Project Control Practical Way by Herve Baron

- 1. ©2015–HervéBaron Welcome to this tutorial It shows the practical ways and tools to control the progress of an Oil & Gas Project. Please download this file so that you can see my trainer’s notes in the top left corner – latest Acrobat Pro feature. Hervé Project Control

- 2. ©2015–HervéBaron Project Control Place your mouse over here Please download this file so that you can see my trainer’s notes in the top left corner – latest Acrobat Pro feature.

- 3. ©2015–HervéBaron Please download this file so that you can see my trainer’s notes in the top left corner – latest Acrobat Pro feature. Project Control Place your mouse over here

- 4. ©2015–HervéBaron Project Control Delayed Project completion are common place What are your bad / good experiences? Phase What happened? Why? How to prevent this? Engineering Procurement Construction

- 5. ©2015–HervéBaron Project Control Delayed Project completion are common place Phase What happened? Why? How to prevent this? Engineering Engineering unable to progress Lack of information from vendors Early placement of POs, identification + penalty for late dwgs, follow-up Procurement Supplier is late Supplier overloaded Purchaser progress control not effective Ensure proper progress data is requested, attach to payments Construction Construction behind plan Lack of accurate progress control Under estimation of certain trades Accurate (detailed) step- wise item-wise progress Eng/Constr interface Construction Timely completion of hydrotests Incentive put in place N/A

- 6. ©2015–HervéBaron Training Objectives Share Good practices, highlight meaningful information and good practices in: • Planning • Scheduling • Progress measurement Provide you with benchmarks, to enable you to control the execution of your CONTRACTOR

- 7. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule • Leading • Lagging Progress measurement & control • General • Engineering • Procurement • Construction

- 8. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions

- 9. ©2015–HervéBaron Training Agenda The plan • The Principle − The contractor/supplier draws its plan as per its workprocess − Risks should be identified − The client reviews the plan − The client monitors achievement against the plan − Recovery/acceleration actions are identified

- 10. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions

- 11. ©2015–HervéBaron Project Control: Starting point The plan

- 12. ©2015–HervéBaron Project Control: Starting point Basis of the schedule

- 13. ©2015–HervéBaron Project Control: Starting point Basis of the schedule What are these assumptions for an EPC Project?

- 14. ©2015–HervéBaron Project Control: Starting point Basis of the schedule • Quantities • Productivities • CPY/Third party approvals • Purchasing cycle • LLI lead time • Other eqt and bulk lead time • Steel structures lead time • Transportation duration • TSF/camp • Early works • Pre-fab • Heavy/large equipment Lifts • Type of foundations • Commissioning sequence: Power > Utilities > Process

- 15. ©2015–HervéBaron Oil & Gas Projects Most likely critical path What is the most likely critical path of Oil & Gas Projects?

- 16. ©2015–HervéBaron Most likely critical path Source: “The Oil & Gas Engineering Guide”, 2nd Edition, 2015, Hervé Baron, Editions Technip

- 17. ©2015–HervéBaron Most likely critical path For the explanation and justification of the most likely critical path, please refer to: ”The Oil & Gas Engineering Guide”, 2nd Edition”, Hervé Baron, Editions Technip, Mars 2015 http://www.editionstechnip.com/en/catalogue-detail/1111/oil-gas-engineering-guide-the.html

- 18. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity

- 19. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity What would you review in the CTR proposed initial schedule?

- 20. ©2015–HervéBaron Project Control: Starting point Schedule integrity • No lags (which cannot be statused during schedule up-dates): to be replaced by activity • No open end, i.e., no activity without a predecessor, except Project Start, no activity without a successor, except Project Finish • No fixed constraints • Resource levelling has been done • Critical paths • Compliance with CONTRACT Milestones, intermediate CD • Float • Number of critical activities (10-15%) • Schedule logic

- 21. ©2015–HervéBaron Project Control: Starting point Schedule integrity • No lags (which cannot be statused during schedule up-dates): to be replaced by activity • No open end, i.e., no activity without a predecessor, except Project Start, no activity without a successor, except Project Finish • No fixed constraints • Resource levelling has been done • Critical paths • Compliance with CONTRACT Milestones, intermediate CD • Float • Number of critical activities (10-15%) • Schedule logic

- 22. ©2015–HervéBaron Project Control: Starting point Checking the schedule logic: typical FEED Engineering schedule Source: “The Oil & Gas Engineering Guide”, 2nd Edition, 2015, Hervé Baron, Editions Technip http://www.editionstechnip.com/en/catalogue- detail/1111/oil-gas-engineering-guide-the.html

- 23. ©2015–HervéBaron Project Control: Starting point Checking the schedule logic: typical EPC Engineering schedule Source: “The Oil & Gas Engineering Guide”, 2nd Edition, 2015, Hervé Baron, Editions Technip http://www.editionstechnip.com/en/catalogue- detail/1111/oil-gas-engineering-guide-the.html

- 24. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule How would you ensure compliance with the schedule?

- 25. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule • Leading: look-ahead schedule / “to do” list • Lagging: review schedule up-dates

- 26. ©2015–HervéBaron Example: FEED Project / Schedule set-up and monitoring

- 27. ©2015–HervéBaron Follow-up: the weekly “to do” list

- 28. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule • Leading: look-ahead schedule / “to do” list • Lagging: review schedule up-dates

- 29. ©2015–HervéBaron Schedule up-dates: Milestones status review

- 30. ©2015–HervéBaron Schedule up-dates Review of she schedule up-dates • Late actual starts % S slips, Avg # days delay • Late actual finish % F slips, Avg # days delay • Change of logic nb logic changes • Change of duration • Increase in number of activities with total float < 50 days • Increase in number of activities with total float <= 0 days • Change in critical paths

- 31. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule • Leading • Lagging Progress measurement & control • General • Engineering • Procurement • Construction

- 32. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule • Leading • Lagging Progress measurement & control • General • Engineering • Procurement • Construction What is the worst measure of progress?

- 33. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule • Leading • Lagging Progress measurement & control • General • Engineering • Procurement • Construction What is the worst measure of progress? Manhours spent

- 34. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule • Leading • Lagging Progress measurement & control • General • Engineering • Procurement • Construction Physical progress is better… here is how we measure it

- 35. ©2015–HervéBaron Progress Measurement/The principles The various activities of a Project are weighted as per their $ value (common denominator). They are broken down in elementary tasks, the progress of each one if tracked by work steps. For instance, procurement of an equipment: 10% for placing of PO, 50% for raw material at supplier’s shop etc. The Individual progress of each task are then integrated to give the overall progress. The schedule information (planned date for each of these activities/tasks) gives the planned progress for each cut-off date and allows to compare planned vs actual progress

- 36. ©2015–HervéBaron Progress Measurement The graphical depiction of the planned progress is the “S” curve, Plotting the actual progress allows to identify delay and cruising speed

- 37. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule • Leading • Lagging Progress measurement & control • General • Engineering • Procurement • Construction

- 40. ©2015–HervéBaron Engineering Progress What additional information do you need to assess Engineering progress performance?

- 41. ©2015–HervéBaron Engineering Progress What conclusions do you derive from the above Progress table?

- 42. ©2015–HervéBaron Engineering Progress What additional information do you need to assess the reason for the lag in Process progress?

- 43. ©2015–HervéBaron Process Progress vs Manhours In your opinion, what is the reason of the lack of progress?

- 44. ©2015–HervéBaron Safety Engineering In your opinion, how is Safety performing?

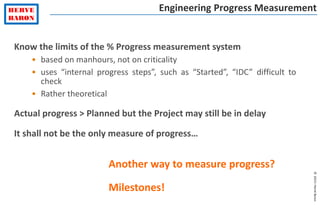

- 45. ©2015–HervéBaron Engineering Progress Measurement Know the limits of the % Progress measurement system • based on manhours, not on criticality • uses “internal progress steps”, such as “Started”, “IDC” difficult to check • Rather theoretical Actual progress > Planned but the Project may still be in delay It shall not be the only measure of progress… Another way to measure progress?

- 46. ©2015–HervéBaron Engineering Progress Measurement Know the limits of the % Progress measurement system • based on manhours, not on criticality • uses “internal progress steps”, such as “Started”, “IDC” difficult to check • Rather theoretical Actual progress > Planned but the Project may still be in delay It shall not be the only measure of progress… Another way to measure progress? Milestones!

- 47. ©2015–HervéBaron Engineering Progress Measurement Source: “The Oil & Gas Engineering Guide”, 2nd Edition, 2015, Hervé Baron, Editions Technip

- 48. ©2015–HervéBaron Engineering Progress Measurement => Request the schedule up-dates to contain the status of these MS

- 49. ©2015–HervéBaron Engineering Progress Measurement Know the limits of the % Progress measurement system • based on manhours, not on criticality • uses “internal progress steps”, such as “Started”, “IDC” difficult to check • Rather theoretical Actual progress > Planned but the Project may still be in delay It shall not be the only measure of progress… Another way to measure progress?

- 50. ©2015–HervéBaron Engineering Progress Measurement Know the limits of the % Progress measurement system • based on manhours, not on criticality • uses “internal progress steps”, such as “Started”, “IDC” difficult to check • Rather theoretical Actual progress > Planned but the Project may still be in delay It shall not be the only measure of progress… Another way to measure progress? Workfront curves

- 51. ©2015–HervéBaron Engineering Progress Measurement Available work front

- 52. ©2015–HervéBaron Engineering Progress Measurement Available work front How many such workfront curves do you draw?

- 53. ©2015–HervéBaron Factors that could delay Engineering Be vigilant with respect to the factors that can impact the schedule • delay in critical vendor drawings => check delays in submission are penalized in POs, monitor timely submission

- 54. ©2015–HervéBaron Factors that could delay Engineering Be vigilant with respect to the factors that can impact the schedule • delay in critical vendor drawings => check delays in submission are penalized in POs, monitor timely submission Source: “The Oil & Gas Engineering Guide”, 2nd Edition, 2015, Hervé Baron, Editions Technip

- 55. ©2015–HervéBaron Factors that could delay Engineering Be vigilant with respect to the factors that can impact the schedule • delay in critical vendor drawings => check delays in submission are penalized in POs, monitor timely submission Source: “The Oil & Gas Engineering Guide”, 2nd Edition, 2015, Hervé Baron, Editions Technip

- 56. ©2015–HervéBaron Factors that could delay Engineering Be vigilant with respect to the factors that can impact the schedule • delay in critical vendor drawings => check delays in submission are penalized in POs, monitor timely submission • dragging pending technical issues, delays will lead to re-work => ensure resolution is expedited • pending open points, e.g. deviation requests => demand a log and its up-date • delay in implementation of HAZOP, 3D model review, P&ID review action points => ask for monthly status Delays in the definition of interfaces with third parties => demand and check status Transfer from home office Engineering center to satellite office => check hand-over plan, detailed work instruction issued describing work to be done, tools to be used, deliverables to be issued, check adequate follow-up

- 57. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule • Leading • Lagging Progress measurement & control • General • Engineering • Procurement • Construction Wrap-up: the Project Control dashboard of the Project during Engineering phase….

- 58. ©2015–HervéBaron Project Control dashboard Source: “The Oil & Gas Engineering Guide”, 2nd Edition, 2015, Hervé Baron, Editions Technip http://www.editionstechnip.com/en/catalogue- detail/1111/oil-gas-engineering-guide-the.html

- 59. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule • Leading • Lagging Progress measurement & control • General • Engineering • Procurement • Construction

- 61. ©2015–HervéBaron Procurement progress control % Progress Milestones How do you measure Procurement Progress? What are the meaningful Procurement progress Milestones?

- 62. ©2015–HervéBaron Procurement schedule Benchmarks All LLI POs placed • Month 3 Last GADs for LLI Equipment • Month 9 1st Piping Inquiry • Month 6 1st Piping PO • Month 10 Last Equipment PO • Month 10

- 63. ©2015–HervéBaron Procurement follow-up table Item RFQ BCD TBT Clarif PO Ex- Works ROS TC GTG Centrif pumps Piping bulk Etc.

- 64. ©2015–HervéBaron Critical Equipment In your opinion, which equipment are critical?

- 65. ©2015–HervéBaron Critical Equipment LLIs How are LLI identified?

- 66. ©2015–HervéBaron Critical Equipment LLIs How are LLI identified? Which other equipment are critical?

- 67. ©2015–HervéBaron Critical Equipment LLIs Equipment critical for site delivery • Heavy or high and large Equipment, for heavy lift • Columns requiring pre-dressing • Pressure vessels for nozzles availability for Piping erection

- 68. ©2015–HervéBaron Critical Equipment LLIs Equipment critical for site delivery • Heavy or high and large Equipment, for heavy lift • Columns requiring pre-dressing • Pressure vessels for nozzles availability for Piping erection What else?

- 69. ©2015–HervéBaron Critical Equipment LLIs Equipment critical for site delivery • Heavy or high and large Equipment, for heavy lift • Columns requiring pre-dressing • Pressure vessels for nozzles availability for Piping erection Equipment critical for vendor information • Rotating • Packages • Fired Equipment

- 70. ©2015–HervéBaron Procurement benchmarks Purchasing cycle: from inquiry to PO Lead Time • Equipment (except LLI): 10-18 months • Piping Bulk: 7 months for pipe, 8 months for fittings, 9 months for valves • Electrical equipment: 10-16 months • DCS: 17 months (including FAT) • Control - Safety - On/Off Valves: 9 to 12 months Transportation

- 71. ©2015–HervéBaron Supplier Progress Control The principle: • A supplier draws its schedule • The Purchaser monitors compliance Critical points • Learn the work sequence: different actors, critical activities • Monitor closely: you get what you inspect, not what you expect! Monitor, i.e. upon receipt of progress report: • Analyze the data critically, • Identify bottlenecks, • Draw list of actions required from the supplier • Request supplier to implement mitigations Progress Report Ensure the supplier puts the priority on your job!

- 72. ©2015–HervéBaron Supplier’s workprocess and reporting tool

- 73. ©2015–HervéBaron Supplier Progress Control Exercise: analyze the steel structure manufacturer’s reports and draw conclusions and recommendations

- 74. ©2015–HervéBaron Supplier Progress Control How are the various parties involved performing? • Drafting office • Planning Dept • Fab shop • Galvanizer What would you recommend?

- 75. ©2015–HervéBaron Incident in supply – case study CTR Material Requisition specifies flanged valves as per CPY spec Vendor offer is based on sandwich type, without flanges, this point is not picked up by purchaser during bid review & clarif The PO is placed with reference to the MR, supplier acknowledges the PO without comment Vendor drawing, showing valve without flange, is approved by purchaser CPY identifies the issue and requests compliance This comes very late => 1 year delay + > 1m USD extra cost In your opinion, how will the problem be solved? Who will pay?

- 76. ©2015–HervéBaron Training Agenda The plan • The Principle • Planning assumptions The schedule • Schedule integrity Monitoring the compliance to the schedule • Leading • Lagging Progress measurement & control • General • Engineering • Procurement • Construction

- 78. ©2015–HervéBaron Construction progress How to monitor construction progress, the case of cables for a FPSO: 254 km of Electrical cables, 166 km of Instrument cables and 69 km of Telecom cables to pull, gland, terminate. What is the progress?

- 79. ©2015–HervéBaron Construction Reporting: overall progress

- 80. ©2015–HervéBaron Construction Reporting: overall progress How to get an accurate progress of each trade?

- 81. ©2015–HervéBaron Construction Reporting: overall progress How to get an accurate progress of each trade? Break the work in elementary steps.

- 82. ©2015–HervéBaron Piping progress You must have a report down to elementary steps, i.e., status of each weld for piping, to actually monitor progress.

- 83. ©2015–HervéBaron E&I cable progress Individual item (cable) and work step (pull/gland/terminate) status Σ

- 84. ©2015–HervéBaron Work steps For various construction activities Foundations • Excavation / Re-bar / Formwork & Anchor bolts / Concrete Placing / Backfill & Compaction Pre-cast concrete • Re-bar / Formwork / Concrete Placing / Excavation / Installation / Backfill Steel Structure • Main steel erection / Bolting & Alignment / Grating / Hand rails, ladders, stairs /QC release (punch cleared) Equipment installation • Pump, Skid: Chipping & padding / Rigging / Leveling & Grouting / First alignment • Pressure vessel: same + Stage & ladders / Internals / Clean-out & box-up / Final check • Air-Cooler: Structure / Tube bundle / Mechanical part / Alignment

- 85. ©2015–HervéBaron Work steps Example: PR column Preparing the foundation to receive the Column Chipping process to enhance bond between column and foundation Erecting the Column Holding the Column with shims Mixing the Grout Pouring the GroutMixing the Grout Column pre-casting

- 86. ©2015–HervéBaron Construction pre-requisite Start activities at Site • Camp and TSF installed Start Civil works • Batching plant ready + on-spec Start Piping Pre-Fab • WPS and Welders qualified Start loop tests • Buildings completed incl. HVAC • DCS installed

- 87. ©2015–HervéBaron Construction schedule Benchmarks Start Civil works with good productivity • 30% IFC dwgs Start Piping Pre-Fab • 50% IFC ISOs • 70% Material (all types) delivered Start Piping erection • 30% Piping pre-fabricated Piping erection cruise • 60% Equipment erected • Civil works completed - area backfilled

- 88. ©2015–HervéBaron Construction The sub-contract arrangement: • Sub-contractor is paid installed quantities x agreed rates

- 89. ©2015–HervéBaron Construction The sub-contract arrangement: • Sub-contractor is paid installed quantities x agreed rates

- 90. ©2015–HervéBaron Construction The sub-contract arrangement: • Sub-contractor is paid installed quantities x agreed rates • This is regardless of resources employed • Hence productivity risk lies with sub-contractor Can you identify the conflict of interest?

- 91. ©2015–HervéBaron Construction The sub-contract arrangement: • Sub-contractor is paid installed quantities x agreed rates • This is regardless of resources employed • Hence productivity risk lies with sub-contractor Can you identify the conflict of interest? How would you avoid this conflict of interest?

- 92. ©2015–HervéBaron Construction Good Engineering / Construction communication • regular up-dates of work volumes to construction contractor for proper planning by SUB and avoid idle resources Check what information (list of steel structures, MTO with work volumes etc.) is exchanged and how frequently Engineering commitments to construction contractor • check the schedule commitments in construction sub-contracts for date of issue of drawings and delivery of equipment and materials (Work Time Schedule Exhibit of Sub-Contract) • Monitor the achievement of these commitments by the EPC contractor Control the timely deliveries of the EPC to its SUBs Good Engineering / Construction work process intergation • transfer of design ISO to construction contractor for spooling • organization for pipe supports mass and on-time fabrication

- 93. ©2015–HervéBaron Schedule commitments in sub-contract: sample

- 94. ©2015–HervéBaron Thank you for having gone through this tutorial It deals only with control of progress, i.e., schedule, but remember that if you are on-time you will also be on-budget as you will not need to extend mobilization of people and equipment! I will be happy to receive your comments which I will include after your agreement. Hervé mailto:Hervé.baron@gmail.com Project Control

- 95. ©2015–HervéBaron The Oil & Gas Engineering Guide - 2nd edition A unique synthesis for the busy Project professional 270 pages 300 illustrations Interested and wanting to know more on Engineering?

- 96. ©2015–HervéBaron The Oil & Gas Engineering Guide - 2nd edition Discipline presentation: activities and deliverables Table of Contents The overall process Methods & tools

- 97. ©2015–HervéBaron The Oil & Gas Engineering Guide - 2nd edition Table of Contents Discipline presentation: activities and deliverables

- 98. ©2015–HervéBaron The work of each Engineering discipline is described

- 99. ©2015–HervéBaron Design activities are explained, e.g., Plant Equipment layout

- 100. ©2015–HervéBaron Complex activities, such as QRA, are explained through a practical example.

- 101. ©2015–HervéBaron How are materials of construction selected ?

- 102. ©2015–HervéBaron How and when are Piping Materials ordered?

- 103. ©2015–HervéBaron A sample of all common Engineering documents is included

- 104. ©2015–HervéBaron A sample of all common Engineering documents is included Use this to specify what you want to your Engineering supplier !

- 105. ©2015–HervéBaron Verify the contents of engineering documents with check lists.

- 106. ©2015–HervéBaron Difference between Engineering and Shop drawings

- 107. ©2015–HervéBaron Understand the main technical aspects, e.g., DCS vs ESD

- 108. ©2015–HervéBaron The common 2 types of package control

- 109. ©2015–HervéBaron The different Plant drainage systems

- 110. ©2015–HervéBaron The dynamic forces to which an Off-Shore Plant is subject

- 111. ©2015–HervéBaron The Oil & Gas Engineering Guide - 2nd edition Table of Contents The overall process

- 112. ©2015–HervéBaron Use this as standard, question deviations.

- 113. ©2015–HervéBaron Understand the new 3D-model centered engineering process

- 114. ©2015–HervéBaron Know the interfaces between disciplines... and with Vendors

- 115. ©2015–HervéBaron Understand what drives the Project schedule

- 116. ©2015–HervéBaron The Oil & Gas Engineering Guide - 2nd edition Table of Contents Methods & tools

- 117. ©2015–HervéBaron Use these methods as standard, question deviations.

- 121. ©2015–HervéBaron The Oil & Gas Engineering Guide - 2nd edition This book is destined to both: Oil & Gas companies Project execution personnel Oil & Gas contractors Project execution personnel Date of publication: March, 2015.

- 122. ©2015–HervéBaron The Oil & Gas Engineering Guide 2nd edition If your are on the Client side, i.e., contracting Engineering services, this book will help you to: Specify to an Engineering supplier what you want: what deliverables and with what contents, Set a standard in Engineering execution that you and your supplier can adhere to: design stages/gates, methods to be used, etc. Specify the progress report you want, with the meaningful indicators, Ask the right questions to assess the true progress,

- 123. ©2015–HervéBaron The Oil & Gas Engineering Guide 2nd edition If your are on the Contractor side, i.e., performing Engineering activities, this book will help you to: Understand the work of each discipline and the overall picture, Challenge what one discipline tells you, Understand the critical areas, Put in place the right methods to be successful,

- 124. ©2015–HervéBaron The Oil & Gas Engineering Guide 2nd edition Order direct from the publisher: http://www.editionstechnip.com/en/catalogu e-detail/1111/oil-gas-engineering-guide- the.html