Validation master plan

- 1. Validation Master Plan Dr. A. Amsavel

- 2. Presentation Overview 1. Definition 2. Qualification and Validation 3. Qualification 4. Validation Process Validation Cleaning Validation Analytical method 5. Change Control 6. Revalidation

- 3. Definition Validation Master Plan- PIC/S A document providing information on the company’s validation work programme. It should define details of and timescales for the validation work to be performed. Responsibilities relating to the plan should be stated.

- 4. Definition Validation Master Plan. (WHO guideline): The validation master plan is a high-level document that establishes an umbrella validation plan for the entire project and summarizes the manufacturer’s overall philosophy and approach. It provides information on the manufacturer’s validation work programme and defines details of and timescales for the validation work to be performed, including a statement of the responsibilities of those implementing the plan.

- 5. Qualification or validation? A system must be Qualified to operate in a Validated process: Qualify: a system and/or equipment Validate: a process E.g. Qualify an autoclave, whereas you validate a Sterilisation process

- 6. Definition Qualification: Documented evidence that premises, systems or equipment are able to achieve the predetermined specifications properly installed, and/or work correctly and lead to the expected results Validation. Action of proving and documenting that any process, procedure or method actually and consistently leads to the expected results.

- 7. Validation Master Plan (VMP) 1. Qualification and Validation 2. Planning for Validation 3. Documentation 4. Qualification 5. Process Validation 6. Cleaning Validation 7. Change Control 8. Revalidation

- 8. Purpose of VMP The VMP should present an overview of the entire validation operation, its organisational structure, its content and planning. A VMP helps management: - to know the validation plan –plan for time, people & money, and - understand the necessity for the programme; A VMP helps all members of the validation team: - to know their tasks and responsibilities. A VMP helps GMP inspectors: - to understand the firm's approach to validation and organisation of all validation activities. - Organisational structure, its content and planning.

- 9. Is it one time activity? Qualification and validation can not be considered once-off exercises, For example, the start-up of a new manufacturing operation. It is an ongoing programme should follow its first implementation.

- 11. VMP procedure Purpose & Scope Responsibility Validation policy Qualification of facilities, systems, equipment & utilities Validation: Process, cleaning, analytical methods & CSV Personal qualification Documentation format: Protocols and Reports Requalification & revalidation: while change & periodic planning and scheduling; change control – Qualification and Validation based on risk Reference to existing documents. Validation schedule User requirement specifications The requirements and specifications for the utility or equipment should be defined by the user and documented in the URS. The URS should be used when selecting the required utility or equipment from an approved supplier, and to verify suitability throughout the subsequent stages of q

- 12. Qualification of Facility, Equipment & system

- 13. Qualification Design Qualification: Documented verification that the proposed design of facilities, systems and equipment is suitable for the intended purpose. Installation Qualification: Documented verification that the installations (such as machines, computer system components, measuring devices, utilities and manufacturing areas) used in a processor system are appropriately selected and correctly installed in accordance with established specifications.

- 14. Qualification Operational Qualification: Documented verification that the system or subsystem operates as intended over all anticipated operating ranges. Performance Qualification: Documented verification that the equipment or system performs consistently and reproducibly within defined specifications and parameters in its normal operating environment (i.e. in the production environment)

- 15. Develop a Validation Master Plan Qualification Purpose Design Qualification (DQ) Design specifications to ensure that all specified design elements have been included and that the design meets the relevant regulatory and statutory requirements. Installation Qualification (IQ) Verifies that the equipment/system/process is installed correctly, supplied as specified, integrated into the site calibration and maintenance systems and available for use. Operational Qualification (OQ) Verifies that the equipment/system/process is operating correctly, compliant with functionality requirements and integrated into the systems and QMS. Performance Qualification (PQ) Verifies that the equipment/system/process is continuously meeting performance criteria for routine use and performing adequately for routine use in commercial production.

- 16. Design qualification Design qualification DQ should provide documented evidence that the design specifications were met and are in accordance with the URS. User requirement specifications : Consider the following for URS; Product Requirements Process & Operation Requirements Operating Ranges GMP, Operation & Safety Requirements

- 17. Design qualification URS: The requirements and specifications for the utility or equipment should be defined by the user and documented in the URS. The URS should be used when selecting the required utility or equipment from an approved supplier, and to verify suitability Factory Acceptance Test and Site Acceptance Test Where appropriate, FAT and SAT should be performed to verify the suitability of the system at site, prior to the subsequent stages of qualification.

- 18. Design qualification Eg: Hydrogenation Reactor: User requirement Design Component 1. Process material Acidic MOC- GL/ hastaloy 2. Immiscible liquids Turbine type agitator to be mixed for rxn & higher RPM ? 3. High pressure hydrogenation Pressure rating ? 4. No gas leakage Mechanical seal 5. Safety issue Rupture disc/Safety value 6. Oil in thermowel Food grade oil (GMP) etc..

- 19. Installation Qualification IQ should include, but not be limited to the following: Installation of equipment, piping, services and instrumentation check to current engineering drawings and specifications; Verification of materials of construction. Calibration requirements; Collection and collation of supplier operating procedure/WI and maintenance requirements;

- 20. Installation Qualification Demonstrate that equipment has been Installed as per design and installation requirements. Installation check list: Civil requirements Electrical Production Measuring instruments Utilities & Piping Safety Issues Operation manuals & SOPs Critical stages Spare parts list etc

- 21. Operational qualification OQ should include, but not be limited to the following: tests that meets the functionality requirement of processes, systems and equipment; tests to include a condition or a set of conditions encompassing upper and lower operating limits, and “worst case” conditions. finalisation of calibration, operating and cleaning procedures, operator training and preventative maintenance requirements. Conclusion to approve/ release the facilities, systems and equipment.

- 22. Operational qualification To demonstrate that the equipment will perform as per design within specified parameters. Define critical tests for OQ with Acceptance criteria Prepare testing procedures to cover upper and lower operating limits Calibrate measuring devices Operation & Cleaning procedure Preventive maintenance plan Prepare OQ report

- 23. Performance qualification PQ should include, but not be limited to the following: test, using production materials, qualified substitutes or simulated product, test to include a condition or set of conditions encompassing upper and lower operating limits. Although PQ is described as a separate activity, it may in some cases be appropriate to perform it in conjunction with OQ. Also considered as process validation

- 24. Documents URS Purchase orders Engineering drawings MOC certificates test certificates & tractability certificates Operating manuals Calibration procedures & certificates Safety instructions Qualification protocol & Reports etc

- 25. Process Validation 1. Prospective validation 2. Concurrent validation 3. Retrospective validation Revalidation as required

- 26. Process validation To Demonstrate with Documented Evidence that a Specific ‘Manufacturing Process’ is Capable of Performing in a Reliable and Consistent Manner to Deliver a Homogenous Product Meeting Defined Quality Attributes Consistently. Purpose: High degree of assurance Consistency Documented proof Built-in Quality

- 27. Process Validation Process validation should normally be completed prior to the distribution and sale of the medicinal product (prospective validation). In exceptional circumstances, where this is not possible, it may be necessary to validate processes during routine production (concurrent validation). Processes in use for some time should also be validated (retrospective validation).

- 28. Process Validation : Pre-requirement The following shall be ensured prior to Process validation; Facilities, systems and equipment to be used are qualified Instruments are calibrated Analytical testing methods are validated. Process is reviewed and ready (development report with QbD concept) Protocol is prepared , reviewed and approved. Personnel involved in the validation are appropriately trained.

- 29. Prospective Validation It is establishing documented evidence prior to process implementation that a system what it purports to do based on a preplanned protocol. It is conducted prior to distribution of either a new product or a product made under a modified Production process, where modifications are significant and may affect product characteristics. This is a preplanned scientific approach and includes initial stages of equipment validation.

- 30. Concurrent Validation It is establishing documented evidence that a process does what it purports to do, based on information generated during actual implementation of the process. It may be practical approach under certain circumstances. When a previously validated process is being transferred to a third party contract manufacturer or to another manufacturing site . When number of batches produced are limited. Revalidation due to changes eg Increase batch size

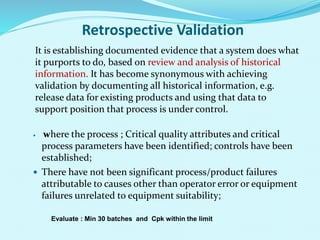

- 31. Retrospective Validation It is establishing documented evidence that a system does what it purports to do, based on review and analysis of historical information. It has become synonymous with achieving validation by documenting all historical information, e.g. release data for existing products and using that data to support position that process is under control. where the process ; Critical quality attributes and critical process parameters have been identified; controls have been established; There have not been significant process/product failures attributable to causes other than operator error or equipment failures unrelated to equipment suitability; Evaluate : Min 30 batches and Cpk within the limit

- 32. Validation protocol contents ‒ the objectives & Scope; ‒ the responsible personnel ‒ description of the SOPs ‒ equipment or instruments to be used; ‒ calibration requirements; ‒ standards and criteria as appropriate; ‒ the stage of validation ‒ the critical processes parameters; critical operations ‒ sampling, testing and monitoring requirements; additional test ‒ stress testing where appropriate; ‒ predetermined acceptance criteria ‒ review and interpretation of results; ‒ deviations ‒ conclusion

- 33. Re-validation Revalidation. Systems and processes should be periodically evaluated to verify that they are still operating in a valid manner. Repeated validation of a previously validated system (or a part thereof) to ensure continued compliance with established requirements.

- 34. Cleaning Validation Equipment and utensils shall be cleaned, maintained and sanitized at appropriate intervals to prevent contamination that would alter the safety, identity, strength, quality or purity of the drug product. Pharmaceuticals can be contaminated by potentially dangerous substances Essential to establish adequate cleaning procedures “Cleaning validation should be performed in order to confirm the effectiveness of a cleaning procedure” (PIC/S) “The data should support a conclusion that residues have been reduced to an ‘acceptable’ level” (FDA)

- 35. Cleaning Validation Strategy on cleaning validation Product contact surfaces After product changeover Between batches in campaigns Bracketing products for cleaning validation Periodic re-evaluation and revalidation

- 36. Cleaning Validation Cleaning Validation protocol: Objective of the validation Responsibility for performing and approving validation study Description of equipment to be used Interval between end of production and cleaning, and commencement of cleaning procedure Possible residues Cleaning procedures to be used (Parameters to be monitored/controlled) Number of cleaning cycles performed consecutively Sampling procedures used and rationale Sampling locations (Rinse and Swab ) Testing method for residue Acceptance Limits with Justifications

- 37. Analytical Method validation Analytical Method shall be validated for it of indented purpose or verified for it suitability Method validation is the process of planned and systematic study to confirm that it is suitable for its intended use. Method is reliable, accurate & reproducible

- 38. Validation Parameters/characteristics Accuracy Precision Repeatability Intermediate Precision Specificity Linearity Range Detection Limit Quantitation Limit Robustness

- 39. Analytical procedure Characteristics Identificat ion Tests for impurities Assay Quantita tive Limit test Accuracy No Yes No Yes Precision- Repeatability No Yes No Yes Intermediate precision No Yes No Yes Specificity Yes Yes Yes Yes Limit of Detection No Yes Yes No Limit of Quantitation No Yes No No Linearity No Yes No Yes Range No Yes No Yes Robustness * No Yes No Yes Characteristics to be validated

- 40. Computerized Systems Validation 1. GMP-related computerized systems should be validated. validation depends on the diversity, complexity, and criticality of the computerized application. 2. Appropriate installation and operational qualifications should demonstrate the suitability of computer hardware and software to perform assigned tasks. 3. Computerized systems should have sufficient controls to prevent unauthorized access or changes to data. There should be controls to prevent omissions in data (e.g., system turned off and data not captured). 4. Written procedures should be available for the operation and maintenance 5. Where critical data are being entered manually, there should be an additional check on the accuracy of the entry. 6. Changes to computerized systems should be documented and validated/ tested 7. A back-up system should be provided.

- 41. Water system design Water system design 1. Constructed of suitable materials such as stainless steel 2. Polished surface & proper welding to prevent microbial film 3. Sanitary fittings & connections 4. Pipes sloped so water does not pool and can drain easily 5. Circulate the water 6. Incorporate non-return valves (NRV)

- 42. Water system The water system documents should have Valves / Sampling points drain points instrumentation flow rates/ velocity Schematic diagram Validation for water systems consists of three phases Phase 1: 2 – 4 weeks Phase 2: 4 weeks Phase 3: 1 year

- 43. Changes that require revalidation Software changes/controllers Site changes Operational changes Change of source of material Change in the process Significant equipment change Production area changes Support system changes

- 44. VMP VMP should contain at least: Validation policy Organizational structure Identifies validation items (products, processes, systems) Summary of facilities, systems, equipment, processes to be validated Documentation format for protocols and reports Planning and scheduling Change control Training requirements

- 45. VMP VMP should state who is responsible for: Preparing the VMP The protocols and SOPs Validation work Report and document preparation and control Approval/authorisation of validation protocols and reports in all stages of validation process Tracking system Training needs in support of validation

- 46. VMP VMP should contain: Validation list/plan with timelne (What to validate) Specific process considerations Specific characteristics briefly outlined premises, systems and equipment processes products Cleaning Analytical method etc

- 47. Reference https://www.picscheme.org www.who.int/medicines/areas/.../validation- without_appendices_2016_05_17.pdf https://ec.europa.eu/health/sites/health/files/files/pharmacos/docs/d oc99/gmpanx15_en.pdf https://www.validation-online.net/user-requirements- specification.html www.usp.org www.ich.org www.fda.gov/cder/

- 48. Questions?