Why High-Tech Multi-Layer PCB Features Add Cost and Processing Time

- 1. Manufacturing That Eliminates Risk & Improves Reliability Why High-Tech Multi-Layer PCB Features Add Cost and Processing Time 5.20.22

- 2. Manufacturing That Eliminates Risk & Improves Reliability 2 Agenda PCB base cost Common cost adders Specialty processing not as common Additional time needed for production Least common specialty process cost and lead time Summary

- 3. Manufacturing That Eliminates Risk & Improves Reliability 3 Base Pricing of a Printed Circuit Board

- 4. Manufacturing That Eliminates Risk & Improves Reliability 4 The Base Cost What are the base cost considerations when costing a PCB? – Layer count – X,Y – Material FR4 • Copper weight – Thickness overall – Classification – II, III, ITAR, domestic, military, or medical grade – Surface finish If we have only the above information for the PCB, we can then calculate a base cost.

- 5. Manufacturing That Eliminates Risk & Improves Reliability 5 Common Cost Adders of a Printed Circuit Board

- 6. Manufacturing That Eliminates Risk & Improves Reliability 6 Common Features That Add Cost From the base pricing, additional costs may be added to the unit price. Depending on what those items are, the price can quickly increase. – Copper wt. above 2oz, mixed • 3oz, 4oz, 5oz are more standard – Impedance • Controlled dielectrics – RoHS finishes • ENIG, Immersion Silver, LF-HASL, OSP, Immersion Tin, Gold Tabs – High-temperature material >130tg, 170tg, 180tg – A specific brand or type of material • Isola, Nelco, Nanya, Arlon, Rogers, Taconic, I-speed, Panasonic – Specifying a brand will add cost

- 7. Manufacturing That Eliminates Risk & Improves Reliability 7 Using IPC-4101 and 4103 Spec Not all fabricators support or stock every possible laminate material. IPC-4101 and IPC-4103 standards specify various requirements for PCB laminate materials that help ensure interchangeability and compatibility in a PCB stack-up. Specs contain 2 sets of data on a particular material system: primary structural/material properties and some testing results as determined under IPC testing standards. Call out a slash number rather than a tradename or brand on your fabrication drawing.

- 8. Manufacturing That Eliminates Risk & Improves Reliability 8 There Are New Materials Available For RF/microwave designs, there are new materials that are: – More available – Cost less per panel – Cost less to process Work with your fabricator so that you get the same performance for less overall cost.

- 9. Manufacturing That Eliminates Risk & Improves Reliability 9 How is the Cost of a PCB Determined? Base Cost from Supplied Fabrication Drawing • LxW of PCB/array • Thickness • Layer count • Material(s) • Copper weight • Surface finish What else to look for? • Impedance • Specified dielectrics • Copper wt. >2oz • High temp. More … • Blind/buried vias • Stacked vias • Via-in-pad • Plated slots • Gold tabs

- 10. Manufacturing That Eliminates Risk & Improves Reliability 10 Printed Circuit Board Specialty Processing

- 11. Manufacturing That Eliminates Risk & Improves Reliability 11 Plated Edges – Castellated Holes Hole/edge plating PCB edge Drill/rout as a primary process > 0.016” – Drill & cleaning – Plating – Image – Routing special requirements

- 12. Manufacturing That Eliminates Risk & Improves Reliability 12 Milling & Excessive Routing Milling – Time-consuming – Cost • Programming/engineering • Control depth routing • Additional processing

- 13. Manufacturing That Eliminates Risk & Improves Reliability 13 Excessive Routing Excessive Routing – Time-consuming – Cost • Materials • Labor • Engineering

- 14. Manufacturing That Eliminates Risk & Improves Reliability 14 Counterbore – Countersink Counterbore – primary drilling, plating, secondary drilling – Processing time – Special tools Not all sizes are available – Setting and controls Countersink – primary drilling, plating or non-plated, secondary – Processing – Tools – Settings and controls Back Drilling – primary drilling, secondary drilling – In lieu of blind via processing – Engineering – production time – Danger of scrapping – high cost

- 15. Manufacturing That Eliminates Risk & Improves Reliability 15 Counterbore – Countersink

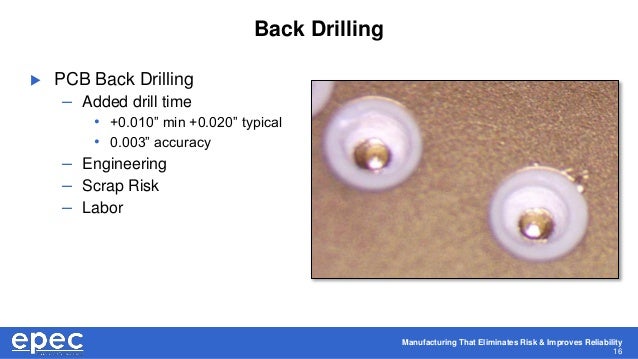

- 16. Manufacturing That Eliminates Risk & Improves Reliability 16 Back Drilling PCB Back Drilling – Added drill time • +0.010” min +0.020” typical • 0.003” accuracy – Engineering – Scrap Risk – Labor

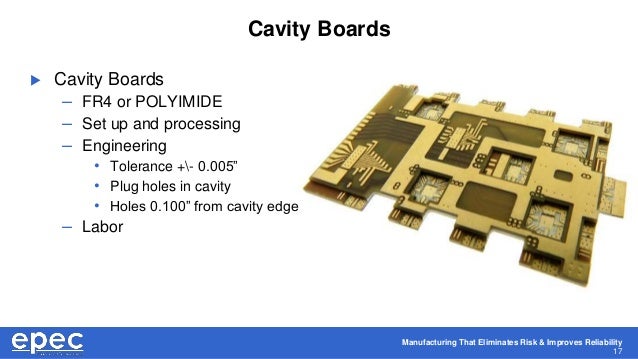

- 17. Manufacturing That Eliminates Risk & Improves Reliability 17 Cavity Boards Cavity Boards – FR4 or POLYIMIDE – Set up and processing – Engineering • Tolerance +- 0.005” • Plug holes in cavity • Holes 0.100” from cavity edge – Labor

- 18. Manufacturing That Eliminates Risk & Improves Reliability 18 Copper Plated Shut Vias Copper plated shut – Price – Processing equipment – DC chemistry – 0.006” - 0.012” single size – 12:1< aspect ratio – Time 15-18hrs – Risk low • Voids • Air/gas • Chemistry

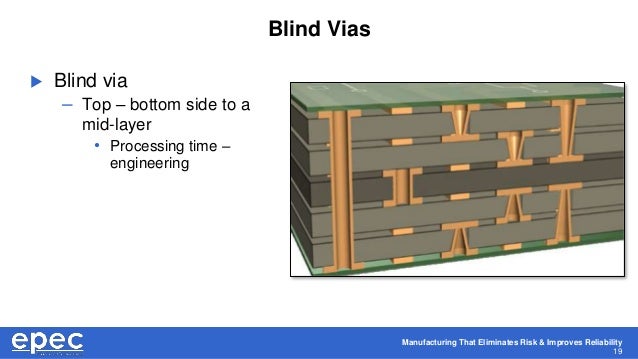

- 19. Manufacturing That Eliminates Risk & Improves Reliability 19 Blind Vias Blind via – Top – bottom side to a mid-layer • Processing time – engineering

- 20. Manufacturing That Eliminates Risk & Improves Reliability 20 Buried Vias Buried via – Mid-layer to mid-layer no external connection • Engineering – Processing

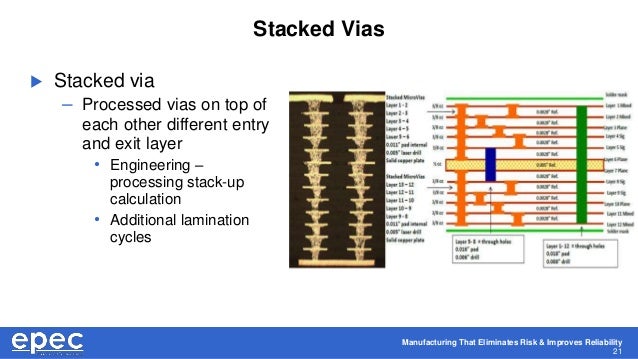

- 21. Manufacturing That Eliminates Risk & Improves Reliability 21 Stacked Vias Stacked via – Processed vias on top of each other different entry and exit layer • Engineering – processing stack-up calculation • Additional lamination cycles

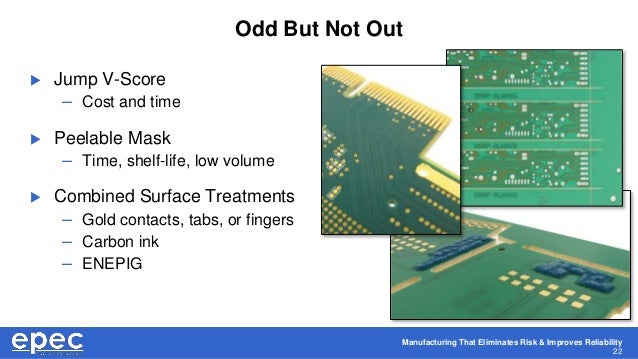

- 22. Manufacturing That Eliminates Risk & Improves Reliability 22 Odd But Not Out Jump V-Score – Cost and time Peelable Mask – Time, shelf-life, low volume Combined Surface Treatments – Gold contacts, tabs, or fingers – Carbon ink – ENEPIG

- 23. Manufacturing That Eliminates Risk & Improves Reliability 23 Summary

- 24. Manufacturing That Eliminates Risk & Improves Reliability 24 Summary PCB costing starts the same way with each unique design. All PCBs are a built-to-print product; because no two are exactly alike, pricing can vary. Engineering and production review during the design and lay out phase can improve on cost and lead time challenges. DFM is another option to help improve costing and material stack-up challenges. Using a trusted supplier with an expansive capable supply chain allows for the best cost, delivery, and quality product.

- 25. Manufacturing That Eliminates Risk & Improves Reliability 25 Our Products Battery Packs Flex & Rigid-Flex PCBs Cable Assemblies Printed Circuit Boards CNC Machining User Interfaces Flexible Heaters EC Fans & Motors

- 26. Manufacturing That Eliminates Risk & Improves Reliability 26 Q&A Questions? – Enter any questions you may have in the control panel – If we don’t have time to get to it, we will reply via email

- 27. Manufacturing That Eliminates Risk & Improves Reliability 27 Thank You Check out our website at www.epectec.com. For more information email sales@epectec.com. Stay Connected with Epec Engineered Technologies Follow us on our social media sites for continuous technical updates and information: