ABOVE. SEE FRAMING PLANS FOR SIZE AND LOCATION. APPLY 1-1/2" x %" FLAT TRIM AROUND EDGE OF PANEL. PANEL TO BE FASTENED AND REMOVABLE FROM BELOW WITHOUT REMOVING THE TRIM. PANEL FINISH TO MATCH CEILING FINISH. SEE 7/A-508. 5. 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com CROWN MOULDING EXTENDS 5" FROM GWB, SEE INTERIOR ELEVATIONS FOR EXTENT OF CROWN MOULDING. 6. CONSULTANT: r n L j PROJECT: NationalInstituteof StandardsandTechnology NetZeroEnergy Residential Test Facility NIST Campus Gaithersburg, MD MSS U.S. Department of Energy Research Toward Zero Energy Homes U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY MARK DATE DESCRIPTION ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION PROJECT NO: NIST NZERTF A-PLOT-PLAN-NZERTF CAD DWG FILE: CG DRAWN BY: CHECKED BY: BP COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION SHEET TITLE: FIRST&SECOND FLOORREFLECTED CEILINGPLANS o SCALE AS NOTED A-121 T EQ. EQ. „6-,8 O e o m m * ~o -Y- 3-0 1/2" 3-0 1/2" o CD TO TO o o m m 4^ 4^ o o ¥- EQ. EQ. CO CO 4. 4- ACCESS PANEL □ 7'-6" A.F.F. IM) 00 CM CM CM EQ. EQ. 4. CM D * A an -4- o EQ. EQ. 4 CO TO m CM TO CM ro ro TO TO TO ACCESS PANEL o ^7 CM o m co r “F 7'-9" A.F.F. CN TO I I + CO ¥■ 3'-2' 4'-3" 4'-4 1/2" o 2'-7 3/4" 1 CO CO CM I'D •v -v CM U * CO O CO CO ■ 'Jr CO LO m CM CM o CM CM CM CM 4 CH TO m CO Ob o CO GO 4 II 6'-8" A.F.F. II 0 m CO 4^ LO -Y EQ. EQ. -V TO EQ. EQ. -4 4 LL EQ. 0 EQ. 0 EQ. , EQ. ACCESS PANEL LL m m -Y < 4^ 4-4' TO 00 CO CO 0 -4 -4 4- ,.t7/e l - z m CM n 4, 4, J L ----------- 1

- 20. GENERALSHEETNOTES B D F A.1 A BUILDINGSCIENCE CORPORATION 1. FIRST FLOOR SOFFITS AND SECOND FLOOR SOFFITS TO ALIGN AROUND PERIMETER OF HOUSE. SEE A-601 FOR WINDOW SCHEDULE. 2. 3. SEE A-603 FOR PENETRATION SCHEDULE. 1 SIDING TO BE PAINTED P-12. 4. A-304 ALL TRIM AND SOFFITS TO BE PAINTED P-13. 5. SOIL GAS VENT 12 ALL DOORS TO BE PAINTED P-14. 6. 12 © © 4 CEILINGS OF PORCHES AND BREEZEWAY TO BE PAINTED P-15. 7. 4 R2 FRONT PORCH AND BREEZEWAY COLUMNS TO BE PAINTED P-13. 8. © 12 12 9. EL. +0'-0" IN THE ARCHITECTURAL DRAWINGS CORRESPONDS TO 461.30' IN THE SITE/CIVIL DRAWINGS. 9.67 9.67 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com IF THE HIGH VELOCITY HVAC OPTION IS NOT AWARDED, THE PENETRATION FOR THE CONNECTION WILL NOT BE PROVIDED. 10. 4 B.O. CEILING JOISTS ALIGN EL. +19-7 1/4ii <£> 2k 2k 2k OSHEETKEYNOTES 2 © D © CONSULTANT: 1. ASPHALT ROOF SHINGLES (*> B 2. 1" x 8f" FRIEZE BOARD TRIM MOULDING f x 8 TRIM WITH 3" CROWN MOULDING 1" X 85" TRIM FIBER CEMENT SIDING, 4" EXPOSURE 2x2 TRIM 12 12 22 12 3. 9.67 12 9.67 4 4 4. 12 4 5. $ T.O. SECOND FLOOR SUBFLOOR EL. +10-6 1/411 6. ALIGN f x 10 TRIM 1" x 4 5" WINDOW TRIM BUILT-UP WINDOW CROWN 1" x 6" DOOR TRIM 7. © $ B.O. FLOOR JOISTS 2k ±k 2k 2k. EL. +9'-3 3/811 8. 24 © 9. F F r n 23 10. 28 BUILT-UP DOOR CROWN 5/4 x 8 TRIM f x 6 RAKE EDGE TRIM WITH 3" CROWN MOULDING 11. I CONDUIT FOR FUTURE GAS FURNACE SUPPLY/EXHAUST 12. A A 13. © E3 U E3 □ E3 □ E3 E4 1" x 81" BEAM TRIM EGRESS WINDOW WELL AND LADDER ©© 14. T.O. FIRST FLOOR SUBFLOOR F'0 F9 F4 F10 E11 E11 15. $ Or EL. +0-2 3/8 II L J CONNECTION FOR FUTURE MULTISPLIT OUTDOOR UNIT 1'5 T.O. FOUNDATION WALL r 16. STONE VENEER AT GARAGE FOUNDATION WALL / CONDUIT SUMP PUMP OUTLET r 29 EL. +0-0 PROJECT: 17. CONCRETE DECK CONNECTION FOR FUTURE AIR-TO-AIR OUTDOOR UNIT CONNECTION FOR CENTRAL AIR-TO-AIR OUTDOOR UNIT © 18. CONCRETE WALL WITH STONE VENEER EDGES CONNECTION FOR FUTURE HIGH VELOCITY HVAC AIR-TO-AIR OUTDOOR UNIT (SEE GENERAL SHEET NOTE #10) JHI Jt NationalInstituteof StandardsandTechnology 19. LOAD-BEARING COLUMN B 20. EXTERIOR LANTERN 21. PV ARRAY J'L NetZeroEnergy ResidentialTest Facility 22. SOLAR COLLECTOR (HOT WATER SYSTEM) 23. SCREEN PANEL l_ J RIGHTSIDE(EAST)ELEVATION 2 SCALE: 1/4" = 1'-0" 24. PREFABRICATED PILASTER 25. FIBER CEMENT PANEL 5 1 2 3 6 4 7 26. FIBER CEMENT TRIM NIST Campus Gaithersburg, MD 27. 2" SILL 28. KICK-OUT FLASHING 29. ALUMINUM COIL STOCK COVERING 1 2 1 1 1 U.S. Department of Energy Research Toward Zero Energy Homes A-305 A-305 A-303 A-302 A-301 OWINDOWKEY A. 3-0" x 5'-5" DH U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy ENERGY 3'-2^" x 5-2" DH B. © c. 2'-1" x 3'-7" DH © D. 2'-8" x 2'-3" AWN E. 2'-3" x 4'-0" DH © B.O. CEILING JOISTS 3'-4" x 2'-3" AWN F. EL. +19-7 1/4II 08/03/10 UPDATED G. 3'-4" x 2'-7" AWN 8 2 07/27/10 UPDATED 06/29/10 UPDATED © PENETRATIONKEY © © © MARK DATE DESCRIPTION © ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION B B B B B E1. COLLECTOR PANEL CONDUIT EXTERIOR LANTERN E2. PROJECT NO: NIST NZERTF © E3. WEATHER PROTECTED OUTLET A-PLOT-ELEV-NZERTF CAD DWG FILE: T.O. SECOND FLOOR SUBFLOOR CG DRAWN BY: E1 E1 E4. CONDUIT FOR FUTURE GAS FURNACE EL. +10-6 1/411 © CHECKED BY: BP E5. DRYER VENT * B.O. FLOOR JOISTS COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION E6. RANGE HOOD VENT EL. +9'-3 3/811 © HRV EXHAUST E7. SHEET TITLE: <•> A A E8. HRV INLET E2 E2 □□□□ □□□□ □□□□ EXTERIOR ELEVATIONS <Z> E9. INSTRUMENTATION CONDUIT E2 E2 A A A A A 19 29 E10. CONDUIT FOR FUTURE GAS WATER HEATER © A / E11. FUTURE MULTI-SPLIT OUTDOOR UNIT CONNECTION T.O. FIRST FLOOR SUBFLOOR ^ 16 EL. +0-2 3/8 =«^= I E12. HOSE BIBB OUNDAT ON WALL CONDUIT FOR COLLECTOR PANEL THROUGH WALL AT RIM JOIST UNDER FRONT PORCH ROOF I L. +0'-0 F4. SUMP PUMP OUTLET o SCALE AS NOTED z r ■ ! F9. AIR-TO-AIR OUTDOOR UNIT CONNECTION O. GARAGE SLAB (LOWEST PT) A, EL. -2'-4" (458.3T) T. F10. FUTURE AIR-TO-AIR OUTDOOR UNIT CONNECTION A-201 FRONT(SOUTH)ELEVATION 1 R1. PLUMBING STACK VENT SCALE: 1/4" = 1'-0" R2. SOIL GAS VENT

- 21. GENERALSHEETNOTES F D B E C A A.1 BUILDINGSCIENCE CORPORATION 1. FIRST FLOOR SOFFITS AND SECOND FLOOR SOFFITS TO ALIGN AROUND PERIMETER OF HOUSE. I SEE A-601 FOR WINDOW SCHEDULE. 2. 3. SEE A-603 FOR PENETRATION SCHEDULE. 1 SIDING TO BE PAINTED P-12. 4. A-304 ALL TRIM AND SOFFITS TO BE PAINTED P-13. 5. PLUMBING STACK VENT ALL DOORS TO BE PAINTED P-14. 6. I 12 4 12 CEILINGS OF PORCHES AND BREEZEWAY TO BE PAINTED P-15. 7. 4 R1 © FRONT PORCH AND BREEZEWAY COLUMNS TO BE PAINTED P-13. 8. 12 12 9. EL. +0'-0" IN THE ARCHITECTURAL DRAWINGS CORRESPONDS TO 461.30' IN THE SITE/CIVIL DRAWINGS. 13 9.67 9.67 12 30 FOREST STREET SOMERVILLE, MA T: (978) 589-5100 F: (978) 589-5103 www.buildingscience.com <E> 4 B.O. CEILING JOISTS OSHEETKEYNOTES ALIGN EL. +19-7 1/4n © © ± 2 1. ASPHALT ROOF SHINGLES D © CONSULTANT: 1" x 8f" FRIEZE BOARD TRIM MOULDING f x 8 TRIM WITH 3" CROWN MOULDING 1" X 85" TRIM FIBER CEMENT SIDING, 4" EXPOSURE 2x2 TRIM f x 10 TRIM 1"x4 WINDOW TRIM BUILT-UP WINDOW CROWN 1" x 6" DOOR TRIM BUILT-UP DOOR CROWN 5/4 x 8 TRIM 2. © © 3. A 4. © 12 22 I 5. 4 12 23 6. 4 HRV 4 T.O. SECOND FLOOR SUBFLOOR 7. INLET E9 EL. +10-6 1/4" □ 8. O ALIGN E8 ± 9. 4 B.O. FLOOR JOISTS ^lz EL. +9-3 3/8" 10. : © 11. r n © 12. 27 E2 © f x 6 RAKE EDGE TRIM WITH 3" CROWN MOULDING 1" x 81" BEAM TRIM EGRESS WINDOW WELL AND LADDER STONE VENEER AT GARAGE FOUNDATION WALL 13. 25 A 28 ©© 14. E3 E3 19 15. o □ © 16. 4 T.O. FIRST FLOOR SUBFLOOR 17. CONCRETE DECK EL. +0-2 3/8" tr L J CONCRETE WALL WITH STONE VENEER EDGES T.O. FOUNDATION WALL 18. © EL. +0-011 PROJECT: 19. LOAD-BEARING COLUMN □ CONDUIT FOR INSTRUMENTATION THROUGH WALL AT RIM JOIST UNDER BREEZEWAY ROOF 20. EXTERIOR LANTERN NationalInstituteof StandardsandTechnology 4 T.O. GARAGE SLAB (LOWEST PT) EL. -2'-4" 21. PV ARRAY 22. SOLAR COLLECTOR (HOT WATER SYSTEM) 23. SCREEN PANEL NetZeroEnergy Residential Test Facility LEFTSIDE(WEST)ELEVATION 24. PREFABRICATED PILASTER 2 25. FIBER CEMENT PANEL SCALE: 1/4" = 1'-0" 26. FIBER CEMENT TRIM 5 6 4 3 2 1 7 27. 2" SILL 28. KICK-OUT FLASHING NIST Campus Gaithersburg, MD 29. ALUMINUM COIL STOCK COVERING I I I 1 1 1 3 1 A-301 A-302 A-303 A-305 A-305 U.S. Department of Energy Research Toward Zero Energy Homes oWINDOWKEY I I I R2 R1 A. 3-0" x 5'-5" DH SOIL GAS VENT 3'-25" x 5'-2" DH B. U.S. DEPARTMENT OF Energy Efficiency & Renewable Energy © ENERGY c. 2'-1" x 3'-7" DH PLUMBING STACK VENT © 2'-8" x 2'-3" AWN D. I I I I © E. 2'-3" x 4'-0" DH F. 3-4" x 2'-3" AWN 4 B.O. CEILING JOISTS EL. +19-7 1/411 G. 3-4" x 2'-7" AWN © I I I 08/03/10 UPDATED cm rm <*> <D 07/27/10 UPDATED □m □m G G PENETRATIONKEY 06/29/10 UPDATED E E MARK DATE DESCRIPTION © COLLECTOR PANEL CONDUIT E1. ISSUE: 03/31/10 ISSUED FOR CONSTRUCTION I I I E2. EXTERIOR LANTERN PROJECT NO: NIST NZERTF E3. WEATHER PROTECTED OUTLET DRYER VENT RANGE HOOD HRV EXHAUST IN SOFFIT — VENT IN SOFFIT " IN SOFFIT 4 T.O. SECOND FLOOR SUBFLOOR A-PLOT-ELEV-NZERTF CAD DWG FILE: CONDUIT FOR FUTURE GAS FURNACE E4. EL. +10-6 1/4" CG a hi DRAWN BY: t± m 3 E5. DRYER VENT XL n xu f CHECKED BY: BP 4 B.O. FLOOR JOISTS E6 E5 E7 E6. RANGE HOOD VENT EL. +9-3 3/8" © COPYRIGHT © 2009 BUILDING SCIENCE CORPORATION an □m E7. HRV EXHAUST © rn nnn SHEET TITLE: © E8. HRV INLET E2 E2 C C 19 E E © E9. INSTRUMENTATION CONDUIT EXTERIOR ELEVATIONS A 27 © E10. CONDUIT FOR FUTURE GAS WATER HEATER A A E3 ZL ?| E12 O E10 E11. FUTURE MULTI-SPLIT OUTDOOR UNIT CONNECTION E3 4 T.O. FIRST FLOOR SUBFLOOR ©© E3 O EL. +0-2 3/8" I I T E12. HOSE BIBB 4 T.O. FOUNDATION WALL L. EL. +0-0M o()o F4. SUMP PUMP OUTLET I 29 cr HOSE O SCALE AS NOTED AIR-TO-AIR OUTDOOR UNIT CONNECTION F9. z CONDUIT FOR FUTURE GAS WATER HEATER SUPPLY/EXHAUST BIBB 4 T.O. GARAGE SLAB (LOWEST PT) FUTURE AIR-TO-AIR OUTDOOR UNIT CONNECTION F10. EL. -2'-411 A-202 REAR(NORTH)ELEVATION R1. PLUMBING STACK VENT SCALE: 1/4" = 1'-0" R2. SOIL GAS VENT