Electro Hydro Governing system for turbine ppt

- 2. What is a Governing System To govern means to control and regulate certain parameters to achieve expected results. Turbine Governing system is meant for regulation of turbine speed under no load and varying load condition. It helps in precise control of grid frequency under normal operation and protects the machine as well as grid during emergency situation.

- 3. Gov System of KWU M/C •KWU machines are equipped with Hydraulic and Electro-hydraulic governing system . •Under normal operating condition EH governing system is used •Hydraulic governing system is used as backup governing system on failure of EH governing.

- 4. Electro Hydraulic converter Mechanical Hydraulic converter EL HYD HYD HYD M I N Hydraulic Actuation System for Control v/v positioning Structure of KWU Gov System

- 5. Electro hydraulic governing (EHC) Electro hydraulic controller is an integral part of EAST(Electronic Automation for turbine) supplied with KWU turbines. The EHC has a task to control the steam flow to the turbine by positioning of HP & IP control valves and •control speed during start up •control load of TG after synchronization

- 6. ADVANTAGES OF EHC • i) Increases the life of turboset by conservative operation with the aid of TSE • ii)High operational reliability and safety with integrated circuits , as well as speed and load measurement in multiple channels • iii) Precise maintenance of the rated frequency of the power grid by means of an exact frequency load curve. • iv) Low speed deviation under all operational conditions. • v) Support of the pressure control system

- 7. Elements of EHC • EHC can be divided into following sub-sections: • 1 Speed measurement and Speed controller • 2 Load measurement and Load controller • 3 Pressure controller • 4 Selection circuit(Control mode selection) • 5 Admission /Position Controller

- 8. Speed Control loop Load Control loop Pressure Control loop Selection Circuit Admission control loop EL HYD Structure of EHC

- 9. Speed Controller • Is used to increase turbine speed from barring speed to rated speed in a controlled manner . • To assist Auto synchronizer in synchronizing the machine and taking the block load. • After synchronization speed controller can be used for taking load up to 100% but as a normal practice approx. after 10% of load ,load controller is taken into service. It is done because during speed controller mode a small frequency change will cause corresponding opening in valve ( hence in load)

- 10. Speed controller can be divided into sub sections Speed set point, Speed set point control, Dn/Dt monitoring, Speed control Loop, No load correction. • a) Speed set point can be changed from cabinet, desk, auto Synchronizer and SGC turbine. The set point is called nR. The set point changes at a gradient of 2160 rpm/min up to a setting 2820 rpm. After 2820rpm speed set point changes at a gradient of 360 rpm/min which enables accurate setting of set point in the working range .

- 11. 1a Speed measurement • Hall probes are mounted around a disc (fitted at the turbine shaft) containing 120 magnets (60 N-pole & 60-S pole alternatively) . An advantage of the same is that one rotation of disc will generate 60 positive pulses & So, by counting the pulses for one second we can directly determine the turbo set speed in rpm.

- 12. b) Speed Set Point control • Speed Set Point control :- The set point fixed in the earlier section cannot be passed to speed control loop directly as it is only the desired value which can be changed at a very fast rate and it does not take care of turbine stress margin. Speed set point control circuit decides the acceleration of the turbine depending on TSE margins.

- 13. c) Dn/Dt Monitoring This section detects low acceleration of turbine and brings back the turbine speed to a safe speed of 600 rpm. Dn/ Dt acts when following conditions are fulfilled • A hrnc is more than 0.0 V • B All E S V’s open. • C Generator circuit breaker in open condition. • D Actual speed (n a c t) < 2850 rpm. • E Speed set point (nR) > 2850 rpm • F Dn/Dt < 108 rpm/min

- 14. d)Speed Controller Loop • Speed Controller loop is PD (P) loop . • A deviation of 150 rpm will correspond to full opening of the control valve (with the assumption that full opening of control valve will give full load at rated parameters) • If error + 150 rpm then hRnc will be 10v • if error is -150 rpm then hRnc will be -10v • if error is zero speed controller o/p will be zero

- 15. e)No load Correction • As the speed controller loop is PD (P) so an error in the input is a must to keep the valves open for running the at the rated speed .To Provide this error between set point and actual value a pressure dependent correction signal is given , as the valve opening required for running the machine at rated speed is directly dependent on steam pressure. Hence, for correction purpose practical reading should be taken when the machine is running at rated speed at different pressure

- 16. For example :- Turbine running at 3000 rpm Output of speed controller at (50Kg/Cm2)=1.5V Output of speed controller at (150Kg/Cm2)=0.8V The pressure transmitter ranges is 0=250Kg/Cm2 = 0-10V for 4 to 20mA The correction input as given with a gain of 0.05 and the overall gain of speed controller loo p is 22.22 so net gain for correction signal =0.05x22.22=1.11 Hence correction input required at 50Kg Cm2 =1.5/1.11 =1.35v and correction input require d at 150Kg/Cm2 =0.8/1.11=0.72V .Now two equation can be made with Y=m x +C Y= Correction Signal X = Pressure Signal ( 50 kg/cm2=2v, 150 kg/cm2=6v) 1.35=M x 2+C. .(1) 0.72=M x 6 +C. .(2) By solving above two equation M = -0.16 C= 1.67 Gain (M) should be adjusted by potentiometer AB 099/R11 negative polarity of (M) is take n care by feeding pressure signal to negative port of comparator .Biasing C can be adjusted by Potentiometer AB 115/R 13

- 17. Speed Controller

- 18. 1 SLOW RATE AT NR > 2850 RPM & DN/DT OPERATED. 2 TSE INFLUENCE ON. 3 STOPPING OF NRTD ON GCB OPEN AND Nact < NRTD BY 45 RPM 4 STOPPING OF SPEED CONTROL SET POINT ON (NR > 2850 RPM AND NR >NRTD AND TSE ON AND FAULTED IN GCB OPEN CONDITION) OR STOP COMMAND FROM SGC TURBINE 5 TRACKING IN SYNCHRONIZED CONDITION IF FREQUENCY WITHINLIMIT AND LOAD CONTROLLER OR PRESSURE CONTROLLER IN ACTION. 6 FAST CALIBRATION DURING TRACKING CONDITION OR TURBINE TRIP.

- 19. 2.Load Controller • Load controller is used to maintain the load set by the operator ( at turbine control or at CMC console ) or automatic load dispatch Centre (optional ). • Load controller is also responsible for taking care of frequency changes and correcting the load. • The controller comes into operation only after synchronization, before Synchronization it remains in the follow mode .

- 20. • 2A) Load set point (PR) • 2B) Load Gradient and TSE Margin Influence. • 2C) Load Set Point Control (PRTD) • 2D) Frequency influence. • 2E) Pressure influence • 2F) Load Limiter • 2G) Actual Load Acquisition • 2H) Final Control Loop Sub Sections of load controller

- 21. 2A)Load Set Point • Load Set Point:- Load set point can be changed from cabinet, desk, SGC or CMC or from Auto dispatch Centre (optional).The set point changes at a gradient of 100 MW /Min for 200MW & 250MW/min for 500MW). The gradient remains same through out the range. The load set point indicator is available at desk. The range of the indicator is 0-250 MW for 200 MW M/c & 0-600MW for 500MW M/c.

- 22. 2B)Load gradient and TSE influence • Load gradient is an additional feature available in load controller. The load gradient acts in parallel with TSE margin with minimum Selector. Load gradient range is 0- 25MW/ min : 200MW & 0-60MW/min (500MW). • While for TSE margin 0-30 degree K corresponds to 0- 25 MW/min in 200MW& 0-60MW/min in(500MW) • Both load gradient and TSE margin have got an ON/OFF switched, so if any one is desired to be taken out of service can be switched off.

- 23. 2C) Load set point Control(PRTD ) • If both load gradient and TSE influence is off then PRTD changes at a rate of 25 MW/min • The function of PRTD is similar to the NRTD in speed controller The maximum rate change here is 25MW /min or 60MW in both directions • The set point controller remains in follow mode if generator breaker is off or load controller is off or load is less than station load and MW error is > 5%. • During this mode PRTD follows actual load without delay • STOP command is generated if TSE fault appears

- 24. 2D)Frequency Influence • Frequency influence is used to correct the load set point. The frequency influence has got a droop of 5% • A deviation of + or - 0.5 Hz will cause a load change of + or -40 MW. The correction signal is limited at + or - 40MW • The frequency influence can be switched on/off from Frequency Influence module • Indicator for the correction signal is available at desk of range +/- 100MW for 200MW M/c & +/- 200 MW for 500MW M/c.

- 25. 2E) Load Limiter • Final Set point (addition of PRTD ,PRPR, PRF ) is fed to a minimum selector with the load limiter • Load limiter will limit the actual load and it also can be used for fast reduction of load in emergency cases. • O/P min block is Prabs ( Pr) which is the actual reference signal for load controller.

- 26. 2F) Actual Load Acquisition /Load measurement • The actual load is measured by three load transducers which get the signal from PT and CT and give out put 0-250MW (or 0-500MW M/c) corresponds to 4-20 mA • The middle value of the three load measurement is used for processing • If any value drifts from the other value by more than 5%, a selective fault alarm is generated . The fault doesn’t disturb the working as defective channel is discarded.

- 27. 2G)Final Controller Loop • The final loop is a PI controller • Two major parts consisting of two cards ARL 12& ARL 13 specially designed for this purpose • Error signal is generated from the final set point and actual load in ARL 12 card. It has an inbuilt frequency influence whose responsibility is to prevent the over speeding of the turbine. Hence, this frequency influence acts only to reduce the out put of the controller . This can’t be switched off. • The output of ARL 13 card provides the integrator part of the loop. Apart from the integrator, ARL 13 has also got a filter and provision for follow mode.

- 28. Following Above (hvo) This mode in operation during following conditions • 1- Load Controller Off or • 2- Generator Breaker Off or • 3- Pact <STL & P>5% and Generator breaker closed. During the above condition the load controller output tracks the speed controller output all the time with a constant error of-150mV. This follow-mode ensure that during above conditions, the load controller should not come into action.

- 29. Following Low (hvu) • This mode is present once the breaker is synchronized and speed controller is still in action. During this mode the load controller output tracks the speed controller output with error of –150mV • Only difference is load controller output can go more than speed controller output (hence load controller can take over) but it cannot go 150 mV below the speed controller output. • Load controller can be taken into service anytime without any delay

- 31. 1 CMC ON 2 GRADIENT ENABLING WHEN GCB CLOSED AND LOAD CONTROLLER IN ACTION OR PRESSURE CONTROLLER IN INITIAL PRESSURE MODE 3 TSE ON AND NOT FAULTED. 4 LOAD GRADIENT ON 5 TSE ON AND FAULTED OR STOP COMMAND FROM SGC OR SET POINT RAISED WITH CMC ON. 6 FOLLOW ABOVE CONDITION. 7 FREQUENCY INFLUENCE ON 8 INITIAL PRESSURE MODE SELECTED 9 LOAD CONTROLLER OFF

- 32. 3 Pressure Controller • 3a) Initial Pressure Mode A Pressure deviation signal (difference of required pressure as per load and actual pressure ) is fed to the controller .As long the deviation is more than + 150mV (Actual> required ) the pressure controller output remains as maximum saturation. If the deviation fall between 0 to +150mV, the output of the pr. controller comes out from saturation & match to the output of final minimum selection output • As soon as the deviation becomes negative, the output of the pressure control starts decreasing. • This mode comes when runback action comes into picture or it is selected from console

- 33. 3b Limit pressure mode • The function of this mode is similar to the initial pressure mode .The only difference being that biasing of 10Kg/Cm2 is given in this loop. Hence, all the action start after the pressure drops by more than 10Kg/Cm2. • This mode is used when m/c is in load control; a small pressure correction signal is also applied +/- side to load set point control. • This mode should be used once the load on turbo set is stabilized.

- 34. PRESSURE CONTROLLER CIRCUIT Actual Pressure ( 0-250 BAR ), Pact ( 0-10V ) Pr ( 0-10V ) hr Pr c ( +4V to + 10 V ) Set Pressure ( 0- 250 BAR ) - + Gain 4V ( Lower limit ) 0.4 V (10 BAR) Initial Pressure Mode

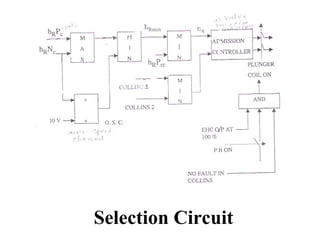

- 35. 4 Control Transfer • This loop receives the signal from speed controller (hrnc), load controller(hr PC) and pr. controller • a set of Max & Min selection and then final value selected is passed on to position /admission controller • hrnc and hrPC pass through a maximum value selector and the value selected is passed on to first MIN value selection. 10.5v is added in hrnc and this value is also fed to first Min value selector. • The value selected in first Min value selector is passed on to the second MIN value selector along with output of pressure controller output (hr PRC) The value selected here is passed on the position / admission controller.

- 37. 5 Position/admission Controller • Position Controller is the final control element in EHC. It receives the signal from control transfer • It receives feedback signal from Collins transmitters.Two Collins transmitters are provided • Selection of transmitter is through MIN value selector • Plunger coil supplied in EHC is an integrator type. • There is Provision to switch ON/OFF the voltage supply to plunger coil. Switching ON /OFF can be done only if the output of position controller is > 100%.

- 38. LOAD SHEDDING RELAY • Load shedding relay is necessary when the hydraulic governor is controlling but is also kept in operation when the EHC is in control to avoid over speeding of turbine . • Upon action of LRR the HPCV & IPCV are closed completely for a short interval(1.4 sec max) • Sudden negative jump in load is detected electrically instantaneously by the load shedding relay when, in 200MW: Load throw off>40% & residual load<15% & frequency>49 Hz • LRR acts therefore earlier on the hydraulic control system i.e. Before HC takes action due to the speed increase

- 44. CONTROL TRANSFER LOGIG & ADMISSION CONTROLLER -

- 45. 2790 2940 3060 3210 RPM output +100% -100% 0% Droop of kwu m/c

- 46. What is Droop? % of frequency change ( % of RPM change) will lead to full travel of Governing valves or full load change. 5% droop means: 5%*50 Hz= 2.5 Hz Will change 500MW. In terms of output total change should take place is 100%