Lecture12_Various Fabrication Techniques1.pdf

- 1. MTT0060 Nanomaterials and nanotechnologies Lecture 12 OUTLINE -How to get at nano scale? -Top – down or bottom – up? -What is bottom-up approach? -What can we do with the help of CVD? -Why electrodeposition?

- 2. No such thing as a “shrinking machine” Must learn how to “Build them Small” Ultimate Goal: Dial in the properties that you want by designing and building at the scale of nature (i.e., the nanoscale)

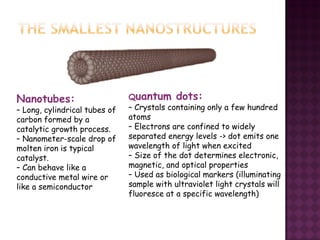

- 3. Nanotubes: – Long, cylindrical tubes of carbon formed by a catalytic growth process. – Nanometer-scale drop of molten iron is typical catalyst. – Can behave like a conductive metal wire or like a semiconductor Quantum dots: – Crystals containing only a few hundred atoms – Electrons are confined to widely separated energy levels -> dot emits one wavelength of light when excited – Size of the dot determines electronic, magnetic, and optical properties – Used as biological markers (illuminating sample with ultraviolet light crystals will fluoresce at a specific wavelength)

- 4. There are two general approaches to the synthesis of nanomaterials and the fabrication of nanostructures Bottom-up approach These approaches include the miniaturization of materials components (up to atomic level) with further self-assembly process leading to the formation of nanostructures. During self-assembly the physical forces operating at nanoscale are used to combine basic units into larger stable structures. Typical examples are quantum dot formation during epitaxial growth and formation of nanoparticles from colloidal dispersion. Top-down approach These approaches use larger (macroscopic) initial structures, which can be externally- controlled in the processing of nanostructures. Typical examples are etching through the mask, ball milling, and application of severe plastic deformation.

- 5. • Top-down methods begin with a pattern generated on a larger scale, then reduced to nanoscale. –By nature, aren’t cheap and quick to manufacture - Slow and not suitable for large scale production. • Bottom-up methods start with atoms or molecules and build up to nanostructures –Fabrication is much less expensive

- 6. Nano-scale structures and micro-scale structures are readily formed using top down and bottom up approaches. Best chance for integration. New Method : Bottom Up + Top Down Self-assembled block copolymers + Optical lithography

- 7. €Gaseous phase methods €Liquid phase methods €Solid phase methods €Biological methods

- 8. Principal: Gas – phase precursors interact with a liquid– or solid- phase material € Gas state condensation € Chemical vapor deposition € Molecular beam epitaxy € Atomic layer deposition € Combustion € Thermolysis € Metal oxide vapor phase epitaxy € Ion implantation

- 9. The inert gas condensation (IGC) process is one of the most known and simplest technique for production of nanoparticles (in particular, Me nanopowders)

- 10. 1. A material, often a metal, is evaporated from a heated metallic source into a chamber which has been previously evacuated to about 10–7 torr and backfilled with inert gas to a low-pressure. 2. The metal vapor cools through collisions with the inert gas atoms, becomes supersaturated and then nucleates homogeneously; the particle size is usually in the range 1–100 nm and can be controlled by varying the inert gas pressure. 3. Ultimately, the particles are collected and may be compacted to produce a dense nanomaterial.

- 11. The population distributions of icosahedral (Ih) decahedral (Dh) and monocrystalline face centered cubic (fcc) morphologies as a function of a size [ K. Koga, K. Sugawara, Surf. Sci. 529 (2003) 23]

- 12. Decahedral gold nanoparticle generated from an inert gas aggregation source using helium and deposited on amorphous carbon film [ K. Koga, K. Sugawara, Surf. Sci. 529 (2003) 23] Icosahedral gold nanoparticles generated from an inert gas aggregation source using helium and deposited on amorphous carbon film [ K. Koga, K. Sugawara, Surf. Sci. 529 (2003) 23]

- 13. Principal: CVD involves the formation of nanomaterials from the gas phase at elevated temperatures— usually onto a solid substrate or catalyst. http://upload.wikimedia.org/wikipedia/commons/9/9e/ThermalCVD.PNG

- 14. A molecular beam epitaxy (MBE) machine is essentially an ultra- high-precision, ultra clean evaporator, combined with a set of in-situ tools, such as Auger electron spectroscopy (AES) and/or reflection high- energy electron diffraction (RHEED), for characterization of the deposited layers during growth.

- 15. Schematic diagram of a molecular beam epitaxy thin film deposition system (adapted from Nanoscale Science and Technology, Eds. R.W. Kelsall, I.W. Hamley, M. Geoghegan, John Wiley&Sons Ltd, 2005).

- 16. In solid-source MBE, ultra-pure elements such as gallium and arsenic are heated in separate quasi-Knudsen effusion cells until they begin to slowly evaporate. The evaporated elements then condense on the wafer, where they may react with each other. In the example of gallium and arsenic, single- crystal gallium arsenide is formed. The term “beam” simply means that evaporated atoms do not interact with each other or any other vacuum chamber gases until they reach the wafer, due to the long mean free paths of the beams. The substrate is rotated to ensure even growth over its surface. By operating mechanical shutters in front of the cells, it is possible to control which semiconductor or metal is deposited.

- 17. Slow but well controlled deposition rate 1 to 300 nm per minute

- 18. Schematics of the commercial MOCVD system

- 20. 1. High precision actuators move atoms from place to place 2. Micro tips emboss or imprint materials 3. Electron (or ion) beams are directly moved over a surface 1. Chemical reactors create conditions for special growth 2. Biological agents sometimes used to help process 3. Materials are harvested for integration

- 21. Parameter Atomic Layer Deposition Chemical Vapor Deposition Precursor Reactivity Highly Reactive/Self-limiting at saturation Less reactive / Can be autocatalytic Potential Materials Metals, semiconductors, insulators/Wide range Metal oxides, semiconductors and carbon compounds Selectivity Highly selective Low selectivity Surfaces Layers conform to surface topography of substrate Surfaces capable of activation Layers conform according to surface topography of substrate Decomposition Reactants and product do not decompose Reactants can decompose at operation temperature Process Time Few seconds per cycle Variable Uniformity Saturation mechanism ensures uniformity Uniformity control by process parameters (partial pressure of reactants, flow, pressure, temperature) – more difficult to execute Thickness Controlled explicitly by number of reaction cycles Deposition rate: ~6 nm * min-1 Thickness control by process parameters – more difficult to execute Conditions Vacuum of inert atmosphere Lower temp. (100 – 400˚ C) P, T, concentration and gas flow distribution have little effect on the process Requires inert atmosphere and higher temperatures (>600˚ C) P,T, concentration and gas flow distribution have significant effect on the process Up-Scale Excellent Good

- 24. € Molecular self-assembly € Supramolecular chemistry € Sol-gel processes € Single-crystal growth € Electrodeposition / electroplating € Anodizing € Molten salt solution electrolysis € Liquid template synthesis € Super-critical fluid expansion

- 25. • Spontaneous organization of molecules into stable, structurally well-defined aggregates (nanometer length scale). • Molecules can be transported to surfaces through liquids to form self- assembled monolayers (SAMs). Polythiophene wires

- 27. Precipitating nanoparticles from a solution of chemical compounds can be classified into five major categories: (1)colloidal methods; (2)sol – gel processing; (3) water – oil microemulsions method; (4) hydrothermal synthesis; and (5) polyol method.

- 28. Principal: solutions of the different ions are mixed under controlled temperature and pressure to form insoluble precipitates.

- 29. The sol is a name of a colloidal solution made of solid particles few hundred nm in diameter, suspended in a liquid phase. The gel can be considered as a solid macromolecule immersed in a solvent. + Sol-gel process consists in the chemical transformation of a liquid (the sol) into a gel state and with subsequent post- treatment and transition into solid oxide material. The main benefits of sol–gel processing are the high purity and uniform nanostructure achievable at low temperatures.

- 31. Start with precursor Form Solution (e.g., hydrolysis) Form Gel (e.g., dehydration) Then form final product Aerogel (rapid drying) Thin-films (spin/dip)

- 32. The Sol-Gel process allows to synthesize ceramic materials of high purity and homogeneity by means of preparation techniques different from the traditional process of fusion of oxides. This process occurs in liquid solution of organometallic precursors (TMOS, TEOS, Zr(IV)-Propoxide, Ti(IV)-Butoxide, etc. ), which, by means of hydrolysis and condensation reactions, lead to the formation of a new phase (SOL). M-O-R + H2O M-OH + R-OH (hydrolysis) M-OH + HO-M M-O-M + H2O (water condensation) M-O-R + HO-M M-O-M + R-OH (alcohol condensation) (M = Si, Zr, Ti)

- 33. The fundamental property of the sol-gel process is that it is possible to generate ceramic material at a temperature close to room temperature.

- 34. In the dip coating process the substrate is immersed into a sol and then withdrawn with a well-defined speed under controlled temperature and atmospheric conditions. The sol left on substrate forms a film with thickness mainly defined by the withdrawal speed, the solid content and the viscosity of the liquid. Next stage is a gelation (densification) of the layer by solvent evaporation and finally annealing to obtain the oxide coating.

- 35. In an angle-dependent dip coating process the coating thickness is dependant also on the angle between the substrate and the liquid surface, so different layer thickness can be obtained on the top and bottom side of the substrate. Spin coating is used for making a thin coating on relatively flat substrates . The material to be made into coating is dissolved or dispersed into a solvent, and then deposited onto the surface and spun off to leave a uniform layer for subsequent processing stages and ultimate use.

- 36. The coating thickness depends on the angle of inclination of the substrate, the liquid viscosity and the solvent e v a p o r a t i o n r a t e . The advantage of the flow- coating process is that non- planar large substrates can be c o a t e d r a t h e r e a s i l y . In the flow coating process the liquid coating system is poured over the substrate to be coated.

- 37. Icosahedral microparticles, pentagonal microtubes and whiskers obtained in the process of copper electrodeposition [ after A.A. Vikarchuk] The principle of electrodeposition is inducing chemical reactions in an aqueous electrolyte solution with the help of applied voltage, e.g. this is the process of using electrical current to coat an electrically conductive object with a relatively thin layer of metal.

- 38. Electrochemically fabricated flip-chip interconnects Electrodeposition (ED) is being exploited now to make complex 3D electrical interconnects in computer chips. The key concept is that electrodeposited materials grow from the conductive substrate outward, and the geometry of the growth can be controlled using an insulating mask (so-called through mask electrodeposition).

- 39. Nanometer-scale cuprous oxide (colorized red) can be electrodeposited through the openings in the hexagonally packed intermediate layer protein (white regions) from the bacterium Deinococcus radiodurans. Purified crystalline protein sheets are first adsorbed to a conductive substrate, and then electrodeposition is carried out to fill the nanometer-scale pores in the protein. Biological fabrication. One way that proteins are being used in electrochemical nanotechnology is as masks for through mask electrodeposition. Proteins can self-organize into complex structures representing all possible two-dimensional (2D) space groups built from chiral molecules. Moreover, they are readily engineered through molecular biology, providing an attractive foundation for nanotechnology.

- 40. Miniature copper mask from the site of Loma Negra on the far north coast of Peru, ca. 200 C.E. Removal of the green copper corrosion products reveals a bright gold surface. The extremely thin layer of gold was applied to the sheet copper by electrochemical replacement plating. [Heather Lechtman, Sci. Amer., 250(6), 56 (1984).] Electrodeposition has three main attributes that make it so well suited for nano-, bio- and microtechnologies. • It can be used to grow functional material through complex 3D masks. • It can be performed near room temperature from water-based electrolytes. • It can be scaled down to the deposition of a few atoms or up to large dimensions.

![The population

distributions of

icosahedral (Ih)

decahedral (Dh) and

monocrystalline face

centered cubic (fcc)

morphologies as a

function of a size

[ K. Koga, K. Sugawara,

Surf. Sci. 529 (2003) 23]](https://image.slidesharecdn.com/lecture12fabrication1-240218135856-c67c6d15/85/Lecture12_Various-Fabrication-Techniques1-pdf-11-320.jpg)

![Decahedral gold nanoparticle generated

from an inert gas aggregation

source using helium and deposited on

amorphous carbon film

[ K. Koga, K. Sugawara, Surf. Sci. 529 (2003) 23]

Icosahedral gold nanoparticles

generated from an inert gas

aggregation source using helium and

deposited on amorphous carbon film

[ K. Koga, K. Sugawara, Surf. Sci. 529 (2003)

23]](https://image.slidesharecdn.com/lecture12fabrication1-240218135856-c67c6d15/85/Lecture12_Various-Fabrication-Techniques1-pdf-12-320.jpg)

![Icosahedral microparticles, pentagonal microtubes and whiskers obtained in

the process of copper electrodeposition [ after A.A. Vikarchuk]

The principle of electrodeposition is inducing

chemical reactions in an aqueous electrolyte

solution with the help of applied voltage, e.g. this

is the process of using electrical current to coat

an electrically conductive object with a relatively

thin layer of metal.](https://image.slidesharecdn.com/lecture12fabrication1-240218135856-c67c6d15/85/Lecture12_Various-Fabrication-Techniques1-pdf-37-320.jpg)

![Miniature copper mask from the site of

Loma Negra on the far north coast of Peru,

ca.

200 C.E. Removal of the green copper

corrosion products reveals a bright gold

surface. The extremely thin layer of gold

was applied to the sheet copper by

electrochemical replacement plating.

[Heather Lechtman, Sci. Amer., 250(6), 56 (1984).]

Electrodeposition has three main

attributes that make it so well

suited for

nano-, bio- and microtechnologies.

• It can be used to grow functional

material through complex 3D masks.

• It can be performed near room

temperature from water-based

electrolytes.

• It can be scaled down to the

deposition of a few atoms or up to

large dimensions.](https://image.slidesharecdn.com/lecture12fabrication1-240218135856-c67c6d15/85/Lecture12_Various-Fabrication-Techniques1-pdf-40-320.jpg)