flow of fluids

- 1. FLUID FLOW V.JAGAN MOHAN RAO M.S.Pharm., MED.CHEM NIPER-KOLKATA Asst.Professor, MIPER-KURNOOL EMAIL- jaganvana6@gmail.com

- 2. FLUID FLOW A fluid is a substance that continually deforms (flows) under an applied shear stress. Fluids are a subset of the phases of matter and include liquids, gases both. Fluid flow may be defined as the flow of substances that do not permanently resist distortion. The subject of fluid flow can be divided into fluid statics and fluid dynamics. Identification of type of flow is important in Manufacture of dosage forms Handling of drugs for administration

- 3. FLUID STATICS Fluid statics deals with the fluids at rest in equilibrium, Behavior of liquid at rest Nature of pressure it exerts and the variation of pressure at different layers Pressure differences between layers of liquids h1 h2 Point 1 Point 2

- 4. Consider a column of liquid with two openings Which are provided atthe wall of the vessel at different height The rate of flow through these opening s are different due tothe pressure exerted at the differentheight Consider a stationary column the pressure ps is acting on the surface of the fluid, column is maintained at constant pressure by applyingpressure The force acting below and above the point 1 areevaluated Substituting the force with pressure x area of cross section in theabove equation Force acting on the liquid At point 1 = Force on the surface + Force excreted by theliquid Above point 1 Pressure at point 1 x Area = Pressure on the surface x area + mass x acceleration

- 5. P1S = PsS + volume x density x acceleration = PsS + height x area x density x acceleration P1S = PsS + h1 S ρ g Since surface area is same P1 = Ps + h1 ρ g Pressure acting on point 2 may be written as P2 = Ps + h2 ρ g Difference in the pressure is obtained by P2 - P1 = g (Ps + h2 ρ ) – ( Ps + h1 ρ) g ∆P = (Ps + h2 ρ– Ps - h1 ρ ) g = ∆ h ρ g

- 6. FLUID DYNAMICS Fluid dynamics deals with the study of fluids in motion This knowledge is important for liquids, gels, ointments which will change their flowbehavior when exposed to different stress conditions MIXING FLOW THROUGHPIPES FILLED IN CONTAINER

- 7. The flow of fluid through a closed channel can be viscous or turbulent and it can be observed by; Reynolds experiment Consider Glass tube which is connected to reservoir of water, rate of flow of water is adjusted by a valve, a reservoir of colored solution is connected to one end of the glass tube with help of nozzle colored solution is introduced into the nozzle as fine stream.

- 9. Laminar flow is one in which the fluid particles move in layersor laminar with one layer sliding with other. There is no exchange of fluid particles from one layer to other. When velocity of the water is increased the thread of the colored water disappears and mass of the water gets uniformly colored, indicates complete mixing of the solution and the flow of the fluid is called as turbulent flow. The velocity at which the fluid changes from laminar flow to turbulent flow that velocity is called as critical velocity.

- 10. REYNOLDS NUMBER Inertial forces are due to mass and the velocity of the fluidparticles trying to diffuse the fluid particles viscous force if the frictional force due to the viscosity of thefluid which make the motion of the fluid in parallel In Reynolds experiment the flow conditions are affectedby Diameter ofpipe Average velocity Density of liquid Viscosity of the fluid This four factors are combined in one way as Reynolds number Reynolds number is obtained by the following equation D u ρ η INERTIALFORCES = ------------------------------ = VISCOUS FORCES MASS X ACCELERATION OF LIQUIDFLOWING --------------------------------------------------------- SHEAR STRESS XAREA

- 11. If Re < 2000 the flow is said to be laminar If Re > 4000 the flow is said to be turbulent If Re lies between 2000 to 4000 the flow change between laminar to turbulent APPLICATIONS Reynolds number is used to predict the nature of theflow Stocks law equation is modified to include Reynolds number to study the rate of sedimentation in suspension

- 12. BERNOULLI'S THEOREM When the principals of the law of conservation energy is applied tothe flow of the fluids the resulting equation is called Bernoulli's theorem Consider a pump working under isothermal conditions between pointsA and B as shown in figure;

- 13. 13

- 14. At point a one kilogram of liquid is assumed to be entering atthis point, pressure energy at joule can be writtenas Pressure energy = Pa /g ρ A Where Pa = Pressure at point a g = Acceleration due togravity ρ A = Density of theliquid Potential energy of a body is defined as the energy possessedby the body by the virtue of its position or configuration Potential energy = XA Kinetic energy of a body is defined as the energy possessed by the body by virtue of its motion, kinetic energy = UA / 2g2 Total energy at point A = Pressure energy + Potential energy+Kinetic energy

- 15. Total energy at point A = Pa /g ρ A +XA + UA / 2g2 According to the Bernoulli's theorem the total energy atpoint A is constant Total energy at point A = Pa /g ρ A +XA + UA / 2g = Constant2 After the system reaches the steady state, whenever one kilogramof liquid enters at point A, another one kilogram of liquid leaves at point B Total energy at point B = PB /g ρ B +XB + UB / 2g2 INPOUT = OUT PUT Pa /g ρ A +XA + U 2 / 2g =PB /g ρ B +XB + U 2 / 2g A B Theoretically all kids of the energies involved in fluid flow should be accounted, pump has added certain amount ofenergy Energy added by the pump = + wJ

- 16. • This equation is called as Bernoulli's equation • Application Used in the measurement of rate of fluidflow It applied in the working of the centrifugal pump, in this kinetic energyis converted in to pressure During the transport some energy is converted to heat due tofrictional Forces Loss of energy due to friction in the line =FJ

- 17. ENERGY LOSS According to the law of conversation of energy ,energy balance have to be properly calculated fluids experiences energy losses in several ways while flowing through pipes, they are Frictional losses Losses in the fitting Enlargement losses Contraction losses

- 18. FRICTIONAL LOSSES During flow of fluids frictional forces causes a loss in pressure Type of fluid flow also influences the losses In general pressure drop will be PRESSURE DROP α VELOCITY (u) α Density of fluid(ρ) α Length of the pipe (L) α 1 / diameter of the pipe (D) These relationships are proposed in Fanning equation for calculating friction losses Fanning equation ∆p = 2fu2Lρ / D F = frictional factor For viscous flow pressure drop Hagen –Poiseullie equation = 32 Luη / D2

- 19. LOSSES IN FITTING Fanning equation is applicable for the losses in straight pipe When fitting are introduced into a straight pipe, They cause disturbance in the flow, Which result in the additional loss of energy losses in fitting may be due to Change in direction Change in the type of fittings Equivalent length of fitting = Equivalent length x internal diameter For globe valve = 300 x 50 = 15 meter That means globe valve is equal to 15 meters straight line, so this length is substituted in fanning equation Tee fitting Equivalent length = 90 Globe valve equivalent length = 300

- 20. ENLARGEMENT LOSS If the cross section of the pipe enlarges gradually, the fluid adaptsitself to the changed section with out any disturbance So no loss of energy If the cross section of the pipe changes suddenly then loss in energy is observed due to eddies These are greater at this point than straight line pipe Than u2< u1 For sudden enlargement = ∆ H = (u1 –u2 )2 / 2g ∆ H = loss of head due to sudden enlargement µ1 µ2 µ1 µ2

- 21. CONTRACTION LOSSES If the cross section of the pipe is reduced suddenly the fluid flow is disturbed, the diameter of the fluid stream is less than the initial value of diameter this point of minimum cross section is known as vena contracta. the velocity of fluid at smaller cross section will be greater than at larger cross section, u2> u1

- 22. MANOMETERS Manometers are the devices used for measuring the pressure difference Different type of manometers are; 1) Simple manometer 2) Differential manometer 3) Inclined manometer

- 23. SIMPLE MANOMETER This manometer is the most commonly used one It consists of a glass U shaped tube filled with a liquid A- of density ρA kg /meter cube and above A the arms are filled with liquid B of density ρB . The liquid A and B are immiscible and the interference can be seen clearly If two different pressures are applied on the two arms the meniscusof the one liquid will be higher than the other Let pressure at point 1 will be P1 Pascal's and point 5 will be P2 Pascal's The pressure at point 2 can be written as = P1+ (m + R ) ρ B g (m + R ) = distance from 3 to 5

- 25. Since the points 2 and 3 are at same height the pressure at 3 can be written as Pressure at 3 =P1+ (m + R ) ρ Bg Pressure at 4 can be written as = P2 + gm ρB or = P1+ ρ B ( m + R ) g- ρ a R g Both the equations should be equal P2 + gm ρ B = P1+ ρ B ( m + R ) g- ρ a R g P1 – P2 = gm ρ B - ρ B ( m + R) g + ρ A R g ∆P = gm ρ B - gm ρ B - R ρ B g + R ρ A =R (ρ A- ρ B )g

- 26. DIFFERENTIAL MANOMETERS These manometers are suitable for measurement of small pressure differences It is also known as two – Fluid U- tube manometer It contains two immiscible liquids A and B having nearly same densities The U tube contains of enlarged chambers on both limbs, Using the principle of simple manometer the pressure differences canbe written as ∆P =P1 –P2 =R (ρc – ρA)g

- 28. INCLINED TUBE MANOMETERS Many applications require accurate measurement of low pressure suchas drafts and very low differentials, primarily in air and gasinstallations In these applications the manometer is arranged with the indicatingtube inclined, as in Figure, therefore providing an expanded scale This enables the measurement of small pressure changes with increased accuracy P1 –P2 = g R (ρ A - ρ B) sin α

- 30. MEASUREMENT OF RATE OF FLOW OF FLUIDS When ever fluid are used in a process it is necessary to measurethe rate at which the fluid is flowing through the pipe, Methods of measurement are Direct weighing or measuring Hydrodynamic methods Orifice meter Venturi meter Pitot meter Rotameter Direct displacement meter

- 31. The liquid flowing through a pipe is collected for specific period at any point and weighed or measured, and the rate of flow canbe determined. Gases can not be determined by thismethod. ORIFICE METER Principle: Orifice meter is a thin plate containing a narrow and sharpaperture When a fluid stream is allowed to pass through a narrow constrictionthe velocity of the fluid increase compared to upstream This results in decrease in pressure drop and the difference inthe pressure may be read from amanometer The velocity of the fluid at thin constriction may be writtenas U0 =C 0 √ 2g∆H DIRECT WEIGHING OR MEASURING

- 32. ∆H = difference in height, can be measured by manometer C0 =constant U0 = velocity of fluid at the point of orificemeter CONSTRUCTION It is consider to be a thin plate containing a sharp aperturethrough which fluid flows Normally it is placed between long straightpipes For present discussion plate is introduced into pipe and manometeris connected at points A and B WORKING Orifice meter is referred as the variable head meter, ie it measure the variation in the pressure across a fixed construction placed in thepath of flow

- 34. When fluid is allowed to pass through the orifice the velocity of the fluid at point B increase, as a result at point A pressure will be increased Difference in the pressure is measured by manometer Bernoulli's equation is applied to point A and point B for experimental conditions √µ0 2 –µ 2 =C √2g ∆H A 0 µ0 = velocity of fluid atorifice µA = velocity of fluid at point A C0 = constant If the diameter of the orifice is 1/5 or less of the pipe diameter thenµA µ0 = C0 √2g ∆His neglected so, Applications Velocity at either of the point A and B can be measured Volume of liquid flowing per hour can be determined

- 35. VENTURI METER • Principle: Venturi meter consist of two tapered sections in the pipe line with a gradual constriction at its centre. When fluid stream is allowed to pass through the narrow throat the velocity of the fluid increases at the venturi compared to velocity of the upstream. This results in decrease in the pressure head. This resulting decrease in the pressure head is measured directly from the manometer.

- 38. 38

- 39. Disadvantages Expensive Need technical expert Not flexible Occupies more space Advantages Power loss is less Head loss is negligible Applications: It is commonly used for liquids, specially for water. It can also be used for the measurement of gases.

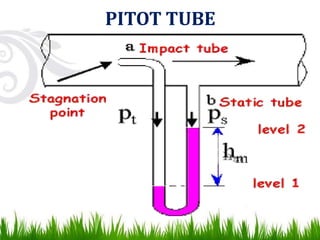

- 40. PITOT TUBE • Principle: Pitot tube consists of sensing element with a small constriction compared to the size of the flow channel. When the sensing element is inserted at the center of the stream, the velocity of flow is increased. This results in decrease in pressure head. ∆Hp = u2 /2g

- 41. PITOT TUBE

- 42. Construction It is also known as insertion meter or insertion tube The size of the sensing element is small compared to theflow channel The point of measurement may be at the center of thechannel One tube is perpendicular to the flow direction and the otheris parallel to the flow Two tubes are connected to themanometer Working Tube are inserted in the flow shown is the figure. Pitot tube is used to measure the velocity head of the flow. In this tube velocity of fluid is increased at the narrow constriction which results in decreased pressure.

- 43. Tube at right angles to the flow measures pressure head only while the tube that points upstream measures pressure head and velocity head. µ2= Cv √2g ∆H Cv coefficient of Pitot tube

- 44. ROTAMETER Principle: Rotameter is known as area meter as it measures area of flow. It consist of a vertical, tapered and transparent tube in which plummet is placed. During the fluid flow through the tube the plummet rises and falls because of variation of flow.

- 46. Construction It consists of vertically tapered and transparent tube with narrow end down, in which a plummet is placed. A solid plummet is placed in the tube. The diameter of the plummet is smaller than the narrowest part of the tube. Floats/plummet is made up of glass, aluminium or plastic. The tube is usually made of glass on which linear scale is given. During the flow the plummet rise due to variation in flow The upper edge of the plummet is used as an index to note the reading

- 47. 47