SUPER ALLOYS.pdf

- 1. 1 Lecture 22: Superalloys MMat 380 Topics Superalloys • Ni vs Co based • History, uses • Strengthening mechanisms Single crystals

- 2. 2 Superalloys • Able to maintain high strengths at high temperatures • Good corrosion and oxidation resistance at high temperatures (Cr, Al) • Good resistance to creep and rupture at high temperatures • 3 main classes of superalloys – Ni – Base – Ni-Fe – Base (cheaper than Ni-base) – Co – Base High temperature strength

- 3. 3 Ni-based superalloys • Since 1950, these alloys have predominated in the range 750-980°C • Due to the presence of very stable γl ordered FCC precipitate (Ni3 Al,Ti) which provide high temperature strength • The γl phase in Co-based superalloys dissolves at 815-1050°C Co-based superalloys • Exhibit superior hot corrosion and strength characteristics at temperatures 980-1100°C • Operating temperatures of the turbine and combustion section • Co-based alloys sometimes used in the lower range of 750°C in preference to Ni-based superalloys • Can be air or argon cast and are less expensive than the vacuum-processed Ni- alloys

- 4. 4 Strengthening mechanisms in superalloys Ni-based superalloys a) solid solution strengthening (Mo and W) b) addition of elements, e.g., Co which decrease the solubility of others to promote ppt of intermetallics c) Al and Ti to form ordered FCC intermetallic precipitates of γl-phase [Ni3Al], [Ni3Ti] d) Carbides on grain boundaries (pin boundaries to stop shear) i.e. control grain boundary sliding Strengthening mechanisms in superalloys Ni-based superalloys e) Small additions of B and Zr which segregate to the grain boundaries and retard sliding process and grain boundary diffusional process f) Large grains; columnar grains; single crystal – to stop grain boundary shear NB – Other phases (e.g. sigma) may form. They are not strengthening phases and their morphology is usually controlled so that they do not impair hot strength (e.g. by forming continuous GB ppts). In effect, they are undesirable, but may have to be tolerated

- 5. 5 Uses of superalloys • Largest application of superalloys: – aircraft and industrial gas turbines • Also used in: – Space vehicles – Rocket engines – Submarines – Nuclear reactors Major phases present • γ (gamma) phase – continuous matrix of FCC austenite • γl (gamma prime) phase – major ppt phase • carbides – various types, mainly M23C6 and MC

- 6. 6 Historical changes in microstructure Microstructure Ni3Al (γ1)

- 7. 7 Trends in microstructure design • Volume fraction of γl is increased • The size of γl first increased and then remained constant at ~1µm • γl became more “cubic” • A secondary ppt of finely divided γl appeared • γ phase – strengthened by addition of solid- solution elements such as Cr, Mo, W, Co, Fe, Ti, Al • γl phase – precipitated in austenite nickel superalloys by precipitation hardening heat treatments – ppt in high-Ni matrices is of the FCC A3B-type compound i.e. Ni3(Al,Ti) or (Ni, Co)3(Al,Ti) – Degree of order in Ni3(Al,Ti) increases with temperature Trends in microstructure design

- 8. 8 • Carbides – C content 0.02-0.2% – Metallic carbides form in the grain boundaries and within the grains – Optimum distribution /amount of carbides along the grain boundaries • No carbides – excess grain boundary sliding • Continuous chain of carbides – continuous fracture paths will be formed (low-impact properties) • Discontinuous chain of carbides along grain boundaries optimum Trends in microstructure design Historical development and typical temperature capability of superalloys 760°C 815°C 870°C 925°C 980°C 1040°C 1100°C Temperature capability for 100 hr life @ 140 MPa

- 9. 9 Microstructure: Astroloy forging Fig 11-18: solution heat treated 1150oC 4h, air cooled, aged 1079oC 4h, oil quenched, (intergranular γ’ ppt) aged 843oC 4h, air-cooled, (Fine γ’ ppt) aged 760oC 16h, air cooled, (Fine γ’ ppt) Effect of Al & Ti content on strength of Ni-based superalloys at 870oC

- 10. 10 Nickel-Iron Base Superalloys • Fe substituted in part for nickel (cheaper) • However lower nickel contents mean they cannot be used at as high temperatures as the Ni-base superalloys (650-815°C) – 25-45 %Ni – 15-60 %Fe – 15-28 %Cr – oxidation resistance – 1-6 %Mo - solid solution strengthening Nickel-Iron Base Superalloys • Most Ni-Fe-based superalloys designed so that they have an austenitic FCC matrix • Solid solution strengtheners: – Cr, Mo, Ti, Al, Nb • Precipitation strengtheners: – Ti, Al, Nb – combine with Ni to form intermetallic phases γI

- 11. 11 Some effect of elements on superalloys Ni-base Co-base Effect B, Zr B, Zr Changes gb morphology, enhances creep-rupture properties Cr Cr Sulfidation resistance Al, Cr, Ta Al, Cr, Ta Oxidation resistance Al, Ti Forms γI Ni3(Al,Ti) W, Ta, Ti, Mo, Nb Cr Cr, Mo, W Mo, W Ti Cr Cr Mo,W Carbide forms: MC type M7C3 type M23C6 type M6C type Co, Cr, Fe, Mo, W, Ta Nb, Cr, Mo, Ni, W, Ta Solid-solution strengtheners *If B present in large amounts, borides are formed Typical compositions of Ni base superalloys

- 12. 12 Co-based superalloys • At room temperature Co: HCP crystal structure • At 417°C Co undergoes an allotropic transformation and changes to an FCC structure • Typical composition – 50-60 %Co – 20-30 %Cr – 5-10 %W – 0.1-1 %C • Strengthening: – solid solution strengthening – carbide precipitation • Lower strength of cobalt alloys at intermediate temperatures due to a lack of γl Stress rupture properties • Ni-based superalloys used in the 760-980 C temperature range • Cast alloys maintain highest strength at the higher temperatures – i.e., MAR-M246 – casting alloy has a rupture strength of 18 ksi after 1000 h at 982 C • Nickel-iron based superalloys used up to 650- 815 C (depending on Ni level) – Note – These alloys rupture at considerably lower strengths than the Ni-based superalloys

- 13. 13 Stress vs T curves for Rupture in 1000h for Ni-base alloys Rupture strengths of wrought and cast Ni-base superalloys at 3 T’s 124 103 55 55 448 379 290 296 110 772 703 469 1000h 1000h 1000h 186 565 MAR-M246 172 503 IN-100 Cast 103 407 Astroloy 117 400 Udimet 700 24 179 552 Inconel X-750 Wrought 100h 100h 100h Alloy 982oC 815oC 650oC Characteristic rupture strengths, MPa

- 14. 14 Stress vs T curves for Rupture in 1000h for Ni-Fe base alloys Co-based superalloys • High temperature stress rupture strengths • At lower and intermediate temperatures cobalt alloys are not as strong as Ni-based superalloys • Reason: lack of coherent γl precipitate • Co alloys used for low-stress high- temperature long life parts such as vanes in industrial turbines Ni3(Al,Ti)(Ni3Ti)

- 15. 15 Stress-T curves for rupture in 1000h for selected Co-based alloys Rupture strengths of wrought and cast Co-base superalloys at 3 T’s 28 55 76 138 179 X-40 38 55 90 117 228 269 MAR-M509 25 110 124 1000h 1000h 1000h Cast 15 41 152 HS-188 172 S-816 Wrought 100h 100h 100h Alloy 982oC 815oC 650oC Characteristic rupture strengths, MPa

- 16. 16 Single crystal’s • 1970’s and 1980’s – introduction of columnar- grained and single-grained castings to replace polycrystal castings of Ni-based superalloys for gas turbine airfoils • Major increase in the strength and Temp. capability of superalloy castings – able to operate 50oC higher with 100 h/ 140 MPa stress rupture capability Ni-base superalloys 0 1 2 3 4 5 6 7 8 9 10 Creep strength Thermal fatigue resistance Corrosion resistance Relative life Polycrystal Columnar crystal Single crystal

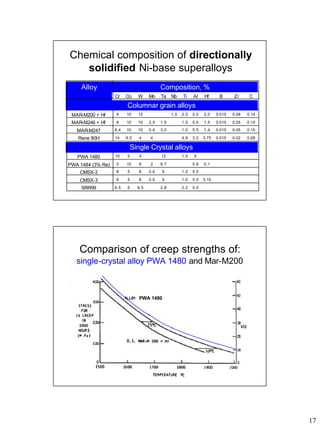

- 17. 17 Chemical composition of directionally solidified Ni-base superalloys 5.5 2.2 2.8 9.5 5 8.5 SRR99 0.15 5.5 1.0 6 0.6 8 5 8 CMSX-3 5.5 1.0 6 0.6 8 5 8 CMSX-2 0.1 5.6 8.7 2 6 10 5 PWA 1484 (3% Re) 5 1.5 12 4 5 10 PWA 1480 Single Crystal alloys 0.08 0.02 0.015 0.75 3.0 4.8 4 4 9.5 14 Rene 80H 0.15 0.05 0.015 1.4 5.5 1.0 3.0 0.6 10 10 8.4 MAR-M247 0.15 0.05 0.015 1.5 5.5 1.5 1.5 2.5 10 10 9 MAR-M246 + Hf 0.14 0.08 0.015 2.0 5.0 2.0 1.0 12 10 9 MAR-M200 + Hf Columnar grain alloys C Zr B Hf Al Ti Nb Ta Mo W Co Cr Alloy Composition, % Comparison of creep strengths of: single-crystal alloy PWA 1480 and Mar-M200 PWA 1480

![4

Strengthening mechanisms in superalloys

Ni-based superalloys

a) solid solution strengthening (Mo and W)

b) addition of elements, e.g., Co which decrease the

solubility of others to promote ppt of intermetallics

c) Al and Ti to form ordered FCC intermetallic

precipitates of γl-phase [Ni3Al], [Ni3Ti]

d) Carbides on grain boundaries (pin boundaries to

stop shear) i.e. control grain boundary sliding

Strengthening mechanisms in superalloys

Ni-based superalloys

e) Small additions of B and Zr which segregate to the grain

boundaries and retard sliding process and grain boundary

diffusional process

f) Large grains; columnar grains; single crystal – to stop

grain boundary shear

NB – Other phases (e.g. sigma) may form. They are not strengthening phases

and their morphology is usually controlled so that they do not impair hot

strength (e.g. by forming continuous GB ppts). In effect, they are

undesirable, but may have to be tolerated](https://image.slidesharecdn.com/superalloys-230712130351-7c4e4dd1/85/SUPER-ALLOYS-pdf-4-320.jpg)