Unit 5 Economic Load Dispatch and Unit Commitment

- 1. DEPARTMENT OF ELECTRICAL ENGINEERING JSPMS BHIVARABAISAWANTINSTITUTEOFTECHNOLOGYANDRESEARCH, WAGHOLI,PUNE A.Y. 2020-21 (SEM-I) Class: B.E. Subject: Power System Operation Control Unit No-5 Economic Load Dispatch & Unit Commitment Prepared by Prof. S. D. Gadekar Santoshgadekar.919@gmail.com Mob. No-9130827661

- 2. Content • Introduction • Input-Output characteristics of thermal power plant & hydro power plant • Incremental Fuel Cost characteristics of thermal power plant & hydro power plant • Plant scheduling methods • Equal Incremental Cost Method-Transmission losses neglected (Method of Lagrange Multiplier) • Numerical based on Lagrange multiplier • Transmission loss formula-Bmn Coefficients • Economic scheduling of thermal plants considering effect of transmission losses and Numerical • Unit Commitment • Constraints in Unit Commitment- • Methods of Unit Commitment-Priority List Method, Dynamic Programming, Numerical

- 3. G1=200 MW G2=100 MW G3=100 MW Total Power Demand=200 MW Which units are you considering to satisfy power demand of 200 MW? What will be the sequence of taking the generating units in to operation?

- 4. Introduction What is mean by Economic Load Dispatch? It determines the power output of each power plant and power output of each generating stations within a power plant , Which will minimize the overall cost of fuel needed to serve the system load.

- 5. Input-Output characteristics of thermal power plant Fuel Input K-Cal/hr Power Output (P) MW Minimum Maximum

- 6. Incremental Fuel Cost characteristics of thermal power plant Incremental Fuel Cost Rs/MW-Hr Power Output (P) MW Minimum Maximum

- 7. Input-Output characteristics of hydro power plant Power Output (P) MW Minimum Maximum Water Discharge 𝑚3 /𝑠𝑒𝑐

- 8. Incremental Fuel Cost characteristics of hydro power plant Water Discharge 𝑚3 /𝑠𝑒𝑐 Power Output (P) MW H1 Incremental Cost Curve H1>H2>H3 H-Water Head H2 H3

- 9. Plant Scheduling Method • Base loading to capacity • Base loading to most efficient load • Proportional loading to capacity

- 10. Equal Incremental Cost Method-Transmission losses neglected (Method of Lagrange Multiplier) For a given load to be allocated between several generating units, the most efficient unit is identified by incremental cost of production should be the one get priority. When this is applied repeatedly to all the units the load allocation will become complete when all of them, that are involved in operation, are all working at the same incremental cost of production. Consider 𝒏𝒈 generating units supplying 𝑃1, 𝑃2…….. 𝑃𝑛𝑔 active powers to supply a total load demand 𝑃 𝐷.

- 11. Continue….. 𝑇ℎ𝑒 𝑜𝑏𝑗𝑒𝑐𝑡𝑖𝑣𝑒 𝑓𝑢𝑛𝑐𝑡𝑖𝑜𝑛 𝑓𝑜𝑟 𝑐𝑜𝑠𝑡 𝑚𝑖𝑛𝑖𝑚𝑖𝑧𝑎𝑡𝑖𝑜𝑛 𝑖𝑠 𝑔𝑖𝑣𝑒𝑛 𝑎𝑠, 𝐹 𝑃𝑖 = 𝑖=1 𝑛𝑔 𝐶𝑖 𝑃𝑖 … … … … … .1 𝑤ℎ𝑒𝑟𝑒 𝑖 = 1,2, … … 𝑛𝑔 𝑇ℎ𝑒 𝑒𝑞𝑢𝑎𝑙𝑖𝑡𝑦 𝑐𝑜𝑛𝑠𝑡𝑟𝑎𝑖𝑛𝑡 𝑖𝑠 𝑔𝑖𝑣𝑒𝑛 𝑏𝑦 𝐺 𝑃𝑖 = 𝑃 𝐷 − 𝑖=1 𝑛𝑔 𝑃𝑖 … … … … … 2 (𝑻𝒐𝒕𝒂𝒍 𝑺𝒖𝒑𝒑𝒍𝒚 = 𝒕𝒐𝒕𝒂𝒍 𝒅𝒆𝒎𝒂𝒏𝒅) 𝑻𝒉𝒆 𝑳𝒂𝒈𝒓𝒂𝒏𝒈𝒆 𝑭𝒖𝒏𝒄𝒕𝒊𝒐𝒏 𝒊𝒔 𝒈𝒊𝒗𝒆𝒏 𝒂𝒔, 𝑳 𝑷, 𝞴 = 𝑭 𝑷 + 𝞴𝑮 𝑷 … … … … … . 𝟑 𝑊ℎ𝑒𝑟𝑒 𝞴 𝑖𝑠 𝑙𝑎𝑔𝑟𝑎𝑛𝑔𝑒 𝑚𝑢𝑙𝑡𝑖𝑝𝑙𝑖𝑒𝑟.

- 12. Continue….. Substitute equation 1, 2 in to 3, 𝑳 𝑷, 𝞴 = 𝑖=1 𝑛𝑔 𝐶𝑖 𝑃𝑖 + 𝞴 𝑃 𝐷 − 𝑖=1 𝑛𝑔 𝑃𝑖 … … … . . 4 𝑇ℎ𝑒 𝑛𝑒𝑐𝑒𝑠𝑠𝑎𝑟𝑦 𝑐𝑜𝑛𝑑𝑖𝑡𝑖𝑜𝑛𝑠 𝑎𝑟𝑒 𝑔𝑖𝑣𝑒𝑛 𝑎𝑠, 𝜕L 𝜕Pi = 0 & 𝜕𝐿 𝜕𝝺 = 0 Now apply above conditions on equation 4 , 𝜕L 𝜕Pi = 𝜕𝐶𝑖 𝑃𝑖 𝜕Pi + 𝞴 −1 = 0 𝑤ℎ𝑒𝑟𝑒 𝑖 = 1,2, … … 𝑛𝑔

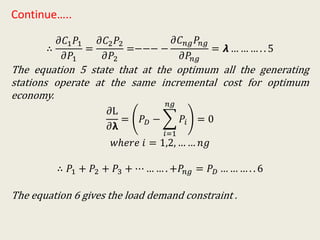

- 13. Continue….. ∴ 𝜕𝐶1 𝑃1 𝜕𝑃1 = 𝜕𝐶2 𝑃2 𝜕𝑃2 =−−− − 𝜕𝐶 𝑛𝑔 𝑃𝑛𝑔 𝜕𝑃𝑛𝑔 = 𝞴 … … … . . 5 The equation 5 state that at the optimum all the generating stations operate at the same incremental cost for optimum economy. 𝜕L 𝜕𝝺 = 𝑃 𝐷 − 𝑖=1 𝑛𝑔 𝑃𝑖 = 0 𝑤ℎ𝑒𝑟𝑒 𝑖 = 1,2, … … 𝑛𝑔 ∴ 𝑃1 + 𝑃2 + 𝑃3 + ⋯ … … . +𝑃𝑛𝑔 = 𝑃 𝐷 … … … . . 6 The equation 6 gives the load demand constraint .

- 14. Numerical No-1 Consider the power system with two stations. The incremental productions cost characteristics for the two stations are, 𝜕𝐹1 𝜕𝑃1 = 27.5 + 0.15𝑃1 𝑅𝑠/𝑀𝑤𝐻𝑟 𝜕𝐹2 𝜕𝑃2 = 19.5 + 0.26𝑃2 𝑅𝑠/𝑀𝑤𝐻𝑟 Given the minimum and maximum powers are to 10 MW and 100 MW at each plant. Schedule the generation at each plant to supply system load given by the load curve as below. Midnight Midnight 12 6 12 3 6 10 12 50 100 150 200

- 15. 𝑪𝒂𝒔𝒆 𝟏 − 𝑃 𝐷 = 𝑃1 + 𝑃2 𝑷 𝟏 + 𝑷 𝟐 = 𝟓𝟎 𝑴𝑾 𝑻𝒊𝒎𝒆 − 𝟏𝟐 𝒕𝒐 𝟔 & 𝟏𝟎 𝒕𝒐 𝟏𝟐 … … . 𝟏 𝜕𝐹1 𝜕𝑃1 = 𝜕𝐹2 𝜕𝑃2 = 𝞴𝑅𝑠/𝑀𝑊𝐻𝑟 27.5 + 0.15𝑃1 = 19.5 + 0.26𝑃2 0.15𝑃1 − 0.26𝑃2 = −8 … … . . 2 S𝑜𝑙𝑣𝑒 𝑒𝑞𝑢𝑎𝑡𝑖𝑜𝑛 1 𝑎𝑛𝑑 2 𝑷 𝟏 = 𝟏𝟐. 𝟐 𝑴𝑾 & 𝑷 𝟐 = 𝟑𝟕. 𝟖 𝐌𝐖 𝞴 = 29.33 𝑅𝑠/𝑀𝑊𝐻𝑟 𝑪𝒂𝒔𝒆 𝟐 − 𝑃 𝐷 = 𝑃1 + 𝑃2 𝑷 𝟏 + 𝑷 𝟐 = 𝟏𝟎𝟎 𝑴𝑾 𝑻𝒊𝒎𝒆 − 𝟔 𝒕𝒐 𝟏𝟐 … … . 𝟑 𝜕𝐹1 𝜕𝑃1 = 𝜕𝐹2 𝜕𝑃2 = 𝞴𝑅𝑠/𝑀𝑊𝐻𝑟 27.5 + 0.15𝑃1 = 19.5 + 0.26𝑃2 0.15𝑃1 − 0.26𝑃2 = −8 … … . . 4 S𝑜𝑙𝑣𝑒 𝑒𝑞𝑢𝑎𝑡𝑖𝑜𝑛 3 𝑎𝑛𝑑 4 𝑷 𝟏 = 𝟒𝟑. 𝟗𝟎 𝑴𝑾 & 𝑷 𝟐 = 𝟓𝟔. 𝟏 𝐌𝐖 𝞴 = 34.08 𝑅𝑠/𝑀𝑊𝐻𝑟

- 16. 𝑪𝒂𝒔𝒆 𝟑 − 𝑃 𝐷 = 𝑃1 + 𝑃2 𝑷 𝟏 + 𝑷 𝟐 = 𝟏𝟐𝟓 𝑴𝑾 𝑻𝒊𝒎𝒆 − 𝟏𝟐 𝒕𝒐 𝟑 … … . 𝟓 𝜕𝐹1 𝜕𝑃1 = 𝜕𝐹2 𝜕𝑃2 = 𝞴𝑅𝑠/𝑀𝑊𝐻𝑟 27.5 + 0.15𝑃1 = 19.5 + 0.26𝑃2 0.15𝑃1 − 0.26𝑃2 = −8 … … . . 6 S𝑜𝑙𝑣𝑒 𝑒𝑞𝑢𝑎𝑡𝑖𝑜𝑛 5 𝑎𝑛𝑑 6 𝑷 𝟏 = 𝟓𝟗. 𝟕𝟔 𝑴𝑾 & 𝑷 𝟐 = 𝟔𝟓. 𝟐𝟒 𝐌𝐖 𝞴 = 36.55 𝑅𝑠/𝑀𝑊𝐻𝑟 𝑪𝒂𝒔𝒆 𝟒 − 𝑃 𝐷 = 𝑃1 + 𝑃2 𝑷 𝟏 + 𝑷 𝟐 = 𝟏𝟓𝟎 𝑴𝑾 𝑻𝒊𝒎𝒆 − 𝟔 𝒕𝒐 𝟏𝟎 … … . 𝟕 𝜕𝐹1 𝜕𝑃1 = 𝜕𝐹2 𝜕𝑃2 = 𝞴𝑅𝑠/𝑀𝑊𝐻𝑟 27.5 + 0.15𝑃1 = 19.5 + 0.26𝑃2 0.15𝑃1 − 0.26𝑃2 = −8 … … . . 8 S𝑜𝑙𝑣𝑒 𝑒𝑞𝑢𝑎𝑡𝑖𝑜𝑛 7 𝑎𝑛𝑑 8 𝑷 𝟏 = 𝟕𝟓. 𝟔𝟏 𝑴𝑾 & 𝑷 𝟐 = 𝟕𝟒. 𝟑𝟗 𝐌𝐖 𝞴 = 38.84 𝑅𝑠/𝑀𝑊𝐻𝑟

- 17. 𝑪𝒂𝒔𝒆 𝟓 − 𝑃 𝐷 = 𝑃1 + 𝑃2 𝑷 𝟏 + 𝑷 𝟐 = 𝟐𝟎𝟎 𝑴𝑾 𝑻𝒊𝒎𝒆 − 𝟑 𝒕𝒐 𝟔 … … . 𝟗 𝜕𝐹1 𝜕𝑃1 = 𝜕𝐹2 𝜕𝑃2 = 𝞴𝑅𝑠/𝑀𝑊𝐻𝑟 27.5 + 0.15𝑃1 = 19.5 + 0.26𝑃2 0.15𝑃1 − 0.26𝑃2 = −8 … … . . 10 S𝑜𝑙𝑣𝑒 𝑒𝑞𝑢𝑎𝑡𝑖𝑜𝑛 9 𝑎𝑛𝑑 10 𝑷 𝟏 = 𝟏𝟎𝟕. 𝟑𝟐 𝑴𝑾 & 𝑷 𝟐 = 𝟗𝟐. 𝟔𝟖 𝐌𝐖 𝞴 = 43.59 𝑅𝑠/𝑀𝑊𝐻𝑟 𝐼𝑓 𝑚𝑎𝑥𝑖𝑚𝑢𝑚 𝑔𝑒𝑛𝑒𝑟𝑎𝑡𝑖𝑜𝑛 𝑙𝑖𝑚𝑖𝑡 𝑜𝑓 100 𝑀𝑊 𝑖𝑠 𝑖𝑚𝑝𝑜𝑠𝑒𝑑 𝑡ℎ𝑒𝑛 𝑷 𝟏 = 𝟏𝟎𝟎 𝑴𝑾 & 𝑷 𝟐 = 𝟏𝟎𝟎 𝐌𝐖

- 18. Numerical No-2 Consider the power system with two stations. The incremental productions cost characteristics for the two stations are, 𝜕𝐹1 𝜕𝑃1 = 220 + 1.32𝑃1 𝑅𝑠/𝑀𝑤𝐻𝑟 𝜕𝐹2 𝜕𝑃2 = 132 + 1.76𝑃2 𝑅𝑠/𝑀𝑤𝐻𝑟 Given the minimum and maximum powers are to 10 MW and 100 MW at each plant. Schedule the generation at each plant to supply system load given by the load curve as below. Midnight Midnight 12 6 12 3 6 10 12 50 100 150 200

- 19. 𝑪𝒂𝒔𝒆 𝟏 − 𝑃 𝐷 = 𝑃1 + 𝑃2 𝑷 𝟏 + 𝑷 𝟐 = 𝟓𝟎 𝑴𝑾 𝑻𝒊𝒎𝒆 − 𝟏𝟐 𝒕𝒐 𝟔 & 𝟔 𝒕𝒐 𝟏𝟐 … … . 𝟏 𝜕𝐹1 𝜕𝑃1 = 𝜕𝐹2 𝜕𝑃2 = 𝞴𝑅𝑠/𝑀𝑊𝐻𝑟 220 + 1.32𝑃1 = 132 + 1.76𝑃2 1.32𝑃1 − 1.76𝑃2 = −88 … … . . 2 S𝑜𝑙𝑣𝑒 𝑒𝑞𝑢𝑎𝑡𝑖𝑜𝑛 1 𝑎𝑛𝑑 2 𝑷 𝟏 = 𝟎 𝑴𝑾 & 𝑷 𝟐 = 𝟒𝟗. 𝟗𝟔 𝐌𝐖 𝞴 = 220 𝑅𝑠/𝑀𝑊𝐻𝑟 𝐼𝑓 𝑚𝑖𝑛𝑖𝑚𝑢𝑚 𝑎𝑛𝑑 𝑚𝑎𝑥𝑖𝑚𝑢𝑚 𝑔𝑒𝑛𝑒𝑟𝑎𝑡𝑖𝑜𝑛 𝑙𝑖𝑚𝑖𝑡 𝑜𝑓 10𝑀𝑊 𝑎𝑛𝑑 100 𝑀𝑊 𝑟𝑒𝑠𝑝𝑒𝑐𝑡𝑖𝑣𝑒𝑙𝑦 𝑖𝑠 𝑖𝑚𝑝𝑜𝑠𝑒𝑑 𝑡ℎ𝑒𝑛 𝑷 𝟏 = 𝟏𝟎 𝑴𝑾 & 𝑷 𝟐 = 𝟒𝟎 𝐌𝐖

- 20. 𝑪𝒂𝒔𝒆 𝟐 − 𝑃 𝐷 = 𝑃1 + 𝑃2 𝑷 𝟏 + 𝑷 𝟐 = 𝟐𝟎𝟎 𝑴𝑾 𝑻𝒊𝒎𝒆 − 𝟔 𝒕𝒐 𝟔 … … . 𝟑 𝜕𝐹1 𝜕𝑃1 = 𝜕𝐹2 𝜕𝑃2 = 𝞴𝑅𝑠/𝑀𝑊𝐻𝑟 220 + 1.32𝑃1 = 132 + 1.76𝑃2 1.32𝑃1 − 1.76𝑃2 = −88 … … . . 4 S𝑜𝑙𝑣𝑒 𝑒𝑞𝑢𝑎𝑡𝑖𝑜𝑛 3 𝑎𝑛𝑑 4 𝑷 𝟏 = 𝟖𝟓. 𝟕 𝑴𝑾 & 𝑷 𝟐 = 𝟏𝟏𝟒. 𝟑 𝐌𝐖 𝞴 = 333.12 𝑅𝑠/𝑀𝑊𝐻𝑟 𝐼𝑓 𝑚𝑖𝑛𝑖𝑚𝑢𝑚 𝑎𝑛𝑑 𝑚𝑎𝑥𝑖𝑚𝑢𝑚 𝑔𝑒𝑛𝑒𝑟𝑎𝑡𝑖𝑜𝑛 𝑙𝑖𝑚𝑖𝑡 𝑜𝑓 10𝑀𝑊 𝑎𝑛𝑑 100 𝑀𝑊 𝑟𝑒𝑠𝑝𝑒𝑐𝑡𝑖𝑣𝑒𝑙𝑦 𝑖𝑠 𝑖𝑚𝑝𝑜𝑠𝑒𝑑 𝑡ℎ𝑒𝑛 𝑷 𝟏 = 𝟏𝟎𝟎 𝑴𝑾 & 𝑷 𝟐 = 𝟏𝟎𝟎 𝐌𝐖

- 21. Transmission loss formula- 𝐵 𝑚𝑛 𝐶𝑜𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑡𝑠 Consider the power system with generator and load currents as shown in figure, For simplicity 𝑛𝑔 = 2, 𝐺1 𝐺2 𝐺 𝑛𝑔 𝑖 𝑔1 𝑖 𝑔2 𝑖 𝑔𝑛𝑔 𝑖 𝐿3 𝑖 𝐿2 𝑖 𝐿1 𝑃𝑜𝑤𝑒𝑟 𝑁𝑒𝑡𝑤𝑜𝑟𝑘 𝐼 𝐾 𝑁𝑒𝑡𝑤𝑜𝑟𝑘 𝐸𝑙𝑒𝑚𝑒𝑛𝑡 Now consider a network element K (an interconnected line in the system) carrying current 𝐼 𝐾. 𝐼 𝐾 = 𝐼 𝐾1 + 𝐼 𝐾2 Let the ratio of 𝐼 𝐾 and 𝐼𝑔 be 𝑑 𝐾1 = 𝐼 𝐾1 𝐼𝑔1 𝑎𝑛𝑑 𝑑 𝐾2 = 𝐼 𝐾2 𝐼𝑔2

- 22. The power losses in the network comprising of 𝑛𝑔 network elements or branches 𝑃𝑙𝑜𝑠𝑠 is given by, 𝑃𝐿 = 𝐾=1 𝑛𝑔 3 𝐼 𝐾 2 𝑅 𝐾 … … … 1 𝑤ℎ𝑒𝑟𝑒 𝑅 𝐾is the resistance of element K. 𝐼 𝐾 2 = 𝑑 𝐾1 𝑃1 3 𝑉1 cos 𝜑1 2 + 𝑑 𝐾2 𝑃2 3 𝑉2 cos 𝜑2 2 + 2𝑑 𝐾1 𝑑 𝐾2 cos 𝛿1 − 𝛿2 3 𝑉1 𝑉2 cos 𝜑1 cos 𝜑2 … … 2 Substituting equation 2 in to 1 𝑃𝐿 = 𝑃1 2 𝐾=1 𝑛𝑔 𝑑 𝐾1 2 𝑅 𝐾 𝑉1 2 cos 𝜑1 2 + 𝑃2 2 𝐾=1 𝑛𝑔 𝑑 𝐾2 2 𝑅 𝐾 𝑉2 2 cos 𝜑2 2 + 2𝑃1 𝑃2 𝐾=1 𝑛𝑔 𝑑 𝐾1 𝑑 𝐾2 cos 𝛿1 − 𝛿2 3 𝑉1 𝑉2 cos 𝜑1 cos 𝜑2 … 3 𝑃𝐿 = 𝑃1 2 𝐵11 + 𝑃2 2 𝐵22 + 2𝑃1 𝑃2 𝐵12 𝑃𝐿 = 𝑚=1 2 𝑃𝑚 𝑛=1 2 𝑃𝑛 𝐵 𝑚𝑛

- 23. Economic scheduling of thermal plants considering effect of transmission losses- 𝑇ℎ𝑒 𝑜𝑏𝑗𝑒𝑐𝑡𝑖𝑣𝑒 𝑓𝑢𝑛𝑐𝑡𝑖𝑜𝑛 𝑓𝑜𝑟 𝑐𝑜𝑠𝑡 𝑚𝑖𝑛𝑖𝑚𝑖𝑧𝑎𝑡𝑖𝑜𝑛 𝑖𝑠 𝑔𝑖𝑣𝑒𝑛 𝑎𝑠, 𝐹 𝑃𝑖 = 𝑖=1 𝑛𝑔 𝐶𝑖 𝑃𝑖 … … … … … .1 𝑤ℎ𝑒𝑟𝑒 𝑖 = 1,2, … … 𝑛𝑔 𝑇ℎ𝑒 𝑒𝑞𝑢𝑎𝑙𝑖𝑡𝑦 𝑐𝑜𝑛𝑠𝑡𝑟𝑎𝑖𝑛𝑡 𝑖𝑠 𝑔𝑖𝑣𝑒𝑛 𝑏𝑦 𝐺 𝑃𝑖 = 𝑃 𝐷 + 𝑃𝐿 − 𝑖=1 𝑛𝑔 𝑃𝑖 … … … … … 2 (𝑻𝒐𝒕𝒂𝒍 𝑺𝒖𝒑𝒑𝒍𝒚 = 𝒕𝒐𝒕𝒂𝒍 𝒅𝒆𝒎𝒂𝒏𝒅) 𝑻𝒉𝒆 𝑳𝒂𝒈𝒓𝒂𝒏𝒈𝒆 𝑭𝒖𝒏𝒄𝒕𝒊𝒐𝒏 𝒊𝒔 𝒈𝒊𝒗𝒆𝒏 𝒂𝒔, 𝑳 𝑷, 𝞴 = 𝑭 𝑷 + 𝞴𝑮 𝑷 … … … … … . 𝟑 𝑊ℎ𝑒𝑟𝑒 𝞴 𝑖𝑠 𝑙𝑎𝑔𝑟𝑎𝑛𝑔𝑒 𝑚𝑢𝑙𝑡𝑖𝑝𝑙𝑖𝑒𝑟.

- 24. Continue….. Substitute equation 1, 2 in to 3, 𝑳 𝑷, 𝞴 = 𝑖=1 𝑛𝑔 𝐶𝑖 𝑃𝑖 + 𝞴 𝑃 𝐷 + 𝑃𝐿 − 𝑖=1 𝑛𝑔 𝑃𝑖 … … … . . 4 𝑇ℎ𝑒 𝑛𝑒𝑐𝑒𝑠𝑠𝑎𝑟𝑦 𝑐𝑜𝑛𝑑𝑖𝑡𝑖𝑜𝑛𝑠 𝑎𝑟𝑒 𝑔𝑖𝑣𝑒𝑛 𝑎𝑠, 𝜕L 𝜕Pi = 0 & 𝜕𝐿 𝜕𝝺 = 0 Now apply above conditions on equation 4 , 𝜕L 𝜕Pi = 𝜕𝐶𝑖 𝑃𝑖 𝜕Pi + 𝞴 𝜕𝑃𝐿 𝜕Pi + 𝞴 −1 = 0 𝑤ℎ𝑒𝑟𝑒 𝑖 = 1,2, … … 𝑛𝑔

- 25. Continue….. 𝜕𝐶𝑖 𝑃𝑖 𝜕Pi + 𝞴 𝜕𝑃𝐿 𝜕Pi = 𝞴 … … … . . 5 The equation 5 state that the sum of the incremental production cost of power at any plant i and the incremental transmission losses incurred due to generation 𝑃𝑖 at the rate of 𝞴 𝑚𝑢𝑠𝑡 𝑏𝑒 𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡 𝑓𝑜𝑟 𝑎𝑙𝑙 𝑔𝑒𝑛𝑒𝑟𝑎𝑡𝑜𝑟𝑠 𝑎𝑛𝑑 𝑒𝑞𝑢𝑎𝑙 𝑡𝑜 𝞴. 𝜕L 𝜕𝝺 = 𝑃 𝐷 + 𝑃𝐿 − 𝑖=1 𝑛𝑔 𝑃𝑖 = 0 𝑤ℎ𝑒𝑟𝑒 𝑖 = 1,2, … … 𝑛𝑔 ∴ 𝑃1 + 𝑃2 + 𝑃3 + ⋯ … … . +𝑃𝑛𝑔 = 𝑃 𝐷 + 𝑃𝐿 … … … . . 6 The equation 6 gives the load demand constraint .

- 26. Penalty Factor- 𝜕𝐶𝑖 𝑃𝑖 𝜕Pi + 𝞴 𝜕𝑃𝐿 𝜕Pi = 𝞴 𝑤ℎ𝑒𝑟𝑒 𝑖 = 1,2, … … 𝑛𝑔 𝞴 = 𝜕𝐶𝑖 𝑃𝑖 𝜕Pi 1 − 𝜕𝑃𝐿 𝜕Pi When transmission losses are included , the incremental production cost at each plant ‘i ‘ must be multiplied by a factor 1 1− 𝜕𝑃 𝐿 𝜕Pi which then will be equal to the incremental cost of power delivered. Hence the factor 1 1− 𝜕𝑃 𝐿 𝜕Pi is called Penalty Factor.

- 27. Numerical No-3 Given a two bus system as shown in figure. The incremental productions cost characteristics for the two stations are, 𝜕𝐹1 𝜕𝑃1 = 15 + 0.03𝑃1 𝑅𝑠/𝑀𝑤𝐻𝑟 𝜕𝐹2 𝜕𝑃2 = 18 + 0.05𝑃2 𝑅𝑠/𝑀𝑤𝐻𝑟 It is observed that when a power of 75 MW is imported to bus 1, the loss amounted to 5 MW. Find the generation needed from each plant and also the power received by the load, if the system 𝞴 𝑖𝑠 𝑔𝑖𝑣𝑒𝑛 𝑏𝑦 20𝑅𝑆/𝑀𝑊𝐻𝑟. G1 G2 200𝑀𝑊 75 𝑀𝑊 Load 1 2 Line

- 28. Solution- The power loss equation is given as, 𝑃𝐿 = 𝑃1 2 𝐵11 + 𝑃2 2 𝐵22 + 2𝑃1 𝑃2 𝐵12 The load is at bus 1, hence 𝑃1 will no have any effect on the line losses. Therefore 𝐵11 = 𝐵12 = 𝐵21 = 0 𝑷 𝑳 = 𝑷 𝟐 𝟐 𝑩 𝟐𝟐 … … 𝟐 when a power of 75 MW is imported to bus 1, the loss amounted to 5 MW. 𝟓 = 𝑩 𝟐𝟐 ∗ 𝟕𝟓 𝟐 𝑩 𝟐𝟐 = 𝟖. 𝟗 ∗ 𝟏𝟎−𝟒 = 𝟎. 𝟎𝟎𝟎𝟖𝟗 Equation 2 becomes, 𝑷 𝑳 = 𝟎. 𝟎𝟎𝟎𝟖𝟗𝑷 𝟐 𝟐 … … 𝟑 𝛛𝑷 𝑳 𝛛𝑷 𝟏 = 𝟎 𝐚𝐧𝐝 𝛛𝑷 𝑳 𝛛𝑷 𝟐 = 𝟐 ∗ 𝟎. 𝟎𝟎𝟎𝟖𝟗 ∗ 𝑷 𝟐

- 29. Now consider at station 1- 𝛛𝑷 𝑳 𝛛𝑷 𝟏 = 𝟎 𝜕𝐶1 𝑃1 𝜕P1 + 𝞴 𝜕𝑃𝐿 𝜕P1 = 𝞴 15 + 0.03𝑃1 + 𝞴 ∗ 0 = 𝞴 𝞴 = 20 𝑅𝑆/𝑀𝑊𝐻𝑟 𝑷 𝟏 = 𝟏𝟔𝟔. 𝟔𝟕 𝑴𝑾

- 30. Now consider at station 2- 𝛛𝑷 𝑳 𝛛𝑷 𝟐 = 𝟐 ∗ 𝟎. 𝟎𝟎𝟎𝟖𝟗 ∗ 𝑷 𝟐 𝜕𝐶2 𝑃2 𝜕P2 + 𝞴 𝜕𝑃𝐿 𝜕P2 = 𝞴 18 + 0.05𝑃2 + 𝞴 ∗ 𝟐 ∗ 𝟎. 𝟎𝟎𝟎𝟖𝟗 ∗ 𝑷 𝟐 = 𝞴 𝞴 = 20 𝑅𝑆/𝑀𝑊𝐻𝑟 𝑷 𝟐 = 𝟐𝟑. 𝟑𝟔 𝑴𝑾

- 31. Total Transmission loss is when 𝑷 𝟐 = 𝟐𝟑. 𝟑𝟔 𝑴𝑾 is transmitted from bus 2 to the load connected at bus 1 is given as 𝑷 𝑳 = 𝟎. 𝟎𝟎𝟎𝟖𝟗𝑷 𝟐 𝟐 𝑷 𝑳 = 𝟎. 𝟎𝟎𝟎𝟖𝟗 ∗ 𝟐𝟑. 𝟑𝟔 𝟐 𝑷 𝑳 = 𝟎. 𝟒𝟖𝟓𝟖 𝐌𝐖 The total load demand at bus 1 is 𝑷 𝑫 = 𝑷 𝟏 + 𝑷 𝟐 − 𝑷 𝑳 𝑷 𝑫 = 𝟏𝟔𝟔. 𝟔𝟕 + 𝟐𝟑. 𝟑𝟔 − 𝟎. 𝟒𝟖𝟓𝟖 𝑷 𝑫 = 𝟏𝟖𝟗. 𝟓𝟒 𝑴𝑾

- 32. Unit Commitment- The topic of unit commitment deals with specifying the units which should be operated for a given load . That means which units should be committed to supply a given load. It is economical to de-commit certain units when load is low. “To commit a unit means to bring the boiler to the required temperature, bring the turbine and generator to synchronous speed and synchronise the generator to the system”.

- 33. Constraints in Unit Commitment- The problem of deciding which units to for a certain load is beset with many constraints, Spinning Reserve Minimum up time Minimum down time Crew Constraints Transition cost Hydro Constraints Nuclear Constraints Must runtime Units Fuel Supply Constraints

- 34. Methods of Unit Commitment- 1. Priority List Methods In this method we prepare priority list of the order in which the generating units should be added to the system. This list would also include the order of the shutting down the units when the system load decreases. When the load is very low, the units with the lowest heat rate supplies the entire load. As the load increases the units having heat rates in ascending order are successively added.

- 35. Consider the three thermal plants operating with the following incremental fuel rate characteristics, Plant 1 𝐹1 = 7 + 0.003𝑃1 ∗ 103 𝐾 − 𝐶𝑎𝑙/𝑀𝑤𝐻𝑟 𝑃1 𝑚𝑎𝑥 = 500 𝑀𝑊 & 𝑃1 𝑚𝑖𝑛 = 50 𝑀𝑊 Plant 2 𝐹2 = 7.5 + 0.002𝑃2 ∗ 103 𝐾 − 𝐶𝑎𝑙/𝑀𝑤𝐻𝑟 𝑃2 𝑚𝑎𝑥 = 400 𝑀𝑊 & 𝑃2 𝑚𝑖𝑛 = 40 𝑀𝑊 Plant 3 𝐹3 = 8 + 0.004𝑃3 ∗ 103 𝐾 − 𝐶𝑎𝑙/𝑀𝑤𝐻𝑟 𝑃3 𝑚𝑎𝑥 = 200 𝑀𝑊 & 𝑃3 𝑚𝑖𝑛 = 20 𝑀𝑊 The fuel cost at the plant is given as 𝐶𝑃1 = 1.1 𝑅𝑆/𝐾𝑐𝑎𝑙 𝐶𝑃2 = 1.05 𝑅𝑆/𝐾𝑐𝑎𝑙 𝐶𝑃3 = 1.2 𝑅𝑆/𝐾𝑐𝑎𝑙

- 36. The full load average production cost is Plant 1- 𝑃1 𝑚𝑎𝑥 = 500 𝑀𝑊 𝐹1 ∗ 𝐶𝑃1 = 7 + 0.003 ∗ 500 ∗ 103 ∗ 1.1 𝑅𝑆/𝑀𝑤𝐻𝑟 = 𝟗. 𝟑𝟓 ∗ 𝟏𝟎 𝟑 𝑹𝑺/𝑴𝒘𝑯𝒓 Plant 2 𝑃2 𝑚𝑎𝑥 = 400 𝑀𝑊 𝐹2 ∗ 𝐶𝑃2 = 7.5 + 0.002 ∗ 400 ∗ 103) ∗ 1.05 𝑅𝑆/𝑀𝑤𝐻𝑟 = 𝟖. 𝟕𝟏𝟓 ∗ 𝟏𝟎 𝟑 𝑹𝑺/𝑴𝒘𝑯𝒓 Plant 3 𝑃3 𝑚𝑎𝑥 = 200 𝑀𝑊 𝐹3 ∗ 𝐶𝑃3 = 8 + 0.004 ∗ 200 ∗ 103 ∗ 1.2 𝑅𝑆/𝑀𝑤𝐻𝑟 = 𝟏𝟎. 𝟓𝟔 ∗ 𝟏𝟎 𝟑 𝑹𝑺/𝑴𝒘𝑯𝒓

- 37. The priority list for supplying load up to 1000 MW is prepared as, Units Maximum(MW) Minimum(MW) 2,1,3 1000 110 2,1 900 90 2 400 40 In order of increasing cost the following table is constructed as, Unit RS/MWHr Maximum(MW) Minimum(MW) 2 𝟖. 𝟕𝟏𝟓 ∗ 𝟏𝟎 𝟑 400 40 1 𝟗. 𝟑𝟓 ∗ 𝟏𝟎 𝟑 500 50 3 𝟏𝟎. 𝟓𝟔 ∗ 𝟏𝟎 𝟑 200 20

- 38. Methods of Unit Commitment- 2. Dynamic Programming This method can be applied to problems in which many sequential decisions are required to be taken in defining the optimum operation of a system or process composed of distinct number of stages. However , it is suitable only when the decisions at later stages do not affect the operation at the earlier stages.

- 39. Let the cost of operating the first unit be 𝐹1 𝑃1 when supplying power 𝑃1is , 𝑭 𝟏 𝑷 𝟏 = 𝑓1 𝑝1 The optimal combination of this unit with a second unit can be derived next to supply a load of 𝑃1 + 𝑃2 for which the optimal cost is 𝐹2 𝑃1 + 𝑃2 = min[𝑓2 𝑝2 + 𝑭 𝟏 𝑷 𝟏 ] As 𝐹1 𝑃1 is already the optimal value, the best units to supply 𝑃2 from the rest of (N-1) units will be picked during second stage of optimization for lowest possible cost of production. 𝐹3 𝑃1 + 𝑃2 + 𝑃3 = min[𝑓3 𝑝3 + 𝐹2 𝑃1 + 𝑃2 ] In general 𝐹 𝑁 𝑖=1 𝑁 𝑃𝑖 = min[𝐹 𝑁 𝑃 𝑁 + 𝐹 𝑁−1 𝑃𝑛 𝑖=1 𝑁−1 𝑃𝑖

- 40. Numerical-4 Obtain the economic schedule for the two units , the production cost of which are given as follows, to supply a load of 3 MW , in steps of 1 MW. 𝐹1 = 0.8𝑃1 2 + 25𝑃1 𝐹2 = 1.2𝑃2 2 + 22𝑃2 Using Dynamic Programming. Solution- 𝐹1 3 = 0.8 ∗ 32 + 25 ∗ 3 = 82.2 𝑭 𝟐 𝟑 = 𝐦𝐢𝐧[𝒇 𝟐 𝟎 + 𝒇 𝟏 𝟑 , 𝒇 𝟐 𝟏 + 𝒇 𝟏 𝟐 , 𝒇 𝟐 𝟐 + 𝒇 𝟏 𝟏 , 𝒇 𝟐 𝟑 + 𝒇 𝟏 𝟎 ] 𝑓1 2 = 0.8 ∗ 22 + 25 ∗ 2 = 53.2 𝑓1 1 = 0.8 ∗ 12 + 25 ∗ 1 = 25.8 𝑓1 0 = 0.8 ∗ 02 + 25 ∗ 0 = 0 𝑓2 3 = 1.2 ∗ 32 + 22 ∗ 3 = 76.8 𝑓2 3 = 1.2 ∗ 22 + 22 ∗ 2 = 48.8 𝑓2 1 = 1.2 ∗ 12 + 22 ∗ 1 = 23.2 𝑓2 0 = 1.2 ∗ 02 + 22 ∗ 0 = 0

- 41. 𝐹1 3 = 82.2, 𝑓1 2 = 53.2, 𝑓1 1 = 25.8, 𝑓1 0 = 0 𝑓2 3 = 76.8, 𝑓2 2 = 48.8 , 𝑓2 1 = 23.2, 𝑓2 0 = 0 𝑭 𝟐 𝟑 = 𝐦𝐢𝐧[𝒇 𝟐 𝟎 + 𝒇 𝟏 𝟑 , 𝒇 𝟐 𝟏 + 𝒇 𝟏 𝟐 , 𝒇 𝟐 𝟐 + 𝒇 𝟏 𝟏 , 𝒇 𝟐 𝟑 + 𝒇 𝟏 𝟎 ] 𝑭 𝟐 𝟑 = 𝐦𝐢𝐧[ 𝟎 + 𝟖𝟐. 𝟐, 𝟐𝟑. 𝟐 + 𝟓𝟑. 𝟐, 𝟒𝟖. 𝟖 + 𝟐𝟓. 𝟖, 𝟕𝟔. 𝟖 + 𝟎] 𝑭 𝟐 𝟑 = 𝐦𝐢𝐧[ 𝟖𝟐. 𝟐, 𝟕𝟔. 𝟒, 𝟕𝟒. 𝟔, 𝟕𝟔. 𝟖] The most economical combination is unit 2 supplying 2 MW and unit supplying 1 MW.

![Let the cost of operating the first unit be 𝐹1 𝑃1 when supplying power 𝑃1is ,

𝑭 𝟏 𝑷 𝟏 = 𝑓1 𝑝1

The optimal combination of this unit with a second unit can be derived next to

supply a load of 𝑃1 + 𝑃2 for which the optimal cost is

𝐹2 𝑃1 + 𝑃2 = min[𝑓2 𝑝2 + 𝑭 𝟏 𝑷 𝟏 ]

As 𝐹1 𝑃1 is already the optimal value, the best units to supply 𝑃2 from the

rest of (N-1) units will be picked during second stage of optimization for

lowest possible cost of production.

𝐹3 𝑃1 + 𝑃2 + 𝑃3 = min[𝑓3 𝑝3 + 𝐹2 𝑃1 + 𝑃2 ]

In general

𝐹 𝑁

𝑖=1

𝑁

𝑃𝑖 = min[𝐹 𝑁 𝑃 𝑁 + 𝐹 𝑁−1 𝑃𝑛

𝑖=1

𝑁−1

𝑃𝑖](https://image.slidesharecdn.com/unit5economicloaddispatchunitcommitment-201109165132/85/Unit-5-Economic-Load-Dispatch-and-Unit-Commitment-39-320.jpg)

![Numerical-4

Obtain the economic schedule for the two units , the production cost of which

are given as follows, to supply a load of 3 MW , in steps of 1 MW.

𝐹1 = 0.8𝑃1

2

+ 25𝑃1

𝐹2 = 1.2𝑃2

2

+ 22𝑃2

Using Dynamic Programming.

Solution-

𝐹1 3 = 0.8 ∗ 32

+ 25 ∗ 3 = 82.2

𝑭 𝟐 𝟑 = 𝐦𝐢𝐧[𝒇 𝟐 𝟎 + 𝒇 𝟏 𝟑 , 𝒇 𝟐 𝟏 + 𝒇 𝟏 𝟐 , 𝒇 𝟐 𝟐 + 𝒇 𝟏 𝟏 ,

𝒇 𝟐 𝟑 + 𝒇 𝟏 𝟎 ]

𝑓1 2 = 0.8 ∗ 22 + 25 ∗ 2 = 53.2

𝑓1 1 = 0.8 ∗ 12 + 25 ∗ 1 = 25.8

𝑓1 0 = 0.8 ∗ 02 + 25 ∗ 0 = 0

𝑓2 3 = 1.2 ∗ 32

+ 22 ∗ 3 = 76.8

𝑓2 3 = 1.2 ∗ 22 + 22 ∗ 2 = 48.8

𝑓2 1 = 1.2 ∗ 12 + 22 ∗ 1 = 23.2

𝑓2 0 = 1.2 ∗ 02 + 22 ∗ 0 = 0](https://image.slidesharecdn.com/unit5economicloaddispatchunitcommitment-201109165132/85/Unit-5-Economic-Load-Dispatch-and-Unit-Commitment-40-320.jpg)

![𝐹1 3 = 82.2, 𝑓1 2 = 53.2, 𝑓1 1 = 25.8, 𝑓1 0 = 0

𝑓2 3 = 76.8, 𝑓2 2 = 48.8 , 𝑓2 1 = 23.2, 𝑓2 0 = 0

𝑭 𝟐 𝟑 = 𝐦𝐢𝐧[𝒇 𝟐 𝟎 + 𝒇 𝟏 𝟑 , 𝒇 𝟐 𝟏 + 𝒇 𝟏 𝟐 , 𝒇 𝟐 𝟐 + 𝒇 𝟏 𝟏 ,

𝒇 𝟐 𝟑 + 𝒇 𝟏 𝟎 ]

𝑭 𝟐 𝟑 = 𝐦𝐢𝐧[ 𝟎 + 𝟖𝟐. 𝟐, 𝟐𝟑. 𝟐 + 𝟓𝟑. 𝟐, 𝟒𝟖. 𝟖 + 𝟐𝟓. 𝟖, 𝟕𝟔. 𝟖 + 𝟎]

𝑭 𝟐 𝟑 = 𝐦𝐢𝐧[ 𝟖𝟐. 𝟐, 𝟕𝟔. 𝟒, 𝟕𝟒. 𝟔, 𝟕𝟔. 𝟖]

The most economical combination is unit 2 supplying 2 MW and unit

supplying 1 MW.](https://image.slidesharecdn.com/unit5economicloaddispatchunitcommitment-201109165132/85/Unit-5-Economic-Load-Dispatch-and-Unit-Commitment-41-320.jpg)