Root Cause Failure Analysis by Eugene Cottle-Lifecycle Engineering

- 1. Root Cause Failure Analysis with Case Histories Eugene T. Cottle Reliability Engineer Life Cycle Engineering

- 2. 2© Life Cycle Engineering 2008 A confluence of events, factors and conditions which conspire to produce an (undesirable) outcome. Event(s), factor(s) or condition(s) which are under your control and which, if corrected or eliminated, will prevent recurrence of the undesirable outcome.

- 3. 3© Life Cycle Engineering 2008 More Terminology… • RCA: Root Cause Analysis – A disciplined process for focusing ideas to identify root causes. A class of problem solving methods • RCFA: Root Cause Failure Analysis – Reactive, in response to a failure • RCCA: Root Cause and Corrective Action – Incorporates preventive corrective action into the process(i.e., elimination of special causes

- 4. 4© Life Cycle Engineering 2008 Root Cause Analysis • Safety-based RCA – accident analysis and – occupational safety and health • Production-based RCA – quality control for industrial manufacturing • Process-based RCA – Expanded scope to include business processes • Failure-based RCA – Based on failure analysis – employed in engineering and maintenance. • Systems-based RCA – amalgamation of the all the others, and includes • change management, • risk management, and • systems analysis

- 5. 5© Life Cycle Engineering 2008 Objectives • Prevent Recurrence • Responsibility – “Hand-off” the investigation • Begins with an assumption of “cause” – Liability – Blame

- 6. 6© Life Cycle Engineering 2008 Deming’s 14 points 1. Create constancy of purpose toward improvement of product and service, with the aim to become competitive and stay in business, and to provide jobs. 2. Adopt the new philosophy. We are in a new economic age. Western management must awaken to the challenge, must learn their responsibilities, and take on leadership for change. 3. Cease dependence on inspection to achieve quality. Eliminate the need for inspection on a mass basis by building quality into the product in the first place. 4. End the practice of awarding business on the basis of price tag. Instead, minimize total cost. Move towards a single supplier for any one item, on a long-term relationship of loyalty and trust. 5. Improve constantly and forever the system of production and service, to improve quality and productivity, and thus constantly decrease cost. 6. Institute training on the job. 7. Institute leadership (see Point 12 and Ch. 8 of "Out of the Crisis"). The aim of supervision should be to help people and machines and gadgets to do a better job. Supervision of management is in need of overhaul, as well as supervision of production workers. 8. Drive out fear, so that everyone may work effectively for the company. (See Ch. 3 of "Out of the Crisis") 9. Break down barriers between departments. People in research, design, sales, and production must work as a team, to foresee problems of production and in use that may be encountered with the product or service. 10. Eliminate slogans, exhortations, and targets for the work force asking for zero defects and new levels of productivity. Such exhortations only create adversarial relationships, as the bulk of the causes of low quality and low productivity belong to the system and thus lie beyond the power of the work force. 11. a. Eliminate work standards (quotas) on the factory floor. Substitute leadership. b. Eliminate management by objective. Eliminate management by numbers, numerical goals. Substitute workmanship. 12. a. Remove barriers that rob the hourly worker of his right to pride of workmanship. The responsibility of supervisors must be changed from sheer numbers to quality. b. Remove barriers that rob people in management and in engineering of their right to pride of workmanship. This means, inter alia, abolishment of the annual or merit rating and of management by objective (See CH. 3 of "Out of the Crisis"). 13. Institute a vigorous program of education and self- improvement. 14. Put everyone in the company to work to accomplish the transformation. The transformation is everyone's work.

- 7. 7© Life Cycle Engineering 2008 Deming’s 14 points 1. Create constancy of purpose toward improvement of product and service, with the aim to become competitive and stay in business, and to provide jobs. 2. Adopt the new philosophy. We are in a new economic age. Western management must awaken to the challenge, must learn their responsibilities, and take on leadership for change. 3. Cease dependence on inspection to achieve quality. Eliminate the need for inspection on a mass basis by building quality into the product in the first place. 4. End the practice of awarding business on the basis of price tag. Instead, minimize total cost. Move towards a single supplier for any one item, on a long-term relationship of loyalty and trust. 5. Improve constantly and forever the system of production and service, to improve quality and productivity, and thus constantly decrease cost. 6. Institute training on the job. 7. Institute leadership (see Point 12 and Ch. 8 of "Out of the Crisis"). The aim of supervision should be to help people and machines and gadgets to do a better job. Supervision of management is in need of overhaul, as well as supervision of production workers. 8. Drive out fear, so that everyone may work effectively for the company. (See Ch. 3 of "Out of the Crisis") 9. Break down barriers between departments. People in research, design, sales, and production must work as a team, to foresee problems of production and in use that may be encountered with the product or service. 10. Eliminate slogans, exhortations, and targets for the work force asking for zero defects and new levels of productivity. Such exhortations only create adversarial relationships, as the bulk of the causes of low quality and low productivity belong to the system and thus lie beyond the power of the work force. 11. a. Eliminate work standards (quotas) on the factory floor. Substitute leadership. b. Eliminate management by objective. Eliminate management by numbers, numerical goals. Substitute workmanship. 12. a. Remove barriers that rob the hourly worker of his right to pride of workmanship. The responsibility of supervisors must be changed from sheer numbers to quality. b. Remove barriers that rob people in management and in engineering of their right to pride of workmanship. This means, inter alia, abolishment of the annual or merit rating and of management by objective (See CH. 3 of "Out of the Crisis"). 13. Institute a vigorous program of education and self- improvement. 14. Put everyone in the company to work to accomplish the transformation. The transformation is everyone's work.

- 8. 8© Life Cycle Engineering 2008

- 9. 9© Life Cycle Engineering 2008 5 Whys Method 5 Whys Method: Car not Starting 1. Why? - The battery is dead. (first why) 2. Why? - The alternator is not functioning. (second why) 3. Why? - The alternator belt has broken. (third why) 4. Why? - The alternator belt was well beyond its useful service life and has never been replaced. (fourth why) 5. Why? - I have not been maintaining my car according to the recommended service schedule. (fifth why, root cause) Sakichi Toyoda (豊田 佐吉 Toyoda Sakichi, February 14, 1867 – October 30, 1930)

- 10. 10© Life Cycle Engineering 2008 5 why’s continued • Why 5 Questions? – Nothing magic about the number 5 – After about 5 it can get absurd or go out of scope – Do we have control over this cause? – Will eliminating this cause prevent recurrence? • Shortcoming of Procedure – Oversimplifies cause and effect relationships • Multiple causal and contributing factors • Confluence of events – Not a structured method for effective investigations • Other methods help identify possible factors • Fundamental idea underlying all RCA’s Cause Effect

- 11. 11© Life Cycle Engineering 2008 Ishikawa Diagram Method Also named: “Fish-Bone” Diagram • Can come at any point in the process • Helps direct activities • Brainstorming tool • Followed by data collection, verification, tests, etc. Tague’s, Nancy R. The Quality Toolbox, Second Edition, ASQ Quality Press, 2004, pages 247-249

- 12. 12© Life Cycle Engineering 2008 Ishikawa diagrams The 6 “M”s 1. Machine, 2. Method, 3. Materials, 4. Maintenance, 5. Man and 6. Mother Nature (Environment) The 8 “P”s 1. Price, 2. Promotion, 3. People, 4. Processes, 5. Place / Plant, 6. Policies, 7. Procedures, and 8. Product (or Service) The 4 “S”s 1. Surroundings, 2. Suppliers, 3. Systems, 4. Skills

- 13. 13© Life Cycle Engineering 2008 Failure Model • The level at which any root cause should be identified is the level at which it is possible to identify an appropriate failure management policy

- 14. 14© Life Cycle Engineering 2008 “8 Disciplines” or “8D” • The 8 Disciplines 1. Use Team Approach 2. Describe the Problem 3. Implement and Verify Short-Term Corrective Actions 4. Define and Verify Root Causes 5. Verify Corrective Actions 6. Implement Permanent Corrective Actions 7. Prevent Recurrence 8. Congratulate Your Team • Other tools can be incorporated into the steps of an 8D

- 15. 15© Life Cycle Engineering 2008

- 16. 16© Life Cycle Engineering 2008 Kepner-Tregoe (KT) analysis Pioneered in early 1960’s USAF and NASA “built on the premise that people can be taught to think critically” • Invite someone from a different area as a “fresh set of eyes” – “Could you please explain…?” – “How do you know…? – “Do you have any data to show that…”

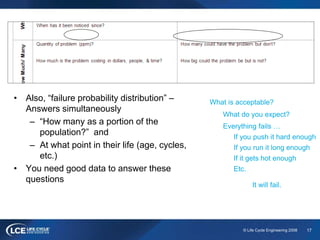

- 17. 17© Life Cycle Engineering 2008 What is acceptable? What do you expect? Everything fails … If you push it hard enough If you run it long enough If it gets hot enough Etc. It will fail. • Also, “failure probability distribution” – Answers simultaneously – “How many as a portion of the population?” and – At what point in their life (age, cycles, etc.) • You need good data to answer these questions

- 18. 18© Life Cycle Engineering 2008 Statistical Analysis • Important to understand… – Coincidence – Correlation – Cause • Tools… – Design of Experiments (DOE) – Analysis of Variance (ANOVA) – Correlation analyses – Hypothesis testing “Smoking is one of the leading causes of statistics.” -- Fletcher Knebel

- 19. 19© Life Cycle Engineering 2008 Selecting and prioritizing actions • Requires some knowledge of probability of occurrence - Data SEVERITY Catastrophic Critical Marginal Negligible From To Definition Probability ~1 8 x10 –2 Likely to occur frequently Frequent 1 3 6 10 8 x10 –2 8 x10 –3 Will occur several times in life of an item Probable 2 5 9 14 8 x10 –3 8 x10 –4 Likely to occur sometime in life of an item Occasional 4 8 13 17 8 x10 –4 8 x10 –5 Unlikely but possible to occur in the life of an item Remote 7 12 16 19 8 x10 –5 ~0 So unlikely it may be assumed that it won't occur Improbable 11 15 18 20 Probability Range Customer Notification Containment Corrective Action 1~5 Immediate Restrict field use. Purge existing stock. Complete field retrofit as quickly as possible. 6~10 Immediate Warn customer to avoid conditions leading to the failure. Hold shipments till design change is incorporated. Complete paced field retrofit at earliest opportunity. 11~15 Service Bulletin No containment required Change design, offer upgrade to customer. 16~20 Revision notes No containment required Change design at next opportunity, or correct the problem in the next generation product.

- 20. 20© Life Cycle Engineering 2008 Selecting and prioritizing actions • FMEA: Failure Modes and Effects Analysis • Requires some knowledge of probabilities

- 21. 21© Life Cycle Engineering 2008 Keys for Success • You aren’t the expert – Challenge everything – Speak with data, act on fact • Have the data – and use it • Don’t let motivations drive conclusions • Resources – Always resource-constrained – Depends on risk and criticality • Finish the job - verification

- 22. 22© Life Cycle Engineering 2008 “In theory, there is no difference between theory and practice; In practice, there is.” -- Chuck Reid

- 23. 23© Life Cycle Engineering 2008

- 24. 24© Life Cycle Engineering 2008 Boeing C-17 landing Gear

- 25. 25© Life Cycle Engineering 2008 • Brake Sensors designed for and subjected to 600 hour durability test, vibration and thermal as specification requirement. • A couple of redesigns already – Identified location and failure mechanism – Made it more robust both times • Discarding 10-13 sensors per month • Problem: Solve the high failure rate.

- 26. 26© Life Cycle Engineering 2008 • Discarding 10-13 sensors per month • A couple of redesigns already • Problem: Solve the high failure rate. • Although each redesign had made the sensor stronger, there was never clear definition of the requirement • Initial problem was an inadequate specification • Most of the sensors currently being discarded had not failed • Swaptronics…Resolution: Improve troubleshooting

- 27. 27© Life Cycle Engineering 2008 Blue Screen of Death BSOD

- 28. 28© Life Cycle Engineering 2008 BSOD continued…Software Errors

- 29. 29© Life Cycle Engineering 2008 Key take-aways • Conclusion – Micro-bubbles forming on the control computer disk drives – Only happens if the computer is left on all the time – Corrective action was to turn off the computers and restart them once every 24 hours • Not a true corrective action • Lessons for RCFA – Took about 18 months from initiation of activity to report – Dedicated and determined engineer

- 30. 30© Life Cycle Engineering 2008 Conveyor Drive Failures • High failure Rate – Motors Tripping – Gearbox Failures • Solve the high failure rate

- 31. 31© Life Cycle Engineering 2008 Conveyor Failures continued… • Problem definition – The corrective action team determined that the failures were generally of two types, 1. Premature wear out consistent with long term, slightly elevated loading, and 2. Failures consistent with transient torque overloads. – One side has a higher failure rate than the other – Load?

- 32. 32© Life Cycle Engineering 2008 Strain gauges applied at the couplings on both conveyors • Setup a remote data acquisition system (WebDaq) • Began gathering long-term data – About 8 days of continuous data – Then about 137 hours of intermittent (triggered) data Cutout s for strain gauge s. Strain gauge locatio ns

- 33. 33© Life Cycle Engineering 2008 Normal operation Overload event Overload event (zoom) • Frequency indicates coupling slipping

- 34. 34© Life Cycle Engineering 2008 Conveyor Failures conclusion • Life difference between drives is normal wear-out due to higher load during normal operation • Premature failures due to overload events… – “Clamping” of the belts due to programming errors in control system • Latent causes not addressed… – Development, installation and run-off process that permitted the programming errors – Process that failed to catch the errors • Fundamental Principles / Lessons Learned for Root Cause Failure Analysis… – Devoted adequate resources – Did not do a design change based on initial “apparent” cause – Problem definition / Data collection – Time commitment • 10 Months from identification of failure for RCFA to final report

- 35. 35© Life Cycle Engineering 2008 Mobile Hydraulic Truck Pumps Leakage • Problem – Reported substantial increase in failure rate due to leakage – Initial conclusion (assumed) faulty pump – Initiated a campaign to replace all the pumps • Very good data – Extensive details on every failure • Model, serial number, application, hours in service, calendar time in service…

- 36. 36© Life Cycle Engineering 2008 Mobile Hydraulic Truck Pumps Continued… • Established 13 year timeline showing entire history of design and application • Reviewed detailed removal history and failure probability distributions • Identified 2 different failure modes… 1.00 100.0010.00 0.10 0.50 1.00 5.00 10.00 50.00 90.00 99.00 0.10 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6 2.0 3.0 4.0 6.0 b h ReliaSoft's Weibull++ 6.0 - www.Weibull.com Probability - Weibull Time in Service (months) Unreliability,F(t) 478 610 809 938 1153 1193 1314 1289 1378 1307 1251 134111691120105393388877267163755350743241538330332126621322817118915411812292433227149 Weibull AllParts_Months_Warr W5 MLE - SRM MED F=24896 / S=334701 CB[FM]@90.00% 1-Sided-U [T1] b[1]=2.2600, h[1]=16.5572, R[1]=0.0921 ; b[2]=1.8892, h[2]=163.0341, R[2]=0.9079

- 37. 37© Life Cycle Engineering 2008 1.00 100.0010.00 0.01 0.05 0.10 0.50 1.00 5.00 10.00 50.00 90.00 99.00 0.01 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6 2.0 3.0 4.0 6.0 b h ReliaSoft's Weibull++ 6.0 - www.Weibull.com Probability - Weibull Time in Service (months) Unreliability,F(t) 80 99 124 120 112 94 1188910590807880576147564042172322917121510888892354 Weibull 16000K W5 MLE - SRM MED F=1752 / S=9223 b1[1]=1.8996, h1[1]=11.4709, R1[1]=0.1469 ; b1[2]=1.7402, h1[2]=133.6546, R1[2]=0.8531 13 3 12 8 11 8 5 7 11336364 52 2 3 16000L W5 MLE - SRM MED F=120 / S=209 b2[1]=1.8024, h2[1]=9.8963, R2[1]=0.3433 ; b2[2]=1.5343, h2[2]=116.0825, R2[2]=0.6567 223 280 427 473 622 665 731 703 7947346957576455655694674594223753443023132732542361621841571151348610976525942158 16000M W5 MLE - SRM MED F=13527 / S=89454 b3[1]=2.2610, h3[1]=14.0255, R3[1]=0.0997 ; b3[2]=1.8634, h3[2]=121.8553, R3[2]=0.9003 8 17 19 21 20 1512111617141413101179332623222 16000N W5 MLE - SRM MED F=264 / S=9106 b4[1]=1.9221, h4[1]=12.1015, R4[1]=0.0298 ; b4[2]=4.4799, h4[2]=91.3611, R4[2]=0.9702 37 50 50 423228 44383334292637172311121915138677665443 AllOthers W5 MLE - SRM MED F=648 / S=42756 CB[FM]@90.00% 1-Sided-U [T1] b5[1]=1.6788, h5[1]=12.0507, R5[1]=0.0137 ; b5[2]=1.7057, h5[2]=612.6454, R5[2]=0.9863 Further analysis permitted us to isolate and identify subpopulations with distinctly different failure distributions

- 38. 38© Life Cycle Engineering 2008 Mobile Hydraulic Truck Pumps Continued… • Truck test results – 1. The highest acceleration levels are always associated with rapid pressure drops, |dP/dt| about 1800 bar per second or greater. – 2. Pressure drops (|dP/dt|) on Truck 2 were on average a little greater truck 1, but they never result in the impact signature. – 3. |dP/dt| >= about 1800 bar per second ALWAYS results in an impact signature on truck 1

- 39. 39© Life Cycle Engineering 2008 Mobile Hydraulic Truck Pumps Continued… • Have the data • Statistical tools • Resources – About 1 year

- 40. 40© Life Cycle Engineering 2008 Acme* Gearbox - Background 3-stage, 1800 kW gearbox driving a rock crusher Late in the evening there was a vibration alarm Alarm was “not unusual”, they continued operating Early the next morning there was a loud noise, and shutdown for vibration *Some details have been changed

- 41. 41© Life Cycle Engineering 2008 Background continued… • Over the next few days they replaced the gearbox with a spare • Vendor was consulted. They “knew exactly what went wrong” • Insurance company requested an independent Root Cause Failure Analysis

- 42. 42© Life Cycle Engineering 2008 Background continued… • Over the next few days they replaced the gearbox with a spare • Vendor was consulted. They “knew exactly what went wrong” • Insurance company requested an independent Root Cause Failure Analysis

- 43. 43© Life Cycle Engineering 2008 Complications • “Independent” – Implies limited cooperation between experts • People who designed and built the equipment • People who maintained and operated equipment – Don’t take everything at face value • Consider everyone’s motivations • There are vested interests in different possible conclusions • Limited access to the hardware – Resources

- 44. 44© Life Cycle Engineering 2008 Investigation What did the people do? Why did they do it? (systems, procedures, motivations) This is where you usually find the “root” cause

- 45. 45© Life Cycle Engineering 2008 Investigation Induced • Application • Environment • “You broke it” (vendor) Inherent • Design • Materials • “It broke” (user) Answers the question “which humans?”

- 46. 46© Life Cycle Engineering 2008 Data “Describe the problem” from 8D form • Loading, both before the incident and historically • Equipment design, ratings (what was it expected to do?) • Maintenance history • Vibration analyses / reports

- 47. 47© Life Cycle Engineering 2008 Oil Contaminant report…

- 48. 48© Life Cycle Engineering 2008 Vibration • Requested source data, FFT parameters, etc. (monthly checks… one year history) (motor bearing)

- 49. 49© Life Cycle Engineering 2008 Vibration (source data)

- 50. 50© Life Cycle Engineering 2008 0:00 12:00 24:00 36:00 48:00 60:00 72:00 84:00 96:00 Loading Attime of failure 1 Year Earlier 2 Years Earlier

- 51. 51© Life Cycle Engineering 2008 Power – 30 days leading up to failure

- 52. 52© Life Cycle Engineering 2008 Power – 30 days 1 year earlier

- 53. 53© Life Cycle Engineering 2008 Motor is replaced (-2 days) Internal winding failure Gearbox is rebuilt Maintenance crew fixes an oil leak Maintenance crew fixes an oil leak Maintenance crew fixes an oil leak Oil leaks repaired “many” times, most undocumented due to vibration alarm (date and time) Plant shuts down Tripped due to vibration alarm (-2 hours) Supervisor decides to continue running (-2 hours) Maintenance crew fixes an oil leak (-2 days)

- 54. 54© Life Cycle Engineering 2008 Interviews – the picture that emerges • 2 days prior – high speed shaft was not properly drawn up to engage the pinion – Crew did not have specs or manuals – No one knew where they were • Oil leaks had been repaired “many times” since rebuild • Could have been improperly reinstalled any of those times • Prior to failure, crews heard “Rumble” typical of loading too much material (common occurrence); Overloading. • Other crews described the proper procedure, “tribal knowledge” • Maintenance records were incomplete • Vendor reported no apparent problems when new motor was installed • Control room vibration monitoring was not helpful • Alarms occurred “all the time” with no action taken • There were indications a failure was imminent

- 55. 55© Life Cycle Engineering 2008

- 56. 56© Life Cycle Engineering 2008 Remaining questions: • Was damage accumulating over time? • Were there material or design contributors?

- 57. 57© Life Cycle Engineering 2008 Metallurgical report • Two contact patterns… – “Frosting” below the pitch line, indicating a period of normal wear – Obvious indications of wear near tooth tips • Bearings indicated a severe misalignment • Nothing anomalous in material properties (hardness, case depth, chemical and microstructure) • Failure was due to low cycle fatigue prior to overload

- 58. 58© Life Cycle Engineering 2008 Root Cause Conclusions • Induced failure due to – improper maintenance, resulting in low cycle fatigue then overload – High loads due to material overloading were a likely contributor • Latent factors: – Poor cooperation with supplier(s) – Inadequate documentation and equipment specific training – Ineffective warning system and propensity to ignore warnings • Proposed corrective actions – Acquire up-to-date specifications, documentation and maintenance procedures for critical equipment – Ensure equipment specific training for maintenance personnel – Review adequacy of alarm system to ensure warnings are adequate and meaningful – Define appropriate responses – Instill a culture that expects response and action

- 59. 59© Life Cycle Engineering 2008 Conclusions; or if you remember nothing else about root cause analysis, remember this: Do it. RCA is the engine that drives continuous improvement. Have the data Keep good records, not just of failures but of All maintenance actions When did it begin service? … end? Operating conditions If you don’t have a good CMMS, get one. If you do (or when you do), USE IT Resources. Have the right People Training, and Tools.

- 60. 60© Life Cycle Engineering 2008 The last word… Problem Solving Flow Chart Don’t Mess With It! YES NO YES YOU POOR FOOL! NO Are You In Hot Water? NO Throw Away The Evidence Does Anyone Know? TOO BAD! YESYES NO Hide It Can You Blame Someone Else? NO NO PROBLEM! YES Is It Working? Did You Mess With It?

Editor's Notes

- #3: How you define the “root” cause will depend on your objectives and motives in undertaking the investigation (Do a demonstration dropping a ball… ask what the root cause is…)

- #10: History, development, different “schools of thought”

- #11: For example… Why did the ball fall?

- #15: http://www.national.com/analog/quality/8d

- #18: How many could have the problem but don’t Suspensions – what portion of the population is failing? At what rate? What is acceptable? What is the threshhold?

- #19: Use of statistics in medical, pharmaceutical fields

- #22: Have the data… One of the primary roles of the Reliability Engineer is to see that the correct data is collected Collect data on non-failures You aren’t the expert… On which piece of equipment at your facility are you the most knowledgeable person in the plant? If you are the most knowledgeable person, what don’t you know? You are not the expert… For What % RCFA’s you are likely to be involved in, are you the single greatest repository of knowledge about possible causes and effects? Even then… There is critical information you don’t know or have The “apocryphal” story of the great engineer who “just saw” an obscure answer that noone else saw… that is a rare event. That is why it makes such a great story.

- #23: Assume that you will have some responsibility to do RCFA’s within your organization Things that illustrate some of the basic principles… one or two key take-aways Some (not all) things that they might have occasion to deal with Vibration wherever possible

- #24: Brake temperature constrains operations Excessive temperature

- #25: Department of Defense Inspector General Auditing Report 99-193, C-17 Landing Gear Durability and Parts Support, June 24, 1999

- #26: Expensive, failed attempts to solve the problem already “Failure rate…”

- #36: References:

- #37: References: C:\Documents and Settings\GCottle\My Documents\0\Archived\Vol1041\0\Automation Group R&M\2004\BRM\Background history and reference.zip\ETC_timeline-International Plugs and Fittings History.doc C:\Documents and Settings\GCottle\My Documents\0\Archived\Vol1041\0\Automation Group R&M\2004\BRM\20040607_HEUI_Warranty_Review.zip

- #38: Ref C:\Documents and Settings\GCottle\My Documents\0\Archived\Vol1041\0\Automation Group R&M\2004\BRM\20041116_Sleuthing.zip\PRES.2004.11.15.LB TO Cottle T. Hanks Talking Points

- #39: Ref: 20050114 R&M Overview

- #42: What to do with the contractor’s conclusion… Don’t discard it. They know more about the design than most of us. Can you accept it? (Obviously not…)

- #43: What to do with the contractor’s conclusion… Don’t discard it. They know more about the design than most of us. Can you accept it? (Obviously not…)

- #57: Note that this is not a complete fault tree

![36© Life Cycle Engineering 2008

Mobile Hydraulic Truck Pumps Continued…

• Established 13 year

timeline showing

entire history of

design and

application

• Reviewed detailed

removal history and

failure probability

distributions

• Identified 2 different

failure modes…

1.00 100.0010.00

0.10

0.50

1.00

5.00

10.00

50.00

90.00

99.00

0.10

0.5

0.6

0.7

0.8

0.9

1.0

1.2

1.4

1.6

2.0

3.0

4.0

6.0

b

h

ReliaSoft's Weibull++ 6.0 - www.Weibull.com

Probability - Weibull

Time in Service (months)

Unreliability,F(t)

478

610

809

938

1153

1193

1314

1289

1378

1307

1251

134111691120105393388877267163755350743241538330332126621322817118915411812292433227149

Weibull

AllParts_Months_Warr

W5 MLE - SRM MED

F=24896 / S=334701

CB[FM]@90.00%

1-Sided-U [T1]

b[1]=2.2600, h[1]=16.5572, R[1]=0.0921 ; b[2]=1.8892, h[2]=163.0341, R[2]=0.9079](https://image.slidesharecdn.com/rootcausefailureanalysisbylifecycleengineering-200710114627/85/Root-Cause-Failure-Analysis-by-Eugene-Cottle-Lifecycle-Engineering-36-320.jpg)

![37© Life Cycle Engineering 2008

1.00 100.0010.00

0.01

0.05

0.10

0.50

1.00

5.00

10.00

50.00

90.00

99.00

0.01

0.5

0.6

0.7

0.8

0.9

1.0

1.2

1.4

1.6

2.0

3.0

4.0

6.0

b

h

ReliaSoft's Weibull++ 6.0 - www.Weibull.com

Probability - Weibull

Time in Service (months)

Unreliability,F(t)

80

99

124

120

112

94

1188910590807880576147564042172322917121510888892354

Weibull

16000K

W5 MLE - SRM MED

F=1752 / S=9223

b1[1]=1.8996, h1[1]=11.4709, R1[1]=0.1469 ; b1[2]=1.7402, h1[2]=133.6546, R1[2]=0.8531

13

3

12

8

11

8 5 7

11336364 52 2 3 16000L

W5 MLE - SRM MED

F=120 / S=209

b2[1]=1.8024, h2[1]=9.8963, R2[1]=0.3433 ; b2[2]=1.5343, h2[2]=116.0825, R2[2]=0.6567

223

280

427

473

622

665

731

703

7947346957576455655694674594223753443023132732542361621841571151348610976525942158

16000M

W5 MLE - SRM MED

F=13527 / S=89454

b3[1]=2.2610, h3[1]=14.0255, R3[1]=0.0997 ; b3[2]=1.8634, h3[2]=121.8553, R3[2]=0.9003

8

17

19

21

20

1512111617141413101179332623222 16000N

W5 MLE - SRM MED

F=264 / S=9106

b4[1]=1.9221, h4[1]=12.1015, R4[1]=0.0298 ; b4[2]=4.4799, h4[2]=91.3611, R4[2]=0.9702

37

50

50

423228

44383334292637172311121915138677665443

AllOthers

W5 MLE - SRM MED

F=648 / S=42756

CB[FM]@90.00%

1-Sided-U [T1]

b5[1]=1.6788, h5[1]=12.0507, R5[1]=0.0137 ; b5[2]=1.7057, h5[2]=612.6454, R5[2]=0.9863

Further analysis

permitted us to

isolate and

identify

subpopulations

with distinctly

different failure

distributions](https://image.slidesharecdn.com/rootcausefailureanalysisbylifecycleengineering-200710114627/85/Root-Cause-Failure-Analysis-by-Eugene-Cottle-Lifecycle-Engineering-37-320.jpg)