presentation.pptx presentation presentation

- 1. There are two specific routes for fermentation depening upon the microorganisms (Shuler, 2003) • HOMOFERMENTATIVE GROUP • Homofermentative Lactic acid bacteria produce pure or almost pure (90%) lactate. • They metabolize glucose via the fructose-bis phosphate pathway and produce 1 molecule of Lactate from 1 molecule of glucose. • Examples are: Lactococcus lactis, Streptococci, Enterococcus faecclis. • HETEROFERMENTATIVE GROUP • Heterofermentative lactic acid bacteria produce 1 molecule of lactate along with 1 molecule of ethanol and 1 molecule of carbon dioxide (or acetic acid). • Examples are Leuconostoc sp., Lactobacillus brevis, Lactobacillus fermentum.

- 2. Bioprocess parameters in Lactic acid Production: 1. Nutrients: Nitrogen Inorganic Salts 2. pH 3. Oxygen supply 4 Temperature

- 3. Nutrients: Nutrients are the essential substances required in any fermentation process. Supplement of sufficient carbon, nitrogen, phosphate, sulfur and other salts is vital to maintain the growth of microorganisms and formation of products. In general, Rhizopus species have relatively lower nutritional demands compared with bacteria, requiring only small amount of inorganic salts to achieve asatisfactory fermentation performance. The optimum nutrient concentration depends on the nature of the substrate, the strain and the method involved in the Nitrogen: Nitrogen is needed for the synthesis of amino acids, purines, pyrimidines, some carbohydrates and lipids, enzyme cofactors and other substances. Nitrogen sources can be inorganic salts, such as ammonium sulfate and ammonium nitrate, and organic substances, such as peptone, yeast extract and corn steep liquor. Ammonium sulfate is the most widely used nitrogen source.

- 4. Inorganic salts pH ➤ The favorable pH range is 5.0-6.0. ➤ Tay and Yang (2002) found that production. of lactic acid, ethanol and fumaric acid decreased as pH decreased from 6.0 to 4.0. ➤ Miura et. al., (2003) results showed that the highest lactic acid yield (93 g/L) was achieved at pH 6.0-6.5. Neutralizing agents ➤ To control the pH during the fermentation, neutralizing agents such as calcium carbonate, sodium carbonate and sodium hydroxide need to be added into fermentation medium.

- 5. 3. Oxygen supply ➤ Fungal fermentation by Rhizopus species is an aerobic process and oxygen supply plays an important role in lactic acid production. ➤ A high DO level of 70-90% was required in the fermentation medium to achieve a high lactic acid yield and productivity. ➤ The enhanced DO level can improve the lactic acid production and limit the formation of ethanol.

- 6. 4. Temperature ➤ A Huang et. al., (2003) found that R. arrhizus DAR 36017 could grow well from 22 to 38 C, ➤ Although the production of lactic acid was temperature sensitive. ➤ Lactic acid concentration was obtained at the highest level at 30 C, ➤ while biomass production decreased with increasing temperature. ➤ Liu et. al., (2005) found that 27 C was an optimal temperature for the production of I(+)- lactic acid from cull potato by R. oryzae NRL 395 Optimum range of temperature for lactic acid fermentation is 27-35

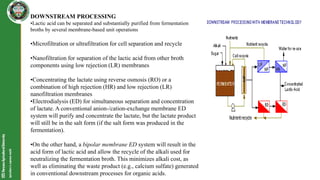

- 7. DOWNSTREAM PROCESSING •Lactic acid can be separated and substantially purified from fermentation broths by several membrane-based unit operations •Microfiltration or ultrafiltration for cell separation and recycle •Nanofiltration for separation of the lactic acid from other broth components using low rejection (LR) membranes •Concentrating the lactate using reverse osmosis (RO) or a combination of high rejection (HR) and low rejection (LR) nanofiltration membranes •Electrodialysis (ED) for simultaneous separation and concentration of lactate. A conventional anion-/cation-exchange membrane ED system will purify and concentrate the lactate, but the lactate product will still be in the salt form (if the salt form was produced in the fermentation). •On the other hand, a bipolar membrane ED system will result in the acid form of lactic acid and allow the recycle of the alkali used for neutralizing the fermentation broth. This minimizes alkali cost, as well as eliminating the waste product (e.g., calcium sulfate) generated in conventional downstream processes for organic acids.

- 8. A continuous membrane bioreactor (CMB) as a continuous stirred tank reactor (CSTR) coupled in a semi closed loop configuration to a membrane module, as shown in the diagram below. Synthetic semi-permeable membranes are used to separate and recycle the lactic acid bacteria, while simultaneously removing the lactate as it is formed. The continuous separation and recovery of the bacterial cells will reduce cycle time of the fermenters, since there will be little or no time lost due to start-up and shut down as in present batch fermenters. BIOREACTOR DESIGN

- 9. • The recycle of the cells will allow us to obtain much higher cell densities than currently practiced. Laboratory studies have shown a 100-fold increase in cell numbers in the CMB during operation. The high concentration allows us to pump the feedstock through the fermenters much faster. • "Cell wash-out" is eliminated, thereby allowing operation at dilution rates greater than the specific growth rate of the organism. • The continuous removal of lactate allows us to maintain the fermenter at just below the lactate level which inactivates the cells. Thus the cells are always viable and producing lactate.

- 10. Food industries: • Lactic acid is added to margarine, butter, yogurts etc. for its pleasant taste (taste enhancer). • Lactic acid is used as pickling agent for olives and pickled vegetables.It is also used as jelling agent for jams and jellies. • Calcium-lactate is added to milk and other sports drink as mineral supplement. • Lactic acid and its salt can increase the shelf life of food products like sausages, hams, poultry, fish, etc • .A large mass fraction of (>50%) fermentation grade Lactic acid is used to produce emulsifying agents such as sodium and calcium stearoyl lactate in bakery goods. • Calcium salt of this acid is a good dough conditioner and the sodium salt is both conditioner and emulsifier for Yeast leavened bakery products.

- 11. Pharmaceutical Industries: Poly lactic acid polymers are biocompatible, biodegradable and restorable materials used in medical application as sutures, orthopedic implants, controlled drug release etc. Polymers of Lactic acid interf badljusting the composition and the molecular wt., can control the degradation of biodegradable transparent thermoplamolec. Other applications in applications are formulation of ointments, lotions, anti-acne Otherons and dialysis applications. Ca-lactate can be used for calcium, denta therapy and as anti carries agents. Chemical Industries: Lactic acid is used as acidulant in Leather tanning industries. In small scale operations like pH adjustments, hardening baths for cellophanes used in food packaging, terminating agent for phenol formaldehyde resins, alkyl resin modifiers, solder flux, lithographic and textile printing developers, adhesive formulations, in electroplating and electro polishing baths, detergent builders etc. Lactic acid esters like ethyl/butyl lactates can be used as green solvents. They are high boiling, non-toxic and degradable components.

- 12. Thank You