Unit_1_Casting Processes.pdf

- 2. Unit I: CASTING PROCESSES Syllabus • SAND CASTING – Pattern- types, material and allowances, • Molding sand- types, properties and testing, • Molding – types, equipment’s, tools and machines, • Core – types and manufacturing, • Gating system and Riser – types and design (Numerical), • Heating and pouring, cooling and solidification process and time estimation (Numerical), • Cleaning and Finishing, Defects and remedies, Inspection techniques. • Die casting, Investment casting, Centrifugal Casting, Continuous Casting- Types, equipment, process parameters, material to cast.

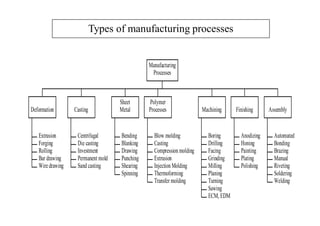

- 3. Types of manufacturing processes Extrusion Forging Rolling Bar drawing Wiredrawing Deformation Centrifugal Die casting Investment Permanent mold Sand casting Casting Bending Blanking Drawing Punching Shearing Spinning Sheet Metal Blow molding Casting Compression molding Extrusion Injection Molding Thermoforming Transfer molding Polymer Processes Boring Drilling Facing Grinding Milling Planing Turning Sawing ECM, EDM Machining Anodizing Honing Painting Plating Polishing Finishing Automated Bonding Brazing Manual Riveting Soldering Welding Assembly Manufacturing Processes

- 4. Casting since about 4000 BC… 4 Ancient Greece; bronze statue casting circa 450BC Iron works in early Europe, e.g. cast iron cannons from England circa 1543

- 5. Casting • Foundry is a process of producing metal castings. • Casting is an operation of shaping metal by pouring it in the liquid state into a mold followed by solidification. • Casting is a process in which molten metal flows into a mold where it solidifies in the shape of the mold cavity. The part produced is also called casting. • In some cases casting is the only method of shaping a metal or alloy: when the alloy is not malleable and therefore it’s plastic deformation is not possible or when a large detail of complex shape is to be produced.

- 6. Advantages • Complex shapes • Net-shape ability • Very large parts • Variety of metals • Mass production Disadvantages • Poor accuracy • Poor surface • Internal defects • Mechanical properties • Environmental impact Applications Big parts: engine blocks and heads for automotive vehicles, wood burning stoves, machine frames, railway wheels, pipes, church bells, big statues, and pump housings Small parts: dental crowns, jewelry, small statues, and frying pans Cameras

- 7. Casting Processes • 1. Expendable mold processes Uses an expendable mold which must be destroyed to remove casting Mold materials: sand, plaster & ceramic • 2. Permanent mold processes Uses a permanent mold which can be used many times to produce many castings Mold materials :Made of metal

- 8. Casting Processes Expendable mould Permanent mould Sand mould Gravity die casting Pressure die casting Centrifugal casting Continuous casting Investment mould

- 9. Sand Casting • Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. • - has a low production rate. • The sand casting process involves the use of a furnace, metal, pattern, and sand mold.

- 10. CASTING TERMINOLOGY • Pattern: It is the replica of the final object to be made.

- 11. CASTING TERMINOLOGY •Core: A separate part of the mould, made of sand which is placed in mould to create openings and various shaped cavities in the castings.

- 12. CASTING TERMINOLOGY • Flask(Mould box): A metal or wood frame/container, without fixed top or bottom which is used to create the mould.

- 13. CASTING TERMINOLOGY • Mould: In sand casting, the primary piece of equipment is the mould, which contains several components. The mould is divided into two halves - the cope (upper half) and the drag (bottom half), which meet along a parting line. • Mould cavity: The mould cavity is formed by packing sand around the pattern in each half of the flask. The mould cavity is made with the help of pattern.

- 14. CASTING TERMINOLOGY • Gating system: It consist of pouring basin,sprue,runner, gates, riser. It is used to feed the molten metal. • (1)Pouring basin(feeder:) A small funnel shaped cavity at the top of the mould into which the molten metal is poured. • (2)Sprue: The passage through which the molten metal, from the pouring basin, reaches the mold cavity. In many cases it controls the flow of metal into the mold.

- 15. • (3)Runner: The channel through which the molten metal is carried from the sprue to the gate. • (4)Gate: A channel through which the molten metal enters the mold cavity. • (5)Riser: A column of molten metal placed in the mold to feed the castings as it shrinks and solidifies. Also known as feed head.

- 19. Steps in Sand Casting

- 20. Steps in Sand Casting

- 21. Steps in Sand Casting 1 2 3 4 5 6 7 8 9 10 Fettling

- 22. What is basic requirement for sand casting process…? • 1. Pattern. • 2. Core • 3. Gating system • 4. Sand casting • 5. Mold

- 23. I. PATTERN

- 24. •It is the replica of the final object to be made. •Pattern is the solid form that is used to make mold cavity. •The quality of the castings produced depends on the design of the pattern, its material and construction. • One major requirement is that patterns (and therefore the mold cavity) must be oversized • (i) to account for shrinkage in cooling and solidification, and • (ii) to provide enough metal for the subsequence machining operation(s). I. PATTERN

- 26. Shrinkage

- 27. FACTORS EFFECTING SELECTION OF PATTERN MATERIAL 1. Number of castings to be produced. Metal pattern----- large in number. 2. Type of mold material used. 3. Kind of molding process. 4. Method of molding (hand or machine). 5. Degree of dimensional accuracy and surface finish required. 6. Minimum thickness required. 7. Shape, complexity and size of casting. 8. Cost of pattern and chances of repeat orders of the pattern

- 28. COMMON PATTERN MATERIALS • The common materials used for making patterns are wood, metal, plastic, plaster, wax or mercury. Pattern properties are • Easily worked, shaped and joined • Light in weight • Strong, hard, durable etc • Resistance to wear and abrasion, chemical reaction • Dimensionally stable • Available at low cast Pattern Materials • Wood-pine (softwood), or mahogany (hardwood), • Metals and alloys • Plaster of Paris • Plastic and rubber • Wax and resins

- 29. 1. Wood- shisham, kail, deodar, teak and mahogany. Advantages of wooden patterns 1 Wood can be easily worked. 2 It is light in weight. 3 It is easily available. 4 It is very cheap. 5 It is easy to join. 6 It is easy to obtain good surface finish. 7 Wooden laminated patterns are strong. 8 It can be easily repaired. Disadvantages 1 It is susceptible to moisture. 2 It tends to warp. 3 It wears out quickly due to sand abrasion. 4 It is weaker than metallic patterns.

- 30. 2. Metal- cast iron, brass and bronzes and aluminum alloys. • i). Cast Iron Advantages • 1. It is cheap • 2. It is easy to file and fit • 3. It is strong • 4. It has good resistance against sand abrasion • 5. Good surface finish Disadvantages • 1 It is heavy • 2 It is brittle and hence it can be easily broken • 3 It may rust

- 31. ii). Brasses and Bronzes Advantages • 1. Better surface finish than cast iron. • 2. Very thin sections can be easily casted. Disadvantages • 1. It is costly • 2. It is heavier than cast iron. iii). Aluminum Alloys Advantages • 1. Aluminum alloys pattern does not rust. • 2. They are easy to cast. • 3. They are light in weight. • 4. They can be easily machined. Disadvantages • 1. They can be damaged by sharp edges. • 2. They are softer than brass and cast iron. • 3. Their storing and transportation needs proper care.

- 32. • Iv). White Metal (Alloy of Antimony, Copper and Lead) • Advantages • 1. It is best material for lining and stripping plates. • 2. It has low melting point around 260°C • 3. It can be cast into narrow cavities. • Disadvantages • 1. It is too soft. • 2. Its storing and transportation needs proper care • 3. It wears away by sand or sharp edges.

- 33. 3. Plastic • Advantages • lighter, stronger, moisture and wear resistant, non sticky to molding sand, durable and they are not affected by the moisture of the molding sand. • Moreover they impart very smooth surface finish on the pattern surface. Disadvantages • These materials are somewhat fragile, less resistant to sudden loading and their section may need metal reinforcement. • The plastics used for this purpose are thermosetting resins. • Phenolic resin plastics are commonly used.

- 34. 4. Plaster • The main advantages of plaster are that it has high compressive strength and is of high expansion setting type which compensate for the shrinkage allowance of the casting metal. • It is also preferred for production of small size intricate castings and making core boxes. • preferable for producing highly intricate casting.

- 35. 5. Wax • The commonly used waxes are paraffin wax, shellac wax, bees- wax, cerasin wax, and micro-crystalline wax. • used in the process of investment casting where accuracy is linked with intricacy of the cast object.

- 36. TYPES OF PATTERN 1. One piece or solid pattern 2. Two piece or split pattern 3. Cope and drag pattern 4. Three-piece or multi- piece pattern 5. Loose piece pattern 6. Match plate pattern 7. Follow board pattern 8. Gated pattern 9. Sweep pattern 10. Skeleton pattern 11. Segmental or part pattern

- 37. 1. Loose pattern: • Loose pattern are patterns which are not connected to other patterns or mounted on a plate. Loose patterns may be further classified into: • 1. Solid or Single piece pattern • 2. Self core pattern • 3. Split patterns • 4. Loose piece pattern

- 38. 1.Solid Pattern/single piece pattern • Solid pattern is made of single piece without joints, partings lines or loose pieces. It is the simplest form of the pattern. • It is an easy pattern to manufacture, but determining the parting line between cope and drag is more difficult for the foundry worker.

- 39. 2. Self core patterns: • Self core type solid patterns are patterns having a hollow portion with straight draft which is used for producing its own core during moulding process itself. • This type of pattern eliminates the need for core box.

- 40. 3. Split Pattern: • The split pattern is comprised of two separate parts that when put together will represent the geometry of the casting. • Split pattern is made in two pieces which are joined at the parting line by means of dowel pins. • The splitting at the parting line is done to facilitate the withdrawal of the pattern.

- 41. 4. Match Plate Pattern: • -- high production. • In the match plate pattern, however, each of the parts are mounted on a plate. • The plates come together to assemble the pattern for the casting process. • - more proficient and makes alignment of the pattern in the mold quick and accurate.

- 42. 5. Cope and Drag Pattern: • Each of the two halves are mounted on a separate plate for easy alignment of the pattern and mold. • The cope and drag pattern enables the cope section of the mold, and the drag section of the mold to be created separately and latter assembled before the pouring of the casting.

- 43. 6. Shell patterns: • --used for piping work or for producing drainage fittings. • This pattern consists of a thin cylindrical or curved metal piece parted along the center line. • The two halves of the pattern are held in alignment by dowels.

- 44. 6. Gated patterns: • Gated patterns are number of loose patterns connected with a gating system. • They are molded like a single pattern and withdrawn from the mould in one piece thus reducing moulding time. • Gated patterns are useful when a number of small castings are to be produced Eg. Investment casting

- 45. 7. Sweep pattern • Sweep patterns are used for forming large circular moulds of symmetric kind by revolving a sweep attached to a spindle. • Actually a sweep is a template of wood or metal and is attached to the spindle at one edge and the other edge has a contour depending upon the desired shape of the mould. • The pivot end is attached to a stake of metal in the center of the mould.

- 46. 8. Skeleton pattern • When only a small number of large and heavy castings are to be made, it is not economical to make a solid pattern. • In such cases, however, a skeleton pattern may be used. • This is a ribbed construction of wood which forms an outline of the pattern to be made. • This frame work is filled with loam sand and rammed. • The surplus sand is removed by stickle board. • For round shapes, the pattern is made in two halves which are joined with glue or by means of screws etc.

- 47. 9. Three-piece or multi-piece pattern • Some patterns are of complicated kind in shape and hence can not be made in one or two pieces because of difficulty in withdrawing the pattern. • Therefore these patterns are made in either three pieces or in multi-pieces. • Multi molding flasks are needed to make mold from these patterns.

- 48. 10. Segmental pattern • Patterns of this type are generally used for circular castings, for example wheel rim, gear blank etc. • Such patterns are sections of a pattern so arranged as to form a complete mould by being moved to form each section of the mould. • The movement of segmental pattern is guided by the use of a central pivot.

- 49. 11. Follow board pattern • When the use of solid or split patterns becomes difficult, a contour corresponding to the exact shape of one half of the pattern is made in a wooden board, which is called a follow board and it acts as a molding board for the first molding operation

- 50. PATTERN ALLOWANCES • The size of a pattern is never kept the same as that of the desired casting because of the fact that during cooling the casting is subjected to various effects and hence to compensate for these effects, corresponding allowances are given in the pattern. • These various allowances given to pattern can be enumerated as, • allowance for shrinkage, • allowance for machining, • allowance for draft, • allowance for rapping or shake, • allowance for distortion and • allowance for mould wall movement.

- 51. 1. Shrinkage Allowance • In practice it is found that all common cast metals shrink a significant amount when they are cooled from the molten state. The total contraction in volume • 1. Liquid contraction, i.e. the contraction during the period in which the temperature of the liquid metal or alloy falls from the pouring temperature to the liquidus temperature. • 2. Contraction on cooling from the liquidus to the solidus temperature, i.e. solidifying contraction. • 3. Contraction that results there after until the temperature reaches the room temperature. This is known as solid contraction. • The first two of the above are taken care of by proper gating and risering. • Only the last one, i.e. the solid contraction is taken care by the pattern makers by giving a positive shrinkage allowance.

- 52. • The contraction allowances for different metals and alloys such as • Cast Iron 10 mm/m. • Brass 16 mm/m, • Aluminium Alloys. 15 mm/m., • Steel 21 mm/m, • Lead 24 mm/m. • Copper 16mm/m. In fact, there is a special rule known as the pattern marks contraction rule / shrinkage rule in which the shrinkage of the casting metals is added.

- 53. 2. Machining Allowance • It is a positive allowance given to compensate for the amount of material that is lost in machining or finishing the casting. • If this allowance is not given, the casting will become undersize after machining. • The amount of this allowance depends on the size of casting, methods of machining and the degree of finish. • the value varies from 3 mm. to 18 mm.

- 54. 3. Draft or Taper Allowance • Taper allowance is also a positive allowance and is given on all the vertical surfaces of pattern so that its withdrawal becomes easier. • The normal amount of taper on the external surfaces varies from 10 mm to 20 mm/mt. On interior holes and recesses which are smaller in size, the taper should be around 60 mm/mt. These values are greatly affected by • the size of the pattern and the molding method. In machine molding its, value varies from 10 mm to 50 mm/mt.

- 55. 4. Rapping or Shake Allowance • Actually by rapping, the external sections move outwards increasing the size and internal • sections move inwards decreasing the size. • This movement may be insignificant in the case of • small and medium size castings, but it is significant in the case of large castings. • This allowance is kept negative and hence the pattern is made slightly smaller in dimensions 0.5-1.0 mm.

- 56. 5. Distortion Allowance • This allowance is applied to the castings which have the tendency to distort during cooling due to thermal stresses developed. • For example a casting in the form of U shape will contract at the closed end on cooling, while the open end will remain fixed in position. • Therefore, to avoid the distortion, the legs of U pattern must converge slightly so that the sides will remain parallel after cooling.

- 57. II. CORE

- 58. II. Core • Cores serve to produce internal surfaces in castings, in some cases, they have to be supported by chaplets for more stable positioning. • For producing hallow casting. • The core is normally a disposable item that is destroyed to get it out of the piece. Eg. the use of cores is in the casting of engine blocks

- 59. Definition of core:- Cores are compact mass of core sand that when placed in mould cavity at required location with proper alignment does not allow the molten metal to occupy space for solidification in that portion and hence help to produce hollowness in the casting.

- 60. Types of core Cores are classified according to shape and position in the mold. 1. Horizontal core 2. Vertical core 3. Balanced core 4. Hanging and cover core –wire support 5. Wind up core- below or above parting line 6. Ram up core- before ramming 7. Kiss core - no core prints (seat)

- 61. •Horizontal •Usually cylindrical, laid horizontally at parting plane •Core rest in seats provided by core print on pattern

- 62. •Vertical •Both in cope and drag •Top and bottom provided with taper - alignment

- 63. •Balanced •Opening on one side of casting •Only one core print •Core print is made large to balance the weight and sufficient support •Long core supported by chaplets

- 64. •Cover Cover hanging from cope plus support at bottom in drag

- 65. •Hanging •Core hangs from cope and no support at bottom of drag

- 66. • Wing • When hole is required in casting above or below the parting line • Side of core is given sufficient amount of taper so core can be placed easily • Also called as drop core, tail core, chair or saddle core

- 67. •Ram – up •Setting the core brfore mould is rammed • core details located in in-acessible position

- 68. •Kiss Core •No core prints and no seta is available •Core is held between cope and drag simply by pressure of cope

- 69. Horizontal Vertical Balanced Cover Hanging Wing Ram-up Kiss core

- 70. Fig. Vertical core Fig. Balancing core

- 71. CORE MAKING • Core making basically is carried out in four stages namely • 1. core sand preparation, • 2. core making, • 3. core baking and • 4. core finishing.

- 72. i. CORE sand characteristics / properties • It is special kind of molding sand. • Those considerations involves • (i) The cores are subjected to a very high temperature and hence the core sand should be highly refractory in nature • (ii) The permeability of the core sand must be sufficiently high as compared to that of the molding sands so as to allow the core gases to escape through the limited area of the core recesses generated by core prints • (iii) The core sand should not possess such materials which may produce gases while they come in contact with molten metal and • (iv) The core sand should be collapsible in nature, i.e. it should disintegrate after the metal solidifies, because this property will ease the cleaning of the casting.

- 73. • The main constituents of the core sand are pure silica sand and a binder. • Silica sand is preferred because of its high refractoriness. • For higher values of permeability sands with coarse grain size distribution are used. • The main purpose of the core binder is to hold the grains together, impart strength and sufficient degree collapsibility. Core Material

- 74. Commonly used binders in core making.. 1. Cereal binder It develops green strength, baked strength and collapsibility in core. The amount of these binders used varies from 0.2 to 2.2% by weight in the core sand. 2. Protein binder It is generally used to increase collapsibility property of core. 3. Thermo setting resin It is gaining popularity nowadays because it imparts high strength, collapsibility to core sand and it also evolve minimum amount of mold and core gases which may produce defects in the casting. The most common binders under this group are phenol formaldehyde and urea formaldehyde. 4. Sulphite binder Sulphite binder is also sometimes used in core but along with certain amount of clay. 5. Dextrin It is commonly added in core sand for increasing collapsibility and baked strength of core

- 75. 1.Core blowing machines • The basic principle of core blowing machine comprises of filling the core sand into the core box by using compressed air. • The velocity of the compressed air is kept high to obtain a high velocity of core sand particles, thus ensuring their deposit in the remote corners the core box. • On entering the core sand with high kinetic energy, the shaping and ramming of core is carried out simultaneously in the core box. ii. The process of core making is basically mechanized using core blowing, core ramming and core drawing machines

- 76. 2. Core ramming machines • Cores can also be prepared by ramming core sands in the core boxes by machines based on the principles of squeezing, jolting and slinging. • Out of these three machines, jolting and slinging are more common for core making. 3. Core drawing machines • The core drawing is preferred when the core boxes have deep draws. After ramming sand in it, the core box is placed on a core plate supported on the machine bed. • A rapping action on the core box is produced by a vibrating vertical plate. • This rapping action helps in drawing off the core from the core box. • After rapping, the core box, the core is pulled up thus leaving the core on the core plate. • The drawn core is then baked further before its use in mold cavity to produce hollowness in the casting.

- 77. iii. Core baking • Once the cores are prepared, they will be baked in a baking ovens or furnaces. • The main purpose of baking is to drive away the moisture and hard en the binder, thereby giving strength to the core. Dielectric bakers • After baking of cores, they are smoothened using dextrin and water soluble binders.

- 78. Type of cores 1. GREEN SAND CORES • Green sand cores are made by green sand containing moist condition about 5% water and 15- 30 % clay. • It imparts very good permeability to core and thus avoids defects like shrinkage or voids in the casting. Green sand cores are not dried. • They are poured in green condition and are generally preferred for simple, small and medium castings. • Such cores possess less strength in comparison to dry sand cores and hence cannot be stored for longer period. 2. DRY SAND CORES • Dry sand cores are produced by drying the green sand cores to about 110°C. • These cores possess high strength rigidity and also good thermal stability. • These cores can be stored for long period and are more stable than green sand core. They are used for large castings. • They also produce good surface finish in comparison to green sand cores.

- 79. Core Box • Any kind of hollowness in form of holes and recesses in castings is obtained by the use of cores. • Cores are made by means of core boxes comprising of either single or in two parts. • Core boxes are generally made of wood or metal and are of several types. • The main types of core box are • half core box, • dump core box, • split core box, • strickle core box, • right and left hand core box and • loose piece core box.

- 80. 1. Half core box • This is the most common type of core box. The two identical halves of a symmetrical core prepared in the half core box. • Two halves of cores are pasted or cemented together after baking to form a complete core.

- 81. 2. Dump core box • Dump core box is similar in construction to half core box. • The cores produced do not require pasting, rather they are complete by themselves. • If the core produced is in the shape of a slab, then it is called as a slab box or a rectangular box. • A dump core-box is used to prepare complete core in it. Generally cylindrical and rectangular cores are prepared in these boxes.

- 82. 3. Split core box • Split core boxes are made in two parts. • They form the complete core by only one ramming. • The two parts of core boxes are held in position by means of clamps and their alignment is maintained by means of dowel pins and thus core is produced.

- 83. 4. Right and left hand core box • Some times the cores are not symmetrical about the center line. In such cases, right and left hand core boxes are used. The two halves of a core made in the same core box are not identical and they cannot be pasted together. 5. Strickle core box • This type of core box is used when a core with an irregular shape is desired. The required shape is achieved by striking oft the core sand from the top of the core box with a wooden piece, called as strickle board. The strickle board has the same contour as that of the required core. 6. Loose piece core box • Loose piece core boxes are highly suitable for making cores where provision for bosses, hubs etc. is required. In such cases, the loose pieces may be located by dowels, nails and dovetails etc. In certain cases, with the help of loose pieces, a single core box can be made to generate both halves of the right-left core.

- 84. Color codification for patterns and core boxes • There is no set or accepted standard for representing of various surfaces of pattern and core boxes by different colors. • The American practice is the most popular. • In this practice, the color identification is as follows. surfaces color Unfinished Surfaces black Machined surfaces red Core prints yellow Seats for loose pieces red stripes on yellow background Stop-offs black stripes on yellow base

- 85. CORE PRINTS • When a hole blind or through is needed in the casting, a core is placed in the mould cavity to produce the same. • The core has to be properly located or positioned in the mould cavity on pre-formed recesses or impressions in the sand. • To form these recesses or impressions for generating seat for placement of core, extra projections are added on the pattern surface at proper places. • These extra projections on the pattern (used for producing recesses in the mould for placement of cores at that location) are known as core prints.

- 86. • The core is placed in the metal casting after the removal of the pattern.

- 87. III. Gating System • In order for this mold to be functional to manufacture a casting, in addition to the impression of the part, the mold cavity will also need to include a gating system. • Sometimes the gating system will be cut by hand or in more adept manufacturing procedures the gating system will be incorporated into the pattern along with the part. • Basically a gating system functions during the metal casting operation to facilitate the flow of the molten material into the mold cavity.

- 91. Pouring Basin: • This is where the molten metal employed to manufacture the part enters the mold. The pouring basin should have a projection with a radius around it to reduce turbulence. Down Sprue: • From the pouring basin the molten metal for the casting travels through the down sprue. This should be tapered so its cross-section is reduced as it goes downward. Sprue Base: • The down sprue ends at the sprue base. It is here that the casting's inner cavity begins.

- 92. Gate • It is a small passage or channel being cut by gate cutter which connect runner with the mould cavity and through which molten metal flows to fill the mould cavity. • It feeds the liquid metal to the casting at the rate consistent with the rate of solidification. Choke • It is that part of the gating system which possesses smallest cross- section area. • In choked system, gate serves as a choke, but in free gating system sprue serves as a choke.

- 93. Chaplets • Chaplets are metal distance pieces inserted in a mould either to prevent shifting of mould or locate core surfaces. • The distances pieces in form of chaplets are made of parent metal of which the casting is. These are placed in mould cavity suitably which positions core and to give extra support to core and mould surfaces. • Its main objective is to impart good alignment of mould and core surfaces and to achieve directional solidification. • When the molten metal is poured in the mould cavity, the chaplet melts and fuses itself along with molten metal during solidification and thus forms a part of the cast material.

- 94. Chills • At that particular position, the special mould surface for fast extraction of heat is to be made. • The fast heat extracting metallic materials known as chills will be incorporated separately along with sand mould surface during molding. • Thus, the main function of chill is to provide a hard surface at a localized place in • the casting by way of special and fast solidification.

- 95. Runners: • Runners are passages that distribute the liquid metal to the different areas inside the mold. Main Cavity: • The impression of the actual part to be cast is often referred to as the main cavity. Vents: • Vents help to assist in the escape of gases that are expelled from the molten metal during the solidification phase of the metal casting process.

- 96. Risers: • Risers are reservoirs of molten material. They feed this material to sections of the mold to compensate for shrinkage as the casting solidifies. There are different classifications for risers. Top Risers: Risers that feed the metal casting from the top. Side Risers: Risers that feed the metal casting from the side. Blind Risers: Risers that are completely contained within the mold. Open Risers: Risers that are open at the top to the outside environment. Figure . Illustrates the difference between top risers and side risers.

- 97. Why Riser? • The shrinkage occurs in three stages, 1. When temperature of liquid metal drops from pouring to zero temperature 2. When the metal changes from liquid to solid state, and 3. When the temperature of solid phase drops from freezing to room temperature • The shrinkage for stage 3 is compensated by providing shrinkage allowance on pattern, while the shrinkage during stages 1 and 2 are compensated by providing risers. • The riser should solidify in the last otherwise liquid metal will start flowing from casting to riser. It should promote directional solidification. The shape, size and location of the risers are important considerations in casting design

- 98. IV. MOLDING SAND • The general sources of receiving molding sands are the beds of sea, rivers, lakes, granular elements of rocks, and deserts. • The common sources of molding sands available in India are as follows: • 1 Batala sand ( Punjab) • 2 Ganges sand (Uttar Pradesh) • 3 Oyaria sand (Bihar) • 4 Damodar and Barakar sands (Bengal- Bihar Border) • 5 Londha sand (Bombay) • 6 Gigatamannu sand (Andhra Pradesh) and • 7 Avadi and Veeriyambakam sand (Madras)

- 99. • Molding sands may be of two types namely natural or synthetic. • Natural molding sands contain sufficient binder. • Whereas synthetic molding sands are prepared artificially using basic sand molding constituents (silica sand in 88-92%, binder 6-12%, water or moisture content 3-6%) and other additives in proper proportion by weight with perfect mixing and mulling in suitable equipments.

- 100. CONSTITUENTS OF MOLDING SAND • The main constituents of molding sand involve silica sand, binder, moisture content and additives. 1. Silica sand • Silica sand in form of granular quarts is the main constituent of molding sand having enough refractoriness which can impart strength, stability and permeability to molding and core sand. • But along with silica small amounts of iron oxide, alumina, lime stone, magnesia, soda and potash are present as impurities. • The chemical composition of silica sand gives an idea of the impurities like lime, magnesia, alkalis etc. present. • The presence of excessive amounts of iron oxide, alkali oxides and lime can lower the fusion point to a considerable extent which is undesirable. • The silica sand can be specified according to the size (small, medium and large silica sand grain) and the shape (angular, sub-angular and rounded).

- 101. 2. Binder • In general, the binders can be either inorganic or organic substance. • The inorganic group includes clay sodium silicate and port land cement etc. In foundry shop, the clay acts as binder which may be Kaolonite, Ball Clay, Fire Clay, Limonite, Fuller’s earth and Bentonite. • Binders included in the organic group are dextrin, molasses, cereal binders, linseed oil and resins like phenol formaldehyde, urea formaldehyde etc. • Organic binders are mostly used for core making. • Among all the above binders, the bentonite variety of clay is the most common. • However, this clay alone can not develop bonds among sand grins without the presence of moisture in molding sand and core sand.

- 102. 3. Moisture • The amount of moisture content in the molding sand varies generally between 2 to 8 percent. • This amount is added to the mixture of clay and silica sand for developing bonds. • This is the amount of water required to fill the pores between the particles of clay without separating them. • This amount of water is held rigidly by the clay and is mainly responsible for developing the strength in the sand. • The effect of clay and water decreases permeability with increasing clay and moisture content. • The green compressive strength first increases with the increase in clay content, but after a certain value, it starts decreasing.

- 103. 4 Additives • Additives are the materials generally added to the molding and core sand mixture to develop some special property in the sand. 4.1 Coal dust • Coal dust is added mainly for producing a reducing atmosphere during casting. • This reducing atmosphere results in any oxygen in the poles becoming chemically bound so that it cannot oxidize the metal. • It is usually added in the molding sands for making molds for production of grey iron and malleable cast iron castings.

- 104. 4.2 Corn flour • It belongs to the starch family of carbohydrates and is used to increase the collapsibility of the molding and core sand. • It is completely volatilized by heat in the mould, thereby leaving space between the sand grains. • This allows free movement of sand grains, which finally gives rise to mould wall movement and decreases the mold expansion and hence defects in castings. • Corn sand if added to molding sand and core sand improves significantly strength of the mold and core.

- 105. 4.3 Dextrin • Dextrin belongs to starch family of carbohydrates that behaves also in a manner similar to that of the corn flour. It increases dry strength of the molds. 4.4 Sea coal • Sea coal is the fine powdered bituminous coal which positions its place among the pores of the silica sand grains in molding sand and core sand. • When heated, it changes to coke which fills the pores and is unaffected by water: Because to this, the sand grains become restricted and cannot move into a dense packing pattern. • Thus, sea coal reduces the mould wall movement and the permeability in mold and core sand and hence makes the mold and core surface clean and smooth.

- 106. 4.5 Pitch • It is distilled form of soft coal. It can be added from 0.02 % to 2% in mold and core sand. • It enhances hot strengths, surface finish on mold surfaces and behaves exactly in a manner similar to that of sea coal. 4.6 Wood flour • This is a fibrous material mixed with a granular material like sand; its relatively long thin fibers prevent the sand grains from making contact with one another. • It can be added from 0.05 % to 2% in mold and core sand. • It also increases collapsibility of both of mold and core. 4.7 Silica flour • It is called as pulverized silica and it can be easily added up to 3% which increases the hot strength and finish on the surfaces of the molds and cores. It also reduces metal penetration in the walls of the molds and cores.

- 107. Moulding Sand/ Foundry Sand • Moulding Sands: • Most sand casting operations use Silica sand (SiO2). Usually sand used to manufacture a mould for the casting process is held together by a mixture of water and clay. A typical mixture by volume could be 89% sand, 4% water, 7% clay.

- 108. Types Of Moulding Sands • Classification of moulding sands: 1. Green sand: • It is sand used in the wet condition for making the mould. It is mixture of silica sand with 15-25 per cent clay and 6-8 per cent water • As explained earlier green sand moulds are not dried and metal is poured in them in the wet condition • Being damp the sand can be easily worked with hand to give it any desired shape This sand is used for producing small to medium sized moulds which are not very complex

- 109. 2. Dry sand: • Dry sand is the green sand that has been dried or baked after preparing the mould. • Drying sand gives strength to the mould so that it can be used for larger castings

- 110. • 3. Loam sand: • Loam sand is sand containing up to 50 % clay which has been worked to the consistency of builder mortar. • This sand is used for loam sand moulds for making very heavy castings usually with the help of sweeps and skeleton patterns.

- 111. 4. Parting sand: • This sand is used during making of the mould to ensure that green sand does not stick to the pattern and the cope and drug parts can be easily separated for removing the pattern without causing any damage to the mould. • Parting sand consists of fine grained clay free dried silica sand, sea sand or burnt sand with some parting compounds. • The parting compounds used include charcoal, ground bone and limestone, groundnut shells, talc and calcium phosphate.

- 112. 5. Facing sand: • Facing sand is the sand which covers the pattern all around it. The remaining box is filled with ordinary floor sand. • Facing sand forms the face of the mould and comes in direct contact with the molten metal when it is poured. • High strength and refractoriness are required for this sand. • It is made of silica sand and clay without the addition of any used sand. • Graphite, mollases, plumbago etc. may be added to the facing sand. Thickness of the sand layer varies from 20 to 30 mm.

- 113. 6. Backing sand: • Backing sand is the bulk of the sand used to back up the facing sand and to fill up the volume of the flask. • It consists mainly of old, repeatedly used moulding sand which is generally black in colour due to addition of coal dust and burning on contact with hot metal. • Because of the colour backing sand is also sometimes called black sand. • The main purpose for the use of backing sand is to reduce the cost of moulding.

- 114. 7. System sand: • This is the sand used in mechanized foundries for filling the entire flask. • No separate facing sand in used in a mechanized foundry. • Sand, cleaned and reactivated by the addition of water and binders is used to fill the flask. Because of the absence of any fresh sand, system sand must have more strength, permeability and refractoriness compared to backing sand.

- 115. 8. Core sand: • Core sand is the sand used for making cores. This is silica sand mixed with core oil. That is why it is also called oil sand. • The core oil consists of linseed oil, resin, light mineral oil with some binders. • For larger cores, sometimes pitch or flour and water may also be used to save on cost.

- 116. Important characteristics of sand are: • 1. These sands are refractory in nature and can withstand temperature of the metal being poured, without fusing. • 2. The moulding sands do not chemically react or combine with molten metal and can therefore be used repeatedly. • 3. The sands have a high degree of permeability and thus allow the gases formed during pouring to escape. • 4. The strength, permeability and hardness of the sand mix can be varied by changing the structure or ingredients of sand.

- 117. Properties of moulding sands: 1. Strength 2. Permeability 3. Grain Size and Shape 4. Thermal stability 5. Refractoriness 6. Flow ability 7. Sand Texture 8. Collapsibility 9. Adhesiveness 10. Reusability 11. Easy of preparation and control 12. Conductivity

- 118. Strength: • The sand should have adequate strength in its green, dry and hot states • Green strength is the strength of sand in the wet state and is required for making possible to prepare and handle the mould. • If the metal is poured into a green mould the sand adjacent to the metal dries and in the dry state it should have strength to resist erosion and the pressure of metal. • The strength of the sand that has been dried or basked is called dry strength. • At the time of pouring the molten metal the mould must be able to withstand flow and pressure of the metal at high temperature otherwise the mould may enlarge, crack, get washed or break

- 119. Strength of the moulding sand depends on: • 1. Grain size and shape • 2. Moisture content • 3. Density of sand after ramming • The strength of the mould increases with a decrease of grain size and an increase of clay content and density after ramming. • The strength also goes down if moisture content is higher than an optimum value.

- 120. 2. Permeability: • The moulding sand must be sufficiently porous to allow the dissolved gases, which are evolved when the metal freezes or moisture present or generated within the moulds to be removed freely when the moulds are poured. • This property of sand is called porosity or permeability.

- 121. 3. Grain size and shape: • ·The size and shape of the grains in the sand determine the application in various types of foundry. These are three different sizes of sand grains. • 1. Fine • 2. Medium • 3. Coarse • Fine sand is used for small and intricate castings. • Medium sand is used for benchmark and light floor works. • If the size of casting is larger coarse sand is used • Sand having fine, rounded grains can be closely packed and forms a smooth surface. Although fine-grained sand enhances mould strength.

- 122. 4. Thermal stability: • The sand adjacent to the metal is suddenly heated and undergoes expansion. • If the mould wall is not dimensionally stable under rapid heating, cracks, buckling and flacking off sand may occur.

- 123. 5. Refractoriness: • Refractoriness is the property of withstanding the high temperature condition moulding sand with low refractoriness may burn on to the casting. • It is the ability of the moulding material to resist the temperature of the liquid metal to be poured so that it does not get fused with the metal. • The refractoriness of the Silica sand is highest.

- 124. 6. Flowability: • Flowability or plasticity is the property of the sand to respond to the moulding process so that when rammed it will flow all around the pattern and take the desired mould shape. High flowability of sand is desirable for the sand to get compacted to a uniform density and to get good impression of the pattern in the mould. Flowability is also very important in machine moulding ·Flowability of sand increases as clay and water content are increased.

- 125. 7. Sand texture: • As mentioned earlier the texture of sand is defined by its grain size and grain size distribution. • The texture chosen for an application should allow the required porosity, provide enough strength and produce the desired surface finish on the casting. 8. Collapsibility: • The moulding sand should collapse during the contraction of the solidified casting it does not provide any resistance, which may result in cracks in the castings. • Besides these specific properties the moulding material should be cheap, reusable and should have good thermal conductivity

- 126. 9. Adhesiveness & Cohesiveness: • The sand particles must be capable of adhering to another body, then only the sand should be easily attach itself with the sides of the moulding box and give easy of lifting and turning the box when filled with the stand. Cohesiveness

- 127. 10. Reusability: • Since large quantities of sand are used in a foundry it is very important that the sand be reusable otherwise apart from cost it will create disposal problems 11. Easy of preparation and control: • Sand should lend itself to easy preparation and control by mechanical equipment 12. Conductivity: • Sand should have enough conductivity to permit removal of heat from the castings.

- 128. • 1. Moisture content test • 2. Clay content test • 3. Grain fitness test • 4. Permeability test • 5. Strength test • 6. Refractoriness test • 7. Mould hardness test 1. Moisture content Test 2. Clay content Test 3. Chemical composition of sand 4. Grain shape and surface texture of sand. 5. Grain size distribution of sand 6. Specific surface of sand grains 7. Water absorption capacity of sand 8. Refractoriness of sand 9. Strength Test 10. Permeability Test 11. Flowability Test 12. Shatter index Test 13. Mould hardness Test. SAND TESTING METHODS AND SAND TESTING EQUIPMENT

- 129. 1. Moisture content test: • Moisture is the property of the moulding sand it is defined as the amount of water present in the moulding sand. Low moisture content in the moulding sand does not develop strength properties. High moisture content decreases permeability.

- 130. Procedures are: • 1. 20 to 50 gms of prepared sand is placed in the pan and is heated by an infrared heater bulb for 2 to 3 minutes. • 2. The moisture in the moulding sand is thus evaporated. • 3. Moulding sand is taken out of the pan and reweighed. • 4. The percentage of moisture can be calculated from the difference in the weights, of the original moist and the consequently dried sand samples.

- 131. • Percentage of moisture content = (W1-W2)/(W1) % Where, W1-Weight of the sand before drying, W2-Weight of the sand after drying.

- 132. 2. Clay content test • Clay influences strength, permeability and other moulding properties. It is responsible for bonding sand particles together.

- 133. Procedures are: • 1. Small quantity of prepared moulding sand was dried • 2. Separate 50 gms of dry moulding sand and transfer wash bottle. • 3. Add 475cc of distilled water + 25cc of a 3% NaOH. • 4. Agitate this mixture about 10 minutes with the help of sand stirrer. • 5. Fill the wash bottle with water up to the marker. • 6. After the sand etc., has settled for about 10 minutes, Siphon out the water from the wash bottle. • 7. Dry the settled down sand. • 8. The clay content can be determined from the difference in weights of the initial and final sand samples. Percentage of clay content = (W1-W2)/(W1) * 100 Where, • W1-Weight of the sand before drying, • W2-Weight of the sand after drying.

- 134. 3. Grain fitness test: • The grain size, distribution, grain fitness are determined with the help of the fitness testing of moulding sands. • The apparatus consists of a number of standard sieves mounted one above the other, on a power driven shaker. • The shaker vibrates the sieves and the sand placed on the top sieve gets screened and collects on different sieves depending upon the various sizes of grains present in the moulding sand. • The top sieve is coarsest and the bottom-most sieve is the finest of all the sieves. In between sieve are placed in order of fineness from top to bottom.

- 135. • Procedures are: • 1. Sample of dry sand (clay removed sand) placed in the upper sieve • 2. Sand is vibrated for definite period • 3. The amount of same retained on each sieve is weighted. • 4. Percentage distribution of grain is computed.

- 136. 3. Permeability test: • The quantity of air that will pass through a standard specimen of the sand at a particular pressure condition is called the permeability of the sand. • Following are the major parts of the permeability test equipment: • 1. An inverted bell jar, which floats in a water. • 2. Specimen tube, for the purpose of hold the equipment • 3. A manometer (measure the air pressure)

- 139. Steps involved are: • 1. The air (2000cc volume) held in the bell jar is forced to pass through the sand specimen. • 2. At this time air entering the specimen equal to the air escaped through the specimen • 3. Take the pressure reading in the manometer. • 4. Note the time required for 2000cc of air to pass the sand • 5. Calculate the permeability number • 6. Permeability number (N) = ((V x H) / (A x P x T)) • Where, • V-Volume of air (cc) • H-Height of the specimen (mm) • A-Area of the specimen (mm2) • P-Air pressure (gm / cm2) • T-Time taken by the air to pass through the sand (seconds)

- 140. Strength test: • Measurements of strength of moulding sands can be carried out on the universal sand strength testing machine. The strength can be measured in compression, shear and tension. • The sands that could be tested are green sand, dry sand or core sand. The compression and shear test involve the standard cylindrical specimen that was used for the permeability test. Steps involved are: 1. Specimen is held between the grips 2. Apply the hydraulic pressure by rotating the hand wheel 3. Taking the deformation use of the indicators.

- 141. Refractoriness test • The refractoriness is used to measure the ability of the sand to withstand the higher temperature. Steps involved are: 1. Prepare a cylindrical specimen of sand 2. Heating the specimen at 1500 C for 2 hours 3. Observe the changes in dimension and appearance 4. If the sand is good, it retains specimen share and shows very little expansion. If the sand is poor, specimen will shrink and distort.

- 142. Mould hardness test • Hardness of the mould surface can be tested with the help of an “indentation hardness tester”. It consists of indicator, spring loaded spherical indenter. The spherical indenter is penetrates into the mould surface at the time of testing. The depth of penetration w.r.t. the flat reference surface of the tester. Mould hardness number = ((P) / (D – (D2-d2)) Where, P- Applied Force (N) D- Diameter of the indenter (mm) d- Diameter of the indentation (mm)

- 143. Advantages and disadvantages of sand casting • Advantages of sand casting • Low cost of mold materials and equipment. • Large casting dimensions may be obtained. • Wide variety of metals and alloys (ferrous and non-ferrous) may be cast (including high melting point metals). • Disadvantages of sand casting • Rough surface. • Poor dimensional accuracy. • High machining tolerances. • Coarse Grain structure. • Limited wall thickness: not higher than 0.1”-0.2” (2.5-5 mm).

- 144. Advantages: Can produce very large parts Can form complex shapes Many material options Low tooling and equipment cost Scrap can be recycled Short lead time possible Disadvantages: Poor material strength High porosity possible Poor surface finish and tolerance Seondary machining often required Low production rate High labor cost Applications: Engine blocks and manifolds, machine bases, gears, pulleys, crankshafts, connecting rods, and propellers, cylinder heads, and transmission cases

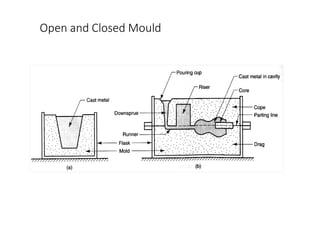

- 145. V. The Mold A typical mold is shown in figure •The pattern is placed in the mold and the mold material is packed around it. • The mold contains two parts, the drag (bottom), and the cope (top). •The parting line between the cope and drag allows for the mold to be opened and the pattern to be removed once the impression has been made. •For some moulds additional intermediate boxes called “Cheeks” may be required.

- 146. Mold (used in us ) / Mould ( used in Britain et al.) • A mold is formed into the geometric shape of a desired part. • Molten metal is then poured into the mold, the mold holds this material in shape as it solidifies. A metal casting is created. • Molds can be classified as either open or closed. • A open mold is a container, like a cup, that has only the shape of the desired part. • The molten material is poured directly into the mold cavity which is exposed to the open environment.

- 147. Open and Closed Mould

- 148. • Two main branches of methods can be distinguished by the basic nature of the mold they employ. • There is expendable mold casting and permanent mold casting. •Expendable Mold Can produce one metal casting only •Made of sand, plaster, or other similar material. Binders used to help material hold its form. •Mold that metal solidifies in must be destroyed to remove casting •More intricate geometries are possible for casting •Permanent Mold Can manufacture many metal castings •Usually made of metal or sometimes a refractory ceramic •Mold has sections that can open or close permitting removal of the casting •Need to open mold limits part shapes

- 149. Mould Making • Making a mould properly means a casting half done. • A sand mould is formed by packing sand into each half of the mould. • The sand is packed around the pattern, which is a replica of the external shape of the casting. • When the pattern is removed, the cavity that will form the casting remains. • Any internal features of the casting that cannot be formed by the pattern are formed by separate cores which are made of sand prior to the formation of the mould.

- 150. Characteristics of Mold • 1. The mould should be strong enough to resist erosion by the flow of the metal and to take the weight of the metal. • 2. The mould material should not produce too much of gases as the gases may enter the mould cavity and get entrapped with metal or violently boil out the metal. • 3. The mould should be made in such a way that gases generated are vented out of the mould. • 4. The mould should be refractory enough to withstand the high temperature of liquid metal. • 5. The cores should be collapsible enough to permit contraction of the metal after solidification. • 6. Flow should be laminar i.e. smooth flow • 7. There should be a proper riser system in the mould to provide sufficient extra metal to account for the liquid and solidification shrinkage. • 8. The mould material and moulding process should be such that cleaning of castings is facilitated.

- 151. Molding Tools 1.Mallet: • It is a mallet to loosen the pattern in the mould by striking slightly, so that it can be withdrawn without damaging the mould

- 152. • 2. Gate cutter: • It is a metal piece to the gate the opening that connects tee sprue with the mould cavity. (sleek)

- 153. 3. Rapping plate (or) Lifting plate: • It is used to facilitate shaking and lifting large pattern from the mold.

- 154. 4. Spirit level: • It is used to check that the sand bed, moulding box or table of moulding machine is horizontal.

- 155. • 5. Clamps: • Clamps are used to hold the cope and drag of the complete mould together so that the cope may not float or rise when the molten metal is poured into the mould.

- 156. 6. Moulding box: • Sand moulds are prepared specially constructed boxes called the moulding boxes or flasks. The function and construction of a molding box have already been described. Moulding flasks

- 157. 7.Shovel: • It is just like rectangular pan fitted with a handle. It is used for mixing the moulding sand and for moving it from one place to the other.

- 158. 8. Riddle: • It is used for removing foreign materials like nails, shot metal splinters of wood etc from the moulding sand.

- 159. 9. Rammer: • It is a wooden tool used for ramming or packing the sand in the mould. Rammers are made in different shapes.

- 160. 10. Strike-off bar: • It is a cast iron or wrought iron bar with a true straight edge. It is used to remove the surplus sand from the mould after the ramming has been completed.

- 161. 11. Vent wire: • It is a mild steel wire used for making vents or openings in the mould.

- 162. 12. Lifter: • It is a metal piece used for patching deep section of the mould and removing loose sand from pockets of the mould. 13. Slick: • Different types of slicks are used for repairing and finishing moulds. 14. Trowel: It contains of a flat and thick metal sheet with upwards projected handle at one end. It is used for making joints and finishing flat surface of a mould. 15. Swab: It is made of flax or hemp. It is used for applying water to the mould around the edge of the pattern.

- 163. Moulding Machines • Moulding processes may be classified as hand moulding or machine moulding according to whether the mould is prepared by hand tools or with the aid of some moulding machine. • Hand moulding is generally found to be economical when the castings are required in a small number. • The major functions of molding machines involves ramming of molding sand, rolling over or inverting the mould, rapping the pattern and withdrawing the pattern from the mould. • Most of the molding machines perform a combination of two or more of functions.

- 164. Types of Moulding machine: 1. Hand Operated molding machine a. Pattern draw type b. Pattern draw and Squeeze type c. Pin Lift type machine d. Roll Over type machine 2. Power operated Molding Machine a. Squeeze machine b. Jolt machine c. Jolt squeeze machine d. Jolt squeeze roll over pattern draw machine e. Sand Slinger

- 165. Squeezer •1.table 2. pattern 3. flask. 4.Sand frame 5. platen 6. squeezer head. 7. frame

- 166. Squeezer •Molding sand squeezed between machine table and overhead squeeze board •Pneumatic or hydraulic •Top squeezing •Bottom squeezing •Limitation- sand is packed more densely on top of mould •Density deceases uniformly with depth •At parting plane density is lowest •Restricted to molds up to 150 mm depth

- 167. Jolt machine •1.table.3.patern and flask.8. plunger.9 hose.10. channel. •11. opening •12. guide cylinder •13. springs

- 169. •Flask is filled with moulding sand •Table supporting flask is raised and dropped in succession •Due to sudden change in inertia – sand gets packed and rammed •Action of raising and sudden dropping – jolt •Drawback – sand is rammed hardest at parting plane sand remains les dense at tops •Preferred fro horizontal surfaces

- 170. Jolt squeeze machine • Jolting action to consolodate sand on face of pattern • Squeezing – desired density throughout mass of sand • Mold with maximum hardness,unform ramming

- 171. Sand slinger •Overhead impellar head 1. housing. 2. blade 3. opening 4. outlet •Conveyor buckets Slinging – consolidation and ramming due to impact of sand which falls at very high velocity Rate – 500 to 2000kg per min. Mold of adequate strength , hardness

- 173. 5. Pattern draw machines • These machines enable easy withdrawal of patterns from the molds. • They can be of the kind of stripping plate type and pin lift or push off type. • The pattern is drawn through the stripping plate either by raising the stripping plate and the mould up and keeping the pattern stationary or by keeping the stripping plate and mould stationary and moving the pattern supporting ram downwards along with the pattern and pattern plate. • A suitable mechanism can be incorporated in the machine for these movements.

- 174. •6. stripping pins •1.pattern, 3. pattern plate, table 5, molding box 2 •4. stripping plate between patern plate and flask

- 175. 6 Roll-over machine • The pattern is mounted on a plate which is secured to the roll-over frame. • The platen of the machine can be moved up and down. • For preparation of the mould, the roll-over frame is clamped in position with the pattern facing upward. • Molding box is placed over the pattern plate and clamped properly. • Molding sand is then filled in it and rammed by hand and the extra molding sand is struck off and molding board placed over the box and clamped to it.

- 176. •Turn over •Flask together with work table rotates 1800 and pin 6 lifts table with pattern •Pins 6

- 177. Foundry Safety Hand Pouring Equipment

- 178. Ladles • Moving molten metal from melting furnace to mold is sometimes done using crucibles • More often, transfer is accomplished by ladles Figure 11.21 Two common types of ladles: (a) crane ladle, and (b) two-man ladle. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e

- 179. The casting process ( Special Casting process) 1 - Expendable mold casting (sand, plastic, shell, and investment (lost-wax technique) mouldings.) 2 - Nonexpendable mold casting (permanent, die, centrifugal, and continuous casting). Classification of die casting: (a)Gravity Die Casting (also called permanent mould process) (b)Pressure Die Casting

- 181. Precision or investment casting (lost wax casting) • Investment (lost wax) casting is a method of precision casting complex near-net-shape details using replication of wax patterns. • Precision or investment casting employed techniques that enable very smooth highly accurate castings to be made from both ferrous and non-ferrous alloys • The process is useful in casting unmachinable alloys and radioactive metals. • In investment casting, the pattern is made of wax, which melts after making the mold to produce the mold cavity.

- 182. Ceramic particles, wet plaster Investment, up to 3-5 mm

- 183. Ceramic slurry materials Mullite: Al2O3 44-48%, SiO2 47-51%, Fe2O3 max. 1%, TiO2 max. 1%. Zircon flour. Binders: Colloidal Silica SiO2 25-45%, Na2O max.1% in distilled water; sodium silicate NaO*nSiO2*mH2O; ethyl silicate Si(OC2H5)4.

- 185. Investment casting process • The investment casting process uses expendable patterns made of investment casting wax. • The wax patterns are commonly prepared by injection molding technology which involves injection of wax into a prefabricated die having the same geometry of the cavity as the desired cast part. • The wax patterns are then attached to a gating system (a set of channels through which a molten metal flows to the mold cavity). • The next stage is the shell building - the wax assembly is immersed into refractory ceramic slurry of hardening mixtures followed by drying. This operation is repeatedly carried out resulting in formation of a solid ceramic shell of 1/4” -3/8” (6mm – 9mm) thick. • The next stage is dewax. At this stage the assembly is heated in an autoclave where the most of the wax is melted out. This operation is followed by burning out the residual wax in a furnace. • The mold is then preheated to 1830°F (1000°C). Now the mold is ready for filling with a molten metal. • Casting stage is conventional operation involving pouring a molten metal into the shell through the gating system. • After the metal has solidified and cooled to a desired temperature, the shell is broken and the castings are cut away from the gates and sprue. • The last stage is finishing carried out by sandblasting or machining.

- 186. Advantages and disadvantages of investment casting Advantages: • Excellent surface finish. • Tight dimensional tolerances. • Complex and intricate shapes may be produced. • Capability to cast thin walls. • Wide variety of metals and alloys (ferrous and non-ferrous) may be cast. • Draft is not required in the molds design. • Low material waste. Disadvantages: • Individual pattern is required for each casting. • Limited casting dimensions. • Relatively high cost (tooling cost, labor cost).

- 187. Turbine blades Applications: Turbine blades, armament parts, pipe fittings, lock parts, handtools, art pieces, jewelry, dental fixtures, automotive, aircraft, and military industries.

- 188. Die Casting A permanent mold casting process in which molten metal is injected into mold cavity under high pressure up to 30,000 psi (200 MPa). • Pressure is maintained during solidification, then mold is opened and part is removed • Molds in this casting operation are called dies; hence the name die casting • Use of high pressure to force metal into die cavity is what distinguishes this from other permanent mold processes

- 189. Die Casting Machines • Designed to hold and accurately close two mold halves and keep them closed while liquid metal is forced into cavity • Two main types: 1. Hot-chamber machine 2. Cold-chamber machine (1) Cold-chamber Die Casting: • Material to be cast is molten outside the machine. • Used for materials having high melting temperature Tm> 550°C, i.e. brass, aluminum, and magnesium. (2) Hot-chamber Die Casting: • Materials to be cast is molten inside the machine. • Used for materials having low melting temperature Tm< 550°C, i.e. zinc, tin, and lead.

- 190. Hot-Chamber Die Casting Metal is melted in a container, and a piston injects liquid metal under high pressure into the die • High production rates - 500 parts per hour not uncommon • Applications limited to low melting - point metals that do not chemically attack plunger and other mechanical components • Casting metals: zinc, tin, lead, and magnesium

- 192. Hot-Chamber Die Casting Figure. Cycle in hot-chamber casting: (1) with die closed and plunger withdrawn, molten metal flows into the chamber (2) plunger forces metal in chamber to flow into die, maintaining pressure during cooling and solidification.

- 193. Cold-Chamber Die Casting Machine • Molten metal is poured into unheated chamber from external melting container, and a piston injects metal under high pressure into die cavity • High production but not usually as fast as hot-chamber machines because of pouring step • Casting metals: aluminum, brass, and magnesium alloys • Advantages of cold-chamber process favor its use on low melting - point alloys (zinc, tin, lead)

- 195. Cold-Chamber Die Casting Figure 11.14 Cycle in cold-chamber casting: (1) with die closed and ram withdrawn, molten metal is poured into the chamber

- 196. Molds for Die Casting • Usually made of tool steel, mold steel, or maraging steel • Tungsten and molybdenum (good refractory qualities) used to die cast steel and cast iron • Ejector pins required to remove part from die when it opens • Lubricants must be sprayed into cavities to prevent sticking Common metals for die casting. Alloys of aluminum Zinc Magnesium Lead Copper Tin

- 197. Die casting Advantages: Can produce large parts Can form complex shapes High strength parts Very good surface finish and accuracy High production rate Low labor cost Scrap can be recycled Disadvantages: Trimming is required High tooling and equipment cost Limited die life Long lead time Applications: Engine components, pump components, automobile components, household appliances, railway and aircraft fittings, bath room hardware, business machines, locks, pullers

- 199. Centrifugal casting • Centrifugal casting is a method of casting parts having axial symmetry. The method involves pouring molten metal into a cylindrical mold spinning about its axis of symmetry. • The mold is kept rotating till the metal has solidified. • • As the mold material steels, Cast irons, Graphite or sand may be used. • The rotation speed of centrifugal mold is commonly about 1000 RPM (may vary from 250 RPM to 3600 RPM).

- 200. Centrifugal casting is carried out as follows • The mold wall is coated by a refractory ceramic coating (applying ceramic slurry, spinning, drying and baking). • Starting rotation of the mold at a predetermined speed. • Pouring a molten metal directly into the mold (no gating system is employed). • The mold is stopped after the casting has solidified. • Extraction of the casting from the mold. The centrifugal group includes: A. True centrifugal casting B. Semi-centrifugal casting C. Centrifuge casting

- 202. A. True Centrifugal Casting Fig. Setup for true centrifugal casting.

- 203. 2.03.2021 CHAPTER3 SPECIALCASTINGPROCESSES 203 Non-metallic and slag inclusions and gas bubbles being less dense than the melt are forced to the inner surface of the casting by the centrifugal forces. This impure zone is then removed by machining. used for manufacturing of iron pipes, bushings, wheels, pulleys bi-metal steel-bronze bearings and other parts possessing axial symmetry.

- 204. B. Semi-centrifugal Casting Centrifugal force is used to produce solid castings rather than tubular parts • Molds are designed with risers at center to supply feed metal • Density of metal in final casting is greater in outer sections than at center of rotation • Often used on parts in which center of casting is machined away, thus eliminating the portion where quality is lowest • The process is suitable for large axis-symmetrical castings like gear blanks, fly wheels and track wheels.

- 206. C. Centrifuge Casting Mold is designed with part cavities located away from axis of rotation, so that molten metal poured into mold is distributed to these cavities by centrifugal force • Used for smaller parts • Radial symmetry of part is not required as in other centrifugal casting methods

- 207. The process is used on parts in which the center of the casting is machined away, such as wheels and pulleys. Centrifuge Casting

- 208. Continuous casting • Continuous casting is a casting method, in which the steps of pouring, solidification and withdrawal (extraction) of the casting from an open end mold are carried out continuously. • Cross-sectional dimensions of a continuous casting are constant along the casting length and they are determined only by the dimensions of the mold cavity. • The length of a continuous casting is limited by the life time of the mold. • Continuous casting technology is used for both ferrous and non-ferrous alloys. Depending on the mold position (vertical or horizontal) continuous casting machines may be vertical or horizontal: • Vertical continuous casting • Horizontal continuous casting

- 209. Vertical continuous casting • Molten metal is continuously supplied from the ladle to the intermediate ladle (tundish) from which it is continuously poured into the mold at a controllable rate keeping the melt level at a constant position. • The water-cooled copper mold (primary cooling zone) extracts the heat of the metal causing its solidification. The mold oscillates in order to prevent sticking with the casting. • When the casting goes out from the mold it is cooled in the secondary cooling zone by water (or water with air) sprayed on the casting surface. • The casting is continuously extracted from the mold by the withdrawal unit followed by a cut-off unit. • Then a molten metal is poured into the mold where it solidifies and grips the end of the dummy bar.

- 211. Horizontal continuous casting • Horizontal continuous casting machine is generally used for casting non-ferrous alloys. • Horizontal continuous casting in stationary mold with graphite water-cooled molds, Twin-roll caster and Twin-belt caster are most popular methods of this type. • Due to the water cooling (primary and secondary) solidification rate provided by continuous casting is higher than in other casting methods therefore continuous castings have more uniform and finer grain structure and enhanced mechanical properties.

- 215. Comparison of Casting Processes

- 217. Additional Steps After Solidification • Trimming • Removing the core • Surface cleaning • Inspection • Repair, if required • Heat treatment

- 218. Trimming Removal of sprues, runners, risers, parting-line flash, fins, chaplets, and any other excess metal from the cast part • For brittle casting alloys and when cross sections are relatively small, appendages can be broken off • Otherwise, hammering, shearing, hack-sawing, band-sawing, abrasive wheel cutting, or various torch cutting methods are used

- 219. Removing the Core If cores have been used, they must be removed • Most cores are bonded, and they often fall out of casting as the binder deteriorates • In some cases, they are removed by shaking casting, either manually or mechanically • In rare cases, cores are removed by chemically dissolving bonding agent • Solid cores must be hammered or pressed out

- 220. Cleaning and Finishing 1. Casting is taken out of the mould by shaking and the Moulding sand is recycled often with suitable additions. 2. The remaining sand, some of which may be embedded in the casting, is removed by means of Shot blasting. 3. The excess material in the form of sprue, runners, gates etc., along with the flashes formed due to flow of molten metal into the gaps is broken manually in case of brittle casting or removed by sawing and grinding in case of ductile grinding. 4. The entire casting is then cleaned by either shot blasting or chemical pickling. 5. Sometimes castings are heat treated to achieve better mechanical properties.

- 221. Surface Cleaning Removal of sand from casting surface and otherwise enhancing appearance of surface • Cleaning methods: tumbling, air-blasting with coarse sand grit or metal shot, wire brushing, buffing, and chemical pickling • Surface cleaning is most important for sand casting • In many permanent mold processes, this step can be avoided • Defects are possible in casting, and inspection is needed to detect their presence

- 222. Heat Treatment • Castings are often heat treated to enhance properties • Reasons for heat treating a casting: • For subsequent processing operations such as machining • To bring out the desired properties for the application of the part in service

- 223. Casting Quality • There are numerous opportunities for things to go wrong in a casting operation, resulting in quality defects in the product • The defects can be classified as follows: • General defects common to all casting processes • Defects related to sand casting process

- 224. Casting defects Surface Defect Internal Defect Visible defects Blow Scar Blister Drop Scab Penetration Buckle Blow holes Porosity Pin holes Inclusions Dross Wash Rat tail Swell Misrun Cold shut Hot tear Shrinkage/Shift

- 225. A casting that has solidified before completely filling mold cavity Casting Defects: Misrun

- 226. Two portions of metal flow together but there is a lack of fusion due to premature freezing Casting Defects: Cold Shut

- 227. Metal splatters during pouring and solid globules form and become entrapped in casting Casting Defects: Cold Shot

- 228. Depression in surface or internal void caused by solidification shrinkage that restricts amount of molten metal available in last region to freeze Casting Defects: Shrinkage Cavity

- 229. Balloon-shaped gas cavity caused by release of mold gases during pouring Sand Casting Defects: Sand Blow/ blow holes

- 230. Blow holes are large spherical shaped gas bubbles, while porosity indicates a large number of uniformly distributed tiny holes. Pin holes are tiny blow holes appearing just below the casting surface. Sand Casting Defects: Pin Holes and porosity

- 231. • Hot tears are ragged irregular internal or external cracks occurring immediately after the metal have solidified. • Hot tears occur on poorly designed castings having abrupt section changes or having no proper fillets or corner radii. Wrongly placed chills. Sand Casting Defects: Hot tears

- 232. When fluidity of liquid metal is high, it may penetrate into sand mold or core, causing casting surface to consist of a mixture of sand grains and metal Sand Casting Defects: Penetration

- 233. A step in cast product at parting line caused by sidewise relative displacement of cope and drag Sand Casting Defects: Mold Shift/ Mismatch

- 234. Sand Casting Defects: Sand Inclusions Inclusions are the non-metallic particles in the metal matrix, Lighter impurities appearing the casting surface are dross.

- 235. • Scabs are rough, irregular projections on surface of castings containing embedded sand. • Scabs occur when a portion on the face of mould or core lifts and metal flows underneath in a thin layer. Sand Casting Defects: Scabs

- 236. • Scar is shallow blow generally occurring on a flat surface. A scar covered with a thin layer of metal is called blister. Sand Casting Defects: Scar and Blister

- 237. Sand Casting Defects: Rat tails Rat tail is a long, shallow, angular depression caused by expansion of the sand

- 238. • Drop is an irregularly-shaped projection on the cope surface caused by dropping of sand. Sand Casting Defects: Drop

- 239. • Wash is a low projection near the gate caused by erosion of sand by the flowing metal. Swell is the deformation of vertical mould surface due to hydrostatic pressure caused by moisture in the sand. Sand Casting Defects: Wash and swell

- 241. Classification of casting defects Casting defects Surface Defect Internal Defect Visible defects Blow Scar Blister Drop Scab Penetration Buckle Blow holes Porosity Pin holes Inclusions Dross Wash Rat tail Swell Misrun Cold shut Hot tear Shrinkage/Shift

- 242. Surface Defects • These are due to poor design and quality of sand molds and general cause is poor ramming • Blow is relatively large cavity produced by gases which displace molten metal from convex surface. Scar is shallow blow generally occurring on a flat surface. A scar covered with a thin layer of metal is called blister. These are due to improper permeability or venting. Sometimes excessive gas forming constituents in moulding sand

- 243. • Drop is an irregularly-shaped projection on the cope surface caused by dropping of sand. • A scab when an up heaved sand gets separated from the mould surface and the molten metal flows between the displaced sand and the mold. • Penetration occurs when the molten metal flows between the sand particles in the mould. These defects are due to inadequate strength of the mold and high temperature of the molten metal adds on it. • Buckle is a vee-shaped depression on the surface of a flat casting caused by expansion of a thin layer of sand at the mould face. A proper amount of volatile additives in moulding material could eliminate this defect by providing room for expansion.

- 244. Internal Defects • The internal defects found in the castings are mainly due to trapped gases and dirty metal. Gases get trapped due to hard ramming or improper venting. These defects also occur when excessive moisture or excessive gas forming materials are used for mould making. • Blow holes are large spherical shaped gas bubbles, while porosity indicates a large number of uniformly distributed tiny holes. Pin holes are tiny blow holes appearing just below the casting surface. • Inclusions are the non-metallic particles in the metal matrix, Lighter impurities appearing the casting surface are dross.

- 245. Visible Defects