Specification: Test procedure and acceptance criteria

- 1. ICH Q6(A) - Specification Specifications: Test procedure and Acceptance criteria

- 2. ICH Q6(A) - Specification DEFINITION A list of tests, reference to analytical procedures, and acceptance criteria (numerical limits, ranges or other specific criteria) to which an API or FPP should conform to considered acceptable for its intended use. Confirm the predefined quality, rather than fully characterize the API or the FPP Should focus on those characteristics found to be useful in ensuring the safety and efficacy of the drug substance and drug product

- 3. ICH Q6(A) - Specification OBJECTIVE To establish harmonized global specification for drug substance and drug product. To provide the guidance on the selection of the test, setting the acceptance criteria for them along with justification for same. To design and propose one part of total control strategy for the drug substance and drug product to ensure product quality and consistency and approved by regulatory authorities as conditions of approval .

- 4. ICH Q6(A) - Specification ICH Q6- SPECIFICATION Two guidelines addressing the selection of tests and methods and setting specifications for quality control of API and finished products (chemicals and biotechnologically derived proteins and polypeptides)

- 5. ICH Q6(A) - Specification ICH Q6- SPECIFICATION Q6A - For Chemical substances Q6B - For Biotechnological and biological products Applicability Chemically synthesized • Drug subtance • Drug products (including combination products) • Proteins and polypeptides produced from recombinant • proteins and polypeptides produced from non- recombinant cell-culture expression systems, their derivatives • Products of which protein and polypeptides are components (e.g., conjugates). May be applicable • synthetic and semi-synthetic antibiotics • Low molecular weigh synthetic peptides. • Proteins and polypeptides isolated from tissues and body fluids Not Applicable • Drug substances or drug products during the clinical research stages of drug development. • Antibiotics • Synthetic peptides, polypeptides and Heparin • Vitamins, cell metabolites. • DNA products, allergenic extracts, conventional vaccines, cells, whole blood, and cellular blood components

- 6. ICH Q6(A) - Specification GENERAL CONCEPT: Periodic or skip testing : Specified tests at release on pre-selected batches and/or at predetermined intervals, rather than on a batch-to-batch on the basis of product understanding that those batches must meet the acceptance criteria even if not tested. This concept should therefore generally be implemented post-approval. Example: Residual solvent and microbiological testing in case of solid oral dosage form. Release vs Shelf life acceptance criteria: Applicant may choose to have tighter in-house limits at the time of release to provide increased assurance within the regulatory acceptance criterion throughout its shelf-life. In Japan and the US, the regulatory acceptance criteria are the same from release throughout shelf-life whereas in EU, there is a regulatory requirement for distinct specifications for release and for shelf-life.

- 7. ICH Q6(A) - Specification GENERAL CONCEPT: In-process Tests: Performed during the manufacture of either the drug substance or drug product. used for the purpose of adjusting process parameters within an operating range. Example: Hardness, friability of core tablet in case of coated tablet. This approach should be validated to show that test results or product performance characteristics do not change from the in-process stage to finished product

- 8. ICH Q6(A) - Specification GENERAL CONCEPT: Design and Development Considerations : Basis for the setting of specification to propose inclusion and exclusion of the certain testing during the in-process, release and shelf life. Experience and data accumulated during development. Scientific consideration by thorough understanding of the manufacturing process of DS and DP. Universal test and product specific test considering the region specific regulatory requirement. Examples: Microbiological testing for drug substances and solid dosage forms which have been shown during development not to support microbial viability or growth. Refer Decision tree# 6 and 8. Dissolution testing for immediate release solid oral drug products made from highly water soluble drug substances may be replaced by disintegration testing, if these products have been demonstrated during development to have consistently rapid drug release characteristics. Refer Decision tree # 7(1) and 7(2).

- 9. ICH Q6(A) - Specification GENERAL CONCEPT: Limited Data Available at Filing: Limited amount of data may be available at the time of filing, which can influence the process of setting acceptance criteria. Initially approved tests and acceptance criteria should be reviewed as more information is collected, with a view towards possible modifications (loosening as well as tightening of the acceptance criteria) The basis for the acceptance criteria at the time of filing should necessarily focus on safety and efficacy.

- 10. ICH Q6(A) - Specification GENERAL CONCEPT: Parametric release: An operational alternative to routine release testing for the drug product in certain cases when approved by the regulatory authority . Example: Sterility testing for terminally sterilized drug products. Release of each batch is based on satisfactory results from monitoring specific parameters, e.g., temperature, pressure, and time during the terminal sterilization phase(s) of drug product manufacturing When parametric release is performed, the attribute which is indirectly controlled (e.g., sterility), together with a reference to the associated test procedure, still should be included in the specifications.

- 11. ICH Q6(A) - Specification GENERAL CONCEPT: Alternative procedures used to measure an attribute when such procedures control the quality of the drug substance or drug product to an extent that is comparable or superior to the official procedure . Example: use a spectrophotometric procedure for assay during release as opposed to the official procedure, which is chromatographic method. However the chromatographic procedure should still be used to demonstrate compliance with the acceptance criteria during the shelf-life of the product. Pharmacopoeial procedures should be utilized wherever found appropriate. New analytical technologies, and modifications to existing technology should be used when they are considered to offer additional assurance of quality, or are otherwise justified. It should not be necessary to test the drug product for quality attributes uniquely associated with the drug substance Example: It is normally not considered necessary to test the drug product for synthesis impurities which are controlled in the drug substance and are not degradation products. Refer ICH Q3B

- 12. ICH Q6(A) - Specification JUSTIFICATION OF SPECIFICATION: Justification should be presented for each procedure and each acceptance criterion included in the specification considering following aspects. Product development data Pharmacopoeial standards Test data for drug substances and drug products used in toxicology and clinical studies. Results from accelerated and long term stability studies. A reasonable range of expected analytical and manufacturing variability Justification may consider theoretical tolerances for a given procedure or acceptance criterion, but the actual results obtained should form the primary basis for whatever approach is taken

- 13. ICH Q6(A) - Specification JUSTIFICATION OF SPECIFICATION: Test results from stability and scale-up / validation batches, with emphasis on the primary stability batches, should be considered in setting and justifying specifications. It may be valuable to consider data from multiple sites in establishing the initial tests and acceptance criteria in case of multiple sites are planned. If data from a single representative manufacturing site are used in setting tests and acceptance criteria, product manufactured at all sites should still comply with these criteria. Presentation of test results in graphic format may be helpful in justifying individual acceptance criteria, particularly for assay values and impurity levels. Justification for proposing exclusion of a test from the specification should be based on development data and on process validation data (where appropriate)

- 14. ICH Q6(A) - Specification UNIVERSAL TESTS/CRITERIA (FOR DS AND DP) Following test and criteria applicable to all drug substance and drug product. Description/Appearance – state, colon, size, shape Identification Must be specific for drug substance (e.g., Infrared spectroscopy) Identification solely by a single chromatographic retention time is not considered as specific. Combination of tests, such as HPLC/UV diode array, HPLC/MS, or GC/MS is generally acceptable . Identification testing should be specific for the individual ions, in case of DS is salt. Specific identification testing or performance of a chiral isomer required in case of optically active DS. Assay Specific, stability-indicating procedure to determine the potency/strength. Use of a non-specific assay method should be justified using other explored analytical procedures to demonstrate overall specificity. Content uniformity testing for new drug products can be used for quantitation of drug product strength, if the methods used for content uniformity are also appropriate as assays.

- 15. ICH Q6(A) - Specification UNIVERSAL TESTS/CRITERIA (FOR DS AND DP) Impurities (Organic, inorganic, residual solvent and elements) Organic and inorganic impurities and residual solvents are included in the drug substance.(Q3A,C and D) Organic and inorganic impurities (degradation products) and residual solvents are included in the drug product.(Q3B) Organic impurities arising from degradation of the DS and impurities that arise during the manufacturing process for the drug product should be monitored in the new drug product. Process impurities from the new drug substance synthesis are not included in total impurities. Specific, stability-indicating procedure must be used. Degradation product testing may be reduced or eliminated upon approval by the regulatory authorities, in case of conclusively demonstrated via appropriate analytical methodology, that the drug substance does not degrade in the specific formulation, and under the specific storage conditions proposed in the new drug application. Reporting of the impurities should be inline to ICH Q3 guidance. ICH Q6 decision tree #1 for establishing the impurity limit in drug substance. ICH Q6 decision tree #2 for establishing the impurity limit in drug product.

- 16. ICH Q6(A) - Specification SPECIFIC TESTS/CRITERIA – DRUG SUBSTANCE : Solubility: Qualitative solubility should be part of specification. BCS solubility should be known for the drug product development. Particle size Particle size distribution should be carried out using an appropriate procedure, and acceptance criteria should be provided incase Particle size of drug substance can have a significant effect on dissolution rates, bioavailability, and / or stability. ICH Q6 Decision tree # 3 for additional guidance on when PSD should be considered. Polymorphism Polymorphism should be investigated. If polymorphism is a factor, a test is required in specs ICH Q6 decision tree #4 for guidance on when, and how, polymorphic forms should be monitored and controlled. A surrogate test can generally used to monitor product performance as technically it is difficult to measure polymorphic changes in the drug product. Polymorph content should only be used as a test and acceptance criterion of last resort

- 17. ICH Q6(A) - Specification SPECIFIC TESTS/CRITERIA – DRUG SUBSTANCE : Physicochemical properties Physical nature of the new drug substance and by its intended use (i.e. pH, melting point / range, and refractive index) Procedures usually unique and do not need much elaboration. Water content Important in cases of hygroscopic substance or degraded by moisture or known to be a stoichiometric hydrate. Acceptance criteria may be justified with data on the effects of hydration or moisture absorption. Loss on Drying procedure may be considered adequate; however, a detection procedure that is specific for water (e.g., Karl Fischer titration) is preferred. Inorganic impurities ,elements Need for inclusion of organic impurities to evaluated based on the knowledge of manufacturing process. ICH Q3D to be taken in to consideration for elemental impurities.

- 18. ICH Q6(A) - Specification SPECIFIC TESTS/CRITERIA – DRUG SUBSTANCE : Test for chiral drug substances: Chiral isomers should be considered in the same manner as for other impurities. An enantioselective determination of the drug substance should be part of the specification (e.g. Chiral assay or Achiral assay and other appropriate control of enantiomeric impurity) A stereospecific identity test is not generally needed in the drug product release specification when racemization is insignificant during process and storage. ICH Decision Tree# 5 for when and if chiral identity tests, impurity tests, and assays may be needed for both new drug substances and new drug products. Microbial Limits: Microbiological testing for drug substances and solid dosage forms which have been shown during development not to support microbial viability or growth. ICH Decision tree #6 for microbiological quality attributes of drug substance and excipient. ICH Decision tree #8 for microbial attributes of non-sterile drug products

- 19. ICH Q6(A) - Specification SPECIFIC TESTS/CRITERIA – DRUG PRODUCT : Performance test (e.g. dissolution, disintegration test) Uniformity of dosage units – Mass, content uniformity, fill volume Physical test – LOD/Water, pH, friability, hardness, particle size Preservative content Microbial contamination Sterility, bacterial endotoxins, particulate matter

- 20. ICH Q6(A) - Specification SPECIFIC TESTS/CRITERIA – DRUG PRODUCT : DISSOLUTION In-vitro release of active from drug product. Dissolution test is product specific. Method and limit should be appropriate for proposed drug product. Release and shelf-life specification should be identical. Single-point measurements for IR dosage forms, two-stages for DR dosage forms, multiple time point testing for extended-release dosage forms. Acceptance criteria should be set to reject batches with unacceptable bioavailability, in case of affects on bioavailability In vitro / in vivo correlation may be used to establish acceptance criteria, if BA data available for different release rate. Permitted variability in mean release rate at any given time point should not exceed a total numerical difference of +/-10% of the labeled content of drug substance unless wider range supported by BE study. Develop test conditions which can distinguish batches with unacceptable bioavailability, where changes in dissolution rate have been demonstrated to significantly affect bioavailability . Appropriate to adopt dissolution test conditions which can distinguish changes in formulation or process variables in case of changes are not controlled by another aspect of the specification. ICH decision tree # 7 For setting acceptance criteria for drug product dissolution.

- 21. ICH Q6(A) - Specification SPECIFIC TESTS/CRITERIA – DRUG PRODUCT : DISINTEGRATION May be acceptance for DT in place of dissolution: Rapidly dissolving product containing high soluble drugs Supported via development data Relationship to dissolution has been established Disintegration is shown to be more discriminating than dissolution Robustness of the formulation and manufacturing process with respect to the selection of dissolution vs. disintegration testing

- 22. ICH Q6(A) - Specification UNIVERSAL TESTS/CRITERIA: Test results from stability and scale-up / validation batches, with emphasis on the primary stability batches, should be considered in setting and justifying specifications.

- 23. ICH Q6(A) - Specification SPECIFIC TESTS/CRITERIA – DRUG SUBSTANCE : Microbial limits: Control of the other enantiomer should be considered in the same manner as for other impurities. An enantioselective determination of the drug substance should be part of the specification. considered acceptable for this to be achieved either through use of a chiral assay procedure or by the combination of an achiral assay together with appropriate methods of controlling the enantiomeric impurity. Control of the other enantiomer in a drug product is considered necessary unless racemization has been shown to be insignificant during manufacture of the dosage form, and on storage. A stereospecific identity test is not generally needed in the drug product release specification when racemization is insignificant during process and storage. Refer Decision Tree#5 for when and if chiral identity tests, impurity tests, and assays may be needed for both new drug substances and new drug products. Inorganic impurities: Need for inclusion of organic impurities to evaluated based on the knowledge of manufacturing process. ICH Q3D to be taken in to consideration for elemental impurities.

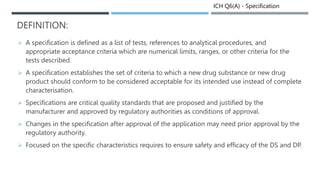

- 24. ICH Q6(A) - Specification DEFINITION: A specification is defined as a list of tests, references to analytical procedures, and appropriate acceptance criteria which are numerical limits, ranges, or other criteria for the tests described. A specification establishes the set of criteria to which a new drug substance or new drug product should conform to be considered acceptable for its intended use instead of complete characterisation. Specifications are critical quality standards that are proposed and justified by the manufacturer and approved by regulatory authorities as conditions of approval. Changes in the specification after approval of the application may need prior approval by the regulatory authority. Focused on the specific characteristics requires to ensure safety and efficacy of the DS and DP.

- 25. ICH Q6(A) - Specification GENERAL CONCEPT Periodic/Skip testing: Specified tests at release on pre-selected batches and / or at predetermined intervals, rather than on a batch-to-batch.(e.g. residual solvents and microbiological testing, for solid oral dosage forms) Only one batch testing required if product is clearly Photostable or Photolabile. Additional two batches testing required if results are equivocal. If immediate pack is completely impenetrable to light, such as aluminium tubes or cans, testing should only be conducted on directly exposed drug product. It may be appropriate to test certain products such as infusion liquids, dermal creams, etc., to support their photostability in-use. The extent of this testing should depend on and relate to the directions for use, and is left to the applicant’s discretion. The samples should be positioned to provide maximum area of exposure to the light source. For example, tablets, capsules, etc., should be spread in a single layer. A 2 per cent weight/volume aqueous solution of quinine monohydrochloride dihydrate is use for calibrating ultraviolet radiation intensity in light-stability testing of pharmaceuticals. If direct exposure is not practical (e.g., due to oxidation of a product), the sample should be placed in a suitable protective inert transparent container (e.g., quartz). Depending on the extent of change special labeling or packaging may be needed to mitigate exposure to light. c

- 26. ICH Q6(A) - Specification DECISION TREE#1 (ESTABLISHING ACCEPTANCE CRITERION FOR SPECIFIED IMPURITY IN DRUG SUBSTANCE)

- 27. ICH Q6(A) - Specification DECISION TREE#2 (ESTABLISHING ACCEPTANCE CRITERION FOR SPECIFIED IMPURITY IN DRUG PRODUCT)

- 28. ICH Q6(A) - Specification DECISION TREE#3 SETTING ACCEPTANCE CRITERION FOR PARTICLE SIZE DISTRIBUTION IN DRUG SUBSTANCE)

- 29. ICH Q6(A) - Specification DECISION TREE#4(1) INVESTIGATING THE NEED TO SET ACCEPTANCE CRITERIA FOR POLYMORPHISM IN DS AND DP.

- 30. ICH Q6(A) - Specification DECISION TREE#4(2) INVESTIGATING THE NEED TO SET ACCEPTANCE CRITERIA FOR POLYMORPHISM IN DS AND DP.

- 31. ICH Q6(A) - Specification DECISION TREE#4(3) INVESTIGATING THE NEED TO SET ACCEPTANCE CRITERIA FOR POLYMORPHISM IN DS AND DP.

- 32. ICH Q6(A) - Specification DECISION TREE#5 ESTABLISHING NVESTIGATING THE NEED TO SET ACCEPTANCE CRITERIA FOR POLYMORPHISM IN DS AND DP.