Ae2_19_plastic analysis_beams

- 1. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS

- 2. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION 1.- ELASTIC ANALYSIS OF GRIDS 1.1.- COMPATIBILITY METHOD 1.2- SLOPE DEFLECTION METHOD 2.- PLASTIC ANALYSIS OF STRUCTURES 2.1- PLASTIC ANALYSIS OF BEAMS 2.2- PLASTIC ANALYSIS OF FRAMES 2.2.1- KINEMATIC METHOD 2.2.2- INCREMENTAL ANALYSIS. HINGE BY HINGE METHOD 3.- INTRODUCTION TO SECOND ORDER ANALYSIS OF STRUCTURES 2.3- PLASTIC ANALYSIS OF SLABS. FEBRUARY MARCH APRIL

- 3. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS of beams Specially useful to calculate one way slabs small continuous beams

- 4. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION

- 5. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION ELASTIC BEHAVIOUR: The original position is recovered

- 6. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC BEHAVIOUR: The original position is NOT recovered

- 7. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION Force per unit area Displacement per unit area

- 8. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION

- 9. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION

- 10. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION ELASTIC ANALYSIS PLASTIC ANALYSIS ≠ RESULTS* Part of the structure material is working beyond the plastic limit The material should be ductile enough to have a plastic behaviour All the structure material is working below the plastic limit The material can be fragile or ductile to apply elastic analysis

- 11. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION ELASTIC ANALYSIS PLASTIC ANALYSIS ≠ RESULTS* Part of the structure material is working beyond the plastic limit The structure should be ductile enough to have a plastic behaviour All the structure material is working below the plastic limit The structure can be fragile or ductile to apply elastic analysis SAFER? SAFER

- 12. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION STRUCTURAL ANALYSIS II PLASTIC ANALYSIS ELASTIC ANALYSIS PLASTIC ANALYSIS ≠ RESULTS* Part of the structure material is working beyond the plastic limit The material should be ductile enough to have a plastic behaviour All the structure material is working below the plastic limit The material can be fragile or ductile to apply elastic analysis CHEAPER? SAFER CHEAPER

- 13. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION ELASTIC ANALYSIS PLASTIC ANALYSIS ≠ RESULTS* Part of the structure material is working beyond the plastic limit The material should be ductile enough to have a plastic behaviour All the structure material is working below the plastic limit The material can be fragile or ductile to apply elastic analysis SAFER CHEAPER Superposition Principle cannot be applied Superposition Principle can be applied

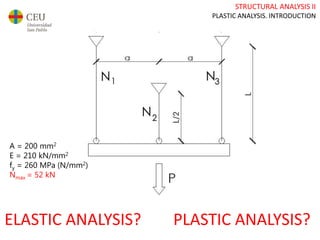

- 14. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION A = 200 mm2 E = 210 kN/mm2 fy = 260 MPa (N/mm2) Maximun load supported by each cable Nmax = fy x A = 52000 N = 52 kN

- 15. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION ELASTIC ANALYSIS? PLASTIC ANALYSIS? A = 200 mm2 E = 210 kN/mm2 fy = 260 MPa (N/mm2) Nmax = 52 kN

- 16. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION STRUCTURAL ANALYSIS II PLASTIC ANALYSIS ELASTIC ANALYSIS Compatibility Method: v1 = v2 = v3

- 17. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION ELASTIC ANALYSIS v1 = ∆ L 1 = N 1 x L 1 / EA = v2 = ∆ L 2 = N 2 x L 2 / EA Symmetry N1 = N3

- 18. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION STRUCTURAL ANALYSIS II PLASTIC ANALYSIS ELASTIC ANALYSIS N2 = 2 N1 Symmetry N1 = N3

- 19. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION ELASTIC ANALYSIS As Nmax = 52 kN , N2 = 52 kN and N1 = 26 kN Symmetry N1 = N3

- 20. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION ELASTIC ANALYSIS P = 104 kN As Nmax = 52 kN , N2 = 52 kN and N1 = 26 kN Symmetry N1 = N3

- 21. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS? A = 200 mm2 E = 210 kN/mm2 fy = 260 MPa (N/mm2) Nmax = 52 kN N1 = N2 = N3

- 22. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS? A = 200 mm2 E = 210 kN/mm2 fy = 260 MPa (N/mm2) Nmax = 52 kN N1 = N2 = N3 = 52 kN

- 23. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS P = 156 kN A = 200 mm2 E = 210 kN/mm2 fy = 260 MPa (N/mm2) Nmax = 52 kN N1 = N2 = N3 = 52 kN

- 24. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION ELASTIC ANALYSIS PLASTIC ANALYSIS A = 200 mm2 E = 210 kN/mm2 fy = 260 MPa (N/mm2) P = 104 kN Pu = 156 kN

- 25. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION SAFETY FACTOR? 156 / 104 = 1,5 A = 200 mm2 E = 210 kN/mm2 fy = 260 MPa (N/mm2) Nmax = 52 kN P = 104 kN Pu = 156 kN

- 26. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION IF L = 3 m DL = 26 x 3 /EA DL = 52 x 3 /EA

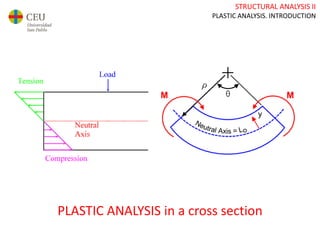

- 27. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS in a cross section

- 28. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS in a cross section Neutral axis Fibers in compression Fibers in tension

- 29. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS in a cross section

- 30. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION

- 31. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS in a cross section Elastic section modulus We = 𝑏 𝑥 ℎ2 6 Plastic section modulus Wp = 𝑏 𝑥 ℎ2 4

- 32. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION SHAPE FACTOR PLASTIC ANALYSIS in a cross section Elastic section modulus / Plastic section modulus

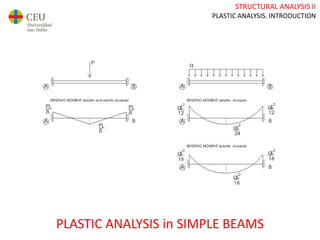

- 33. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS in SIMPLE BEAMS

- 34. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS in SIMPLE BEAMS

- 35. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS in SIMPLE BEAMS

- 36. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS in SIMPLE BEAMS

- 37. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS in SIMPLE BEAMS

- 38. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION PLASTIC ANALYSIS in CONTINOUS BEAMS 30 kN/ m 4 m 5 m 6 m 20 kN/ m 10 kN/ m vano AB vano BC vano CD A B C D HIPÓTESIS1 considerando la carga dada, calcular el momento plástico mínimo necesario para construir toda la viga 3 HIPÓTESIS2 considerando que la viga se construye con un IPE240 (Mp = 105,1 cm ) determina la carga de rotura. HIPÓTESIS3 considerando la carga dada y el perfil IPE240 determina el factor de seguridad de la viga. 3 (mínimo momento de diseño) 1.- DESIGNING PROCESS: Minimum plastic moment capacity required to build the beam (if we use a smaller profile, the beam breaks) 2.- CHECKING PROCESS: Maximum load the beam can carry (if we apply a higher load the beam breaks) 3.- SAFETY FACTOR

- 39. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION 30 kN/ m 4 m 5 m 6 m 20 kN/ m 10 kN/ m vano AB vano BC vano CD A B C D HIPÓTESIS1 considerando la carga dada, calcular el momento plástico mínimo necesario para construir toda la viga 3 HIPÓTESIS2 considerando que la viga se construye con un IPE240 (Mp = 105,1 cm ) determina la carga de rotura. HIPÓTESIS3 considerando la carga dada y el perfil IPE240 determina el factor de seguridad de la viga. 3 (mínimo momento de diseño) CAN WE TELL WHICH SPAN IS GOING TO FAIL FIRST?

- 40. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION 30 kN/ m 4 m 5 m 6 m 20 kN/ m 10 kN/ m vano AB vano BC vano CD A B C D HIPÓTESIS1 considerando la carga dada, calcular el momento plástico mínimo necesario para construir toda la viga 3 HIPÓTESIS2 considerando que la viga se construye con un IPE240 (Mp = 105,1 cm ) determina la carga de rotura. HIPÓTESIS3 considerando la carga dada y el perfil IPE240 determina el factor de seguridad de la viga. 3 (mínimo momento de diseño) SPAN AB SPAN BC SPAN CD Mp(AB) = q L2 / 11,67= 41,13 kNm Mp(BC) = q L2 / 16= 20 x 25/16 = 31,25 kNm Mp(CD) = q L2 / 11,67= 10 x 36/11,67 = 30,84 kNm CAN WE TELL WHICH SPAN IS GOING TO FAIL FIRST?

- 41. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION 2.- CHECKING PROCESS: Maximum load the beam can carry (if we apply a higher load the beam breaks) (we know Wp, this is, the profile capacity) 3.- SAFETY FACTOR (we know both the load and the profile and the load value) 1.- DESIGNING PROCESS: Minimum plastic moment capacity required to build the beam (if we use a smaller profile, the beam breaks) (we know the load values)

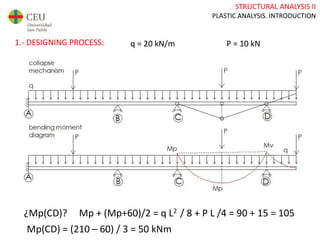

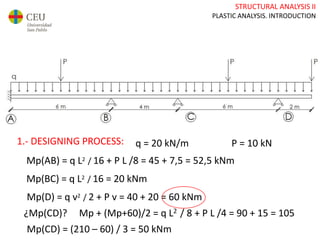

- 42. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION 1.- DESIGNING PROCESS: q = 20 kN/m P = 10 kN Mp(AB) = q L2 / 16 + P L /8 = 45 + 7,5 = 52,5 kNm

- 43. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION 1.- DESIGNING PROCESS: q = 20 kN/m P = 10 kN Mp(BC) = q L2 / 16 = 20 kNm

- 44. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION 1.- DESIGNING PROCESS: q = 20 kN/m P = 10 kN ¿Mp(CD)? Mp + (Mp+60)/2 = q L2 / 8 + P L /4 = 90 + 15 = 105 Mp(CD) = (210 – 60) / 3 = 50 kNm

- 45. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION 1.- DESIGNING PROCESS: q = 20 kN/m P = 10 kN Mp(D) = q v2 / 2 + P v = 40 + 20 = 60 kNm

- 46. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION 1.- DESIGNING PROCESS: q = 20 kN/m P = 10 kN Mp(AB) = q L2 / 16 + P L /8 = 45 + 7,5 = 52,5 kNm Mp(BC) = q L2 / 16 = 20 kNm Mp(D) = q v2 / 2 + P v = 40 + 20 = 60 kNm ¿Mp(CD)? Mp + (Mp+60)/2 = q L2 / 8 + P L /4 = 90 + 15 = 105 Mp(CD) = (210 – 60) / 3 = 50 kNm

- 47. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION 3.- SAFETY FACTOR if HEB300? Sx = 934 cm3 fy = 0,275 kN/mm2 DESIGNED Mp(D) = 60 kNm Wp(HEB300) = 2 Sx = 1868 cm3 Mp (HEB300)= Wp x fy = 1868 x 0,275 = 513,7 kNm Safety factor (or factor load) = 8,56

- 48. STRUCTURAL ANALYSIS II PLASTIC ANALYSIS. INTRODUCTION