Quality Course 2, Including Iso9001

- 1. Responsibility One point to remember – this course can only provide an overview of Quality and how the ISO Quality standard might apply to your organisation. It is not stating that you must or should apply all the items mentioned in it. That decision is up to each organisation – only you can decide which parts should apply.

- 2. Quality Training Course Why are you here ? What is your experience (if any) in Quality ? What do you hope to get from this course ? Are there any areas in Quality on which you would like more time spent ? If a question on Quality occurs to you during the course, please let me know.

- 3. Quality Training Course Course Outline

- 4. Product and Service Quality Please note that examples have been used that make reference to areas that apply to both manufacturing and non manufacturing organisations, but there will be certain areas that will apply more to manufacturing Also remember that even a manufacturing organisation also provides services – invoicing of suppliers, payment to customers, engineering support staff, Quality contacts with the customer, sales staff, etc.

- 5. Course Objectives To ensure that : participants understand the reason for good Quality participants understand the ISO 9001:2000 standard participants can prepare a Quality manual for their organisation To encourage all participants to suggest and implement Quality improvements in their organisation.

- 6. Quality Course Detail What is Quality ? Who is responsible for Quality ? Why is Quality important ? A short history of Quality What is the Quality standard ISO9001 and how does it affect me in my work ? How and why top management should be involved in Quality Overview of a Quality Management System (QMS) Detailed review of the ISO9001:2000 standard.

- 7. What is Quality ? Does ‘Quality’ concern products ? Service ? People ? Which of these needs to be addressed first ? Product Quality is usually defined as ‘fitness for purpose’ is this sufficient ? Service Quality can be defined as ‘satisfying the customer’ is this sufficient ? Quality - the degree to which a set of inherent characteristics fulfils requirements.

- 8. Who is responsible for Quality ? Quality Quality department Production department Top management Shop Floor staff QC inspectors Everyone in an organisation. Office staff Suppliers Customers

- 9. Why is Quality important ? (1/2) Because : I am told that Quality is important My customer demands it Everyone talks about it It might help me attract more customers My business will run better if I have a good Quality system in place I will save money…

- 10. Why is Quality important ? (2/2) Because we want to improve : Customer loyalty Repeat business and referral Market share and revenue Flexible and fast responses to market changes Costs and cycle times through the efficient use of resources Alignment of processes Understanding and motivation of employees.

- 11. A Short History of Quality (1/8) Originally, many items were hand made and we relied on the skill and expertise of the craftsman With mechanisation and the industrial revolution, jobs became less skilled and people performed the same part of a job rather than making a complete item or providing a complete service Because of the reduction in skill (or rather a reduction in training and restrictions on what people were allowed to do), people were less likely to ‘own’ what they made and felt less responsible for the finished item. This did not help Quality. Following on from this, it became necessary to check what people had made…

- 12. A Short History of Quality (2/8) This resulted in having people whose job it was to check the Quality of the products made. These were called Quality controllers and they inspected the products. So a lot of time and money was spent on inspection because no-one felt confident that there was control over the process The inspection process became quite sophisticated and used various techniques such as sampling tables and acceptance levels, and this way of working was fine for many years. But of course it had several flaws…

- 13. A Short History of Quality (3/8) Some of the flaws were : It further alienated the people who made the product. They felt less and less responsible for it – after all, it was Quality Control’s job to check it, and find the faults. This eventually resulted in the situation where people felt QC were responsible for Quality The tendency was to focus on the final product rather than the stages in between. This meant that if something was found to be wrong, it was often too late to correct it, and while the fault may not have reached the customer, rejects became an expensive item. Also…

- 14. A Short History of Quality (4/8) The focus was on the product or service and not on the processes that were involved in making the product. So at best, even with 100 % inspection, faulty parts were produced before any action was taken Wouldn’t it be nice if we could do something to : Find problems before they occurred ? Measure and correct the processes so that we minimised the chances of non conforming product being made or a poor service being provided ?...

- 15. A Short History of Quality (5/8) This brings us to where we are today. Tools were developed to prevent problems rather than detect them. Tools such as : Documented procedures for carrying out work Preventive / predictive maintenance Statistical Process Control Customer feedback / surveys Quality Management Systems…

- 16. A Short History of Quality (6/8) The other thing that was happening was that the major customers (e.g. car companies, aircraft manufacturers, food companies, pharmaceutical companies…) wanted to ensure that their suppliers were producing good products for them So the concept of auditing was introduced, where a representative of the customer would visit the supplier and go through their Quality system to ensure that it was up to the customer standard The problem was that this was an expensive process, especially if you had hundreds of suppliers…

- 17. A Short History of Quality (7/8) Wouldn’t it be good if customers could agree on an independent audit that would mean a supplier met certain standards ? So from these parallel issues (trying to prevent problems before they happened, and trying to minimise the costs of auditing all one’s suppliers) : The Quality Management System standard was born. It was only natural that ISO should be the organisation to do it. The standard is now in its 3 rd revision. Most Irish companies that are certified, are certified to the 1994 version. But this version becomes obsolete at the end of 2003, and all companies must update to the 2000 version by then…

- 18. A Short History of Quality (8/8) Service organisations did not change as much over time, and it could be said that the Quality and level of service over the years has not improved as much as that of manufacturing organisations But whereas the service provision may be similar, the expectations of the customer have changed a lot and it could be argued that the level of service has not kept pace with customer requirements and expectations However, it is often the case that the end user, the public, are less strict or fussy about Quality than when you supply to another organisation – this can result in poor service to the public. Furthermore, organisations in a monopoly situation have a tendency to be less Quality conscious Some areas are so critical to our health, that special regulations are involved – e.g. medical, pharmaceutical, food industry.

- 19. What is the Quality standard ISO9001:2008 and how does it affect me ? ISO9001:2008 is a Quality management system that uses a process approach to devise, document, implement, and review an organisation’s plans, objectives, and procedures relating to Quality. It is based on 8 key principles as shown on the following page.

- 20. 8 Key Management Principles Customer focus Leadership Involvement of people : at all levels Process approach System approach to management : managing inter-related processes to ensure effective and efficient achievement of objectives Continual improvement Factual basis to decision making : data analysis Mutually beneficial suppler relationships to create value.

- 21. How and why top management should be involved in Quality (1/2) Top management must provide evidence of its commitment to developing and implementing the organisation’s Quality management system Top management must be involved in setting the Quality policy and Quality objectives Top management must ensure that all relevant Quality information is communicated throughout the organisation Top management must review the effectiveness of the Quality management system…

- 22. How and why top management should be involved in Quality (2/2) There is one key reason why top management must be involved with and committed to Quality : Without their agreement, it will be virtually impossible to implement any effective Quality system – why ?

- 23. Process Based System (1/2) A process approach emphasises the importance of : Understanding and fulfilling customer requirements (and those of other interested parties – employees, suppliers, owners, the public) Considering processes in terms of added value Obtaining results of process performance and effectiveness Continual improvement of processes based on objective measurement…

- 24. Process Based System (2/2) Because the new standard in process based, a good approach can be to : Identify all the processes in an organisation Draw up a process flow chart for each process (can help to include the standard clause number) Show the controls involved for each of these processes (plan – do – check – act) Don’t forget the supporting processes (maintenance, calibration, inspection…) May have a separate page to refer to the scope of the document, who is responsible, the purpose of the document, what records are kept… The next slide shows an overview of the standard as a system of related processes.

- 25. Process of repairing a faulty vacuum cleaner Repair of item – Written instructions required ? Training and experience of repairer Defined sequence of actions Control of purchase orders Confirmation that correct component arrives When will the item be repaired ? Test item. Receipt of item Identification of item Note fault as reported Knowledge of repairer Sequence of actions New part required ? – P.O. Tools and equipment Identify item as being ok

- 26. Process-based QMS Continual improvement of the Quality Management System Customers (and other interested parties) Requirements Management responsibility Resource management Measurement analysis and improvement Product realisation Product / service Customers (and other interested parties) Satisfaction 5.x 6.x 7.x 8.x Output Input Value adding activities Information flow

- 27. QMS and Business Plan (1/2) The new standard makes it easier to link the organisation’s Quality Management System with its overall business plan The business plan should be a controlled document It should be referenced in the Quality manual It should be reviewed at specified frequencies The business plan will cover all areas of an organisation (manufacturing, marketing, sales, purchasing, service level…), and might be set up as indicated on the next slide…

- 28. QMS and Business Plan (2/2) Example of section of organisation business plan 3 2 Weekly reject reports Complete. WIP. Behind schedule 30 Apr 31 May 17 Apr M.D. Q.M. P.M. 1.1 1.2 1.3 Reduce defects by 5% over 2002 level 1 Perf. indicator Status Due date Resp. Actions Description Objective

- 29. Overview of Standard 4 Quality Management System 4.1 General requirements 4.2 Documentation requirements 4.2.1 General 4.2.2 Quality manual 4.2.3 Control of documents 4.2.4 Control of records This section deals with the setting up and administration of the Quality Management System (QMS).

- 30. 4.1 General Requirements The organisation shall establish, document, implement, and maintain a Quality management system, and continually improve its effectiveness. To do this, it needs to : Identify all the processes involved, their sequence and how they interact Determine criteria and methods Ensure availability of resources and information Monitor, measure, and analyse the processes Ensure control over any processes that are outsourced and that affect product conformity Implement actions to achieve planned results and ensure continual improvement.

- 31. ISO9004 : 2000 – 4.1 Q.1 : How does management apply the process approach to achieve the effective and efficient control of its processes, resulting in performance improvement ?

- 32. 4.2 Documentation Requirements 4.2.1 Documentation requirements – general A Quality policy Quality objectives Quality manual Documented procedures – 6 mandatory Other documentation/procedures to ensure effective planning, operation, and control of its processes Records.

- 33. 4.2 Benefits of effective documentation (1/2) Defines the nature and inter-relationship of business processes Describes how the organisation operates Assigns responsibilities for actions and decisions Encourages consistency of action and uniformity of understanding throughout the organisation Communicates instructions and information, as well as proposed changes Enables new employees to become more productive and effective…

- 34. 4.2 Benefits of effective documentation (2/2) Ensures that activities can continue to function effectively even if key personnel are absent Enables systematic auditing to verify effectiveness Nominates the records to be kept, and reference documents, including work instructions Stipulates key performance indicators Demonstrates the commitment to Quality, to customers and employees.

- 35. ISO9004 : 2000 – 4.2 Q.2 : How are documents and records used to support effective and efficient operation of the processes of the organisation ?

- 36. 4.2.2 Quality Manual (1/5) 4.2.2 Quality manual Covers the scope of the QMS, including any details on exclusions Includes or refers to documented procedures Shows or describes the interaction between processes – perhaps an overall flow chart...

- 37. 4.2.2 A Quality Manual is : (2/5) A rule book by which the organisation functions A source of information from which customers may derive confidence A means of defining responsibilities and inter related activities of all employees A medium for defining the level of Quality that an organisation wishes to consistently deliver A vehicle for auditing, reviewing, and evaluating an organisation’s QMS A single point of reference required to run an organisation’s Quality system…

- 38. 4.2.2 A Quality Manual Must : (3/5) Include a statement of the organisation’s policy towards Quality Contain details of the organisation’s Quality management structure and organisation , together with job descriptions and responsibilities Describe the organisation’s Quality control requirements, training programmes…

- 39. 4.2.2 A Quality Manual Should : (4/5) Identify lower level documents such as procedures, work instructions, standard operating procedures Ideally cover each clause and requirements in the standard It may also include form templates used internally and with suppliers (can hyperlink from the Manual to the template)…

- 40. 4.2.2 Typical Quality Manual Structure (5/5) Organisational overview : Quality objectives and commitment to Quality General statement about Quality Business principles Organisational charts Core business processes and supporting processes Key Quality responsibilities Manual administration Scope and field of application Process definitions and system outline : How processes are controlled Reference matrix or list of documented procedures.

- 41. 4.2.3 Control of Documents This is one of the 6 documented procedures. Ensure documents are approved before use Review and update documents – revision status Relevant versions available at point of use – could apply to our suppliers (e.g. purchase orders) Ensure documents remain legible, retrievable, and identifiable Prevent use of obsolete documents External documents also need to be controlled – including standards, drawings, specifications, etc.

- 42. 4.2.4 Control of records This is one of the 6 documented procedures. Records exist to prove evidence of conformity to requirements and of effective operation of the QMS. They must be : Legible Readily identifiable Retrievable How do we store and protect records and for how long ? How do we dispose of records and who is responsible for this ?

- 43. 5 Management Responsibility 5.1 Management commitment 5.2 Customer focus 5.3 Quality policy 5.4 Planning 5.5 Responsibility, authority, and communication 5.6 Management review.

- 44. 5.1 Management Commitment (1/4) Top management must : Communicate throughout the organisation the importance of meeting the customers’ as well as statutory requirements Establish the Quality policy Establish Quality objectives Conduct management reviews Ensure the availability of resources…

- 45. 5.1 Management Commitment (2/4) Top management should : Be actively involved in developing and maintaining an effective and efficient QMS. It should lead by example Participate in improvement projects – new methods, products, solutions Look for feedback on the effectiveness of the QMS Create an environment that encourages employee involvement Provide the structure and resources that are necessary to support the organisation’s strategic plans Define methods for measurement of the organisation’s performance in order to determine whether planned objectives have been achieved…

- 46. 5.1 Management Commitment (3/4) Top management should also demonstrate leadership in, and commitment to : Understanding current and future customer needs, expectations, and requirements Promoting policies and objectives to increase awareness, motivation, and involvement of employees Establishing continual improvement as an objective for all organisational processes Planning for the future of the organisation and managing change Developing and communicating a framework for achieving customer satisfaction, and satisfaction of other interested parties…

- 47. 5.1 Management Commitment (4/4) Top management should consider : Ensuring that the sequence and interaction of processes are designed to achieve the desired results effectively and efficiently Ensuring that process inputs, activities, and outputs are clearly defined and controlled Monitoring inputs and outputs to verify that individual processes are linked, and operate effectively and efficiently Identifying and managing risks Exploiting performance improvement opportunities Identifying process owners and giving them responsibility and authority.

- 48. ISO9004 : 2000 – 5.1 Q. 3 : How does top management demonstrate its (visible) leadership, commitment, and involvement ?

- 49. 5.2 Customer Focus (1/2) Top management must ensure that customer requirements are determined and are met, with the aim of enhancing customer satisfaction (see also 7.2.1 and 8.2.1 later)…

- 50. 5.2 Customer Focus (2/2) In order to understand and meet the needs and expectations of interested parties, and organisation should : Identify all interested parties Translate identified needs and expectations into requirements Communicate the requirements throughout the organisation Focus on process improvement to ensure value for all interested parties.

- 51. ISO9004 : 2000 – 5.2 Q. 4 (a) : How does the organisation identify customers needs and expectations on a continual basis ? Q. 4 (b) : How does the organisation identify people’s needs for recognition, work satisfaction, competence, and personal development ? Q. 4 (c) : How does the organisation consider the potential benefits of establishing partnerships with its suppliers ? Q. 4 (d) : How does the organisation identify other interested parties’ needs and expectations that can result in setting objectives ? Q. 4 (e) : How does the organisation ensure that statutory and regulatory requirements have been considered ?.

- 52. 5.3 Quality policy (1/2) Top management needs to devise a Quality policy that : Is appropriate for the organisation Includes a commitment to comply with the requirements of the QMS, and to continually improve its effectiveness Provides a framework for establishing and reviewing the Quality objectives Is communicated and understood throughout the organisation – how might this be done ? Is reviewed for continuing suitability…

- 53. 5.3 A Quality Policy Should Consider : (2/2) The level and type of future improvement needed for the organisation to be successful The expected/desired degree of customer satisfaction The development of people in the organisation The needs and expectations of other interested parties The resources needed to achieve and go beyond the ISO9001 requirements The potential contributions of suppliers and partners.

- 54. ISO9004 : 2000 – 5.3 Q. 5 (a) : How does the Quality policy ensure that the needs and expectations of customers and other interested parties are understood ? Q. 5 (b) : How does the Quality policy lead to visible and expected improvements ? Q. 5 (c) : How does the Quality policy consider the organisation’s vision of the future ?.

- 55. 5.4.1 Quality Objectives (1/2) Top management needs to establish Quality objectives that : Fulfil product requirements Are measurable and consistent with the Quality policy Are established at relevant functions and levels within the organisation The Quality objectives should be S.M.A.R.T. and have key performance indicators…

- 56. 5.4.1 Setting the Quality Objectives (2/2) Should consider : The current/future needs of the organisation and the markets Relevant findings from the management reviews The current product and process performance The levels of satisfaction of customers Self assessment results (e.g. internal audits) Competitor analysis, benchmarking, other opportunities for improvement The resources needed to meet the objectives.

- 57. 5.4.2 QMS planning (1/4) Top management must ensure that : The planning of the QMS is carried out in order to meet the requirements (4.1 ) as well as the objectives, and The integrity of the QMS is maintained when changes are planned and implemented QMS planning is concerned with how to achieve the specified Quality objectives – the plan, do, check, act cycle…

- 58. 5.4.2 QMS planning (2/4) The planning should include The processes required in the QMS, considering permissible exclusions The resources needed The continual improvement of the QMS Maintenance of the integrity of the QMS during changes to it Who is responsible for each of the QMS planning aspects and methods of monitoring…

- 59. 5.4.2 QMS planning (3/4) Inputs to the planning include : The strategies of the organisation The defined organisational objectives The defined needs and expectations of the customers and other interested parties Evaluation of statutory and regulatory requirements Evaluation of performance data of the products/service Evaluation of performance data of processes Lessons learned from previous experience Indicated opportunities for improvement Related risk assessment data…

- 60. 5.4.2 QMS planning (4/4) Outputs to the planning include : Areas that define the product/service realisation and support processes Skills and knowledge needed by the organisation The responsibility and authority for implementing the process improvement plans The resources needed (finance, infrastructure) Performance indicators for evaluating the achievement of the organisation’s performance improvement Documentation and records requirements.

- 61. ISO9004 : 2000 – 5.4 Q. 6 (a) : How do the Quality objectives translate the Quality policy into measurable goals ? Q. 6 (b) : How are the Quality objectives deployed to each management level to assure individual contribution to achievement ? Q. 6 (c) : How does management ensure the availability of resources needed to meet the Quality objectives ?.

- 62. 5 Management Responsibility 5.5 Responsibility, authority, and communication 5.5.1 Responsibility and authority 5.5.2 Management representative 5.5.3 Internal communication.

- 63. 5.5.1 Responsibility and authority Top management must ensure that responsibilities and authorities are defined and communicated within the organisation : Who is responsible for what – may include job descriptions. This helps identify not only who is responsible, but also the limit of their responsibility Who has authority for decisions or for over-riding decisions The above is only partially useful unless everyone is aware of who to contact.

- 64. 5.5.2 Management Representative Top management must appoint a member of management who irrespective of other responsibilities, will have responsibility and authority for : Ensuring that the processes needed for the QMS are established, implemented, and maintained Reporting to top management on the performance of the QMS and any need for improvement Ensuring the promotion of awareness of customer requirements throughout the organisation.

- 65. 5.5.3 Internal Communication Top management needs to ensure that appropriate communication processes are established and implemented within the organisation and that communication takes place regarding the effectiveness of the QMS, and communicating the Quality policy, Quality objectives, accomplishments, and interested party requirements. How might this be done ? Management should encourage feedback and communication from people in the organisation as a means of involving them.

- 66. ISO9004 : 2000 – 5.5 Q. 7 (a) : How does top management ensure that responsibilities are established and communicated to people in the organisation ? Q. 7 (b) : How does communicating Quality requirements, objectives, and accomplishments contribute to improvement of the organisation’s performance ?.

- 67. 5 Management Responsibility 5.6 Management review 5.6.1 General 5.6.2 Review input 5.6.3 Review output.

- 68. 5.6.1 Management Review - General (1/3) Top management must review the organisation’s QMS at planned intervals to ensure its continuing suitability, adequacy, efficiency, and effectiveness. Also, opportunities for improvement and assessing the need for changes to the QMS need to be reviewed, including the Quality policy and Quality objectives Records must be maintained There should be an agenda (covering all clauses in the standard plus the items on the next page), minutes, and corrective action plans…

- 69. 5.6.1 Management Review – General (2/3) Top management should stimulate the exchange of new ideas, should encourage open discussion, and evaluate the review inputs The frequency of the review is determined by the needs of the organisation Outputs from the review should provide information for planning performance improvement…

- 70. 5.6.1 Management Review – General (3/3) The objective of a management review is to ensure that the QMS : Is achieving the expected results Meets the organisation’s requirements Conforms to the requirements of ISO9001:2000 Continues to satisfy the customers’ needs and expectations Is functioning according to the established operating procedures Is capable of identifying weaknesses and evaluating possible improvements.

- 71. 5.6.2 Management Review Input (1/2) The management review input must include information on : Results of audits Customer feedback Process performance and product conformity Status of corrective and preventive actions Follow-up actions from previous management reviews Changes that could affect the QMS (e.g. a new project or product line) Recommendations and opportunities for improvement…

- 72. 5.6.2 Management Review Input (2/2) Other inputs can include : Status and results of Quality objectives and improvement activities Feedback from other interested parties, perhaps even including their participation External factors such as technology changes, R & D, competitor performance, environmental changes, regulatory changes… Results from benchmarking activities Supplier performance Control of product and process non conformities Financial aspects of Quality activities (new investment, training, Quality costs, etc.).

- 73. 5.6.3 Management Review output (1/2) The output of a management review shall include any decisions and actions relating to : The improvement of the effectiveness of the QMS and its processes The improvement of product related to customer requirements Resource needs The output from a review should feed into the organisation’s overall business review and strategy The records should be sufficiently detailed to allow traceability and evaluation of the management review process itself, to ensure it is effective…

- 74. 5.6.3 Management Review output (2/2) The outputs should be communicated throughout the organisation, because there will usually be new product/service and process objectives arising from the review The output may result in : modifications to the organisation’s structure or resource requirements New initiatives for other departments (e.g. marketing, product development, design) Plans to reduce identified risks Performance objectives for products and processes Performance improvement objectives for the organisation.

- 75. ISO9004 : 2000 – 5.6 Q. 8 (a) : How does top management ensure valid input information is available for the management review ? Q. 8 (b) : How does the management review activity evaluate information to improve the effectiveness and efficiency of the processes of the organisation ?.

- 76. Overview of Standard 6 Resource Management 6.1 Provision of resources 6.2 Human resources 6.3 Infrastructure 6.4 Work environment This section deals with resource management and allocation.

- 77. 6 Resource Management 6.1 Provision of resources – determining and providing the resources needed To implement and maintain the QMS and continually improve its effectiveness To enhance customer satisfaction by meeting customer requirements.

- 78. ISO9004 : 2000 – 6.1 Q. 9 : How does top management plan for resources to be available in a timely manner ?

- 79. 6 Resource Management 6.2 Human resources 6.2.1 General 6.2.2 Competence, awareness, and training.

- 80. 6.2.1 Human Resources – General (1/3) People performing work affecting Quality shall be competent on the basis of : Appropriate education Training Skills Experience Whose work affects Quality ?...

- 81. 6.2.1 Human Resources – General (2/3) Top management needs to involve and support its employees for maximum result. This can be done through : ongoing training and support defining people’s responsibilities and authorities (very important that both are defined. There is nothing worse than having the responsibility but not the authority) establishing individual and team objectives facilitate involvement in objectives, target setting, and decision making…

- 82. 6.2.1 Human Resources – General (3/3) by facilitating open, 2-way communication by communicating suggestions and opinions by continually reviewing the needs of the employees by ensuring effective teamwork by recognising and rewarding by facilitating open, 2-way communication by checking why people join and leave the organisation.

- 83. 6.2.2 Competence, Awareness, and Training (1/4) The organisation shall : Determine the necessary competence (both current and future) for people performing work affecting product or service Quality Provide training or take other actions to satisfy these needs Evaluate the effectiveness of the actions taken (because training is a process) – how ? Ensure that people are aware of the relevance and importance of their activities and how they contribute to the achievement of the Quality objectives Maintain appropriate records of education, training, skills and experience…

- 84. 6.2.2 Competence, Awareness, and Training (2/4) Evaluation of training needs should include : People’s current experience People’s implicit and explicit knowledge Teamwork requirements Problem solving skills Communications skills Current and future needs and expectations of customers Need for creativity and innovation Specific skills required for the job Current and future needs of the organisation…

- 85. 6.2.2 Competence, Awareness, and Training (3/4) Need to consider : Future management and succession issues Changes to an organisation’s processes, tools, and equipment Any statutory or regulatory requirements and standards Leadership and management skills The organisation’s policies and objectives Induction programs and periodic refresher training The training and competence of employees should also take account of the customers’ and other interested party’s needs, requirements, and expectations…

- 86. 6.2.2 Competence, Awareness, and Training (4/4) Training plans should include : Objectives Training methods Resources needed Identification of necessary internal support Evaluation in terms of enhanced competence of people Measurement of the effectiveness and the impact on the organisation The training and education should be evaluated in terms of expectations and impact on the effectiveness and efficiency of the organisation, and as a means of evaluating future training plans.

- 87. ISO9004 : 2000 – 6.2 Q. 10 (a) : How does management promote involvement and support of people for improvement of the effectiveness and efficiency of the organisation ? Q. 10 (b) : How does management ensure that the competence of the people in the organisation is adequate for current and future needs ?.

- 88. 6.3 Infrastructure (1/2) The organisation shall determine, provide and maintain the infrastructure needed to achieve conformity to product requirements while considering the needs and expectations of interested parties. This includes, as applicable : Buildings, workspace, and associated utilities (tools, equipment…) Process equipment (hardware and software) Supporting services (e.g. transport, communication, maintenance) Natural phenomena – weather can affect some outside activities…

- 89. 6.3 Infrastructure (2/2) The process to define the necessary infrastructure for product realisation should include : Defining the objectives, function, performance, availability, cost, safety, security, and renewal Development and implementation of the maintenance to ensure that the infrastructure continues to meet the organisation’s needs Evaluation of the type and frequency of maintenance and verification required, based on criticality, safety, and usage Evaluation of the infrastructure against the needs and expectations of interested parties Consideration of environmental issues – conservation, pollution, waste, recycling Natural phenomena need also to be considered and how to reduce these risks and protect the interests of interested parties.

- 90. ISO9004 : 2000 – 6.3 Q. 11 (a) : How does management ensure that the infrastructure is appropriate for the achievement of the objectives of the organisation ? Q. 11 (b) : How does management consider environmental issues associated with the infrastructure ?.

- 91. 6.4 Work Environment The organisation shall determine and manage the work environment needed to achieve conformity to product requirements. This can include : Opportunities for involvement of people Safety rules, guidance, and use of safety equipment Ergonomics Social interaction Facilities in the organisation – heat, light, humidity, airflow Hygiene, cleanliness, noise, pollution, vibration etc.

- 92. ISO9004 : 2000 – 6.4 Q. 12 : How does management ensure that the work environment promotes motivation, satisfaction, development, and performance of people in the organisation ?

- 93. ISO9004 : 2000 – 6.5 : Information (1/2) This is NOT part of ISO9001:2000 Management should treat data as a fundamental resource for conversion to information and the continual development of an organisation’s knowledge. The organisations should : Identify its information needs Identify and access internal and external sources of information Convert information to knowledge of use to the organisation Use the information to set and meet its strategic objectives Ensure appropriate security and confidentiality Evaluate the benefits derived from information use in order to improve information management and knowledge…

- 94. ISO9004 : 2000 – 6.5 : Information (2/2) Q. 13 : How does management ensure that appropriate information is easily available for factually-based decision making ?

- 95. ISO9004 : 2000 – 6.6 : Suppliers and Partnerships (1/3) This is NOT part of ISO9001:2000 Management should establish relationships with suppliers and partners to promote and facilitate communication with the aim of mutually improving the effectiveness and efficiency of processes that create value This can be done by (see over)…

- 96. ISO9004 : 2000 – 6.6 : Suppliers and Partnerships (2/3) Optimising the number of suppliers and partners Establishing 2-way communication at appropriate levels in both organisations to facilitate the rapid solution of problems and to avoid delays and disputes Co-operating with suppliers in the validation of the capability of their processes Monitoring the ability of suppliers to deliver conforming products with the aim of eliminating redundant verifications Encouraging suppliers to implement continual improvement programs and to participate in joint activities Involving suppliers in the organisation’s design and development activities to share knowledge and effectively and efficiently improve the realisation and delivery processes for conforming products Involving suppliers in the identification of purchasing needs Evaluating, recognising, and rewarding efforts and achievements by suppliers and partners…

- 97. ISO9004 : 2000 – 6.6 : Suppliers and Partnerships (3/3) Q. 14 (a) : How does management involve suppliers in the identification of purchasing needs and joint strategy development ? Q. 14 (b) : How does management promote partnership arrangements with suppliers ?.

- 98. ISO9004 : 2000 – 6.7 : Natural Resources (1/2) This is NOT part of ISO9001:2000 Consideration should be given to the availability of natural resources that can influence the performance of the organisation The organisation should have contingency plans to ensure the availability or replacement of these resources in order to minimise or prevent negative effects on the performance of the organisation…

- 99. ISO9004 : 2000 – 6.7 : Natural Resources (2/2) Q. 15 : How does the organisation ensure the availability of necessary natural resources for its realisation processes ?

- 100. ISO9004 : 2000 – 6.8 : Financial Resources (1/3) This is NOT part of ISO9001:2000 Resource management should include activities for determining the needs for, and sources of financial resources This should include activities for comparing actual usage versus planned usage, and taking any necessary action Management should plan, make available, and control the financial resources necessary to implement and maintain an effective and efficient Quality Management System an to achieve the organisation’s objectives…

- 101. ISO9004 : 2000 – 6.8 : Financial Resources (2/3) Improving the QMS can positively affect the financial position of an organisation by : Internally reducing process and product failures, or waste of materials or time Externally reducing product failures, compensation costs (e.g. warranty), and costs of lost customers Reporting the above issues can help determine ineffective or inefficient activities, and initiate improvement actions The financial reporting of activities related to the performance of the QMS and product conformity should be used in management reviews…

- 102. ISO9004 : 2000 – 6.8 : Financial Resources (3/3) Q. 16 (a) : How does management plan, provide, control, and monitor the financial resources necessary to maintain an effective and efficient Quality Management System and to ensure the achievement of the organisation’s objectives ? Q. 16 (b) : How does management ensure awareness of people in the organisation about the link between product Quality and costs ?.

- 103. Overview of Standard 7 Product realisation 7.1 Planning of product realisation 7.2 Customer-related processes 7.3 Design and development 7.4 Purchasing 7.5 Production and service provision 7.6 Control of monitoring and measuring devices.

- 104. 7 Product Realisation Section 7 is the only area where an organisation can have exclusions. For example, if an organisation does not design products, then certain of the following sections do not apply. The organisation must specify these exclusions in its Quality manual.

- 105. 7.1 Planning of Product Realisation The organisation shall plan and develop the processes needed for product realisation. This shall be consistent with the requirements of the other QMS processes. In particular, the organisation shall determine, as appropriate : The Quality objectives and requirements for the product The need to establish processes, documents, and provide resources specific to the product Required verification, validation, monitoring, inspection, and test activities specific to the product and the criteria of product acceptance Management should plan the required outputs of processes, and should identify the necessary inputs and activities required for their achievement Records needed to provide evidence that the realisation process and resulting processes meet requirements.

- 106. ISO9004 : 2000 – 7.1 Product Realisation (1/7) Results from verification and validation of processes and outputs should be considered as inputs to a process to achieve continual improvement The organisation needs to : Identify and communicate the significant features of each process Provide training in the operation of processes Share knowledge and experience in teams and workgroups Measure and audit the processes Analyse, review, and improve the processes…

- 107. ISO9004 : 2000 – 7.1 Product Realisation (2/7) The role of people should be evaluated so that : The health and safety of people are ensured The necessary skills exist Process co-ordination is supported Input from people in process analysis is provided Innovation is promoted…

- 108. ISO9004 : 2000 – 7.1 Product Realisation (3/7) An operation plan should be developed to manage the processes, including : Input and output requirements (e.g. specifications and resources) Activities within the processes Verification and validation of processes and products Analysis of the process including dependability Identification, assessment, and mitigation of risk Corrective and preventive actions Opportunities and actions for process improvement Control of changes to processes and products…

- 109. ISO9004 : 2000 – 7.1 Product Realisation (4/7) Inputs derived from activities not yet fully evaluated should be subject to evaluation through subsequent review, verification, and validation The organisation should identify significant or critical features of products and processes in order to develop an effective and efficient plan for controlling and monitoring the activities within its processes Examples of input issues include competence of people, documentation, equipment capability and monitoring, health, safety, and work environment For verification purposes, the outputs should be recorded and evaluated against the input requirements and acceptance criteria The evaluation should identify corrective and preventive actions, potential improvements Variation of the product can be carried out in the process in order to identify variation…

- 110. ISO9004 : 2000 – 7.1 Product Realisation (5/7) Management should periodically review process performance to ensure it is operating according to planned arrangements Examples include : Reliability and repeatability of the process Identification and prevention of potential non conformities Adequacy of design and development inputs and outputs Consistency of inputs and outputs with planned objectives Potential for improvement Unresolved issues…

- 111. ISO9004 : 2000 – 7.1 Product Realisation (6/7) Management should ensure that the validation of products demonstrates that they meet the needs and expectations of customers and other interested parties Validation activities include modelling, simulation, trials, reviews involving customers and other interested parties Issues to consider include : Quality policy and objectives Capability or qualification of equipment Operating conditions for the product/service Use or application of the product Disposal of the product Product life cycle Environmental impact of the product Impact on the use of natural resources, including materials and energy…

- 112. ISO9004 : 2000 – 7.1 Product Realisation (7/7) Process validation should be carried out at appropriate intervals to ensure timely reaction to changes impacting the process Particular attention should be given to those processes : That have high value or are safety critical Where product deficiency only becomes apparent in use That cannot be repeated Where verification of product/service is not possible.

- 113. ISO9004 : 2000 – 7.1 Q. 17 : How does top management apply the process approach to ensure the effective and efficient operation of the realisation and support processes and the associated process network ?

- 114. 7.2 Customer-related Processes 7.2.1 Determination of requirements related to the product/service 7.2.2 Review of requirements related to the product/service 7.2.3 Customer communication.

- 115. 7.2.1 Determination of Requirements Related to the Product The organisation shall determine : Requirements specified by the customer including delivery and any post-delivery activities Requirements not stated by the customer but necessary for the specified or intended use, where known Statutory or regulatory requirements related to the product Any additional requirements.

- 116. 7.2.2 Review of Requirements Related to the Product This must be done before the organisation commits to supplying a product or service, and it must confirm the requirements to a customer even where the customer has not given any documented requirements. It must ensure that : The product/service requirements are identified Any order or contract changes are resolved. Relevant documents must be amended and relevant people must be made aware of the changed requirements The organisation has the ability to meet the defined requirements Records must be kept of these reviews and of any actions taken.

- 117. 7.2.3 Customer Communication The organisation shall determine and implement effective arrangements for customer communication in relation to : Product information Enquiries, contracts, order handling, including amendments Customer feedback, including customer complaints.

- 118. ISO9004 : 2000 – 7.2 Q. 18 (a) : How has management defined customer-related processes to ensure consideration of customers’ needs ? Q. 18 (b) : How has management defined other interested party processes to ensure consideration of interested parties’ needs and expectations ?.

- 119. 7 Product Realisation 7.3 Design and development 7.3.1 Design and development planning 7.3.2 Design and development inputs 7.3.3 Design and development outputs 7.3.4 Design and development review 7.3.5 Design and development verification 7.3.6 Design and development validation 7.3.7 Control of design and development changes.

- 120. 7.3.1 Design and development planning The organisation needs to determine : The design and development stages Review, verification, and validation, appropriate to each design and development stage The responsibilities and authorities for design and development The planning output needs to be updated as the design and development progresses.

- 121. 7.3.2 Design and development inputs (1/2) Inputs include : Functional and performance requirements Customer (and other interested parties) marketplace needs and expectations Supplier’s contributions Applicable statutory and regulatory requirements Where applicable , information derived from previous similar designs Other requirements essential for design and development Records need to be maintained and the inputs reviewed for adequacy Requirements must be complete, unambiguous, and not in conflict with each other…

- 122. 7.3.2 Design and development inputs (2/2) Internal inputs include : Policies and objectives Technological developments Feedback from previous experience Data and records from existing products and processes Outputs from other processes Needs and expectations of people in the organisation, including those receiving the output of the process Competence requirements for people performing design and development.

- 123. 7.3.3. Design and development outputs (1/2) Shall be in a form that enables verification against the design and development inputs, and shall be approved prior to release. The outputs shall : Meet the input requirements Provide appropriate information for purchasing, production, and service provision Contain or reference product acceptance criteria Specify the characteristics of the product that are essential for its safe and proper use Examples of these outputs are shown on the next slide :

- 124. 7.3.3. Design and development outputs (2/2) Examples : Data demonstrating the comparison of process inputs to process outputs Product specifications, including acceptance criteria Process specifications Material specifications Testing specifications Training requirements User and consumer information Purchase requirements.

- 125. 7.3.4 Design and development review (1/2) Reviews need to be held at suitable stages in accordance with planned arrangements in order to : Evaluate the ability of the design and development results to meet requirements To identify any problems and propose necessary actions Participants in the reviews must include representatives of the functions concerned with the design and development stages – this should include the customer for some of the stages Records must be maintained of the reviews and of any necessary actions agreed The design and development reviews can include :

- 126. 7.3.4 Design and development review (2/2) Review contents : Adequacy of inputs Progress of the planned design and development process, and discussion of delays and their causes Meeting verification and validation goals Evaluation of potential hazards or fault modes in product use – this could also apply to review of an operating or service manual Life cycle data Change control and their effect during the design and development process Identification and correction of problems Opportunities for improvement (Potential) impact of the product on the environment.

- 127. 7.3.5 Design and development verification Shall be conducted in accordance with planned arrangements to ensure that the outputs meet the input requirements Records of the results of the verification and any necessary actions shall be maintained Areas for evaluation include : Comparing input requirements with process output May include looking at alternative designs Evaluating against similar products Testing, simulation, trials, as a means of verification Evaluating against lessons learnt from previous designs and process experience.

- 128. 7.3.6 Design and development validation Shall be conducted in accordance with planned arrangements. The function of validation is to ensure that the product is capable of meeting the requirements for the specified application or intended use, where known Validation shall be completed before construction, delivery, installation, application, or implementation of the product or service Records shall be maintained of the results and of any necessary actions This applies to services and software also In some cases, validation can only be performed on the product components (e.g. a bridge). This partial validation may be necessary to provide confidence in the item’s future application.

- 129. 7.3.7 Control of design and development changes Design and development changes shall be identified, and records maintained of the reviews and of any necessary actions Changes shall be evaluated, reviewed, verified, and validated, as appropriate , and approved before implementation. An agreed change control procedure must be in place. Authority for initiating changes should be defined Changes also need to be considered in the light of their possible effect on other processes Any change in the processes affecting product characteristics should be recorded and communicated in order to maintain the conformity of the product/service, and provide information for corrective action or performance improvement of the organisation Part of the review shall include evaluation of the effects of the changes on component parts and on product already delivered.

- 130. ISO9004 : 2000 – 7.3 Q. 19 (a) : How has top management defined design and development processes to ensure they respond to the needs and expectations of the organisation’s customers and other interested parties ? Q. 19 (b) : How are design and development processes managed in practice, including the definition of design and development requirements and the achievement of planned outputs ? Q. 19 (c) : How are activities such as design review, verification, validation, and configuration management considered in the design and development processes ?.

- 131. 7 Product Realisation 7.4 Purchasing 7.4.1 Purchasing process 7.4.2 Purchasing information 7.4.3 Verification of purchased product.

- 132. 7.4.1 Purchasing Process (1/3) Purchased product must conform to purchase requirements The type and extent of control applied to a supplier and the purchased product shall be dependent upon the effect of the purchased product on subsequent product realisation or the final product The organisation shall evaluate and select suppliers on their ability to supply product in accordance with the organisation’s requirements Criteria for selection, evaluation, and re-evaluation shall be established Records shall be maintained of the results of evaluations and any necessary actions Can include calibration if it is done externally If we evaluate suppliers, we need to specify the frequency and method of re-evaluation Suppliers should be evaluated on the basis of criticality…

- 133. 7.4.1 Purchasing Process (2/3) The purchasing processes should consider : Timely, effective, and accurate identification of needs and purchased product/service specifications Evaluation of the purchased item costs, taking account of item performance, price, and delivery The organisation’s need and criteria for verifying purchased product Unique supplier processes Contract administration requirements Warranty agreements for non conforming items Logistic requirements Product identification and traceability…

- 134. 7.4.1 Purchasing Process (3/3) Cont’d… Preservation of product Documentation, including records (test, inspection, etc.) Control of purchased products which deviates from requirements Product/service delivery, installation or application history Supplier development Identification and mitigation of risks associated with purchased items The organisation should work with suppliers in developing requirements for product specifications and processes, and in agreeing an optimised purchasing process. This could also result in better control and availability of inventory The organisation should define the needs for records of purchased item verification, and response to non conformities.

- 135. 7.4.2 Purchasing Information Purchasing documents shall include, where appropriate : The requirements for approval of product, procedures, processes, and equipment The requirements for qualification of personnel Any Quality Management System requirements The organisation must ensure that all purchase requirements are adequate before sending them to a supplier.

- 136. 7.4.3 Verification of Purchased Product (1/5) The organisation shall establish and implement any inspection activities necessary to ensure the purchased product meets the specified purchase requirements…

- 137. 7.4.3 Verification of Purchased Product (2/5) Inputs to the supplier control process can include : Evaluation of supplier’s relevant experience Performance of supplier against competitors Review of purchased item Quality, price, delivery performance and response to problems Supplier audits – evaluation of their potential capability to provide the required items effectively and efficiently and within schedule Checking supplier references and any available data on customer satisfaction Financial assessment to ensure the viability of the supplier throughout the intended period of supply (after sales period should also be taken into account)…

- 138. 7.4.3 Verification of Purchased Product (3/5) Cont’d Supplier response to inquiries, quotation requests, and tendering Supplier service, installation, and support capability, and history of performance to requirements Supplier awareness of, and competence with relevant statutory and regulatory requirements The supplier’s logistic capability, including locations and resources in each location The supplier’s standing in the community and its perception in society Management should consider any actions needed to maintain the organisation’s performance and to satisfy interested parties in the event of supplier failure (late deliveries, bad Quality items, fire/flood/vandalism at supplier’s plant, supplier goes out of business)…

- 139. 7.4.3 Verification of Purchased Product (4/5) This is not part of ISO9001:2000 It is important to clarify with suppliers at an early stage, the procedure for dealing with non conforming goods – will the supplier : replace the batch pay for sorting send a representative to you first give a discount ask for a sample to be returned, etc. But what do you do while this is happening ? What happens with the supplier’s invoice ? Do you threaten to not pay it until action has been taken ? What happens if the supplier then threatens not to supply any more goods ? Have you an alternative supplier ? You can’t jump in with heavy tactics every time there is a problem – you need to work with your suppliers…

- 140. 7.4.3 Verification of Purchased Product (5/5) Maybe the goods are not certified as defect-free (commercial grade Quality) If the organisation or its customer intends to perform verification at the supplier’s premises, the organisation shall state the intended verification arrangements and method of product release in the purchasing information.

- 141. ISO9004 : 2000 – 7.4 Q. 20 (a) : How has top management defined purchasing processes that ensure purchased products/services satisfy the organisation’s needs ? Q. 20 (b) : How are purchasing processes managed ? Q. 20 (c) : How does the organisation ensure conformity of purchased products from specification through to acceptance ?.

- 142. 7 Product Realisation 7.5 Production and service provision 7.5.1 Control of production and service provision 7.5.2 Validation of processes for production and service provision 7.5.3 Identification and traceability 7.5.4 Customer property 7.5.5 Preservation of product.

- 143. 7.5.1 Control of production and service provision (1/2) The organisation shall plan and carry out production and service provision under controlled conditions, including, as applicable : Availability of information that describes the characteristics of the product or service Availability or work instructions ( where necessary ) The use and maintenance of suitable equipment Availability and use of suitable monitoring and measuring equipment The implementation of monitoring and measurement The implementation of release, delivery, and post-delivery activities…

- 144. 7.5.1 Control of production and service provision (2/2) Top management should go beyond control of the realisation process in order to achieve both compliance with requirements and provide benefits to interested parties by : Reducing waste Training people Communicating effectively and recording information Developing supplier capability Improving infrastructure Preventing problems Improving yields Reviewing methods of monitoring.

- 145. 7.5.2 Validation of production and service provision Processes for production and service provision must be validated where the resulting output cannot be verified by subsequent monitoring or measurement, or where any deficiencies only become apparent after the product is in use or the service has been delivered The validation shall demonstrate the ability of these processes to achieve planned results Arrangements shall be established for these processes, including, as applicable : Defined criteria for review and approval of the processes Approval of equipment and qualification of personnel The use of specific methods and procedures The requirements for records Re-validation.

- 146. 7.5.3 Identification and Traceability (1/2) This is not an absolute requirement of ISO9001 but usually the customer will demand some form of identification and traceability, plus the organisation will normally benefit from it Suitable means shall be used throughout the processes Must identify the component and product status – is it ok or not ok ? Passed inspection or awaiting inspection ? Requiring rework or scrapping ? The organisation must control and record the unique identification of the product (e.g. batch number) For incoming goods, it is advisable to identify the status of the parts For work in progress goods, the status should be clearly marked or identified so that everyone knows what inspections or tests have been performed and their results…

- 147. 7.5.3 Identification and Traceability (2/2) Non conforming items should be clearly identified as such, with a labelling system that does not easily come off. Many organisations have a ‘material review board’, but it may consist of only one person Usually, the decision on non conforming material is : Repair / rework / rectification Sort Scrap Ask for customer concession Leave as is The above will, of course, vary, depending on whether the non conforming items are purchased goods or processed goods.

- 148. 7.5.4 Customer Property If the organisation is using customers’ property provided for use or incorporation into the product, it must identify, verify, protect, and safeguard it. If any customer property is lost, damaged, or found unsuitable for use or incorporation into the product, this must be reported to the customer and records maintained The organisation should identify responsibilities for looking after customer property Note that customer property can include intellectual property.

- 149. 7.5.5 Preservation of Product Product must be preserved during internal processing and delivery to the intended destination Preservation includes identification, handling, packaging, storage, and protection Preservation also applies to the constituent parts of a product, so suppliers may be involved Management should communicate to interested parties, the resources and methods needed to preserve and protect the product throughout its life cycle.

- 150. ISO9004 : 2000 – 7.5 Q. 21 (a) : How does top management ensure that the input to the realisation process takes account of customers’ and other interested parties’ needs ? Q. 21 (b) : How are realisation processes managed from inputs to outputs ? Q. 21 (c) : How are activities such as verification and validation considered in the realisation process ?.

- 151. 7.6 Control of monitoring and measurement devices (1/2) This area refers to calibration and it is up to the organisation to determine the amount of calibration needed to provide evidence of conformity of product to the determined requirements If we outsource calibration, it then becomes a purchasing and goods inwards situation The organisation must assess and record the validity of previous measurement results when the equipment is found not to conform to requirements, and it must take appropriate action on the equipment and any product affected Where computer software is used for monitoring and measurement, it shall be confirmed prior to initial use and re-confirmed as necessary Records of the results of calibration and verification must be maintained…

- 152. 7.6 Control of monitoring and measurement devices (2/2) Where necessary to ensure valid results, measuring equipment shall : Be calibrated or verified at specified intervals, or prior to use, against measurement standards traceable to national or international measurement standards. Where no standard exists, the basis used for calibration shall be recorded Be adjusted or re-adjusted as necessary Be identified to enable the calibration status to be determined Be safeguarded from adjustments that would invalidate the measurement result Be protected from damage and deterioration during handling, maintenance, and storage.

- 153. ISO9004 : 2000 – 7.6 Q. 22 : How does management control the measuring and monitoring devices to ensure that the correct data is being obtained and used ?

- 154. 8 Measurement, Analysis and Improvement 8 Measurement, analysis, and improvement 8.1 General 8.2 Monitoring and measurement 8.3 Control of non-conforming product 8.4 Analysis of data 8.5 Improvement.

- 155. 8.1 General (1/4) The organisation shall plan and implement the monitoring, measuring, analysis, and improvement processes needed to : Demonstrate conformity of the product Ensure conformity of the Quality Management System Continually improve the effectiveness of the Quality Management System – record the actions taken and their effectiveness or otherwise, and any implementation problems, to help future improvements Satisfy customers…

- 156. 8.1 General (2/4) The outputs of this process must feed into the management review Suitable methods should be used, including statistical techniques, and the extent of their use, where appropriate Examples of measurements relate to : Measurement and evaluation of products and services Capability of processes Achievement of project objectives Customer satisfaction…

- 157. 8.1 General (3/4) Issues to be considered : Measurement data should be converted into information and knowledge to be of benefit to the organisation Measurement data should be used to establish priorities for the organisation The measurement methods and data should be periodically reviewed and verified for accuracy, appropriateness , and completeness Benchmarking of individual processes should be used as an improvement tool Customer satisfaction is a vital measurement…

- 158. 8.1 General (4/4) Information should be current and its purpose should be clearly defined The information should be communicated using appropriate methods Audits are a good way of assessing the QMS and the level of the organisation’s performance, as well as being an opportunity to improve performance There should be no inspection without recording, no recording without analysis, and no analysis without action.

- 159. ISO9004 : 2000 – 8.1 Q. 23 : How does management promote the importance of measurement, analysis, and improvement activities to ensure that the organisation’s performance results in the satisfaction of interested parties?

- 160. 8.2 Monitoring and Measurement 8.2 Monitoring and measurement 8.2.1 Customer satisfaction 8.2.2 Internal audit 8.2.3 Monitoring and measurement of processes 8.2.4 Monitoring and measurement of product/service.

- 161. 8.2.1 Customer Satisfaction (1/2) The organisation must monitor information relating to customer perception as to whether the organisation has met customer requirements (needs and expectations) The methods for obtaining and using this information shall be determined Examples of customer-related information : Customer and user surveys Feedback on aspects of the product Customer requirements and contract information Marketing and sales rep feedback Service delivery data Competition information…

- 162. 8.2.1 Customer Satisfaction (2/2) It is not enough to just fulfil a customer’s current needs : we need to anticipate future needs Examples of sources of information regarding customer satisfaction : Customer complaints Direct customer communications Questionnaires and surveys Focus groups Reports from consumer organisations Media reports Sector and industry studies.

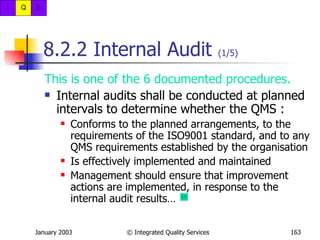

- 163. 8.2.2 Internal Audit (1/5) This is one of the 6 documented procedures. Internal audits shall be conducted at planned intervals to determine whether the QMS : Conforms to the planned arrangements, to the requirements of the ISO9001 standard, and to any QMS requirements established by the organisation Is effectively implemented and maintained Management should ensure that improvement actions are implemented, in response to the internal audit results…

- 164. 8.2.2 Internal Audit (2/5) An audit programme shall be planned, taking into account the status and importance of the processes and areas to be audited, as well as the results of previous audits The audit criteria, scope, frequency, and methods shall be defined Auditors shall be selected shall ensure objectivity and impartiality of the audit process Auditors shall not audit their own work…

- 165. 8.2.2 Internal Audit (3/5) The responsibilities and requirements for planning and conducting audits, and for reporting results and maintaining records shall be defined in a documented procedure The management for the area being audited shall ensure that actions are taken without undue delay, to eliminate detected non-conformities and their causes Follow up activities shall include the verification of the actions taken and the reporting of verification results The internal audit is for senior management – the QMS is THEIR system, and the is a health check on the strengths and weaknesses of the QMS…

- 166. 8.2.2 Internal Audit (4/5) Internal audits should consider : Effective and efficient implementation of processes Opportunities for continual improvement Capability of processes Effective and efficient use of statistical techniques Use of Information Technology Analysis of Quality cost data…

- 167. 8.2.2 Internal Audit (5/5) Effective and efficient use of resources Process and product performance results and expectations Adequacy and accuracy of performance measurement Improvement activities Relationships with interested parties May include evidence of excellent performance to provide opportunities for recognition by management and motivation.

- 168. Other measurement and monitoring tools – ISO9004 : (1/2) Financial measures Can provide comparable measures across processes Prevention and appraisal costs Non conformance cost analysis Internal and external cost analysis Life cycle cost analysis…

- 169. Other measurement and monitoring tools – ISO9004 : (2/2) Self assessment Usually carried out by management Covers the whole organisation (not just the QMS) Often includes benchmarking against other organisations and world class performers Assists in evaluating the performance improvement Should be simple to use, easy to understand, use a minimum of management resources, provide input for enhancing the performance of the QMS.

- 170. 8.2.3 Monitoring and Measurement of Processes (1/2) The organisation shall apply suitable methods for monitoring and, where applicable , measurement of the QMS processes. These methods shall demonstrate the ability of the processes to achieve planned results When planned results are not achieved, corrective action shall be taken, as appropriate , to ensure conformity of the product Examples of these processes include internal audit results, corrective action, preventive action, management reviews, key performance indicators…

- 171. 8.2.3 Monitoring and Measurement of Processes (2/2) Examples of measurements include : Capability Reaction time Cycle time / throughput Measurable aspects of dependability Yield The effectiveness and efficiency of the employees Utilisation of technology Waste reduction Cost allocation and reduction.

- 172. 8.2.4 Monitoring and Measurement of Product (1/3) The organisation shall monitor and measure the characteristics of the product to verify that product requirements have been met This shall be carried out at appropriate stages of the product realisation process in accordance with the planned arrangements Evidence of conformity with the acceptance criteria shall be maintained Records shall indicate the person(s) authorising release of product Product release and service delivery shall not proceed until planned arrangements have been met, unless otherwise approved by a relevant authority or, where applicable , by the customer…

- 173. 8.2.4 Monitoring and Measurement of Product (2/3) The organisation should consider : The types of product characteristics, which then determines the types of measurement, suitable measurement means, the accuracy required and the skills needed The equipment, software and tools required The location of suitable measurement points The characteristics to be measured at each point, and the documentation and acceptance criteria to be used Customer established points for witness or verification…

- 174. 8.2.4 Monitoring and Measurement of Product (3/3) Cont’d Where, when and how the organisation intends to engage qualified third parties to perform testing, verification, or validation Inspections or testing required to be witnessed or is required by statutory or regulatory bodies Qualification of people, materials, products, processes , and the QMS Final inspection to confirm that verification and validation activities have been successfully completed Recording the results of product measurements.

- 175. ISO9004 : Monitoring and Measurement of the Satisfaction of Interested Parties 8.2.4 (1/4) The organisation should identify the measurement information required to meet the needs of other interested parties (apart from customers) in order to balance the allocation of resources For employees, the organisation should survey the opinions of its people regarding how well the organisation satisfies their needs and expectations…

- 176. ISO9004 : Monitoring and Measurement of the Satisfaction of Interested Parties 8.2.4 (2/4) For owners and investors, the organisation should : Assess its capacity to attain defined objectives Assess its financial performance Evaluate the impact of external factors on its results Identify the value contributed by the actions taken…

- 177. ISO9004 : Monitoring and Measurement of the Satisfaction of Interested Parties 8.2.4 (3/4) For suppliers and partners, the organisation should : Survey the opinions of suppliers and partners on their satisfaction with the purchasing processes of the organisation Monitor and supply feedback on the performance of suppliers and partners and their compliance with the organisation’s purchasing policy Assess the Quality of the product purchased, the contributions from suppliers and partners, and the mutual benefits derived from the relationship…

- 178. ISO9004 : Monitoring and Measurement of the Satisfaction of Interested Parties 8.2.4 (4/4) For society, the organisation should : Define and track suitable data relating to its objectives, in order to achieve satisfactory interaction with society Periodically assess the effectiveness and efficiency of its actions and the perceptions of its performance by relevant parts of society.

- 179. ISO9004 : 2000 – 8.2 Q. 24 (a) : How does management ensure collection of customer-related data for analysis, in order to obtain information for improvements ? Q. 24 (b) : How does management ensure the collection of data form other interested parties for analyses and possible improvements ? Q. 24 (c) : How does the organisation use self assessment of the QMS for improving its overall effectiveness and efficiency ?.

- 180. 8.3 Control of non-conforming product (1/3) This is one of the 6 documented procedures Non conforming product must be identified and controlled to prevent unintended use or delivery The procedure must define the controls and related responsibilities and authorities for dealing with non conforming product…

- 181. 8.3 Control of non-conforming product (2/3) Non conforming material shall be dealt with by : Taking action to eliminate the detected non conformity Authorising its use, release, or acceptance under concession by a relevant authority and/or, where applicable , the customer Taking action to preclude its original intended use or application…

- 182. 8.3 Control of non-conforming product (3/3) Records shall be kept of the nature of the non conformities and any subsequent actions taken, including concessions obtained When non conforming product is corrected, it shall be subject to re-verification to demonstrate conformity to requirements When non conforming product is detected after delivery or use has started, the organisation shall take action appropriate to the effects, or potential effects, of the non conformity.

- 183. ISO9004 : 2000 – 8.3 Q. 25 (a) : How does the organisation control process and product non conformity ? Q. 25 (b) : How does the organisation analyse non conformity for lessons learned and product/service and process improvement ?.

- 184. 8.4 Analysis of data (1/2) The organisation shall determine, collect, and analyse appropriate data to demonstrate the suitability and effectiveness of the QMS, and to evaluate where continual improvement of the effectiveness of the QMS can be made. This shall include data generated as a result of monitoring and measurement and from other relevant sources…

- 185. 8.4 Analysis of data (2/2) Data analysis shall provide information relating to : Customer satisfaction, and satisfaction of other interested parties Conformity to product requirements Effectiveness and efficiency of the processes Trends The success of performance improvement objectives Characteristics and trends of processes and products including opportunities for preventive action Benchmarking and competitiveness Suppliers and their contribution.

- 186. ISO9004 : 2000 – 8.4 Q. 26 : How does the organisation analyse data to assess its performance and identify areas for improvement ?

- 187. 8.5 Improvement 8.5.1 Continual improvement 8.5.2 Corrective action 8.5.3 Preventive action.

- 188. 8.5.1 Continual Improvement The organisation shall continually improve the effectiveness (and efficiency) of the QMS through the use of : Quality policy Quality objectives Audit results Analysis of data Corrective action Preventive action Management review.

- 189. ISO9004 : Continual Improvement (1/3) Management should create a culture of involving people in actively seeking opportunities for improvement of performance in processes, activities and products/services Authority should be delegated and people should be encouraged to accept responsibility to identify improvement opportunities. This could be done by : Setting objectives for people, projects, and the organisation Benchmarking competitor performance and best practice Recognition and reward for achievement of improvement Suggestion schemes with timely reaction by management…