Basics of mechanical engineering

- 2. BASICS OF THERMODYNAMICS WORKING SUBSTANCE: The working substance is mostly gas or vapors and liquid in equilibrium. It is very important to know the behavior of the substance and its properties Pure substances are those which have homogeneous chemical structure. Water is the example of pure substance. Air is also considered as a pure substance in gaseous form. Thermodynamics System: It is defined as the space on which attention is concentrated to analyze it. Thermodynamics Surrounding : It is defined as the remaining space of the universe except system Dinesh Panchal

- 3. Boundary: An envelop enclosing the system is known as boundary. Universe: When the system and surrounding are put together, is called universe. Types of Systems: 1. Open System 2. Closed System 3. Isolated System 1. Open system: A system is called open when there is transfer of mass as well as heat between the system and surrounding. 2. closed system: A system is called closed when there is transfer of heat between the system and surrounding and there is no transfer of mass between system and surrounding. 3. Isolated system: A system is called isolated when there is transfer no transfer of mass as well as heat between the system and surrounding Dinesh Panchal

- 4. Property or Parameters of substance: Property or Parameters are those quantities which specify the state of the substance. So we can say that the properties of a substance dependent on the state of substance e.g. Mass, Physical Composition, Vol., Pressure, Temp, Surface Area, Velocity, Thermal Conductivity, Entropy, Enthalpy ect. Types of Properties : 1. Intensive Properties 2. Extensive Properties 1. Intensive Properties: Are those properties which does not depend on the mass of system. E.g. pressure, temp., density, velocity , height, viscosity 2. Extensive Properties: Are those properties which depend on the mass of system. E.g. vol., Surface area, internal energy, potential energy Dinesh Panchal

- 5. Pressure: Pressure is defined as the force per unit area. Its unit is Pascal, Bar, N/M2. Atm. Pressure : It is the pressure exerted by the weight of air column on the surface of earth is called atm. Pressure. Atm. Pressure = hρg Where h is the height of air column, ρ is the density of air, g is acc. due to gravity Gauge. Pressure : Pressure measured by the pressure gauge is called gauge pressure and it is one atm. less pressure than the absolute pressure. It is the pressure above the atm. Pressure. Absolute Pressure : Absolute pressure is the total pressure. Absolute Pressure= Atm. Pressure+ Gauge Pressure gaugeatmabs PPP .. Dinesh Panchal

- 7. Thermodynamic Equilibrium: A system is said to be in thermal equilibrium if the value of property is same at all the points of the system. For thermodynamic equilibrium following condition must be satisfied. 1. Mechanical Equilibrium 2. Chemical Equilibrium 3. Thermal Equilibrium 1. Mechanical Equilibrium: A system is said to be in mechanical equilibrium if Algebraic sum of all the forces and moments are zero 2. Chemical Equilibrium: A system is said to be in chemical equilibrium if there is no chemical reaction with in the system. 3. Thermal Equilibrium: A system is said to be in thermal equilibrium if there is no temp. difference between the parts of system. Dinesh Panchal

- 8. State: Instantaneous condition on of a thermodynamic system is called state. It the condition of the system at any time. The state of the system is define by the temp. pressure vol. density. Path : It is the locus of points of states at different time. Process: A process is defined as when a system changes its state from one state to another state. Dinesh Panchal

- 9. Cyclic Process : When a process or processes are performed on the system in such away that the final state is same with the initial state. Reversible Process: If the process in the reverse, follow the same path from one state to another state as the path traced during forward path called reversible path. Irreversible Process: If the process in the reverse, do not follow the same path from one state to another state as the path traced during forward path called irreversible path. Dinesh Panchal

- 10. Energy : It is the capacity to do work. 1. Mechanical Energy (a) Potential Energy: It is the energy possessed by virtue of its position .e.g. Potential energy due to height P.E. =mgh (b) Kinetic Energy : It is the energy possessed by virtue of its motion . K.E. =1/2mv2 2. Internal Energy: It is the energy possessed by the body due to its molecular arrangement and motion of the molecules. 3. Total Energy: It is the sum of K.E., P.E. and I.E. E=P.E.+K.E.+U Dinesh Panchal

- 11. Law of conservation of Energy : It state that energy can neither be created nor be destroyed, but can be changed from one form to another form. It means electrical energy can be converted in to mech. Energy and vice versa. Similarly thermal energy can be converted in to mechanical or electrical energy. Law of conservation of Mass: It state that mass can neither be created nor be destroyed, but can be changed from one form to another form. A solid can be changed from solid to liquid, liquid to gas or vice versa. Heat: Heat is defined as the energy that is transferred across the boundary of a system due to temp. difference. Heat flow from high temp. to low temp. gsurroundinandsystembetweendifferencetemptheisT-T heatspecifictheisc systemofmasstheismWhere T-TcmferredHeat trans 21 21 Dinesh Panchal

- 12. Specific Heat : Specific Heat is defined as the amount of heat required to raise the temp. of the unit mass through one degree centigrade. It has two type (a) Specific heat at constant volume : It is defined as the amount of heat required to raise the temp. of the unit mass through one degree centigrade at constant volume. It is denoted by (b) Specific heat at constant pressure: It is defined as the amount of heat required to raise the temp. of the unit mass through one degree centigrade at constant Pressure. It is denoted by vC pC Dinesh Panchal

- 13. Sign Convention for Heat and Work : # Work done by the System is +ve # Work done on the System is -ve # Heat Transferred to the system is +ve # Heat Transferred from the system is –ve Gas Law : It is the relation between Temperature, Volume, Pressure and mass of a gas at any particular state. KKgJ/872R KKJ/mol8.314R eTemperaturtheisT molesofno.theis-n masstheism VolumetheisV PressuretheisP nRTPV mRTPV Dinesh Panchal

- 14. Boyle’s Law : (Isothermal Process) The absolute pressure of a given mass of perfect gas varies inversely proportional to its volume at constant temp. 2211So. Constant 1 VPVP PV V P Dinesh Panchal

- 15. Boyle’s Law : (Isobaric Process) The absolute volume of a given mass of perfect gas varies directly proportional to its volume. 2 2 2 1 So. Constant T V T V T V TV Dinesh Panchal

- 16. Gay – Lussac Law : (Isochoric Process) It state that the absolute pressure of a given mass of a perfect gas varies directly as its temperature. 2 2 1 1 So. Constant T T P T P P TP Dinesh Panchal

- 17. Temperature : Temp. is defined as the hotness and coldness of the system or body. Its unit of measurement are Celsius or Centigrade, Fahrenheit and Kelvin. Relation between these temp. measuring scale is given below . Absolute Zero Temp. : It is defined as the temp below which temp. does not fall. Its value is Zeroth Law of Temperature : It state that if body A is in thermal equilibrium with body B and body B is in thermal equilibrium with body C then body A is also thermal equilibrium with body C. 180 32 100 FC KC 00 0273 Dinesh Panchal

- 18. First Law of Thermodynamics : It state that heat and mechanical work are mutually convertible. In others words cyclic integral of heat transfer equal to the cyclic integral of work. Another statement is that Energy can neither be created nor be destroyed, but can be changed from one form to another. WQ 2 2 2 22 1 2 1 11 2 1 21 21 122121 2 1 1 1 2 1 2 2 2stateatsystemofenergyTotal- 1stateatsystemofenergyTotal- procsstheduringgsurroundinon thesystemby thedoneWork- 2stateto1statefromsystemtheoTransfer tHeat- U mV mgzE U mV mgzE E E W Q EEWQ dEWQ dEWQ Dinesh Panchal

- 19. Application of first law to non flow processes: 1. Constant Volume Process: If the volume remains constant during the process , then the process is called Isochoric or constant volume process. WdU iii TTmCU iii VVP ii T P T VP i v Q TransferHeat)( U EnergyInternalinChange)( W Gasby thekdoneWor)( T P VVBut T VP VolumeandeTemperatur,PressurebetweenRelation)( 1221 122-1 2 2 1 1 21 2 22 1 11 Dinesh Panchal

- 20. 2. Constant Temperature (Isothermal Process) : In this process temperature remains constant throughout the process. This process is called Isothermal Process. 0AsQ Q TransferHeat)( 0USo ButU EnergyInternalinChange)( log3.2 log3.2logW Gasby thekdoneWor)( VPVP TTBut T VP VolumeandeTemperatur,PressurebetweenRelation)( 21 121221 1 2 101 1 2 1011 1 2 112-1 2211 21 2 22 1 11 dUW WdU iv U TTTTmCU iii V V mRT V V VP V V VP ii T VP i v e Dinesh Panchal

- 21. Q TransferHeat)( U EnergyInternalinChange)( W Gasby thekdoneWor)( Constant T V T V PPBut T VP VolumeandeTemperatur,PressurebetweenRelation)( 12 1221 122-1 2 2 1 1 21 2 22 1 11 TTmC WdU iv TTmCU iii TTmR ii T VP i p v 2. Constant Pressure (Isobaric Process) : In this process pressure remains constant throughout the process. This process is called Isobaric Process. Dinesh Panchal

- 22. 3. Adiabatic Process (Isentropic Process) : In this process there is no heat addition or removal from the syatem to surrounding. 0Q TransferHeat)( U EnergyInternalinChange)( 1 1 W Gasby thekdoneWor)( PVPV VTVT VPVP VolumeandeTemperatur,PressurebetweenRelation)( 1221 21 2211 2-1 1 22 1 11 1- 22 1- 11 2121 iv TTmCU iii TTmR VPVP ii i v Dinesh Panchal

- 23. QUESTION NO. 1 (A) A dry saturated steam at a pressure of 600KPa is contained in a thermally insulated cylinder fitted with a frictional piston. As the piston moves outwards, the steam expands to a pressure 60KPa.Calculatye the work done by the gas. Dinesh Panchal KJJ Rm Rm K BarKPa KC BarKPa 383.1495.149383 4.0 4.59753 6.2328.314 14.1 1287 TT 1 W J/KgK287RofValueand1KgM:massunitfordoneWork TT 1 WexpansionadiabaticforWorkdone 6.223 6 0.6 8.314T P P TT P P T T processadiabaticFor ?T 6.060P :ConditionsfinalThe Table)SteamFrom(8.4312738.1588.158Tpressureat this TempSaturatedSosaturated.dryissteamtheAnd 6600P :ConditionsInitial 21 21 0 4.1 14.1 2 1 1 2 12 1 1 2 1 2 1 2 00 1 1

- 24. Free Expansion : The free expansion process is an irreversible process. Free expansion is a process in which the fluid expands suddenly in to the vacuum chamber. In this process no external heat is supplied and no external work is done. In this process enthalpy of the system remains constant. Limitations of 1st Law of Thermodynamics: 0 0W0 2-121 dU Q Dinesh Panchal

- 25. Heat Engine : Heat engine is a device which convert heat energy in to mechanical work in cyclic process. In heat engine high pressure and temp steam is generated in the boiler and supplied to the steam turbine. Turbine convert the heat energy of steam in to mechanical work. Suppose a heat engine is working between two heat reservoir one at high temp and one at low temp. Heat is supplied by the reservoir at high temp. and heat is rejected to the reservoir at low temp. h l h l 1 lh lh l h T T 1 Q Q 1 Q QQ SuppliedHeat Workdone EfficiencyThermal QQ engineby theRejectedHeat- enginethetoSuppliedHeatEngineby theWorkdone Qengineby theRejectedHeat QenginethetoSuppliedHeat Dinesh Panchal

- 26. Heat Pump : Heat engine is a device which transfer heat energy from low temp to high temp. this can be done by doing the external work on the system. Suppose a heat pump is working between two heat reservoir one at high temp and one at low temp. Heat is transferred from low temp to high temp. LH H LH H LH H L TT T QQ Q neNet Workdo EffectDesired EfficiencyThermal QQ SuppliedHeat- RejectedHeat PumpHeatby theRequiredWorkdone QPumpHeatby theRejectedHeat QPumpHeatthetoSuppliedHeat NETW Dinesh Panchal

- 27. Second Law of Thermodynamics: 1. Kelvin – Planks Statement : It is impossible to construct a heat engine which operate in a cycle, will produce no effect other than the exchange of heat from a single reservoir and produce work . Or no actual engine operating in a cycle can convert whole of heat energy supplied to it in to work. 2. Clausius Statement : It is impossible to construct a heat pump, which is operating in a cycle, will produce no effect other than the transfer of heat from lower temp. body to higher temp. body. Or heat can not flow from lower temp. to higher temp. without help of external work Third Law of Thermodynamics: This law state that absolute value of entropy can not be achieved. The entropy of perfect crystal is zero at absolute zero temp. Dinesh Panchal

- 28. Enthalpy: Enthalpy is the sum of internal energy and the product of pressure and volume or work done Enthalpy = U + p V Where U is the internal energy P is the pressure V is the volume Internal Energy: Internal energy is defined as the sum of all the microscopic forms of energy of the system. It is the energy associated with the molecular activity of the constituent partials of the system. It is the sum of kinetic energy and potential energy of the partials. It is denoted by U. Entropy : It is the function of quantity of heat which shows the possibility of conversion of that heat in to useful work. It is an important thermodynamic property of a working substance, which increases with the addition of heat and decreases with its removal. Temp.absolutetheisT substanceby theabsoredheattheisWhere Q TdSQ Dinesh Panchal

- 29. THERMODYNAMICS PROPERTIES OF STEAM 1. Vaporization: It is the process of change of liquid to vapor phase. Water vapor are obtained by vaporization and steam from boiling. 2. Evaporation: is the process of vapor generation only from the surface of the liquid. 3. Boiling :- is the process of vapor formation that take place in the whole mass of the liquid. 4. Saturated Temperature:- The boiling of liquid take place at a definite temp. and this temp dependent on the pressure called saturate temp. It is denoted by 5. Saturated Pressure:- The boiling of liquid take place at a definite Pressure at given temp. called Saturate Pressure . It is denoted by . st sp Dinesh Panchal

- 30. THERMODYNAMICS PROPERTIES OF STEAM 1. WET STEAM:- When the steam contain moist or water partial called wet steam. 2. DRY SATURATED STEAM:- When the wet steam is further heated and it does not contain any suspended partials of water it is known as dry saturated steam. Dry saturated steam absorbed its full latent heat. 3. SUPERHEATED STEAM:- When the dry stem is further heated at constant pressure for raising its temp then it is to be said superheated steam. 4. DRYNESS FRACTION:- It is the ratio of mass of actual dry steam to mass of total mass of wet steam denoted by x 5. Latent Heat of Vaporization:- It is the amount of heat absorbed to evaporate 1 kg of water at its boiling point or saturation temp without change in temp. fg g mm m x kgkjhfg /2257 Dinesh Panchal

- 31. 1. Sensible heat of Water:- :- It is the amount of heat absorbed by 1 kg of water, when heated at a constant pressure from to the temp of formation of steam 2. Latent Heat of vaporization: It is the quantity of heat required to convert 1 kg. of water at saturation temp. at a given pressure in to dry saturated steam at that temp. and pressure. It is denoted by 3. Enthalpy or Total Heat of steam:- It is the amount of heat absorbed by the water from freezing point to saturation temp plus heat absorbed during evaporation Enthalpy= Sensible Heat + Latent Heat• (1) Wet Steam (2) Dry Steam (3) Superheated steam KgtKJhf /2.4 fgf xhhh )*1( fgfg hhhh )()( supsupsup ttchttchhh pgpfgf fgh Dinesh Panchal

- 32. Entropy of Steam: Heating and vaporization of water during the steam formation take place at constant pressure. Even superheating is done at constant pressure. Entropy of water : Suppose 1 Kg. of water is heated from temp. T1 to T2 . Then Entropy change is given by (1) Wet Steam (2) Dry Steam (3) Superheated steam fgf xsss T xh ss fg f Thss sss fgfg fgfg / T T css SUP psg 3.2sup fS 1 2 21 log T T Csss T dT C T dQ ds epf p Dinesh Panchal

- 33. FORMATION OF STEAM UNDER DIFFERENT PRESSURE Dinesh Panchal

- 34. Q .No. 2(b) Determine the enthalpy , entropy and volume of steam at 1.4 MPa and 380 C Ans: Dinesh Panchal 305.7PrssureBar14andat380 305.7PrssureBar14andat400 139.7PrssureBar14andat350 -:EntropySpecific 7.3150PrssureBar14andat380 2.2583PrssureBar14andat400 7.1503PrssureBar14andat350 -:EnthalpySpecific 2107.030 50 0175.0 2002.0 350380 350400 2002.02177.0 2002.0PrssureBar14and380at 0.2177PrssureBar14and400at 0.2002PrssureBar14and350at -:VolSpecific 144.1PressureAt :TableSteamFrom 144.1Pressure 380SteamofTemp. :Given 0 2 0 1 0 0 22 0 11 0 1 `12 12 1 0 22 0 11 0 0 xC xC xC yxC yxC yxC xx xx yy yyxC yxC yxC BarMPa BarMPa C

- 35. Dinesh Panchal • Degree of superheat The Degree of Superheat can be defined as the amount by which the temperature of a superheated vapor/steam exceeds the temperature of the saturated vapor/steam at the same pressure. Superheated steam is a steam at a temperature higher than its vaporization (boiling) point at the absolute pressure where the temperature is measured. The difference between the superheated temperature and saturation vapor temperature is called the degree of superheat. It applied to vapors only. It is carried out at constant pressure. It is expressed as degree of superheat. Degree of superheat is the difference between actual temperature and the boiling ( saturation) temperature at a CERTAIN pressure.

- 36. Dinesh Panchal Example : (i) Pressure 1 bar For water vapor Actual temperature is 1070C. Boiling (saturation) temperature is 1000C. Degree of superheat is 107 –100 = 7 0C (ii) Pressure is 2 bars For water vapor Say actual temperature of vapor is 1350C. Boiling (saturation) is 1200C. Degree of superheat is 135 – 120 =150C (iii) Pressure is 1 bar. For refrigerant R-22. Say actual temperature is -350C. Boiling (saturation temperature at 1 bar is –410C. Degree of superheat is -35 –(-41) = 60C

- 37. Dinesh Panchal Degree of sub cooling. • The opposite of this is sub-cooling, the amount of additional heat removed from a fluid below its condensing point. An example would be refrigerant liquid coming off a condenser at its saturation point and then being cooled another ten or so degrees F., which is common. This too allows the fluid (refrigerant) more available capacity for work. It applied to LIQUID PHASE only. It is carried out at constant pressure. It is expressed as degree of sub-cooling. Degree of sub-cooling is the difference between the boiling (saturation) temperature and actual temperature of a liquid at a CERTAIN pressure. Actual temperature will be less than the condensation (saturation) temperature.

- 38. Dinesh Panchal Degree of sub cooling. Example : (i) Pressure 1 bar For water vapor Actual temperature is 400C. Condensation (saturation) temperature is 1000C. Degree of sub-cooling is 100 –40 = 60 0C (ii) Pressure is 2 bars For water vapor Say actual temperature of vapor is 1050C. Condensation (saturation) is 1200C. Degree of sub-cooling is 120 – 105 =150C (iii) Pressure is 1 bar. For refrigerant R-22. Say actual temperature is -450C. Condensation (saturation temperature at 1 bar is –410C. Degree of sub-cooling is -41 –(-45) = 40C

- 39. STEAM TABLE The properties of steam such as pressure temp. specific vol. enthalpy, entropy ect. have been experimentally determined and tabulated and are available in form of tables called steam table. Steam table gives value of specific vol. , enthalpy, entropy, for saturated liquid and dry saturated vapor tabulated against pressure or corresponding saturation temp. The properties of superheated steam are tabulated separately. STEAM TABLE P (Bar) (Ts) t ( centigrade) 200 250 300 350 400 5.0 (151.8) v 0.425 0.474 0.523 0.570 0.617 h 2855.4 2960.7 3064 3167.7 3271.9 s 7.059 7.271 7.46 7.633 7.794 15.0 (198.3) v 0.132 0.172 0.169 0.187 0.203 h 2796.8 2923.3 3037.6 3147.5 3255.8 s 6.455 6.709 6.918 7.102 7.269Dinesh Panchal

- 40. PROPERTIES OF DRY SATURATED STEAM PROPERTIES OF SUPERHEATED STEAM Absolute Pressure (Bar) Saturation temperature Specific Volume Specific Enthalpy (KJ/Kg) Specific Entropy (KJ/Kg K) 10 179.9 0.001127 0.194 762.6 2013.6 2776.2 2.138 4.4446 6.5825 20 233.8 0.001216 0.0666 1008.4 1793.9 2802.2.3 3.5382 3.5382 6.1837 Kgm /3 C0 p st fv gv fh fgh gh fs fgs fgs Absolute Temperature (Bar) Saturation Pressure Specific Volume Specific Enthalpy (KJ/Kg) Specific Entropy (KJ/Kg K) 10 0.0123 0.001000 106.4 42.0 2477.7 2519.7 0.151 8.750 8.901 50 0.1235 0.001012 12.03 209.3 2382.7 2582.7 0.704 7.372 8.076 st p fv gv fh fgh gh fs fgs gs Dinesh Panchal

- 41. INTERPOLATION This method is used to find the intermediate values of steam properties 12 12 1 1 yy pp pp yy Dinesh Panchal

- 42. Temp. and Entropy Diagram It is a graph between the Temp. And Entropy of steam where Entropy on x- axis and Temp on the Y – Axis # The liquid boundary line originates at the axis of ordinate at temp. 273.16 k # The boundary curve (ABCD) and saturated vapor line (EFGHI) divide the diagram in two three parts # To the left of AE is the liquid region. Between AE and EI wet vapor region. To the right of EI Iies the region of superheated steam. # The boundary curve meet at point E which is critical point of water. With pressure 221.2 bar and temp. 647.31 K . # The constant pressure lines are parallel to the constant temp. lines in the wet region. # The wet region has plots of constant dryness fraction and constant vol. lines. # The const. vol. lines are steeper than const. pressure lines in the superheated region. Dinesh Panchal

- 43. Dinesh Panchal

- 44. Mollier Diagram It is a graphical representation of steam table in which enthalpy is plotted along Ordinate and entropy along Abscissa Dinesh Panchal

- 45. Dinesh Panchal

- 46. CARNOT CYCLE Fig shows the P-V and T-S Diagram of Carnot Cycle. This cycle consist of two isentropic and two isothermal processes. 1. Process 1-2 : (Isothermal Expansion Process) : In This process the cylinder piston arrangement put on the source maintained at constant temp. and gas is allowed to expand isothermally. During this process heat is added to the system isothermally and heat addition is given by the equitation 1 2 11 logQSuppliedHeat v v mRT Dinesh Panchal

- 47. Process 2-3 Adiabatic Expansion: In this process the gas in the cylinder piston is allowed to expand adiabatically at the cost of the heat of the system. So the temp. of the system drops up to temp. T2 . In this process there is no heat addition. Process 3-4 Adiabatic Compression: In This process the cylinder piston arrangement put on the sink maintained at constant temp. T2 and gas is compressed isothermally. During this process heat is rejected by the system to the sink isothermally and heat addition is given by the equitation. 3 4 22 logQRejectedHeat v v mRT Dinesh Panchal

- 48. Efficiency of the Cycle: 1 2 1 2 1 21 2 3 2 2 3 21 2 3 21 2 3 2 2 3 1 1 4 2 2 3 1 Net Net 1 1 T logRT logTR SuppliedHeat Work Efiiciency logTR logRTlogRT logRTlogRT CycleoneinRejectedHeat-CycleinSuppliedHeatW Wcyclein theneNet workdo T T T T T T v v v v T v v T v v v v v v v v e e e ee ee Dinesh Panchal

- 49. Efficiency of Rankine Cycle:- Dinesh Panchal 3baa2Area 34112Area Therefore, smallveryiswaterofvol.specificbecause,negligibleisworkPumpThe 3baa22Area 341122Area q w SuppliedHeat Net Work w q q waysameIn the q Process)(Adiabatic0q4,-3ProcessFor q Process)Addition(Heat0w3,-2ProcessFor dhwq energykineticandenergypotentialinchange thegconsiderinwithoutsystemthethetoamicsthermodynoflaw1st applyingandfluid,workingofKg1Consider I I Rankine I I 23 1243 12432143 21 41 43 23 hh hhhh iciencyThermalEff hhhhhhhhww hhdh hhdh hhdh hhdh Boiler Net th PumpTurbineNet PumpPump CondensorCondensor TurbineTurbiner BoilerBoiler

- 50. Reasons for Considering Rankine Cycle as an Ideal Cycle For Steam Power Plants: 1) It is very difficult to build a pump that will handle a mixture of liquid and vapor at state 1’ (refer T-s diagram) and deliver saturated liquid at state 2’. It is much easier to completely condense the vapor and handle only liquid in the pump. 2) In the Rankine cycle, the vapor may be superheated at constant pressure from 3 to 3” without difficulty. In a Carnot cycle using superheated steam, the superheating will have to be done at constant temperature along path 3-5. During this process, the pressure has to be dropped. This means that heat is transferred to the vapor as it undergoes expansion doing work. This is difficult to achieve in practice. Dinesh Panchal

- 51. Question : Discuss the effect of dryness fraction of steam on the performance of the steam power plant. Steam at 15 bar and 300 c is throttled to 10 bar before supplying the steam turbine. It is then undergoes isentropic expansion to 1 bar in the turbine. Determine isentropic heat drop and condition of steam at exit from the turbine. Use enthalpy-entropy chart Ans: With increase in dryness fraction the amount of liquid water decrease. As the liquid particle have lesser velocity than that of vapor particles hence liquid particles obstruct the flow of vapor particle therefore loss in the kinetic energy. Also the steam having high dryness fraction carry high amount of heat. So efficiency of the steam turbine will increase with increase in dryness fraction. Dinesh Panchal

- 52. Dinesh Panchal

- 53. Dinesh Panchal /4502580-3030orkdoneW bar2580HEnthalpy DiagramEntropy-Enthalpythefromofvaluethefind )S(SProcessIsentropicFor (Given)1barPPressure -:turbinetheleavingAfter.3 /3030HDiagramEntropy-EnthalpytheFrom (Given)15barTeTemperatur DiagramEntropy-EnthalpythefromofvaluethefindH&PofvaluetheFrom bar0303HEnthalpy)H(HProcesslingFor thrott (Given)10barPPressure -:turbinetheenteringbeforeandttlingAfter thro2. /3030HDiagramEntropy-EnthalpytheFrom (Given)15barTeTemperatur (Given)15barPPressure -:ThrottlingBefore1. 3 32 3 1 1 21 221 2 1 1 1 kgkj kgKJ kgKJ

- 55. BOILER It is a closed vessel which generate steam at desired pressure and temp. by transferring the heat from the burning fuel to water to change in to steam. Applications of Steam: # Power generation # Industrial Process Work # Heating Installations # Hot water supplies FACTOR AFFECTING THE BOILER SELECTION • # Working pressure of steam • # Quality of stem Required • # Steam generation Rate • # Fuel and water available • #Type of fuel used • # Facilities available for erection • # Operation and Maintenance cost • # Load Factor • # Initial Cost Dinesh Panchal

- 56. REQUIREMENTS OF GOOD BOILER # It should produce max. quantity of steam with min. fuel consumption # It should be light in weight # It should occupies small space # Capable of quick start # Meet Large variation of load # Easy Maintenance # Mud should not deposits on heated plates # Installation should be simple # It should as per safety regulation laid down by boiler act.Dinesh Panchal

- 57. CLASSIFICATION OF BOILERS # According to the Content in the tube 1. Fire Tube Boiler : fire tube boiler hot gases passes through the tubes and water surrounds them. Heat conducted through the wall of the tube from the hot gases to the surrounding water Examples: Cochran Boiler, Lancashire Boiler, Cornish Boiler and Locomotive Boiler . : 2. Water Tube Boiler :- In water tube boiler water flows through the tubes and flue gases flows around the tubes. Heat conducted through the wall of the tube from the hot gases to the water inside the tube. Examples: Babcock and Wilcox Boiler, Strirling Boiler, La mont Boiler and Benson Boiler Dinesh Panchal

- 58. # According to the Method of Firing 1. Internally Fired Boiler : Are those boilers in which furnace is located inside the boiler shell or drum. Most of boiler are internally fired boilers. Examples: Cochran Boiler, Lancashire Boiler, and Locomotive Boiler .2. Externally Fired Boiler : Are those boilers in which furnace is located outside the boiler shell or drum. Most of boiler are internally fired boilers. Examples: Babcock and Wilcox Boiler # According to the Pressure of Steam 1. Low Pressure Boilers: Are those boilers which generates the steam at a pressure below 80 bar is called Low Pressure Boilers Examples: Cochran Boiler, Lancashire Boiler, and Locomotive Boiler 2. High Pressure Boilers: Are those boilers which generates the steam at a pressure More than 80 bar is called Low Pressure Boilers. Examples: Babcock and Wilcox Boiler, Lamont, Benson Boiler Dinesh Panchal

- 59. # According to Method of Circulation Of Water 1. Natural Circulation::: In natural circulation boilers, Circulation of water is due to gravity. Examples: Babcock and Wilcox Boiler, Lancashire Boiler, and Locomotive Boiler 2. Forced Circulation:: In forced circulation boilers Circulation of water by the pump driven by external power. Examples: Lamount , Benson Boiler # According to Axis of Shell or Drum 1. Vertical Boiler::-If the axis of the shell of the boiler is vertical so called vertical boilers. Examples: Cochran Boiler 2. Horizontal Boiler: If the axis of the shell of the boiler is horizontal so called horizontal boilers. Examples: Laocomotive Boiler , Lancashire Boiler Dinesh Panchal

- 60. # According to No. of Tubes 1. Single Tube Boiler : In single tube boiler there is only one water tube or fire tube. Examples: Cornish Boiler 2. Multi Tube Boiler : In multi tube boiler there are two or more than two water tubes or fire tubes. Examples: Cochran Boiler , Lancashire Boiler and Locomotive boiler # According to Nature of Draught 1. Natural draught boiler:- in natural draught boilers , draught is produced by natural circulation of air and gas 2. Forced draught Boilers: in Forced draught boilers , draught is produced by means of mechanical fans Dinesh Panchal

- 61. COMPARISON FIRE TUBE AND WATER TUBE BOILER FIRE TUBE BOILER 1. Hot gases flow through the tubes 2. Generate steam pressure up to 25 bar 3. Rate of steam generation is up to 9 tons per hour 4. Floor area required is more 5. Overall efficiency is 75% 6. Transportation and erection is difficult 7. Water does not circulate in definite direction 8. Operating cost is less 9. Bursting chances are less 10. used in large power plant 11. Greater risk in case of bursting WATER TUBE BOILER 1. Water circulate inside the tubes 2. Generate steam pressure up to 250 bar 3. Rate of steam generation is up to 450 tons per hour 4. Floor area required is less 5. Overall efficiency is 90% 6. Transportation and erection is easy 7. Water circulate in definite direction 8. Operating cost is high 9. Bursting chances are more 10. used in process industries 11. lesser risk in case of bursting Dinesh Panchal

- 62. COCHRAN BOILER It is vertical ,multi tubular, fire tube , internally fired natural circulation Boiler. It consist of a vertical cylindrical shell having a hemispherical top and furnace is also hemispherical . The fire grate is arranged in the furnace and ash pit is provided below the grate . A fire door is attached to the fire box . The boiler has a combustion chamber which is lined with fire bricks. the end of the smoke tube are fitted in the smoke box. The chimney is provided on the top of the smoke box to discharge of gas to the atmosphere. The furnace is surrounded by water on all sides except at opening of the fire door and combustion chamber. Dinesh Panchal

- 63. BABCOCK AND WILCOX BOILER It is a horizontal drum, multi tubular, water tube, externally fired , natural circulation boiler. The water tube boiler are used when pressure above 10 bar and steam capacity more than 7000 kg per hr. is required. It consist of a drum mounted at the top and connected by upper header and down take header. A large no. of. Water tubes connects the uptake and down take header. the water tubes are inclined 5 to 15 degrees to promote water circulation. The heating surface of the tubes. And half of the cylinder surface of the water drum which is exposed to the flue gases. Below the uptake header the furnace of the boiler is arranged. There is a bridge wall deflector which deflect the combustion gases upward. Dinesh Panchal

- 64. Baffles are arranged across the tubes to act as a deflectors for the flue gases and to provide them with gas passes. A chimney is provided for the exit of gases. A damper is placed at the inlet of the chimney to regulate the draught. Working: The hot combustion gases caused by burning of the fuel on the grate rises and are deflected upward by the bridge walls deflectors and passers over to the front portion water tubes and drum. By this way they complete the first pass. With the provision of baffles they deflect downward and complete the second pass .During their travel they give heat to the water and steam is formed. The circulation of the water in the boiler is natural. The hottest water and stem rise from the tube to the uptake header and then through the rise enter the boiler drum. Specification – Dia of Drum – 1.22 to 1.83 m LENGTH – 6.096 To 9.144 M SIZE OF SUPERHEATER TUBE – 3.84 TO 5.71 SIZE OF WATER TUBE – 7.62 To 10.16 WORKING PRESSURE – 40 BAR STEAM CAPICITY- 40000 KG PER HR EFFICIENCY – 60 To 80% Dinesh Panchal

- 65. Boiler Mountings: The boiler mountings are the part of the boiler and are required for proper functioning. In accordance with the Indian Boiler regulations, of the boiler mountings is essential fitting for safe working of a boiler. These mounting are the integral part of the Boiler. Some of the important mountings are: Dinesh Panchal

- 66. 1.WATER LEVEL INDICATOR Water level indicator is a device to show the level of water in boiler. It located in front of boiler in such a position that the level of water can easily be seen by attendant. Two water level indicators are used on all boilers. . It consist three valve and a glass tube . Steam valve D connects the glass tube with steam space and valve E connect the glass tube with water .Drain Valve K is used at frequent intervals. If glass is broken two balls after B and C close the end of the glass tube and protects the water and steam from escaping. Dinesh Panchal

- 67. Fusible Plug :- It is very important safety device, which protects the fire tube boiler against overheating. It is located just above the furnace in the boiler. It consists of gun metal plug fixed in a gun metal body with fusible molten metal. During the normal boiler operation, the fusible plug is covered by water and its temperature does not rise to its melting state. But when the water level falls too low in the boiler, it uncovers the fusible plug. The furnace gases heat up the plug and fusible metal of plug melts, the inner plug falls down The water and steam then rush through the hole and extinguish the fire before any major damage occurs to the boiler due to overheating. Dinesh Panchal

- 68. Pressure Gauge :- The function of the pressure gauge is to indicate the steam pressure of boiler in bar gauge. A pressure gauge is fitted in front of boiler in such a position that the operator can conveniently read it. It reads the pressure of steam in the boiler and is connected to steam space by a siphon tube. The most commonly, the Bourdon pressure gauges used. I A burden tube pressure gauge consist of a elliptical elastic tube ABC bent in to an arc of a circle. One end of the tube is fixed and connected to the steam space in the boiler and other end is connected to a sector link. When pressure increases the tube tends to straighten and pinion and sector arrangement rotate a pointer. The pointer moves over a calibrated scale. Dinesh Panchal

- 69. Blow-Off Cock:- The function of blow-off cock is to discharge mud and other sediments deposited in the bottom most part of the water space in the boiler, while boiler is in operation. It can also be used to drain-off boiler water. Hence it is mounted at the lowest part of the boiler. When it is open, water under the pressure rushes out, thus carrying sediments and mud. The cock is fitted to the bottom of the boiler drum and consist of a conical plug fitted to the body. Dinesh Panchal

- 70. SAFETY VALVES: Safety valves are located on the top of the boiler. They guard the boiler against the excessive high pressure of steam inside the drum. If the pressure of steam in the boiler drum exceeds the working pressure then the safety valve allows blow-off the excess quantity of steam to atmosphere. Thus the pressure of steam in the drum falls. The escape of steam makes a audio noise to warm the boiler attendant. There are four types of safety valve. • 1. Dead weight safety valve. • 2. Spring loaded safety valve • 3. Lever loaded safety valve • 4. High steam and low water safety valve. Dinesh Panchal

- 71. FEED CHECK VALVE :- The feed check valve is fitted to the boiler, slightly below the working level in the boiler. It is used to supply high pressure feed water to boiler. It also prevents the returning of feed water from the boiler if feed pump fails to work. Dinesh Panchal

- 72. Boiler Accessories The accessories are mounted on the boiler to increase its efficiency. These units are optional on an efficient boiler. With addition of accessories on the boiler, the plant efficiency also increases. The following accessories are normally used on a modern boiler: (i) Economizer (ii) Super heater (iii) Air pre heater (iv) Feed water pump (v) Steam injector. Dinesh Panchal

- 73. ECONOMIZER :- An economizer is a heat exchanger, used for heating the feed water before it enters the boiler. The economizer recovers some of waste heat of hot flue gases going to chimney. It helps in improving the boiler efficiency. It is placed in the path of flue gases at the rear end of the boiler just before air pre-heater. Dinesh Panchal

- 74. SUPERHEATER:- It is a heat exchanger in which heat of combustion products is used to dry the wet steam, pressure remains constant, its volume and temperature increase. Basically, a super heater consists of a set of small diameter U tubes in which steam flows and takes up the heat from hot flue gases. Dinesh Panchal

- 75. AIR PRE- HEATER:- The function of an air pre-heater is similar to that of an economizer. It recovers some portion of the waste heat of hot flue gases going to chimney, and transfers same to the fresh air before it enters the combustion chamber. Due to preheating of air, the furnace temperature increases. It results in rapid combustion of fuel with less soot, smoke and ash. The high furnace temperature can permit low grade fuel with less atmospheric pollution. The air pre-heater is placed between economizer and chimney. FEED WATER PUMP:- It is used to feed the water at a high pressure against the high pressure of steam already existing inside the boiler. STEAM INJECTOR:- A steam injector lifts and forces the feed water into the boiler. It is usually used for vertical and locomotive boilers and can be accommodated in small space. It is less costly. It does not have any moving parts thus operation is salient. Dinesh Panchal

- 77. STEAM TURBINE FLOW DIRECTION AXIAL RADIAL WAY OF ENERGY CONVERSION IMPULSE REACTION TYPE OF COMPOUNDING PRESSURE COMPOUNDING VELOCITY COMPOUNDING PRESSURE VELOCITY COMPOUNDING EXHAUSTING CONDITION CONDENSING EXTRACTION BACK PRESSURE REHEAT NO. OF STAGES SINGLE MULTI INLET PRESSURE LOW MEDIUM HIGH STEAM TURBINE CLASSIFICATION Dinesh Panchal

- 78. Stem Turbine : In steam turbine enthalpy of the steam is first converted in to kinetic energy in the nozzle or blade passage. The high velocity steam impinges on the curved blade which change the direction of the steam. The chjange in the flow of direction causes a force to be exerted on the blade fixed on the rotor and power is developed. Advantages of steam turbine over reciprocation steam engine: 1. Highly simplified in construction and operation 2. 2. Condensate can be used directly in the boiler without pretreatment. 3. The vibration and noise in minimum. 4. Much higher speed is possible. 5. Steam turbine can take considerable over load. 6. Steam turbines can be designed ranging from 1KW to 1000MW. Dinesh Panchal

- 79. Classification of Steam turbine: Steam turbine mainly classified in to two group. 1. Impulse Turbine 2. Reaction Turbine 1. Impulse Turbine: The steam coming with very high velocity through the fixed nozzle and the high velocity steam impinges on the blades fixed on the periphery of the rotor. The blade changes the direction of the steam flow without changing its pressure. Due to change in the direction of flow of steam , there is change in the momentum of the steam which exert the force on the blades and hence there rotor moves. Example of impluse turbine are De-Laval, Curties and Rateau. Dinesh Panchal

- 80. Reaction Turbine : The high pressure steam from the boiler is passed through the nozzle . As shown in fig. When the steam comes out from the nozzle they produces the reaction force on the rotation disk and the disk rotate opposite to the direction of the steam flow. Dinesh Panchal

- 81. Impulse Vs Reaction Turbine : 1. In impulse turbine, steam completely expands in the nozzle and its pressure remain constant. In Reaction turbine, steam partially expands in the nozzle and expansion also takes place on the blades. 2. In impulse turbine, relative velocity of the steam passing over the blades remain constant if there is no friction. In impulse turbine, relative velocity of the steam passing over the blades increases as its passes over the blades. 3. In impulse turbine, Blades shape are symmetrical. But reaction turbine have aerofoil section . The area of flow changes along the blade passage similar to the nozzle. Dinesh Panchal

- 83. CONDENSERS • Condenser is a device in which steam is condensed at a pressure lower than atmospheric pressure • Condensation can be done by removing the heat from exhaust steam by using circulating cooling water. • A condenser is basically stem to water exchanger in which heat from the exhaust steam is transferred to the circulating water. • Function of condensers is to reduce the turbine exhaust presure so as to increase the specific output and hence increase the plant efficiency and to reduce the specific steam consumption. • It also condense the exhaust steam from the turbine and reuse it as a pure feed water in the boiler. Dinesh Panchal

- 84. Advantages of Condensers: # High pressure ratio provide the larger enthalpy drop # work output per kg of steam increases and hence specific steam consumption is reduced. # condensate can be reused as a hot feed water to the boiler. This reduces the fuel consumption. # No feed water treatment is required. Hence reduce the cost of plant. # Formation of deposit in the boiler surface can be prevented with the use of condensate instead of feed water from out sources. Elements of condensers: 1. Condensers 2. Air extraction Pump 3. Condensate extraction Pump 4. Circulating cooling water pump 5. Hot well 6. Cooling Tower 7. Make up water pump 8. Boiler feed water pump Dinesh Panchal

- 85. Dinesh Panchal

- 86. Classification of condensers : Dinesh Panchal

- 87. CLASSIFICATION OF CONDENSER condenser JET CONDENSER PARALLEL FLOW LOW LEVEL TYPE HIGH LEVEL TYPE COUNTER FLOW EJECTOR FLOW SURFACE CONDENSER DOWN FLOW TYPE CENTRAL FLOW TYPE INVERTED FLOW TYPE REGENERATIVE TYPE EVAPORATIVE TYPE Dinesh Panchal

- 88. Dinesh Panchal

- 89. Dinesh Panchal

- 90. Jet Condensers: They are used in small capacity units where fresh clean water is available in plenty. In jet condenser water is in direct contact with exhaust steam. Hence they are called direct type or mixed type condensers Advantages of jet Condensers: 1. As result of effective mixing, it require less circulating cooling water 2. Equipments are simple and occupy less space 3. Maintenance is cheap Disadvantages : 1. Not suitable for higher capacity 2. Condensate can not be used as feed water to boiler 3. Air leakage are more 4. Require larger air pump 5. Less vacuum is maintained. Dinesh Panchal

- 91. Surface condenser are used in large capacity plants. In surface condenser, exhaust steam and water do not mix together. Hence they are called Indirect contact type or non mixed type. Advantages: 1. Can be used for large capacity plants. 2. High Vacuum is created. 3. Condensate is free from impurities and can be reused as feed water to the boiler. 4. Air leakage is completely less, hence less power is required to operate air pump. Disadvantages : 1. Design is complicated and costly 2. High maintenance cost 3. Occupies more space 4. Require more circulating water. Dinesh Panchal

- 93. I.C.ENGINES ENGINE:- An Engine is a device which transforms the chemical energy of a fuel into thermal energy and uses this thermal energy to produce mechanical work. Engines normally convert thermal energy into mechanical work and therefore they are called heat engines. TYPES OF ENGINES:- Heat engines can be broadly classified into : i) External combustion engines ( E C Engines) ii) Internal combustion engines ( I C Engines ) Dinesh Panchal

- 94. External combustion engines:- are those in which combustion takes place outside the engine. For example, In steam engine or steam turbine the heat generated due to combustion of fuel and it is employed to generate high pressure steam, which is used as working fluid in a reciprocating engine or turbine. See Figure 1. Internal combustion engines:- are those in which combustion takes place inside the engine or cylinder . For example, Diesel engine, petrol engine , gasoline engine the heat generated due to combustion of fuel and it is employed to give the motion to cylinder Dinesh Panchal

- 95. ADVANTAGES OF INTERNAL COMBUSTION ENGINES 1. Greater mechanical simplicity. 2. Higher power output per unit weight because of absence of auxiliary units like boiler , condenser and feed pump 3. Low initial cost 4. Higher brake thermal efficiency as only a small fraction of heat energy of the fuel is dissipated to cooling system 5. These units are compact and requires less space 6. Easy starting from cold conditions DISADVANTAGES OF INTERNAL COMBUSTION ENGINES 1. I C engines cannot use solid fuels which are cheaper. Only liquid or gaseous fuel of given specification can be efficiently used. These fuels are relatively more expensive. 2. I C engines have reciprocating parts and hence balancing of them is problem and they are also susceptible to mechanical vibrations. Dinesh Panchal

- 96. CLASSIFICATION OF INTERNAL COMBUSTION ENGINES. 1. According to thermodynamic cycle i) Otto cycle engine or Constant volume heat supplied cycle. ii) Diesel cycle engine or Constant pressure heat supplied cycle iii) Dual-combustion cycle engine 2. According to the fuel used: i) Petrol engine ii) Diesel engine iii) Gas engine 3. According to the cycle of operation: i) Two stroke cycle engine ii) Four stroke cycle engine 4. According to the method of ignition: i) Spark ignition (S.I) engine ii) Compression ignition (C I ) engine 5. According to the number of cylinders. i) Single cylinder engine ii) Multi cylinder engine Dinesh Panchal

- 97. 6. According to the arrangement of cylinder: I) Horizontal engine ii) Vertical engine iii) V-engine v) In-line engine vi) Radial engine, etc. 7. According to the method of cooling the cylinder: I) Air cooled engine ii) Water cooled engine 8. According to their applications: i) Stationary engine ii) Automobile engine iii) Aero engine iv) Locomotive engine v) Marine engine, etc. Dinesh Panchal

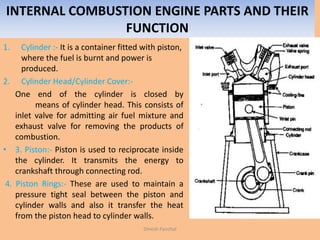

- 98. INTERNAL COMBUSTION ENGINE PARTS AND THEIR FUNCTION 1. Cylinder :- It is a container fitted with piston, where the fuel is burnt and power is produced. 2. Cylinder Head/Cylinder Cover:- One end of the cylinder is closed by means of cylinder head. This consists of inlet valve for admitting air fuel mixture and exhaust valve for removing the products of combustion. • 3. Piston:- Piston is used to reciprocate inside the cylinder. It transmits the energy to crankshaft through connecting rod. 4. Piston Rings:- These are used to maintain a pressure tight seal between the piston and cylinder walls and also it transfer the heat from the piston head to cylinder walls. Dinesh Panchal

- 99. 5. Connecting Rod:- One end of the connecting rod is connected to piston through piston pin while the other is connected to crank through crank pin. It transmits the reciprocatory motion of piston to rotary crank. 6. Crank:- It is a lever between connecting rod and crank shaft. 7. Crank Shaft:- The function of crank shaft is to transform reciprocating motion in to a rotary motion. 8. Fly wheel:- Fly wheel is a rotating mass used as an energy storing device. 9. Crank Case:- It supports and covers the cylinder and the crank shaft. It is used to store the lubricating oil. Dinesh Panchal

- 100. IC ENGINE – TERMINOLOGY 1. Bore: The inside diameter of the cylinder is called the bore. 2. Stroke: The linear distance along the cylinder axis between the two limiting positions of the piston is called stroke. 3.Top Dead Centre (T.D.C) The top most position of the piston towards cover end side of the cylinder” is called top dead centre. In case of horizontal engine, it is called as inner dead centre Dinesh Panchal

- 101. Working of a Four-Stroke Petrol Engine 1. Suction Stroke : During suction stroke, the piston is moved from the top dead centre to the bottom dead centre by the crank shaft. The crank shaft is revolved either by the momentum of the flywheel or by the electric starting motor. The inlet valve remains open and the exhaust valve is closed during this stroke. The proportionate air- petrol mixture is sucked into the cylinder due to the downward movement of the piston. This operation is represented by the line AB on the P- V diagram. 2. Compression Stroke: During compression stroke, the piston moves from bottom dead centre to the top dead centre, thus compressing air petrol mixture. Due to compression, the pressure and temperature are increased and is shown by the line BC on the P- V diagram. Just before the end of this stroke the spark - plug initiates a spark, which ignites the mixture and combustion takes place at constant volume as shown by the line CD. Both the inlet and exhaust valves remain closed during this stroke.Dinesh Panchal

- 102. 3. Working Stroke: The expansion of hot gases exerts a pressure on the piston. Due to this pressure, the piston moves from top dead centre to bottom dead centre and thus the work is obtained in this stroke. Both the inlet and exhaust valves remain closed during this stroke. The expansion of the gas is shown by the curve DE. 4. Exhaust Stroke: During this stroke, the inlet valve remains closed and the exhaust valve opens. The greater part of the burnt gases escapes because of their own expansion. The drop in pressure at constant volume is represented by the line EB. The piston moves from bottom dead centre to top dead centre and pushes the remaining gases to the atmosphere. When the piston reaches the top dead centre the exhaust valve closes and cycle is completed. This stroke is represented by the line BA on the P- V diagram. The operations are repeated over and over again in running the engine. Thus a four stroke engine completes one working cycle, during this the crank rotate by two revolutions.Dinesh Panchal

- 103. Working of 2-S Engine Diagram 1: The piston moves up, compressing the fuel-air mixture in the cylinder. Simultaneously, the bottom of the piston uncovers a port (the inlet port), and sucks a fuel-air charge into the bottom of the engine .It can do this because as the piston moves up, it creates a low pressure zone in the enclosed space behind it, and so the charge rushes in. When the piston gets to the top of its stroke, either the spark plug fires (in a petrol engine), or diesel-fuel is sprayed into the engine and ignites because of the extreme heat produced by the compression of air in the cylinder. Dinesh Panchal

- 104. • Diagram 2: The spark plug fires (or diesel-fuel is injected into the cylinder), the piston is driven down, and the bottom of the piston compresses the charge below it. As the piston moves further down, it uncovers the exhaust port, and the burnt gasses begin to flow out of the cylinder. Near the bottom of its stroke, the piston then uncovers the inlet port, and the compressed charge flows into the top of the cylinder helping to drive the burnt gasses out of the cylinder. Dinesh Panchal

- 105. Diagram 3-4: The spark plug fires (or diesel- fuel is injected into the cylinder), the piston is driven down, and the bottom of the piston compresses the charge below it. As the piston moves further down, it uncovers the exhaust port, and the burnt gasses begin to flow out of the cylinder. Near the bottom of its stroke, the piston then uncovers the inlet port, and the compressed charge flows into the top of the cylinder helping to drive the burnt gasses out of the cylinder Dinesh Panchal

- 106. COMPARISON OF SI AND CI ENGINES 1. Works on otto cycle 2. Petrol is used as a fuel 3. It has lass compression ratio 4. Ignition takes place with the help of electric spark 5. Thermal efficiency is less 6. Initial cost is less 7. Starting is easy 8. Maintenance cost is less 9. It has carburetor to mix air and fuel 10. They are light in weight 1. Works on diesel cycle 2. Diesel is used as a fuel 3. It has more compression ratio 4. Ignition takes place due to compression 5. Thermal efficiency is more 6. Initial cost is higher 7. Starting is difficult 8. Maintenance cost is high 9. It has injector to inject fuel. 10. They are heavy in weight Dinesh Panchal

- 107. Comparison Between 2-S and 4- S Engines 2-Stroke 1. Crank complete one revolution in in one power stroke 2. Turning effort on crank is much uniform. So lighter flywheel is required 3. It has three ports 4. It is compact and light in weight 5. It produce more noise and has more wear and tear 6. Maintenance cost is less 7. Thermal efficiency is less 8. More lubricating oil is consumed 9. Crank case is made gas tight 10. More lubricating oil is consumed 4-Stroke 1. Crank complete two revolution in in one power stroke 2. Turning effort on crank is not uniform. So heavier flywheel is required 3. It has two valves 4. It is heavier and complicated in design 5. It produces less noise 6. Maintenance cost is high 7. Thermal efficiency is high 8. Less lubricating oil is consumed 9. Crank case ins not made gas tight 10. More lubricating oil is consumed Dinesh Panchal

- 108. Otto Cycle Fig. Shows the P-V and T-S Diagram of Otto Cycle Diesel cycle consist four processes:: 1. Process 1-2 (Isentropic Compression): In this Process piston moves from BDC to TDC and compression of air will take place adiabatically. It means there is no heat addition and removal from the gas. 2. Process 2-3 (heat addition at const. vol.): In this Process heat addition will take place at constant vol. Fuel is continuously added to air up to point 3.Dinesh Panchal

- 109. 3. Process 3-4 (Isentropic Expansion): In this Process piston moves from TDC to BDC and expansion of air will take place adiabatically. It means there is no heat addition and removal from the gas. 4. Process 4-1 (heat rejection at const. vol.): In this Process heat rejection will take place at constant vol. Dinesh Panchal

- 110. EFFICIENCY OF OTTO CYCLE 14v23v 21 14v2 2 23v1 1 cmcm QQRejectedHeat-addedHeatWorkdone cmQ DifferenceTemp.*Vol.Const.atHeatSpecific*QRejectedHeat 4-3processtheduringrejectedisHeat cmQ DifferenceTemp.*Vol.Const.atHeatSpecific*QInputHeat 2-1processtheduringaddedisHeat TTTT TT Mass TT Mass Dinesh Panchal

- 111. 1 11- 2 1- 11 2 2 1 1 2 1 11- 2 1- 11 2 1- 22 1- 11 13 14 23 14 23v 14v 23v 14v23v 1 21 1 T V VT RatioompressionButT V VT VTVT SoProcess.isentropicis2-1Process respct.TandTof in termsTandTofvalueput theNow 1..........................................1 cm cm 1 cm cmcm edHeatSuppli Workdone Efficiency c c rT Cr V V V V T TT TT TT TT TT TTTT Q QQ Q W Dinesh Panchal

- 112. c c c cc c c r r r TT rr TT TT TT rT Cr V V V V T RationCompressio ondependentcycleottoofefficiencySo 1 1 TT 1 TT 1 11eq.inofvalueput theNow T RatioompressionBut T V VT VTVT Soexpansion.isentropicis4-3Process 1 14 1 14 1 1 1 4 14 23 14 1 43 3 4 1 3 4 41- 3 1- 44 3 1- 44 1- 33 Dinesh Panchal

- 113. Diesel Cycle Fig. Shows the P-V and T-S Diagram of Diesel Cycle Diesel cycle consist four processes:: 1. Process 1-2 (Isentropic Compression): In this Process piston moves from BDC to TDC and compression of air will take place adiabatically. It means there is no heat addition and removal from the gas. 2. 1. Process 2-3 (heat addition at const. pressure): In this Process heat addition will take place at constant pressure . Fuel is continuously added to air up to point 3.Dinesh Panchal

- 114. 3. Process 3-4 (Isentropic Expansion): In this Process piston moves from TDC to BDC and expansion of air will take place adiabatically. It means there is no heat addition and removal from the gas. 4. Process 4-1 (heat rejection at const. vol.): In this Process heat rejection will take place at constant vol. Dinesh Panchal

- 115. 14v23p 21 14v2 23p1 cmcm Q-QRejectedHeat-addedHeatWorkdone cmQ DifferenceTemp.*Vol.Const.atHeatSpecific*RejectedHeat 4-3processtheduringrejectedisHeat cmQ DifferenceTemp.*PressureConst.atHeatSpecific*InputHeat 2-1processtheduringaddedisHeat TTTT TT Mass TT Mass Dinesh Panchal

- 116. 1 11- 2 1- 11 2 2 1 1 2 1 11- 2 1- 11 2 1- 22 1- 11 1 332 v p 23 14 23p 14v 23p 14v23p 1 21 1 T V VT RatioompressionButT V VT VTVT SoProcess.isentropicis2-1Process respct.Tof in termsTand,T,Tofvalueput theNow c c Because 1...........................1 cm cm 1 cm cmcm edHeatSuppli Workdone Efficiency c c rT Cr V V V V T TT TT TT TT TT TTTT Q QQ Q W Dinesh Panchal

- 117. 1 11 1-1 eq.efficiencyin theT,T,Tofvalueput theNow T 1 * 1 **TT 1 * 1 **T V VT T VTVT SoProcess.isentropicis4-3Process T RatioratiooffCutButT V VT VV SoProcess.isobaricis3-2Process 11 1 1 1 11 432 14 1 1 1 1 3 1 4 2 2 3 344 1 1 1 1 3 1 4 2 2 3 34 1 4 3 3 4 1 33 4 1 44 1 33 1 123 2 3 2 3 2 2 32 3 3 3 2 2 cccc c Ccc c C c Ccc c C ccc c c c c c rrTrT TT T r rT r T V V V V T r rT r T V V V V T V V T rTT V V V V T TT Dinesh Panchal

- 118. QUESTION NO. 3(B) The following data pertains to C.I. Engine working on air standard diesel cycle. Cylinder bore=15cm, stroke length =-25 cm. ,clearance volume= 400 cc. Calculate air standard efficiency if fuel injection take place 5% of the stroke. Dinesh Panchal %5959.0 77.0 85.0 7.2 1 1 155.14.1 155.1 12 1 -1 1 1 r 1 -1CycleDieselofEfficiency 55.1 400 625.441505.0400 Vol.Clearance Vol.Stroke%5Vol.Clearance Vol.Clearance Vol.offCut RatioofCut 12 400 625.4815V rRationCompressio 625.4815400625.4415VVVol.CylinderTotal 625.4415 4 25151514.3 4 VVol.Swept cc400VVol.Clearance cm25LStrokeofLengthcm;15DcylinderofBore : 4.1 4.01- c T c CT 2 S C c c c C S of V ccV cc LD Given

- 119. Q. NO.2 An investor claims to have developed an engine that taken 105 MJ at a temp. of 400 K, rejects 42 MJ at temp of 200 K and deliver 15 KWH of mechanical work. Would you advise investing money to this engine in the market. Dinesh Panchal

- 121. Same Compression Ratio and Heat Addition: Dinesh Panchal

- 122. Same Compression Ratio and Heat Addition: The Otto cycle 1-2-3-4-1, the Diesel cycle 1-2-3'-4'-1 and t he Dual cycle 1-2-2”- 3”-4”-1 are shown in p-V and T-θ diagram in Fig.4.7.1 (a) and (b) respectively for the same compression ratio and heat input. From the T -s diagram, it can be seen that Area 5-2-3-6 = Area 5-2-3'-6’ = Area 5-2-2"- 3"-6" as this area represents the heat input which is the same for all cycles. All the cycles start from the same initial state point 1 and the air is compressed from state 1 to 2 as the compression ratio is same. It is seen from the T-s diagram for the same heat input, the heat rejection in Otto cycle (area 5-1-4-6) is minimum and heat rejection in Diesel cycle (5-1-4'-6') is maximum.. Consequently, Otto cycle has the highest work output and efficiency. Diesel cycle has the least efficiency and Dual cycle having the efficiency between the two. One more observation can be made i.e., Otto cycle allows the working medium to expand more whereas Diesel cycle is least in this respect. The reason is heat is added before expansion in the case of Otto cycle and the last portion of heat supplied to the fluid has a relatively short Dinesh Panchal

- 123. Problem 1 : The compression ratio of an I.C. Petrol Engine is 4 .Find the air standard efficiency. Problem 2: The efficiency of Otto cycle is 505 .What will be the compression ratio if ϒ=1.4 Problem 3: An engine working on Otto cycle has a cylinder dia. Of 18 cm and a stroke of 25 cm. The clearance volume is 1400 cub. Cm. .Find the air standard efficiency of the engine. Problem 4: In an engine working on Otto cycle , the pressure and temp. at the beginning of the adiabatic compression are 1 bar and 30 0C Respectively. Calculate the compression ratio and also calculate the pressure and temperature at the end of the compression if air standard efficiency is 45% and ϒ=1.4 Problem 5 : An engine working on Otto cycle has pressure and temperature at the beginning of the adiabatic compression as 1 bar and 500 respectively. The pressure at the end of the compression is 12 times that at the beginning,. If the temperature of the air at the end of the heat supplied during constant vol. is 20000C . Calculate 1. Compression Ratio 2. Efficiency 3. Heat Supplied/Kg OF Air 4. Work done/Kg of Air 5. Pressure at the end of the adiabatic Compression. Dinesh Panchal

- 124. Problem 6. : Calculate the efficiency of diesel cycle whose compression ratio is 18 and cut off ratio is 2.133. Assume ϒ=1.4 Problem 7. : Calculate the air standard efficiency of a diesel cycle whose compression ratio is 14. The cut off takes place at 65 of stroke. Assume ϒ=1.4 Problem8 : Following data relates to the diesel engine. Stroke Length = 30 cm, Diameter of the cylinder = 20 cm, Clearance Volume = 800 Cubic cm, Cut off ratio take place at 55 of the stroke . Calculate the Compression Ratio, Cut off Ratio and Air Standard Efficiency. Dinesh Panchal

- 125. GAS TURBINE It is a machine which produces power by utilizing the K.E. Obtained by burnt gases under pressure and undergoes a pressure drop in a nozzle. Dinesh Panchal

- 126. GAS TURBINE It is a machine which produces power by utilizing the K.E. Obtained by burnt gases under pressure and undergoes a pressure drop in a nozzle The basic component of Gas Turbine are shown in fig. 1. Air compressor 2. Combustion chamber 3. turbine Dinesh Panchal

- 127. WORKING OF GAS TURBINE In gas turbine air is obtained from the atmosphere and compressed in the compressor. Compression may by 4 to 6 .The compressed air then passed in to the combustion chamber . , where it is heated. The hot air is then made to flow over the moving blade of gas turbine. Which gives the rotational motion. During this process air gets expanded and finally exhausted to the atmosphere. Thermal efficiency of gas turbine varies from 25 to 35%. Fuel used in gas turbine are oil, natural gas, coal ect. Dinesh Panchal

- 128. Types of Gas Turbines 1. Open Cycle gas Turbine 2. Closed Cycle Gas Turbine Open cycle gas turbine:- it is the simplest form and consist compressor , combustion chamber and a gas turbine which drives the generator and compressor. In this turbine air is sucked from the atmosphere and then compressed isentropic ally .This compressed air is heated in the combustion chamber and finally made to flow over the blade of the turbine and this hot air gives the drive to the blades. Dinesh Panchal

- 129. CLOSED CYCLE GAS TURBINE A closed-cycle gas turbine is a turbine that uses a gas (e.g. air, nitrogen helium, argon etc.) for the working as part of a closed thermodynamic system. Heat is supplied from an external source. Such recalculating turbines follow the Brayton Cycle. The diagram shows the closed cycle gas turbine. In this turbine air is compressed isentropic ally in the compressor and then passed in to the heating chamber. The compressed air is heated with the help of some external source and ten made to flow over the turbine blade . The gas while flowing over the turbine blade ,gets expanded. From the turbine , the gas is passed over to the cooling chamber where it get cooled at constant pressure with the help of circulating water to original water. Now the air is made to flow in to the compressor again . Applications : 1. Aviation 2.Central Electric Generation Station 3.Used in Combined Cycle Power Station Dinesh Panchal

- 130. Comparison Between Gas turbine and I.C. Engines 1. Balancing is perfect 2. Pressure used is low 3. Installation and running cost is less 4. Running speed is high 5. Maintenance cost is less 6. Lubrication and ignition system is simple 7. Efficiency is higher. 8. Cooling system is simple. 9. Torque produced is uniform. 10. Starting is not simple. 11. Suitable for air craft. 12. Exhaust is free from smoke and less polluting. 1. Balancing is not perfect 2. Pressure used is high 3. Installation and running cost is more 4. Running speed is low 5. Maintenance cost is more 6. Lubrication and ignition system is complicated. 7. Efficiency is lower. 8. Cooling system is not simple. 9. Torque produced is not uniform. 10. Starting is simple. 11. Less Suitable for air craft. 12. Exhaust is more polluting. Dinesh Panchal

- 132. Machine:- it is a device that is capable of doing useful work. It receive energy in some available form and uses that energy in to useful work. The energy may be electrical, mechanical, thermal, chemical. The machine may be simple or compound. Simple machine:- simple machine has only one point of application of effort and one point for load Examples:- • Lever • Pulley and pulley system • Wheel and axle • Inclined plane • Screw jack 2. Compound Machines:- are those machines which has more than one point of application of effort and more than one point of applying the load.Dinesh Panchal

- 133. Lifting Machine:- it is a device with the help of which we are able to lift the heavy loads by applying the less effort. Examples :- • Lever • Pulley and pulley system • Wheel and axle • Inclined plane • Screw jack Dinesh Panchal

- 134. Some Definitions Load: - a machine is used to lift the load or overcome to some resistance. The weight is to be lifted by the machine is called Load. It is denoted by W Effort: - The force required to lift the load or to overcome the resistance is called Effort . It is denoted by P Input :- input of a machine is the work done on machine. It is the product of effort and distance moved by effort Input=Effort x Distance moved by Effort = P X y Output :- output of a machine is the work done by the machine. It is the product of Load and distance moved by Load Output=Load x Distance moved by Load =W X x Mechanical Advantage:- It is defined as the ratio of the load to the effort applied denoted by M.A. Velocity Ratio :- It is defined as the ratio of the distance moved by effort to the distance moved by load denoted by V.R. P W AppliedEffort LiftedLoad M.A.AdvantageMechanical x y LoadbyMovedDistance EffortbyMovedDistance RatioVelocityDinesh Panchal

- 135. Efficiency of Machine:- it is defined as the ratio of output of a machine to input of a machine. It is denoted by η η = Output of Machine/ Input of Machine = W X x / P X y = M.A. / V.R. So efficiency of a machine is the ratio of Mechanical Advantage to Velocity Ratio. Ideal Machine:- A machine whose efficiency is 100% is called an ideal machine. It has equal input and output Ideal effort :- is the effort required to lift the load by the machine, assuming the machine to be ideal. Dinesh Panchal

- 136. LAW OF MACHINE The law of machine may be defined as by an equitation which gives the relationship between the load lifted (W) and the effort applied (P) This is generally a straight line which does not pass through the origin. The law of machine is given below P=mW+C C – intercept OA , m- Slop of AB P- Effort Applied, W – Load Lifted For an ideal machine the line passes through the origin Max. M.A.=1/m Max. Efficiency=Max. M.A./V.R. m=(P2-P1)/ (W2-W1) Y intercept P1=Mw1+C Fig. A O B C Effort DLoad E F m 1 For Actual Machine ForIdealMACHINE Dinesh Panchal

- 137. REVERSIBILITY OF A MACHINE If a machine is capable of doing work in the reverse direction after the removal of the Effort called reversible machine. Let P be the effort required to lift the load W . Now if P is removed W may fall. It is called reversible machine. Reversibility of a machine dependent on its efficiency, if the efficiency is less than 50% it will be self locking and if it is greater than 50% it is reversible. CONDITION FOR REVERSIBILITY : - W- Load Lifted by Machine P- Effort Applied to Lift the Load y- Distance moved by Effort X- Distance moved by Load Input = output + Work done by Friction = Output + Work done to overcome to Friction Work done Lost in Friction = Input -Output = P . y - W . xDinesh Panchal

- 138. When effort is removed , the load can start moving down if it can overcome the friction resistance(i.e. Input-Output) Hence the condition for the reversibility is the output of the machine is more than that the work lost in friction when effort is removed i.e. P=0 Output > Work Lost in Friction Output > Input-Output W . x > P . y - W . x 2W . x > P . y W/P . x/y >1/2 M.A./V.R. >1/2 η > ½ η > 50% Dinesh Panchal

- 139. • QUESTION NO. 7 In a lifting machine an effort of 16N is required to lift the load of 800 N at an efficiency of 60% . The same machine require an effort 25 N to lift the load of 1500 N. Determine the Law of Machine and calculate max. M.A. and efficiency. • Ans: %9393. 33.83 7.77 R.V. M.A.Max. Max. 7.77 9 700 m 1 M.A.Max. :AdvantageMechanicalMax. 5.710.0128wP :MachineofLaw 71.5 7 40 C;0128.0 700 9 m (ii)and(i)equatationtheSolve ......(ii)..........C1500m25 ....(i)..........C800m16 2and1CasefromWPandofvaluePut the CmWP :MachineofLaw N800WLiftedLoad 16PappliedEffort:2Case 33.83 6.0 16/800M.A. V.R. V.R. M.A. N800WLiftedLoad 16PappliedEffort:1Case 60% : 2 2 1 1 N N Given Dinesh Panchal

- 140. • QUESTION NO. 7 In case of lifting machine, effort required to lift the load 50N and 80N were 12N and 18 N.If the velocity ratio of the machine was 6 . Determine (i) Law of machine (ii) Efficiency of the machine and the effort lost in friction at 50 n load (iii) Max. efficiency expected from the machine • Ans: %8383. 6 5 R.V. M.A.Max. Max. 5 2.0 1 m 1 M.A.Max. :AdvantageMechanicalMax. %707.0 6 2.4 V.R. M.A. (Given)6R.V.And2.4 12 50 M.A. 1220.250P 50WloadAt 2W2.0P :MachineofLaw 2C;20.0 30 6 m (ii)and(i)equatationtheSolve ......(ii)..........Cm0818 ....(i)..........Cm0512 2and1CasefromWPandofvaluePut the CmWP :MachineofLaw N80WLiftedLoad18PappliedEffort N05WLiftedLoad12PappliedEffort 60% : 3 11 11 N N N Given Dinesh Panchal

- 141. WHEEL AND AXLE It consist of two cylinders A and B of different diameters rotating on the same axis. The bigger cylinder A is called wheel and the smaller one B is called axle. Wheel had diameter D and axle diameter is D. a string is wound round the axle. The one end of the string is fixed to the axle and attached to the load W. Another string is wound round on the wheel. One end of the string is fixed to wheel and effort is applied on the other end. These two strings are wound in opposite directions, so that one rope wrap and other unwrap on rotation. Dinesh Panchal

- 142. D – Dia of wheel d – Dia of Axle W – Load Lifted P – Effort Applied Distance moved by Effort in one revolution = ΠD Distance moved by Load in one revolution = πd PD Wd RV AM Efficiency d D d D P W .. .. P W AppliedEffort edWeightLift M.A. d D LoadbymovedDistance effortbymovedDistance V.R. Dinesh Panchal

- 143. Differential Wheel and Axle It has one wheel and two axle. It consist of wheel A of Diameter D , Axle B of Diameter of d1 and axle C of Diameter d2 . All three are keyed to the same shaft. One string is wound round the wheel A . Another end of this string is for applying effort. Second string is wound round the axle B, which after passing rounds to the pulley is wound round on axle C in the opposite direction. So that when the string on wheel A unwound, The string on axle C should also unwind but wound on axle B. Dinesh Panchal

- 144. W – Load Lifted P – Effort Applied D – Diameter of Wheel d1 – Diameter of Axle B D2 – Diameter of Axle C Distance moved by Effort in one revolution = Πd Length of string unwound from cylinder C= πd2 Length of string wounds from cylinder B= πd1 Length of string wound in one revolution = πd1- πd2 Displacement of Load = (πd1- πd2)/2 2121 2121 D d-d P W .. .. P W M.A. D d-dd LoadbymovedDistance effortbymovedDistance V.R. ddP WD RV AM Efficiency D d Dinesh Panchal

- 145. Differential Pulley Block It consist of three pulleys A, B and C. Pulleys A and B having Diameters D, d respectively which rotates about a common axis through O. Pulley C is a movable pulley and load is attached to this pulley. A single string passes around the pulleys as shown in fig. The string first passes round the pulley A then round pulley C and then finally round the pulley B. Effort is applied at the end of the string passing round the pulley A . Dinesh Panchal

- 146. W – Load Lifted P – Effort Applied D – Diameter of Pulley A d1– Diameter of Pulley B When pulley makes one revolution, it moves downwards by an amount of .Then string passes over the pulley B and moves downwards by an amount `So string passes over the pulley C is = Displacement of Effort P in one Revolution of Pulley A = Length of string released by pulley B = Dinesh Panchal

- 147. DP dDW dD D RV AM Efficiency dD D dD D 22 P W .. .. P W AppliedEffort LiftedWeight M.A. 2 2 LoadbymovedDistance effortbymovedDistance V.R. Dinesh Panchal

- 148. Worm and Worm Wheel It consist of a square threaded screw B called worm and a toothed wheel C known as worm wheel. The worm B is in mesh with worm wheel; C and their axis are at right angle the each other. On the axis of worm B , effort wheel A of Diameter D is attached , over which a rope is wounded. The effort is applied at one end of rope. On the axis of the wheel c, a small pulley or a load drum having diameter d provided over which a rope is wounded and one end of the rope is used to attach load. B C A d Dinesh Panchal

- 149. W – Load Lifted P – Effort Applied D – Diameter of Effort Wheel A r=d/2Diameter of load Drum T – Number of teeth on worm wheel C Single Start: Distance moved by effort in one revolution of effort wheel = π D Load Drum will turn in one revolution of worm B = 1/T Revolution Distance moved by Load = 2π r X 1/T A B C D P W M.A. d DT d DT 1 LoadbymovedDistance effortbymovedDistance V.R. T d D Dinesh Panchal

- 151. Single Purchase Winch Crab It consist of an effort axle having a small toothed wheel known as pinion with teeth T1 on it. The pinion gear is the driving gear and it is in mesh with the larger toothed gear known as spur gear having teeth T2 .It is a driven gear. This spur gear is connected to the load drum. When effort is applied to the effort axle, the effort wheel and the pinion wheel attached to it start to move. As the pinion wheel is coupled with spur gear, later also rotates in reverse direction Dinesh Panchal

- 152. L – Length of Arm Lever W - Load Lifted P – Effort Applied d – Dia . Of Load Drum T1 – No. of teeth on pinion T2 – No. of teeth on Spur Gear In one revolution of lever, pinion will complete one revolution. So distance moved by Effort in one revolution of lever = 2π L In one revolution of lever spur wheel will complete T1/T2 revolution. So distance moved by Load in one revolution of lever =T1/T2 X πD L P W M.A. DT 2LT D LT22 LoadbymovedDistance effortbymovedDistance V.R. 1 2 1 2 2 1 T T T D L Dinesh Panchal

- 154. Double Purchase Crab Winch It is the extended version of single purchase crab winch. Velocity ratio of a crab winch is increased by providing another axle with pair of pinion and spur wheel. As shown in Fig. L – Length of Arm Lever W - Load Lifted P – Effort Applied d – Dia . Of Load Drum T1 – No. of teeth on pinion of effort wheel T2 – No. of teeth on Spur wheel of intermediate wheel T3– No. of teeth on pinion of intermediate axle T4 – No. of teeth on Spur wheel of load axle In one revolution of lever pinion will complete one revolution. Dinesh Panchal

- 155. So distance moved by Effort in one revolution of lever = 2π L In one revolution of effort wheel intermediate axle will complete T1/T2 No of revolutions made by spur wheel attached to load axle = T1/T2 X T3/T4 42 31 31 42 31 42 31 42 4 3 2 1 T2LPT TWDT 2.. .. P W M.A. D LT2 D LT22 LoadbymovedDistance effortbymovedDistance V.R. TDT TLT P W RV AM Efficiency TT T TT T T T X T T D L Dinesh Panchal

- 156. Simple Screw Jack In screw jack , a square threaded screw is used to raise the heavy loads by applying smaller effort. It consist of a nut, which form the body. Screw with square thread and handle attached to screw thread. The load lifted is placed on the screw head. The effort P is applied at end of the handle attached to the screw. Pitch of screw = p Distance moved by effort in one revolution of handle = 2π L Distance moved by the Load = p Dinesh Panchal

- 158. Differential Screw Jack Fig shows the differential screw jack. It gives more velocity ratio . So it require less effort to lift the load. It consist of two screws B and C threaded on both inner and outer side passes through a nut, while small screw C threaded only on the outer side meshes through the inner side of screw B. p1 – Pitch of thread of spindle B p2 – Pitch of thread of spindle C Distance moved by effort in one revolution of screw C = 2π L Distance moved by load in one revolution of screw C = p1-p2 Dinesh Panchal

- 159. LP2 pW 2.. .. P W M.A. 2 LoadbymovedDistance effortbymovedDistance V.R. 21 21 21 p pp L P W RV AM Efficiency pp L Dinesh Panchal

- 160. • QUESTION NO. 5 In a simple screw jack the pitch of the screw is 10 mm and the length of the handle is 450mm . Find the velocity ratio. If an effort of 25 N applied on the handle can lift a load of 3KN . Find efficiency of the jack. Also calculate the amount of effort wasted in friction. • Ans: J40.79.58x70.65 )-(1supplikedEnergyfrictionintedEnergy was 70.65 1000 45025xx2π effortbymovedDistanceEffort xmachinetheSuppliedEnergy %5.42 2.282 120 .. .. 120 25 3000 .. 2.282 10 2x3.14x450 2 tan tan .. 3LiftedLoad 25NappliedEffort 450mmhandletheofLength 10mmScrewtheofPitch :Given RV AM P W AM p L oadcemovedbyLDis heEffortcemovedbytDis RV KNW P L p Dinesh Panchal