Effects of Macrocycle Time and Sampling Rates on Control Loop Performance

- 1. Effects of Macrocycle Time and Sampling Rates on Control Loop Performance Dan Daugherty – Sr. Engineer – Product Engineering Ferrill Ford – Sr. Engineer – Product Engineering Mark Coughran – Sr. Industry Consultant – Industry Solutions Group

- 2. Presenters Dan Daugherty Mark Coughran Ferrill Ford

- 3. Why F OUNDATION Fieldbus perceived as slow by some Control Response specifications by end user or process licensor Lack of actual field data Questionable recommendation for oversampling (module execution = 2x macrocycle)

- 4. What Safe place to do a controlled test on a real process Availability of both F OUNDATION Fieldbus and 4-20 mA loops Ability to test Control Response period load frequency response setpoint step response

- 5. Lab setup for hydraulic pressure control Fluid process dynamics are negligible Significant dynamics are in the sensor/transmitter, control valve, controller, communications Control valve first with DVC6010f, then DVC6010 PT FF, 4-20 were Rosemount 3051C PT FAST were Toolkit, 100 Hz All signals recorded with Emerson’s EnTech ™ Toolkit

- 6. 3 rd Loop – Marshalltown Flow Lab PV PT Disturbance EnTech Toolkit

- 7. Timing – 4-20mA PID D/A Conversion DVC 4-20/HART Pneumatic Actuator DVC dead time and time constant Load Valve Motion Hydraulic Pressure (Process) Change 3051 4-20/HART output 3051C Dead Time and Time Constant A/D Conversion

- 8. Timing – FF CIF FF PID FF AO Pneumatic Actuator DVC dead time and time constant Load Valve Motion Hydraulic Pressure (Process) Change 3051 FF AI 3051C Dead Time and Time Constant FF Compel Data

- 9. Control Response Period by subtraction 4-20 mA / HART 0.05 sec Load Valve Motion Hydraulic Pressure (Process) 3051C Dead Time and Time Constant 3051C 4-20 output PID A/D DVC 4-20 input D/A DVC6000 Dead Time and Time Constant Pneumatic Actuator Fast Reference Pressure Sensor 0-750 psig Fast Reference Pressure Sensor 0-50 psig Control Response Period Typical Customer Spec. 0.07 sec Measured Loop Dead Time In Load Step Test

- 10. Control Response Period by subtraction Foundation Fieldbus Control-In-the-Field (CIF) 0.10 sec Load Valve Motion Hydraulic Pressure (Process) 3051 Dead Time and Time Constant 3051 FF AI FF PID FF Compel Data FF AO DVC6000f Dead Time and Time Constant Pneumatic Actuator Fast Reference Pressure Sensor 0-750 psig Fast Reference Pressure Sensor 0-50 psig Control Response Period Typical Customer Spec. 0.07 sec Measured Loop Dead Time In Load Step Test

- 11. Load step tests for Control Response Period Step the output to the load valve The PID control loop approximates proportional-only action Gain = 0.5 Reset = 100000 Fit the responses in Emerson’s EnTech ™ Toolkit Only the “dead time” part of the measurement is significant Subtract the response times of transmitter and control valve that are not defined as part of Control Response Period Average the results from at least 10 measurements

- 12. Sample Control Response Period measurement CIC, module execution = 1.0, macrocycle = 0.5 1.37 – 0.10 – 0.07 = 1.20 seconds

- 13. Sample Control Response Period measurement 4-20 mA, module execution = 0.2 0.30 – 0.05 – 0.07 = 0.18 seconds

- 14. Sample histogram from 21 measurements CIC, module execution = 1.0, macrocycle = 0.5 Mean value of raw dead time = 1.39 seconds Corrected value (Control Response Period) = 1.22 seconds

- 15. Control Response Period results overview 4-20 mA, DeltaV Control in DVC (CIF) Control in DeltaV (CIC) 2:1 Control in DeltaV (CIC) 4:1 Control in DeltaV (CIC) 1:1 Ratio for Fieldbus Control in DeltaV is Module Execution : Macrocycle

- 16. Lambda Tuning for self-regulating processes Closed Loop (Auto) No oscillation is the closed-loop time constant Choose the speed Open loop (Manual) is the open-loop time constant SETPOINT PV 63% 63% PV OUT

- 17. Lambda Tuning for self-regulating process sample Manual step 5% on controller output

- 18. Average process dynamics and recommended tuning

- 19. Controller tuning philosophy Only needed for sine wave load disturbance and setpoint response tests Does not apply to a Control Response Period specification Lambda = 1.5 seconds is fast relative to typical tuning of flow and pressure loops in the field Is based on fast controller execution In principle, this should be changed (detuned) as we increase either module execution time or macrocycle In practice, we didn’t have time to customize tuning for each combination of communication method, module execution, and macrocycle

- 20. Theoretical setpoint step response

- 21. Theoretical load frequency response

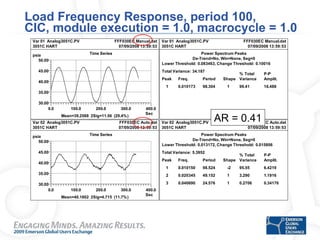

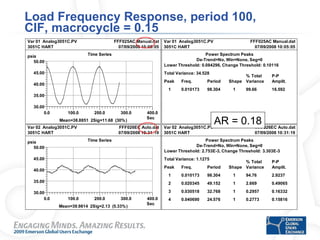

- 22. Load Frequency Response Tests—Introduction and Notation Sinusoidal output to the load valve Most tests used disturbance period = 100 seconds This period gives the feedback loop a chance to attenuate a significant amount of the variability Same PID tuning for all: Gain = 0.35, Reset = 0.48 CIC ≡ Fieldbus, DeltaV, DVC6000f CIF ≡ Fieldbus, DVC6000f Analog ≡ 4-20 mA, DeltaV, DVC6000 AR ≡Amplitude Ratio Auto Amplitude / Manual Amplitude

- 23. Load Frequency Response, period 100, CIC, module execution = 1.0, macrocycle = 1.0 AR = 0.41

- 24. Load Frequency Response, period 100, CIC, module execution = 0.5, macrocycle = 0.5 AR = 0.26

- 25. Load Frequency Response, period 100, CIC, module execution = 1.0, macrocycle = 0.5 AR = 0.38

- 26. Load Frequency Response, period 100, CIF, macrocycle = 0.15 AR = 0.18

- 27. What if 8 loops on the FF segment? CIC (DeltaV) theoretical

- 28. What if 8 loops on the FF segment? CIF (DVC) theoretical

- 29. Conclusions with more loops on the segment Shows even more reason to use CIF CIF should be fast enough for nearly all loops in the plant Exceptional loops already have dedicated controllers; e.g. surge control, compressor lube oil Even these applications can be handled in some cases with CIF; see Rezabek and Peluso, EGUE2008

- 30. Business Results Achieved Density on Fieldbus segments Identifying latency ‘opportunities’ Avoid slow responses

- 31. Acknowledgements In the Marshalltown lab, thanks to Rick Osborne Mike Himes Kyle Hokanson Others Other Emerson sponsors Advanced Applied Technologies in PS&S

- 32. Summary Foundation Fieldbus Control-In-the-Field proved Control Response Period equal to macrocycle Can get 0.18 seconds, adequate for almost all loops Foundation Fieldbus Control-In-the-Controller/Host Control Response Period can be much greater than expected C-I-C not recommended to get full benefit from Fieldbus Oversampling (Module Execution>Macrocycle) did not show any benefit Your comments and questions are welcome

- 33. Where To Get More Information [email_address] Ferrill. [email_address] [email_address] John Rezabek in Control Magazine (www.controlglobal.com); July 2008 “Ready for Control in the Field?”; November 2007 “Load ‘Em Up!” John Rezabek and Marcos Peluso, EGUE2008, “Field- based control for compressor anti-surge” Pang et al., “Analysis of control interval for foundation fieldbus-based control systems”, ISA Transactions , Volume 45, Number 3, July 2006, pages 447-458.

- 35. Setpoint Step Tests—Introduction and Notation Timing of the setpoint steps was not automated Same PID tuning for all: Gain = 0.35, Reset = 0.48 CIC ≡ Fieldbus, DeltaV, DVC6000f CIF ≡ Fieldbus, DVC6000f Analog ≡ 4-20 mA, DeltaV, DVC6000 AST ≡ Average Settling Time Settling time ≡ dead time plus four time constants from first-order curve fit

- 36. Setpoint step test sample data

- 37. Setpoint step test sample data

- 38. Setpoint step test sample data

- 39. Setpoint step test conclusions Did not attempt to optimize PID tuning for each case All SP responses were stable and quick, with settling time on the order of 5* as per theory Settling times generally faster with smaller module execution time and/or macrocycle The limit cycle caused by control valve nonlinearity makes it difficult to measure or compare the responses

Editor's Notes

- #17: Unlike older tuning methods such as Ziegler-Nichols, Lambda tuning gives a smooth non-oscillatory response. But equally important is the ability to design Lambda for the loop requirements. Lambda can be selected based on the performance requirements of the particular loop to separate the dynamics of interacting loops to establish fast vs. slow for inner vs. outer (slave vs. master) loops The testing that we use to determine the process dynamics, required for Lambda tuning, also identifies problems with the control equipment.

- #19: Unlike older tuning methods such as Ziegler-Nichols, Lambda tuning gives a smooth non-oscillatory response. But equally important is the ability to design Lambda for the loop requirements. Lambda can be selected based on the performance requirements of the particular loop to separate the dynamics of interacting loops to establish fast vs. slow for inner vs. outer (slave vs. master) loops The testing that we use to determine the process dynamics, required for Lambda tuning, also identifies problems with the control equipment.

- #22: Add experimental data to support the Bode plot

![Where To Get More Information [email_address] Ferrill. [email_address] [email_address] John Rezabek in Control Magazine (www.controlglobal.com); July 2008 “Ready for Control in the Field?”; November 2007 “Load ‘Em Up!” John Rezabek and Marcos Peluso, EGUE2008, “Field- based control for compressor anti-surge” Pang et al., “Analysis of control interval for foundation fieldbus-based control systems”, ISA Transactions , Volume 45, Number 3, July 2006, pages 447-458.](https://image.slidesharecdn.com/emerson-exchange-effects-of-macrocycle-time-and-sampling-rates-on-control-loop-100113161005-phpapp02/85/Effects-of-Macrocycle-Time-and-Sampling-Rates-on-Control-Loop-Performance-33-320.jpg)