Towards Green and Decarbonized Ports (1).pptx

- 1. Future of Ports: Towards Green and Decarbonized Ports By Dr.Khalid Bichou KL, 28-29 Feb 2024

- 2. 2012-Present Ports & Logistics Consultants Ltd. Khalid Bichou (PhD, DIC, MSc, FCILT, FANI) 1991-2012

- 3. Khalid BICHOU PhD (Imperial), MSc (Plymouth), MSc (WMU), BSc (ENA) www.ports-logistics.com Consulting and Advisory Research and Academia • Over 120 consulting & advisory projects • 100+ countries of work experience • Senior Advisor EBRD Transport Team • Maritime Transport Advisor WB/IFC • Transport Logistics Advisor UNCTAD • Port Advisor UK House of Commons • Port and Supply Chain Advisor UKTI • Maritime and Port Advisor, COMCEC /IOC • Assessor and Rapporteur TEN-TA • Intl.Advisor Supply Chain Logistics Group • Int.Advisor Container Security Laboratory • Port Policy Advisor EP • Port, maritime, and transport logistics advisory: 9 port operators, 4 law firms, 6 IFIs, 36 port and maritime authorities, 12 government agencies, 7 development agencies. • Co-founder and member of Intl. Advisory Board PORTEC (Imperial College) • Founder and Intl. Advisor Global Port Research Alliance -GPRA (Imperial College, MISCI, MIT, Hamburg Uni., HK Polytechnic, NUS, Univ. of Sydney, Univ. of Sao Paulo,TU Delft) • Visiting academic: Imperial College, UCL, City University, MIT,NUS, HK PolyU, Middlesex University, Lloyds Maritime Academy • Lectured in MSc and PhD courses • Supervised 22PhDs and 150+ master students • Designed and delivered over120 training workshops & professional courses • Published 6 books and over 100 articles • Chartered Member (CILT), International Advisor (SCLG), Member (IAME), Member (GPF), Fellow (TEG), Member (GPF), Partner (GFPTT)

- 7. Port environmental risks and concerns The relationship between ports and environmental risks can be categorised into 4 broad areas: 1. Climate Change Rising temperature Sea Level Rise Extreme Weather Conditions 2. Air Pollution GHG emissions from marine and inland systems Air pollutants Air quality and odour 3. Marine,Water and Soil Pollution Biodiversity, water environment and land quality Waste management Pollution from marine and land base sources 4. Other Environmental Risks and Factors Noise Landscape and visual impact Historical environment Community and social impacts Traffic impacts and transport network users

- 8. Port Environmental Management- Regulatory framework 1992 UNFCCC 1997 Kyoto Protocol Post-Kyoto 2012 IMO 2018 Initial GHG Strategy and Short-term measures Various ECAs and SECAs International Maritime Emission Reduction Scheme (proposition by Norway) 2005/21 EU Emission Trading Scheme (ETS) 2008 Climate change levy in the United Kingdom Australia’s GHG abatement programme Carbon tax and negotiated GHG agreement in New Zealand Western Climate Initiative – US and Canada Port Climate Change Action, Eco-ports, CARB, etc.

- 9. United Nations Convention on the Law of the Sea, UNCLOS Prevention of pollution by sea – London Dumping Convention Prevention of pollution by ships – MARPOL Oil Pollution Preparedness, Response and Cooperation – OPRC International Maritime Dangerous Goods Code (IMDG Code) Convention for Safe Containers (CSC) Control and Management of Ships' Ballast Water and Sediments (BWM Convention) Control of Harmful Anti-Fouling Systems on Ships, 2001 (AFS Convention) Biofouling guidelines Guidelines on the Provision of Adequate Reception Facilities in Ports Code of Safe Practice for Cargo Stowage and Securing (CSS Code) International Ship Management (ISM) Code IMO Manual on Oil Pollution Crude Oil Washing guidelines (COW Systems) Procedures for the Control of Ships and Discharges Guidelines for the identification and designation of Particularly Sensitive Sea Areas (PSSAs) Ship recycling, Hong Kong convention Maritime Environment -Relevant regulations (IMO)

- 10. Port Environmental Management Climate Change

- 11. Risk factor Implications on Ports Hot days and heat waves Melting ice (for frozen winters) Large variations Frequent freeze and thaw cycles Changes in water chemistry SLR Extreme weather events Challenges to port development and operating practices Increased maintenance costs, e.g. for dredging, upgrade, retrofitting, etc. Increased energy use; e.g. for refrigerated storage Disruptions to service and operational reliability Route diversions and loss of competitivity and market share Socio-economic, environmental and political implications Longer shipping season (NSR), new sea routes ( e.g. NWP) Need for new or adapted support services, e.g. SAR, AtoNs, ice-breaking, etc. Climate change risks and impacts- rising temperature Source: NOAA Source: IPCC

- 12. Climate change risks and impacts- Sea Level Rise Risk factor Implications on Ports MSL Flooding and inundation Erosion of coastal areas Storm surges Land subsidence Relocation, redesign and construction of port/coastal infrastructure Asset protection schemes (e.g. levees, seawalls, dikes, infrastructure elevation) Asset Insurance, risk and management practices Operational and service disruptions Reduction or avoidance of development/settlement in port and surrounding areas Provision for evacuation routes and operational plans Source: Frederikse et al. (2020) from NASA’s Goddard Space Flight Center/PO.DAAC

- 13. Risk factor Direct Impacts on Ports Tsunamis Damage to infrastructure, utilities, superstructure, vehicles and cargo Hurricanes Erosion, sedimentation, subsidence and landslide Storm surge Operational disruptions, reduced visibility and service reliability Precipitation & rainfall Need for emergency evacuations and management Strong Winds and fogs Need for asset protection schemes (e.g. levees, seawalls, dikes, infrastructure elevation) MSL, tide and waves Increased asset insurance premium, adaptation and mitigation costs Climate change risks and impacts- Extreme weather events Source: Munich Re, Geo Risks Research, NatCatSERVICE. As of March 2019 Weather related natural catastrophes

- 15. Example 1: Port Expansion in Poland 15 Key climate risks: • Changes in sea ice (positive) • Sea level rise • Changes in rainfall intensity • Changes in wave conditions Adaptation measures adopted: • Quayside structures designed to cope with sea level rise of approximately 6-10mm per year over the next 100 years • Communication channel established with the Port Authority to receive relevant information about sea level extremes and wave overtopping of port structures

- 16. Example 2: New Port Facility in Morocco Key climate risks: • Sea level rise • Increased storminess • Increased extreme heat events Adaptation measures adopted: • Analyse breakwater design taking into account expected sea-level rise over the design life of the Port • installation of surfacing, mechanical and electrical equipment designed to withstand • projected temperature extremes (>40 degrees C) • Installation of surface drainage design able to cope with extreme rainfall and overtopping events • Installation of storage facilities able to withstand extreme temperatures and extreme weather events • Adoption of Emergency Response Plan and Coastal Erosion Monitoring Scheme 16

- 17. Scaling up action on climate resilient ports in Morocco Emerging partnerships to rise to this challenge: • PIANC Working Group 178 on Climate Change Adaptation for Ports and Navigation Infrastructure • Moroccan port authorities will be supported to benefit from emerging PIANC guidance • GEF Special Climate Change Fund has awarded USD 6 million grant resources to co-finance innovative investment in port sector climate resilient upgrades in Morocco ‘la houle exceptionelle’ of January 2014 has raised awareness of climate risks to port infrastructure in Morocco

- 18. Port Environmental Management Emissions and Air Pollution

- 19. Emissions, energy use and air pollution in ports Sources of emissions and air pollution in ports may be categorised under7 broad areas: 1. Sulphur and exhaust emissions from ships calling at the port 2. Ship GHG emissions (CO2, NOx, PM, Methane, etc.); 3. Emissions and energy use from port buildings and facilities 4. Emissions from cargo handling and operational use 5. Emissions from port crafts / vessels 6. Emissions from hinterland distribution and traffic congestion 7. Air pollution from port development and operations (dust, fumes, vaporisation, chemicals, etc.)

- 20. Main emissions of concern ◗ Nitrogen Oxides (NOx):. ◗ Particulate Matters (PM): ◗ Sulphur Oxides (SOx): ◗ VOC (Vloatile Organic Compounds) - Some ports ◗ Some carbon monoxide and unburned hydrocarbons

- 21. Source: Port of Los Angeles Inventory of Air Emissions (2021) Port emissions by source Maritime Industry-related Emissions by Category at the port of Los Angeles PM10 tons PM2.5 tons DPM tons NOx tons SOx tons CO tons HC tons CO2e tonnes 2020 Ocean-going vessels 52 48 34 2,867 96 273 127 212,248 Harbor craft 24 22 24 721 1 539 82 60,374 Cargo handling equipment 6 5 4 366 2 643 66 165,961 Locomotives 29 27 29 786 1 189 45 65,987 Heavy-duty vehicles 6 6 6 1,075 4 284 43 398,679 Total 117 108 97 5,814 104 1,928 363 903,250 2005 Ocean-going vessels 611 491 450 5,193 4,668 469 215 281,239 Harbor craft 55 51 55 1,318 6 364 87 56,925 Cargo handling equipment 54 50 53 1,573 9 822 92 134,621 Locomotives 57 53 57 1,712 98 237 89 82,201 Heavy-duty vehicles 248 238 248 6,307 45 1,865 368 474,877 Total 1,025 882 863 16,103 4,826 3,757 852 1,029,863 Change between 2005 and 2020 (percent) Ocean-going vessels -91% -90% -93% -45% -98% -42% -41% -25% Harbor craft -57% -57% -57% -45% -89% 48% -6% 6% Cargo handling equipment -89% -89% -91% -77% -81% -22% -28% 23% Locomotives -48% -49% -48% -54% -99% -20% -50% -20% Heavy-duty vehicles -98% -98% -98% -83% -92% -85% -88% -16% Total -89% -88% -89% -64% -98% -49% -57% -12%

- 22. Port Emissions and Air Pollution Ship Related Emissions

- 23. Ship emissions in ports Ship emissions during anchorage / waiting for berth: • Fuel consumption from Main engines (for limited time queuing) • Fuel consumption from Auxiliary engines (at all times) • Fuel consumption from Auxiliary boilers (when Main engines are switched off) ◗ Port characteristics, performance, sequencing and scheduling influence ship queuing and therefore emissions Ship emissions during approach and pilotage: • Main engines usually off • Fuel consumption from Auxiliary engines (higher loads / spikes) • Fuel consumption from Auxiliary boilers (when Main engines are off) • Tugboat emissions ◗ Port characteristics and pilotage influence ship manoeuvring and therefore emissions Ship emissions at berth: • Main engines turned off (with exceptions) • Fuel consumption from Auxiliary engines (loads depending on ship specs) • Fuel consumption from Auxiliary boilers (loads depend on Main engine requirements) • On cold ironing, only boilers operate ◗ Ship emissions at berth is also influence by port and berth characteristics, handling configurations, bunkering requirements and availability of cold ironing

- 24. Ship sulphur emissions The shipping industry has for long been using bunker fuel grades with a high sulphur content, a level that is not accepted in road or rail transport. IMO 2020 regulations require a reduction of ship’s fuel sulphur content to 0.5% max (down from 3.5% in 2012). For some designated ECAs and jurisdictions, tighter sulphur limits are set to 0.1% max. T o comply with the regulations, ship operators can use one or a combination of many strategies: speed reduction, retrofitting (EGCS / scrubbers), fuel conversion to (V)LSFO, machinery technology solutions, fleet renewal and use of alternative fuel. For ports, and besides compliance monitoring, ports can invest in V/LSFO bunkering, shore power and cold ironing (SSP / AMP), and alternative fuel bunkering and storage. Share of global fleet fitted with scrubber systems (Source: IMCO)

- 26. Ship’s emissions and fuel type

- 27. Ship’s emissions and fuel type

- 28. Solutions to reduce ship emissions in ports ◗ Main measures include: ◗ Efficient Ship operations. ◗ Ship’s cleaner fuels. ◗ Ship’s emissions abatement technologies. ◗ Ship-board energy efficiency when in port. ◗ Use of OPS/AMP.

- 29. Solutions to reduce ship emissions ◗ Numerous operational and technical measures are available for ship-port emissions reduction and energy efficiency. There are no “one size fit all” technical measure solution for ships and ports. The operational measures focus on ship and port energy efficiency, and include reducing ship’s WT (use virtual arrivals, improve cargo handling, upgrade cargo equipment, coordinate port management systems, promote JIT, etc.) ◗ The technical measures are quite extensive including engines, boilers, after treatment technologies, fuel options, etc. ◗ There are solutions underway that focus on the use of alternative maritime power and zero- emission fuels. ◗ Other initiatives look at economic and market-based measures such abatements, price incentives, trading schemes, etc.

- 30. Port activity emissions and energy use Stemming from port activities, buildings, equipment and machinery, etc. Specific operations require more energy use; e.g., night operations (lighting), reefer containers, and building energy requirements Most port machinery and vehicles can be procured, retrofitted or converted to run on electricity and/or other clean fuels. Port operations and processes can also be streamlined to reduce energy use and emissions: Electrify port equipment Reduce queuing and congestion on the water and landside Optimize ship and truck/rail planning, scheduling and booking systems Minimize idling and Optimize cargo (e.g., container) and traffic (e.g., vehicle) management Vessel and truck speed reduction programmes Reward cleaner ships and inland trucks and vehicles Invest in AMP (clod ironing) and cleaner bunker fuels (hydrogen, methanol, ammonia, etc.) Implement regulatory and policy measures; first mover advantage Introduce emissions trading and market-based measures

- 31. Air Pollution from port operations Stemming from various port activities and operations including: Dust, especially from dry bulk handling, stockpiling, and transportation Fumes and vaporizations from O&G and chemical handling and operations Odours, especially from chemicals and some dry bulk cargoes inflammable toxics from IMDG and HAZMAT types of cargo and operations Dark smoke and hazardous substances from fire, explosion and other safety incidents Air pollution stemming from industrial and processing sites inside or next to port areas. Most regulators impose strict rules and requirements to minimize or eliminate air pollution in ports. Requirements for equipment, installations and procedures to minimize dust, fumes, odours, etc. Regulations for safe storage and handling for various types of cargoes and products. Specific or targeted regulations for the handling of HAZMAT and dangerous goods. Certified plans and procedures to assess, manage and mitigate safety, security and air pollution incidents and accidents

- 32. GHG emissions- IMO Strategy IMO 2018 GHG Initial Strategy aims at reducing sector-wide shipping emissions by at least 50% by 2050. Other countries and jurisdictions have set tighter and earlier targets. T o achieve low carbon or zero-carbon shipping, the IMO measures are set as short-term operational and technical measures (2018-2023), medium-term market-based and energy efficiency measures (2023-2030), and long-term alternative fuel and zero-carbon energy measures (2030-2050) The transition towards maritime decarbonisation will likely require a combination of several pathways including new (or improved) technologies and operating systems, alternative fuel and supply and storage infrastructures, innovative business models and financing schemes, and other associated and supporting measures. The success and delivery of each pathway will depend on several factors and uncertainties around technology’s availability and scalability, level of demand, infrastructure and technical challenges, costs and prices, and skills development and transition, Ports are essential to maritime decarbonisation and transition as they feature in all potential tools and solutions, and in some cases they constitute the main component of decarbonisation. In addition, ports themselves have to limit their GHG emissions and must achieve a range of decarbonisation targets set at local or national levels.

- 33. Mapping GHG Solutions: Operational and performance solutions Zero or minimum costs Most relevant to old or end life-cycle assets Includes policy measures, e.g., IMO Ship Energy Efficiency Management Plan (SEEMP) High commercial, coordination & supply chain risk Not relevant to long-term innovation needs Option/ Solution Function /Objective Impact on GHG Commercial & Contractual risks Policy and Regulatory risks Safety & Security risks Interface & Coordinatio n risks Speed Reduction Slow steaming reduces fuel consumption and saves energy. Medium High High Medium Medium Performanc e Management Systems and Plans to measure, track and report fuel consumption and improve energy efficiency Low Low Medium Medium High Weathe r Routing Capture emissions onboard, convert or store them for discharge onshore or at sea Low High Medium Medium High Integrated Planning and data sharing Operational data sharing and integration in order to optimise ship voyage and port interface operations, leading to a reduction in energy use. Medium Low Low High High

- 34. Mapping GHG Solutions: Design and technical solutions Option/ Solution Function / Objective Impact on GHG Technolog y risk Policy & Regulatory risk Investment & Financing risk Design and structural modifications Changes in ship design parameters and shipbuilding materials to increase ship’s capacity and reduce energy use Medium Medium Low Medium Retrofitting and Machinery technology Retrofitting or installation of onboard equipment to meet regulatory requirements and extend asset lifecycle Medium High Medium Medium Carbon Capture and Storage (CCS) Capture emissions onboard, convert or store them for discharge onshore or at sea Medium High Medium High Energy saving devices Energy saving and flow conditioning devices to increase energy efficiency without retrofitting or design changes Low Low Low Low Hull coatings and skin- drag reductions Skin friction reductions and hull coatings to save fuel costs and reduce GHG emissions Medium Low Low Low Renewable technology integration Hybridisation and intelligent power management, integration with renewable energy to increase fuel efficiency and test-pilot renewable systems Low Low Low High Initially rolled out to reduce energy costs Includes policy measures, e.g. IMO’s Energy Efficiency Design Index (EEDI/EEXI) and Carbon Intensity rating (CII). Offer short-to-medium term transition pathway Suffers from technological depreciation, market fluctuations and lender’s risk

- 35. Mapping GHG Solutions: zero-carbon energy and fuel technology options Option/ Solution Function / Objective Impact on GHG reduction Technology & Operational Risk Availability & Scalability Risk Investment and Financing Risk LNG Mature, available and scalable technology for use as a step towards the energy transition Medium Low Low Medium Methanol Low cost and proven use. Can be employed in a dual-fuel engine and make use of existing bunkering facilities Ver y High Medium Medium Medium Biofuels Blending potential with fossil fuels. Lacks global infrastructure and bunkering facilities but can be distributed through existing HFO/MGO systems. Medium Medium Medium Medium Ammonia Large-scale potential for use in ocean shipping; has challenges with supply and mass transport of ammonia.Those can be resolved by developing liquefied ammonia gas carriers. Ver y High High Medium High Hydrogen Large potential with adaptations to marine engines at an early development stage. Liquification needed to achieve a comparable energy density to ammonia and fuel. CCS & land- side investment would also be required. Very High High Medium High Wind & Solar renewables Contribute to auxiliary power requirements, but current technology does not offer sufficient energy density Medium High Offer direct route to low or zero carbon shipping Differences in readiness, cost and scalability Inter-operability risk with supply and port infrastructure Provide ready to deploy options for some markets

- 36. GHG emissions: Market based measures Measure types Examples • Environmentally differentiated rates/dues • Cap and trade (emissions cap and allowance) • Baseline and credit system • Subsidies • ESG financing • Industry-led voluntary schemes • Fairway dues in Sweden, Green Award Scheme, differentiated tonnage tax in Norway • Kyoto CDM and JI • EU ETS • California Air Investment Programme • Preferential contracting • Poseidon principles • Potential global fuel tax A carbon levy directly fixes a price for carbon dioxide (usually per ton as in an emissions trading system) and can be applied as a fuel levy on the carbon content of fossil fuels.As opposed to an emissions trading system, the emissions reduction outcome is not predetermined but the carbon price is (non-market-based price setting).

- 37. Port Initiatives to Reduce Ship’s Emissions

- 38. The formula for the ESI Score is: 2 x ESI NOX+ ESI SOX + ESI CO2 + OPS 3.1 • Some ports have committed themselves to reducing the port-related GHG within an initiative called the World Port Climate Initiative (WPCI)). • Ships receive incentives, via calculation and reduction of WPCI’s Environmental Ship Index (ESI). • The ESI identifies seagoing ships that perform better the IMO requirements. • ESI relies on various formulas to cater for NOx, Sox, CO2 and OPS elements. Green Port Initiatives – Environmental Ship Index (ESI) • ESI gives a bonus for use OPS and reporting / monitoring of energy efficiency. • The ESI Score ranges from 0 (for a ship meeting IMO regulations) and 100 (for a ship that emits no SOx and no NOx and reports or monitors its energy efficiency). • Currently the best performing ships score at around 40 points.

- 39. Green Port Initiatives – Clean Air Programme ◗ A comprehensive initiative used by some ports to address air emissions from shipping and port operations. ◗ Mainly advocated and implemented by a port authority with input from other stakeholders. ◗ Program normally includes: ◗ A set of specific emission reduction targets ◗ A roadmap to achieve those targets. ◗ T o ensure success, the management system style continuous improvement is applied during implementation ◗ Commitment by the management and staff of port authorities and regulatory agencies are essential for success. ◗ Monitoring and benchmarking will be part of the implementation process. ◗ This could be comparable to another management plans (e.g. SEEMP) but a different scope (port environment)

- 40. Green Port Initiatives – Norway Tax and Nox Fund ◗ This is a NOx tax applicable mainly to national industries including shipping. ◗ The NOx tax is collected from participating industries and is fed into a NOx fund. ◗ The NOx fund then provides finances to those organisations that want to implement NOx reduction measures including shipping industry. ◗ This scheme is only applicable to domestic shipping around Norway. ◗ It is an example of an effective local program that tries to create a financail scheme and business case for NOx reduction. ◗ On the basis of the scheme, a large number of ships have so far been equipped with NOx reduction technologies. ◗ This fund has also widely finaced major Norwegian initiatives such as the move to LNG as fuel for ships operating in Norwegian water.

- 41. Market based measures-Examples NOx reduction incentives in port of Gothenburg Differentiated Port Dues Differentiated Flag Dues Singapore-flagged ships registered on or after 1 July 2011, which go beyond the requirements of the IMO’s EEDI, will enjoy a 50% reduction on the Initial Registration Fees and a 20% Annual Tonnage Tax rebate. ….

- 42. OSP, AMP and Cold Ironing • On Shore Power (OSP/SP) is known in the industry by various terms: Cold ironing system, Alternative Maritime Power (AMP), Shore side electricity, and/or Shore power OSP is used when ship is stationary at berth to support non-propulsion functions (ventilation, heating, cooling, pumping, cargo handling, etc.), thus reducing or eliminating air emissions and noise. • Supply of power from onshore (port) to ship. • Allows ships to turn off their engines when in port. Small ships with power requirements of less than 50-100 kw, e.g., tugs and fishing vessels, can draw shore power from normal grid and frequency, as is widely used in most ports around the world. For large ships with higher power requirements, dedicated installations and systems are needed for Alternative Maritime Power (AMP) or cold-ironing: • Grid capacity upgrade and alternative onsite / local off-grids (wind turbines, solar panels, etc.); • New port substations, charging points and connectors, frequency convertors/transformers, • Power Management Systems (PMS) to electronically monitor/control shore power use and peaks in demand. • Onboard ship systems’ adaptations for varying voltage and frequency range, control panel, etc.

- 43. Source: http://www.cruisecritic.co.uk/ Onshore Power Supply (OPS) – Ship and Shore-side infrastructure On the land side, the high power cold ironing system consists of the following: • High voltage grid to the port • Frequency and voltage convertors/transformers • Control panels and connection boxes • Cable reel and connectors On the ship side the following will have to be installed: • The grid power solution and the frequency converters typically represent the costliest elements on the shore side. • Depending on the availability of grid power and the power requirements, the cost of installing shore power on the shore side will vary considerably. • Transformer • Power distribution system • Control panel • Frequency converter (optional for greater flexibility) • Connectors and cable reel (optional for greater flexibility)

- 44. Onshore Power Supply (OPS) – Typical system specs for the different power requirements Power Capacity Typical spec <100kW 230/400/440V – 50/60hz 100 – 500kW 400/440/690V – 50/60hz 500-1000kW 690V/6.6/11kV – 50/60hz >1MW 6.6/11kV – 50/60hz

- 45. Onshore Power Supply (OPS) – Typical system requirements for different ship types and sizes Vessel types <= 999 1000 – 4999 GT 5000 – 9999 GT 10000 – 24999 GT 25000 – 49999 GT 50000 – 99999 GT >= 100000 GT Oil tankers 230/400/440 V – 50/60hz 400/440/690V – 50/60hz 690V/6.6/11k VV – 50/60hz 690V/6.6/11kV V – 50/60hz 690V/6.6/11kV V – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz Chemical/product tankers 400/440/690 V – 50/60hz 400/440/690V – 50/60hz 690V/6.6/11k VV – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz Gas tankers 400/440/690 V – 50/60hz 400/440/690V – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz Bulk carriers 230/400/440 V – 50/60hz 400/440/690V – 50/60hz 400/440/690 V – 50/60hz 400/440/690V – 50/60hz 400/440/690V – 50/60hz 690V/6.6/11kVV – 50/60hz General cargo 230/400/440 V – 50/60hz 400/440/690V – 50/60hz 400/440/690 V – 50/60hz 400/440/690V – 50/60hz 690V/6.6/11kV V – 50/60hz Container s vessels 400/440/690V – 50/60hz 400/440/690 V – 50/60hz 690V/6.6/11kV V – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz Ro Ro vessels 230/400/440 V – 50/60hz 400/440/690V – 50/60hz 400/440/690 V – 50/60hz 690V/6.6/11kV V – 50/60hz 690V/6.6/11kV V – 50/60hz 6.6/11kV – 50/60hz Reefers 230/400/440 V – 50/60hz 400/440/690V – 50/60hz 400/440/690 V – 50/60hz 690V/6.6/11kV V – 50/60hz Passengers vessels 230/400/440 V – 50/60hz 400/440/690V – 50/60hz 400/440/690 V – 50/60hz 690V/6.6/11kV V – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz Offshore supply vessel 230/400/440 V – 50/60hz 400/440/690V – 50/60hz 6.6/11kV – 50/60hz Other offshore service vessels 230/400/440 V – 50/60hz 400/440/690V – 50/60hz 690V/6.6/11k VV – 50/60hz 690V/6.6/11kV V – 50/60hz 690V/6.6/11kV V – 50/60hz 690V/6.6/11kVV – 50/60hz 690V/6.6/11kV V – 50/60hz Other activities 230/400/440 V – 50/60hz 400/440/690V – 50/60hz 690V/6.6/11k VV – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz 6.6/11kV – 50/60hz

- 46. Onshore Power Supply (OPS) – Estimated cost for implementing shore power on board vessels vestment cost for vessel (USD) 1000 – 4999 GT 5000 – 9999 GT 10000 – 24999 GT 25000 – 49999 GT 50000 – 99999 GT >= 100000 GT Crude tankers $50 000 – $350 000 $100 000 – $400 000 $100 000 – $400 000 $100 000 – $400 000 $300 000 – $750 000 $300 000 – $750 000 Chemical / product tankers $50 000 – $350 000 $100 000 – $400 000 $300 000 – $750 000 $300 000 – $750 000 Gas tankers $50 000 – $350 000 $300 000 – $750 000 $300 000 – $750 000 $300 000 – $750 000 $300 000 – $750 000 $300 000 – $750 000 Bulk carriers $50 000 – $350 000 $50 000 – $350 000 0,5 – 3 Mill 0,5 – 3 Mill $100 000 – $400 000 General cargo $50 000 – $350 000 $50 000 – $350 000 0,5 – 3 Mill $100 000 – $400 000 Container vessels $50 000 – $350 000 $50 000 – $350 000 $100 000 – $400 000 $300 000 – $750 000 $300 000 – $750 000 $300 000 – $750 000 Ro Ro vessels $50 000 – $350 000 $50 000 – $350 000 $100 000 – $400 000 $100 000 – $400 000 $300 000 – $750 000 Reefer $50 000 – $350 000 $50 000 – $350 000 $100 000 – $400 000 Passenger ship $50 000 – $350 000 $50 000 – $350 000 $100 000 – $400 000 $300 000 – $750 000 $300 000 – $750 000 $300 000 – $750 000 Offshore supply ship $50 000 – $350 000 $100 000 – $400 000 Other offshore service ships $50 000 – $ 350 000 $100 000 – $400 000 $100 000 – $400 000 $100 000 – $400 000 $100 000 – $400 000 $100 000 – $400 000 Other activities $50 000 – $ 350 000 $100 000 – $400 000 $300 000 – $750 000 $300 000 – $750 000 $300 000 – $750 000 $300 000 – $750 000 Fishing vessels $50 000 – $ 350 000 $100 000 – $400 000

- 47. Onshore Power Supply (OPS) – Need for Standardisation • No IMO regulation yet. • There have been proposals to add some new regulations to MARPOL Annex VI; but mainly on the following topics: Exemptions: • For ships with low emissions or high ship-board energy efficient power generation as compared to OPS. • Period in port: Not required to connect to OPS when the berth stay is less than some hours. Availability of OPS: The port shall provide sufficient electrical power to sustain all operations including peak consumptions. Cost of OPS electricity: The electricity costs for the ship to connect to shore power at berth should not exceed the cost of supplied electricity. • ISO SO/IEC/IEEE 80005-1:2012: Utility connections in port — Part 1: High Voltage Shore Connection (HVSC) Systems- General requirements; (See https://www.iso.org/standard/53588.html)

- 48. Progress made so far… https://electrek.co/2022/06/08/meet-sparky-the-electric-tugboat-operating-in-the-ports-of- auckland-with-2784-kwh-of-power/ https://maritime-executive.com/article/video-world-s-first-hydrogen-carrier-departs-japan-on- maiden-voyage https://youtu.be/xv-cZt-FpGM https://youtu.be/JpFOf4jrlpI https://sea-lng.org/why-lng/ global-fleet/

- 49. Relevant Benchmarks and References CEM Global Ports Hydrogen Coalition (https://www.iea.org/programmes/cem-hydrogen-initiative) • https://pla.co.uk/Sea-Land-and-Port-Smart-Integration-of-a-Hydrogen-Highway • https://www.portofamsterdam.com/en/news/how-do-we-safely-bunker-alternative-fuels • https://cleanairactionplan.org/ • ISO SO/IEC/IEEE 80005-1:2012: Utility connections in port — Part 1: High Voltage Shore Connection (HVSC) Systems- General requirements; (https://www.iso.org/standard/53588.html )

- 50. Initiatives to Reduce Port Emissions

- 51. Port Emissions and Energy Use • Greening port equipment: • E-RTG, E-STS, E-SL, E-Trains, E-trucks, etc. • E-mooring, E-reefer plug-ins, E-warehouse systems, etc. • Hybrid models re also widely used • Energy efficiency • Port efficiency • Good practices • Lighting • Green Training • Production of Green Energy (wave, offshore wind, etc.) • Considerations of charging points and voltage lines • Considerations for energy source, use, grid capacity • Considerations of energy costs and conversion costs

- 52. Electrification of Handling Equipment: Some early adopters in Asia

- 53. Electrification of Handling Equipment: Some early adopters in Asia

- 54. Port Environmental Management Marine, water and soil Pollution

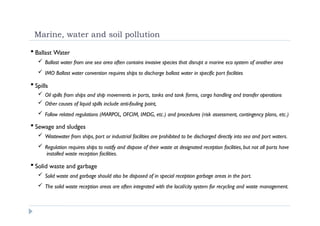

- 55. Marine, water and soil pollution Ballast Water Ballast water from one sea area often contains invasive species that disrupt a marine eco system of another area IMO Ballast water convention requires ships to discharge ballast water in specific port facilities Spills Oil spills from ships and ship movements in ports, tanks and tank farms, cargo handling and transfer operations Other causes of liquid spills include anti-fouling paint, Follow related regulations (MARPOL, OFCIM, IMDG, etc.) and procedures (risk assessment, contingency plans, etc.) Sewage and sludges Wastewater from ships, port or industrial facilities are prohibited to be discharged directly into sea and port waters. Regulation requires ships to notify and dispose of their waste at designated reception facilities, but not all ports have installed waste reception facilities. Solid waste and garbage Solid waste and garbage should also be disposed of in special reception garbage areas in the port. The solid waste reception areas are often integrated with the local/city system for recycling and waste management.

- 56. Other pollution and risks in ports Dredging and channel works Harbour and quay construction Modification of currents Alters natural environment Habitat loss or degradation Accidents, collusion and grounding Land and sea contamination Industrial effluent Hazardous cargo Port and area maintenance

- 57. Port noise and visual intrusion Port noise stems from various sources: ships, machinery, vehicles, etc. and at various stages of port development and operations. Many ports limit noise-producing activities by working zone or time of operation. Port visual intrusion takes place where seascape, landscape and visual characteristics of the port are negatively impacted, especially for port localities depending on tourism or those surrounded by protected/ preserved areas. Often, a Landscape and Visual Impact Appraisal (LVIA) is undertaken prior to port facility development, expansion or upgrade.

- 59. Assessment of Environmental Sustainability • T o assess environmental sustainability in ports, relevant port data and information should be regularly collected, assessed, and monitored against established standards. • Environmental sustainability indicators should cover at least, but are not necessarily limited to the following areas: GHG emissions Air pollutants Energy use and energy efficiency Solid waste Liquid waste (incl. oil pollution, ballast water and wastewater) Noise pollution Light pollution Biodiversity • Ports should be assessed on both their physical infrastructure and operational practices to have a comprehensive overview of their environmental sustainability. Environmental assessment frameworks can also use both quantitative and qualitative ranking systems for internal evaluation and external benchmarking.

- 60. Guides and Steps • To-date, there is no common international standard or regulation for assessing or certifying port emissions.There are several international guidelines, (e.g. IAPH and WSP) while some ports have developed their own standards and guidelines. • In general, port emissions assessment consists of two to three stages: • Emissions inventories; cataloguing various port emissions sources and their activities, translate these into energy consumption levels and then translate energy consumption into emissions. • Emission metrics and indicators; establishing baselines, targets and benchmarks for emissions monitoring, control and reduction. • Emissions forecasts; estimates of future emissions projections based on ship and vehicle traffic and cargo throughput forecasts and changes in design, equipment and operations. Forecasts help in port planning and decision making.

- 61. Scopes of Emissions Assessment and Reporting Greenhouse Gas Protocol (GHP) is an internationally accepted set of (accounting) standards which sets global standards for how to measure, manage and report GHG. Under GHP guidelines, the terminal operator calculate their emissions taking into consideration all their scope 1and 2 Emissions. Scope emissions describe the categorisation of GHG emissions into groups to facilitate universal international accounting and reporting.There are 3 main distinct scopes: • Scope 1 emissions or direct emissions are GHG emissions from the sources that are owned or controlled by the reporting entity. For ports, this refers primarily to emissions from port infrastructures and operations. • Scope 2 or indirect emissions are GHG emissions specifically from the generation of purchased or acquired electricity, steam, heat, or cooling consumed by the reporting entity. • Scope 3 emissions refers to all indirect GHG emissions from all sources whether upstream or downstream of a value chain and which are not owned or controlled by the reporting entity directly.

- 62. Carbon offsetting, Insetting and Neutrality Offsetting describes the climate action that enables individuals and organisations to compensate for their emissions, by supporting worthy projects that reduce emissions somewhere else. More specifically, it is a term used to describe the act of reducing GHG emissions or increasing GHG removals through activities external to an activity or outside of the supply chain, to reduce the net contribution to global emissions. Offsetting is typically arranged through a marketplace for carbon credits or other exchange mechanism. Offsetting claims are only valid under a rigorous set of conditions, including ensuring that the reductions/removals involved are additional, not over-estimated, and exclusively claimed. Insetting is similar of offsetting but whilst the principles are the same it differs as it applies to a company offsetting its emissions through a project within its own value chain Carbon neutrality is where carbon emission generated, throughout the life cycle of the product/activity, are removed during the same cycle as a result of carbon reduction measures such as environmental actions, carbon capture, operational efficiencies, use of green fuels and renewables, as well as carbon offsetting and insetting.

- 63. Planning for emission assessment A general framework for planning emission assessment follows 10 generic steps: 1. Catalogue and group drivers 2. Define intended uses 3. Select air pollutants 4. Select emissions sources 5. Select geographical and operational domains 6. Identify outside emissions sources near port 7. Select inventory period and frequency 8. Identify documentation and reporting requirements 9. Select level of detail 10. Select assessment platform

- 64. Cataloguing group drivers ERS – Emissions reduction strategy CSR – Corporate social responsibility Examples of priority grouping of drivers for a port emissions assessment (WPCT)

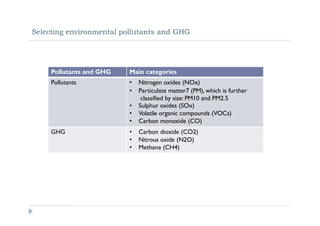

- 65. Selecting environmental pollutants and GHG Pollutants and GHG Main categories Pollutants • Nitrogen oxides (NOx) • Particulate matter7 (PM), which is further classified by size: PM10 and PM2.5 • Sulphur oxides (SOx) • Volatile organic compounds (VOCs) • Carbon monoxide (CO) GHG • Carbon dioxide (CO2) • Nitrous oxide (N2O) • Methane (CH4)

- 66. Scoping / selecting emission sources Emission source category Coverage Mobile Cargo handling equipment Trucks and vehicles Railroad vehicles and locomotives Port owned vessels Seagoing and domestic vessels Construction equipment Stationary Electrical grids Power Plant Power generators Industrial facilities Buildings and offices Other stationary facilities: wastewater plants, reception facilities, ops. sites, .. Purchased Electricity Lighting, instrumentation, comfort cooling, computers, ventilation, etc. Employee Commuting Emissions from the transportation of employees between their homes and worksites. Scope 1: Mobile + Stationary + Employee Commuting (Authority) Scope 2: Purchased Electricity (Authority) Scope 3 : Mobile + Stationary + Purchased Electricity + Employee Commuting (Tenants)

- 67. Select Operational boundaries and identify emissions near ports In tandem with emissions properly, the port should select the geographical and operational boundaries to be included in (excluded from) emissions inventory and assessment. The Port of Rotterdam has limited its geographical domain to include its administrative boundary and its operational domain to its owned and operated emissions sources. The Hamburg Port Authority has limited its emissions inventory to the local port administrative boundary.This boundary was set in conjunction with the Hamburg environmental agency’s emissions inventory geographical domain. Port of Vancouver Port Emission Inventory includes cargo-related and administrative emissions sources and includes an overwater and overland boundary related to the air quality modelling domain for Metro Vancouver (greater than the port’s administrative boundary). PLOA/PLOB geographical domain includes all cargo operational boundaries, extends inland to cover a city-port area of 10 million inhabitants and waterside to 130 nm out to sea.

- 68. Select assessment platforms Internal: Spreadsheets, desktop database, server-based database, etc. External: Off the shelf tool calculators (commercial, governments, NGOs, etc.) Purpose built: Purpose built software by external consultants or internally.

- 69. Emissions estimating methods Ships: • General data: tanker, containership, bulker, tugs, dredgers, river boats, etc. • Technical data: age, speed, engine, load factor, etc. • Operation data: manoeuvring, transit, stationary/berthing • Geographical domain data: by anchorage/terminal/port site • Fuel type: HFO, LFO,VLFO, LNG, etc. Equipment and Vehicles • Type: crane, truck, vehicle, etc. • Technical data: model, age, engine, certification, etc. • Energy data: fuel type, rated power, etc. • Activity data: hours of ops., load factor, energy consumption, etc. • Geographical domain data: yard, terminal, port, hinterland, etc.

- 70. Emissions estimating methods: Some equations for ships Ei = Energyi x EF x FCF x CF Where: Ei = Energyi = EF = FCF = CF = emissions by operating mode i energy demand by mode i, calculated using Equation 2 below as the energy output of the engine(s) or boiler(s) over the period of time, kWh emission factor, expressed in terms of g/kWh, depends on engine type, IMO NOx standards and fuel used fuel correction factor, unitless control factor(s) for emissions reduction technologies, unitless Ei = Loadi x Activityi Where: Energyi = Loadi = energy demand by mode i, kWh maximum continuous rated (MCR) power times load factor (LF) for propulsion engine power, kW; reported operational load of the auxiliary engine(s), by mode i, kW; or operational load of the auxiliary boiler, by mode i, kW Activityi = activity for mode i, hours Activityi = Di / Speedi Where: Activityi = activity, hours Di = distance travelled while in mode i, nautical miles Speedi = actual ship speed by mode i, knots Emissions Energy Activity

- 71. Emissions estimating methods: Some equations for equipment Emissions Energy E = Fuel Consumption x EF x FCF x CF Where: E = Fuel Consumption = EF = FCF = CF = emissions, grams/year fuel consumed, litres emission factor, grams of pollutant per gallon of fuel consumed, g/litre fuel correction factors are used to adjust from a base fuel associated with the EF and the fuel being used, dimensionless control factor to reflect changes in emissions due to installation of emissions reduction technologies not originally reflected in the emission factors, dimensionless E = Energy x EF x FCF x CF Where: E = Energy = EF = FCF = CF = emissions, grams/year energy demand per engine, kWh, calculated using Equation 10 emission factor, grams of pollutant per unit of work, g/kWh or g/hp-hr, depends on engine type, emissions standards applicable in the region of operation and fuel type fuel correction factors are used to adjust from a base fuel associated with the EF and the fuel being used, dimensionless control factor to reflect changes in emissions due to installation of emissions reduction technologies not originally reflected in the emission factors, dimensionless

- 72. Developing metrics Asset based Activity base Emission base Baseline Forecast Emissions-based emissions/time period total PM tonnes/year total NOx tonnes/year total CO2e tonnes/year seagoing vessel PM tonnes/year cargo handling equipment NOx tonnes/year heavy duty vehicle CO2e tonnes/year bulk ship PM tonnes/year cargo handling equipment NOx tonnes/year rubber-tyred gantry PM tonnes/year assist tug NOx tonnes/year grid-based CO2e tonnes/year emissions/cargo throughput total PM tonnes/tonne container-related NOx tonnes/10,000 teus bulk liquid-related CO2e tonnes/barrel containership PM tonnes/10,000 teus cargo handling equipment NOx tonnes/tonne heavy duty vehicle CO2e tonnes/10,000 teus cruise ship PM tonnes/passenger crane NOx tonnes/10,000 teus grid-based CO2e tonnes/tonne locomotive NOx tonnes/10,000 teus general cargo ship CO2e tonnes/tonne of steel

- 73. Emission reduction plans A general framework for an emissions reduction plan follows 10 generic steps: 1. Select target pollutants for reduction 2. Selection reduction targets 3. Evaluate emission inventory data 4. Review emission programmes of other ports 5. Benchmark in time series 6. Benchmark in cross-sectional 7. Review and monitor 8. Identify corrective actions 9. Develop implementation plan 10. Formalise implementation plan

- 75. Green Port Road Map

- 76. GPH and Environmental Reporting • GHG emissions are usually measured by using CO2-conversion factors recommended by GHP. UK DEFRA are widely used in the UK and elsewhere, covering all types of fuels. • The adoption of common CO2-conversion factors are important to ensure common standards. • Other common denominators include the ‘number of boxes entering and leaving the terminal”. So total GHG emissions are divided by the number of boxes / containers handled to lead to a KgCO2e/box.The same approach is used for other cargo (e.g., KgCO2e/ton)

- 77. GPH and Environmental Reporting

- 78. Green Port Benchmarks- Dredging Management Plan Examples of analogous plan: •In 2003 the Port of London Authority (PLA) published the Maintenance Dredging Framework for the Thames to guide decisions on maintenance dredging and ensure sustainability.This Framework provides for the coordinated assessment and management of dredging operations on the tidal Thames and includes the consideration of any likely impacts on designated conservation sites. •Wheatstone Project - Dredging and Dredge Spoil Placement Environmental Monitoring and Management Plan. This is a state of the art plan, made for a project in an area with very sensitive habitats (e.g. corral). It may be too complex for the PoB situation, but it is always easier to simplify a good plan than to start from scratch. Recommendation on the structure of the plan should be based on the following guidance documents: • OSPAR Guidelines for the Management of Dredged Material at Sea (Agreement 2014-06); •Technical Annex included in both the OSPAR and HELCOM guidelines to minimize the effects on the environment of dredging operations as far as practicable; •PIANC, IADC and CEDA dredging guidance documents for monitoring and management of dredging activities. • Environmental, Health and Safety Guidelines for Ports, Harbours and Terminals (IFC, 2017); and • General EHS Guidelines - Waste management guidance for non-hazardous and hazardous waste (IFC, 2017).

- 79. Green Port Benchmarks- Cold Ironing in European Ports In the Port of Rotterdam for example there is a prohibition for inland vessels to use their power generators and all inland ships must use shore power instead of generator power. 16 Megawatt power supply in Kristiansand for cruise ships 10 Megawatt shore installation entered service at the German port of Cuxhaven, in the North Sea, west of Hamburg, in May 2018 Other installations are also under consideration or under way in ports in Northern Europe including the ports of Antwerp,Amsterdam, Bremen, Gothenburg, the Hamburg Port Authority, Port of Le Havre, Stadtwerke Lubeck,̈ port of Kiel, and the port of Copenhagen/Malmö.

- 80. Green Port Benchmarks- Air Emissions in European Ports Emission inventory: • Port of London Emission Inventory 2016. • Port of Long Beach Air Emission inventory 2017-Present Incentive schemes on reduction of carbon emissions •Port of Rotterdam ambition: energy transition leader.The Port of Rotterdam Authority stimulates the use of clean shipping fuels by offering incentives to inland shipping (e.g. the Environmental Ship Index and the discount on port dues for inland shipping) and by lobbying to reduce the sulphur content in shipping fuels, for example (IMO 2020), as well as by contributing to research on climate-friendly production technology.The study commissioned in 2018 by the Port of Rotterdam, Deep decarbonisation pathways for transport and logistics identified the following pathways: energy efficiency, modal shift and fuel shift. • Hamburg Port Authority: LNG, shoreside power and more. •Port of London Authority introduced in January 2017 the UK’s first Green Tariff, incentivising operators to use cleaner vessels. It exceeds the standards set by the International Maritime Organisation. • In 2011, the Hamburg Port Authority (HPA) has introduced a discount on port dues for environmentally friendly ships, the so-called Green Port Fee (based Environmental Ship Index). • Cleaner Air Strategy 2018-2025 Port of Southampton. Hydrogen fuel cells: • Ports of Auckland to build Auckland’s first hydrogen production and refuelling facility •Valencia Launches Hydrogen Pilot Scheme •Toyota has unveiled the second iteration of its hydrogen fuel cell electric Class 8 truck which will help clean up emissions at the Ports of Long Beach and Los Angeles.

- 82. Relevant ISO Standards ISO 14001: Environmental management systems ISO 14064: Quantifying and reporting GHG ISO 14090:Adaptation to Climate Change ISO 14083: GHG from transport chain operations ISO 16304: Marine environment protection ISO 50001: Energy management systems

- 83. ESPO EcoPorts PERS The Port Environmental Review System (PERS) does not only incorporate the main general requirements of recognised environmental management standards (e.g. ISO 14001), but also takes into account the specificities of ports. PERS builds upon the policy recommendations of ESPO and gives ports clear objectives to aim for.Its implementation is independently reviewed by LRQA Nederland B.V.A PERS certification is valid for a period of 2 years. Self Diagnosis Method (SDM) is user-friendly environmental checklist comprised of three parts: - SDM checklist: Filling in the SDM checklist is your 'passport' to the EcoPorts network. - SDM Comparison: Compare your SDM score with the European average - SDM Review: Review your SDM score and receive expert's advice and customised recommendations. SDM is a checklist that allows you to identify and reflect on environmental risks in your port. Aggregated and anonymised data provided by EcoPorts members are used to build and update the sector’s benchmark of performance in environmental management. A completed SDM is valid for a period of 2 years.

- 84. IAPH World Ports Sustainability Awards The objective of E(S)IA is to identify the most environmental parameters spanning pollutants, emissions, waste and noise during both construction and operation phases; emphasize their negative impacts and externalities, and propose recommendations, measures and action plans for mitigation ESIA has three dimensions depending on the Project Category: Scoping exercise; Preliminary assessment, or Detailed assessment ESIA preparation shall be caried out in accordance with national regulations and procedural guidelines as well as those of IFIs and MDBs. ESIA often includes a public consultation component. Any EIA starts with the collection of baseline project data and environmental parameters including the physical environment (geology, geography, hydrology), climate, air quality, noise, soil and ground water pollution, biodiversity, and protected areas where applicable.

- 85. Port Environmental Management Environmental (and Social) Impact Assessment E(S)IA

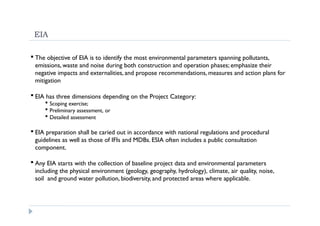

- 86. EIA The objective of EIA is to identify the most environmental parameters spanning pollutants, emissions, waste and noise during both construction and operation phases; emphasize their negative impacts and externalities, and propose recommendations, measures and action plans for mitigation EIA has three dimensions depending on the Project Category: Scoping exercise; Preliminary assessment, or Detailed assessment EIA preparation shall be caried out in accordance with national regulations and procedural guidelines as well as those of IFIs and MDBs. ESIA often includes a public consultation component. Any EIA starts with the collection of baseline project data and environmental parameters including the physical environment (geology, geography, hydrology), climate, air quality, noise, soil and ground water pollution, biodiversity, and protected areas where applicable.

- 87. Some environmental elements of a port project Ecological Characteristics Natural habitats Flora Fauna Natural drainage Surface features General environmental quality Air Quality (including GHG emission) Noise Level Ground Water Quality Soil and surface deposits Public and Private Services Transportation services Drinking water supply Sewage services Energy services Education Health care facilities Housing Emergency services Traffic flow Parking Public security Shopping Socioeconomic Elements Local economy Accessibility to public services Community development potential Land use pattern Aesthetic and Cultural Aspects Attractiveness and view opportunities Archaeological, landmarks and historical sites

- 88. Environmental impacts during a port or terminal life-cycle Planning and site selection Construction Operation • Land acquisition • Acquisition of the land and areas necessary for the “right of way” • Site surveys and investigations • Increased truck traffic (construction material and waste) • Vehicle/construction equipment parking/storage outside the site • Base camp establishment and operation • Workers’ accommodation • Construction activities at areas accessible to the public. • Workers' activities and construction site management • Levelling, land clearing and earthworks/railway embankment • Paving/asphalting • General construction • Noise generation • Air pollution emissions • Hazardous emissions • Water consumption • Increased truck traffic • Railway traffic • Vehicular emissions • On-site train sidings (rail yard) • Truck loading area • Container Storage areas (yard) (including refrigerated containers) • Engineering workshops • Customs and Health inspection sites • Administrative offices • Solid waste management • Infrastructure buildings • Main incoming power sub-station • Power distribution sub-stations • Generator house • Pumps house • Fire pumps house • Fuel storage and fuel filling stations