Beyond the Elements XRD Mineralogy & XRF Analysis for Advanced Mud Logging

- 1. Beyond the Elements: XRD Mineralogy & XRF Analysis for Advanced Mud Logging

- 2. Agenda Meet the Speakers Jose Brum, Field Sales Engineer, Olympus Dawn Snyder, Geologist, Diversified Well Logging Topics XRF & XRD Basics X-ray technology in oil & gas drilling Advanced mud logging techniques On-site XRF and XRD Q&A Session

- 3. Save Time Easy sample prep On-site analysis Fast results Reduce Costs Send fewer samples to outside lab Avoid downtime waiting for results Prevent re-drilling with real-time data Be Decisive Continuously test while drilling Geosteering without guesswork View drill depth vs mineralogy comparison plots Benefits of on-site XRD & XRF analysis

- 4. What is X-ray fluorescence? Quantitative elemental analysis Mg - U Measures ppm - % for most elements

- 5. What is X-ray fluorescence? Typical XRF Spectra

- 7. What is X-ray diffraction? Direct mineralogy with XRD Quantitative mineral phase analysis Rough range of analysis is ~ 2% - 100%

- 8. What is X-ray diffraction? Typical XRD Patterns Quartz Dolomite Gypsum Illite 2650 ft 6250 ft

- 9. XRD vs XRF? Both use an X-ray source and detector Both measure the response to X-rays interacting with a substance Both provide a measurement to help identify a substance XRF XRD Elemental Analysis Compound Analysis Contains Fe Contains Fe2O3 vs Fe3O4 Contains Ca Polymorphs: CaCO3 calcite vs aragonite vs vaterite

- 10. Unconventional resources CHALLENGE: Majority of wells being drilled in N.A. are in unconventional resource plays SOLUTION: Advancements in horizontal drilling and hydraulic fracturing have made production from unconventional resources commercially viable

- 11. Finding the sweet spot CHALLENGE: Geology, geochemistry, geo-mechanical properties can vary significantly throughout the play within visually homogenous shales SOLUTION: XRD & XRF shows molecular level to identify areas with more carbonates, areas that are more siliceous, and places of changes in the clay

- 12. Monitoring mineralogy trends with XRD

- 13. Monitoring mineralogy trends with XRD

- 14. Brittle zones CHALLENGE: Brittle zones necessary to pinpoint sweet spots for fracking can appear and disappear quickly in horizontal sections SOLUTION: XRD data can be used to derive the brittleness of the shales within reservoirs

- 15. Rock type CHALLENGE: Need to identify oil & gas bearing zones, permeability and porosity for optimum production SOLUTION: XRD can identify the rock types that indicate oil & gas bearing zones

- 16. Marker elements CHALLENGE: Finding boundary layers and staying in the pay zone while drilling SOLUTION: XRF can identify upper and lower marker elements to indicate when you have entered the pay zone or if you have left it

- 18. Elemental composition vs drilling depths

- 19. Downhole vs surface techniques CHALLENGES: Downhole measurements such as gamma, resistivity or wireline tools can fail due to temperature, pressure or vibration in the wellbore SOLUTION: Surface-based data from XRD and XRF have little to no impact on the drilling operations and can provide the mineralogy data regardless of downhole conditions

- 20. Compatible Fluids CHALLENGE: Drilling and injection fluids can interact with the formation in undesirable ways SOLUTION: XRD can analyze the mineralogy so the compatible fluid can be used

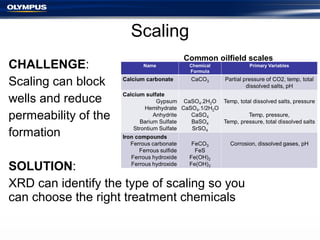

- 21. Scaling CHALLENGE: Scaling can block wells and reduce permeability of the formation SOLUTION: XRD can identify the type of scaling so you can choose the right treatment chemicals Common oilfield scales

- 22. Optimizing Production CHALLENGE: Typical well has between 25-50 stages, costing close to $250k per stage, with a typical production rate of 2% SOLUTION: Placing stages in the most brittle areas of the formation will help to optimize production, reduce cost and minimize environmental impact of fracturing

- 23. Advanced Mudlogging CHALLENGE: Surface-based measurements need to provide a detailed and reliable view of what is happening sub- surface SOLUTION: Field XRD and XRF combined with the mud logger and the microscope provides detailed results using visual and analytical techniques

- 24. Advanced Mudlogging CHALLENGE: Problems such as wellbore stability and fluid losses can arise while drilling SOLUTION: If pilot well cuttings were logged, subsequent cavings can be immediately identified with on-site XRD and XRF to pinpoint the location of losses. Used with permission from Aaron Watkins

- 26. XRD Data - Pattern Comparison Waterfall plot of 13 samples showing change in mineralogy through depth of several thousand feet of drilling with intensities normalized to 100% for visualization Range = Red at 2350 – Blue at 6250

- 27. XRD Data - Pattern Comparison Comparisons show visual changes in the diffraction pattern that do not require technical training to notice

- 28. XRD Data - Pattern Comparison Quartz Dolomite Gypsum Illite 2650 ft 6250 ft

- 29. XRD Data - Pattern Comparison 3400 ft 3870 ft Illite Illite Chlorite

- 30. XRD Data - Analysis Speed secondary peaks clear 1 min / 4 exposures 3 min / 11 exposures 10 min / 36 exposures For identifiable peaks, quantification stabilizes very quickly secondary peaks visible primary peaks visible - likely identifiable

- 31. XRD Quantification Quick Semi-Quant (XPowder) can be set-up with a few patterns and turned into a push-button operation Select phases visually from a small database Setting up reference files for future quantification of similar matrices

- 32. Field XRD vs lab XRD

- 33. XRF Analysis Output Depth Al Si P S K Ca Ti V Mn Fe Ni Cu Zn Zr 12430 4.04 13.7 0.17 0.24 2.31 2.05 0.44 0 0.03 5.11 0.02 12450 2.82 13.3 0.14 0.29 1.33 3.27 0.34 0.04 0.03 4.39 0.01 0.03 12470 3.31 14.2 0.2 0.33 1.38 3.34 0.35 0.04 4.53 0.03 12490 3.53 12.1 0.2 0.74 1.57 4.29 1.78 1.03 0.22 5.15 0.01 0.01 0.03 12510 3.39 11.8 0.17 0.5 1.64 4.37 1.03 0.6 0.12 4.8 0.03 12530 3.77 11.2 0.26 0.38 1.36 7.95 1.28 0.75 0.18 4.45 0.02 0.02 12550 3.44 10.9 0.15 0.41 1.46 7.3 1.21 0.55 0.14 4.28 0.03 12570 2.77 9.38 0.18 0.26 1.27 8.26 0.75 0.26 0.08 3.87 0.01 0.03 12590 3.11 10.5 0.17 0.62 1.42 6.16 1.88 1.19 0.34 4.78 0.02 0.01 0.03 12610 3.07 9.91 0.15 0.26 1.34 7.82 0.58 0.17 0.09 3.82 0.01 0.01 0.02 12630 3.19 10.7 0.17 0.33 1.59 5.29 0.5 0.11 0.08 4.52 0.01 0.03

- 34. On-site XRD & XRF Analysis CHALLENGE: Samples sent to lab for XRD & XRF analysis can take days/wks for results SOLUTION: Advances in XRD & XRF units have made them accessible for use in mobile labs Inside the Diversified Well Logging Trailer

- 35. Your Mobile Lab Starts with Olympus X5000 Portable XRF BTX-II Benchtop XRD TERRA Portable XRD Submit your questions now!

Editor's Notes

- #4: Thank you Gregg. I’m glad to have the opportunity to be here today with Dawn to talk to all of you about the use of field XRD and XRF in mud logging applications. The development of field-based XRD and XRF instrumentation has really expanded the use of these technologies in this industry as an on-site tool. It has had a huge affect on - the time it takes to get analysis - the cost of sending samples back to a main lab and - the ability to make decisions in real-time Dawn will be talking more specifically about how the mud logger uses these technologies but first I want to start at the basics of XRD and XRF technology, how they are similar and how they differ

- #9: Other techniques calculate or infer what the mineralogy is but XRD identifies and quantifies the mineralogy directly from the crystal structure.

- #11: The majority of wells being drilled in N.A. are primarily shales in unconventional resource plays – tight formations that trap the hydrocarbons and require stimulation techniques to allow them to flow.

- #12: Using these X-rays, we can now see vivid differences in visually homogenous shales. With clarity, you can see and quantitate the areas of the well that have more carbonates, are more siliceous, and changes in the clay.

- #15: Brittleness is directly controlled by mineralogy and the fabric and texture of the mineral components Accurate measurements of clay content are imperative to evaluating the relative brittleness through a shale play, which can greatly improve the effectiveness of fracking strategies. XRD and XRF are used in determining the contribution of clay minerals to the engineering behavior of rocks and soils.

- #21: Certain clays (smectites) will swell up in the presence of water. When they swell, they can trap the drillpipe and block up the wellhole. You will want to switch to an oil-based drilling mud.

- #22: Scaling – seawater can combine with certain minerals (e.g. sulfates) to form scale both in the formation and in the drillpipe. If you see these minerals, you know to not use a sea-water based drilling mud and to be very cautious using seawater in nearby injection wells.

- #23: Accurate measurements of clay content are imperative to evaluating the relative brittleness through a shale play can greatly improve the effectiveness of fracking strategies. XRD and XRF are used in determining the contribution of clay minerals to the engineering behavior of rocks and soils.

- #26: Using these X-rays techniques, we can now see vivid differences in visually homogenous shales. With clarity, you can see the areas of the well that have more carbonates, are more siliceous, and places of changes in the clay. One great benefit having of XRD on site is that when problems arise while drilling, such as wellbore stability and fluid losses, the subsequent cavings can be immediately identified to help pinpoint the location of losses. Trace and Marker minerals have a myriad of applications in exploration and reservoir characterization. Also, XRD will help define the brittle zones and sweet spots for fracking and production.

- #27: (12 minute acquisition time Co-Ka energy)

- #29: Looking more closely at certain depths we can see the changes in mineralogy

- #31: Our customers are typically doing ~ 5-10 minute test, depending upon how much they care about quantification of the secondary peaks.

- #33: Semi-quant RIR data from Terra in blind comparison to lab based system

- #35: Not only do the Olympus XRD and XRF instruments provide fast analysis but having them on site eliminates the time involved to send samples to an outside lab. This puts the information in the operators hands almost immediately allowing them to make decisions in real-time. As you can see from the examples we have given during this presentation - there are many benefits for having these instruments in the well logging trailer as part of the routine analysis. - They can provide more detailed information than was possible in the past - They can provide back up information and verification to other analysis tools and - They can provide data that can help optimize the operations and better understand what is going on under ground

- #36: Jose - I would like to extend my personal thank you to Dawn for joining me today and thank you also to Diversified Well Logging for having Dawn collaborate with us on this webinar. Dawn – (you can chime in with any thank you and closing remarks) Jose – We are looking forward to answering some of your questions now so I’ll turn it back over to Gregg to get us started