Brick Classification

- 2. European StandardsEuropean Standards Currently bricks are manufactured and tested to British Standard 3921:1985. By the end of 2004 BS EN 771, the new European Standard will be introduced. It will run alongside BS 3921 until the end of 2005 when BS 3921 will be withdrawn. This training module is based upon BS3921 and will be updated to take into account the new European Standard when necessary.

- 3. What is a brick? A brick is defined in BS3921:1985 as a masonry unit with overall dimensions not exceeding 338mm in length, 225mm in width and 113mm in height. BS 3921 : 1985 Definitions

- 4. Stretcher Bed Header FACES Note Bricks are guaranteed to be faced on 1 stretcher and 1 header

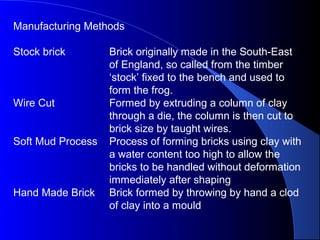

- 5. Manufacturing Methods Stock brick Brick originally made in the South-East of England, so called from the timber ‘stock’ fixed to the bench and used to form the frog. Wire Cut Formed by extruding a column of clay through a die, the column is then cut to brick size by taught wires. Soft Mud Process Process of forming bricks using clay with a water content too high to allow the bricks to be handled without deformation immediately after shaping Hand Made Brick Brick formed by throwing by hand a clod of clay into a mould

- 6. Varieties of Clay bricks Common Useful but plain Engineering Strong & dense Facing Beautiful

- 7. Varieties of Clay Bricks Common unit Masonry unit suitable for general construction work Engineering brick Fired-clay brick having a dense and strong semi-vitreous body, conforming to defined limits for water absorption and compressive strength Facing brick Masonry unit specially made or selected to give an attractive appearance

- 8. Types of Clay bricks Solid Perforated Frogged

- 9. Types of Clay Bricks BS3921:1985 Solid brick A brick without any perforations or frogs I.e. 100% solid clay un

- 10. Frogged brick Masonry unit in which any frogs do exceed 20% of the gross volume of the brick

- 11. Perforated brick Masonry unit in which any perforations do exceed 25% of the gross volume of the brick

- 12. BS 3921 : 1985 Clay Bricks Introduction Scope Definitions Sizes Dimensional deviations Durability – soluble salt content amended 1995 Efflorescence – omitted 1995 Compressive strength Water absorption Sampling for testing Marking

- 13. BS 3921 : 1985 Sizes Work size Coordinating size 215mm 65mm 102.5mm Note – Bricks are guaranteed faced on 1 stretcher and 1 header Scanned image here

- 14. Why 215 X 102.5 X 65 1 stretcher 2 Headers + 1 joint 3 Bricks on edge + 2 joints 215 102.5 102.5 65 65 65

- 15. BS 3921 : 1985 Appendix A Take 24 bricks as described in clause 9. Remove any blisters, small projections or loose particles of clay adhering to each brick. Place the bricks in contact with each other in a straight line upon a level surface, using the appropriate arrangement for each work size in figure 1. Measure the overall dimension (length, width or height) to the nearest millimetre, using inextensible measure long enough to measure the whole row at one time, e.g. a steel tape. Record each result. Alternatively, divide the sample in half and form two rows of 12 bricks. Measure each row separately and record the sum of two rows. Using a gauge box or similar means, check that the size of any brick in the sample does not exceed the coordinating size given in table 1. Scanned image

- 16. BS 3921 : 1985 Dimensional Deviations The overall measurements of 24 bricks sampled in accordance with clause 9 and measured as described in appendix A shall not fall outside the limits given in table 2. In addition, the size of any individual brick in the sample shall not exceed the coordinating size given in table 1. Scanned table here

- 17. Durability Will the brick stand up to the conditions prevailing in the wall? Will it be durable? Is it frost resistant? These are typical designers/specifiers questions. Durability is a function of the brick but also the type of situation it will be used in. For example a brick durable in London may fail on the west coast of Scotland When water freezes it expands by about 9%. In so doing it exerts tremendous force. Frost resistant bricks are able to withstand freezing and thawing cycles whilst saturated either :- a) Because clay is so composed that it has spaces to absorb the forces, e.g. H1 soft mud or b) The brick is so dense that little water is able to get into the brick and it is strong enough to withstand the forces, Sedgley or Kingsbury

- 18. BS 3921 : 1985 Durability 5.1 Frost resistance :- The bricks shall be classified into one of the following categories: Frost resistant (F). Bricks durable in all building situations including those where they are in a saturated condition and subjected to repeated freezing and thawing. Moderately frost resistant (M). Bricks durable except when in a saturated condition and subjected to repeated freezing and thawing. Not frost resistant (O). Bricks liable to be damaged by freezing and thawing if not protected as recommended in BS5628 : part 3 during construction and afterwards, e.g. by an impermeable cladding. Such units may be suitable for internal use. 5.2 Soluble Salt Content :- The bricks shall be classified into one of the following categories: Low (L). A limited percentage by mass of soluble salts. Normal (N). No limit on soluble salt content.

- 19. BS 3921 : 1985 Durability Scanned table here

- 20. Strength Nowadays the brickwork leaf is generally only carrying its own self weight. However, there may be the need for the bricks to have sufficient strength to carry the loads imposed by the roof, floors, or even retained earth. Will the brick have sufficient strength. Scanned images here

- 21. Water Absorption Some designers believe that the amount of water a brick can absorb indicates how frost resistant it will be. THIS BELIEF IS WRONG A low absorption is not always an indicator or frost resistance whilst a high one doesn’t always mean a poor frost resistance. Structural engineers can use lower absorption’s to reduce safety factors in their designs. This is the most relevant use of water absorption figures. (The lower the absorption, the higher the brick/mortar bond.) To obtain the figures we quote, e.g. 7%, 23%, etc bricks are first boiled for 5 hours to try and fill the accessible pores (spaces). The weights before and after boiling are compared and the difference expressed as a percentage.

- 22. BS 3921 : 1985 Engineering Bricks 2 classes of engineering bricks are defined :- Compressive Strength N/sq mm Water Absorption % by mass Class A 70 4.5 Class B 50 7.0 Compressive strength value is a minimum water absorption is a maximum Compressive strength, water absorption alone designate engineering bricks. We make no claims about their appearance. Users choosing to build them into facing brickwork do so at their own responsibility. Engineering bricks are traditionally used in manholes, sewerage works, foundations, etc where the strength and low absorption are desirable.

- 23. Test Certificates The properties we claim for our bricks are listed on the data sheets. These are usually “safe” figures which we know our bricks will comfortably exceed / better. However, some customers will not accept Baggeridge’s word and they ask for independent information to confirm our claims. To provide this independent information confirmation for the customer and as part of ongoing quality control, we send bricks to testing laboratories not commercially connected with Baggeridge. Their test results come back to us in the form of TEST CERTIFICATES. Test Certificates are used to show that our CLAIMS (on data sheets) are met or bettered in practice. Designers should actually design based on the information on the data sheets.

- 24. Mortars Mortar makes up 17% of the surface area of facing brickwork. We recommend cement, lime and sand mortars mixes in line with British Standards designations (i) (ii) or (iii) In general, the weakest mix possible should be selected except in more secerley exposed areas, such as below d.p.c’s, cappings and cills etc. where a stronger mix is advised. All mortar joints should be fully filled with a thouroughly mixed mortar to avoid “bleaching”. Bucket handle or weather struck joints recommend to assist weathering of brickwork. Recessed joints may be used after cafeful consideration

- 25. Movement Brickwork movement is a combination of both : a) Long term moisture expansion of the bricks – between 20 and 60 years. b) Reversible thermal movement caused by temperature changes. As a rule of thumb BS.5628 : Part 3, 2001 advises an expansion of 1mm per metre run of brickwork – both horizontally and vertically. Movement joints should be typically spaced at 12 metre centres – BS.5628 allows spacing up to 15 metres. Maximum. Joints should be filled with a compressible filler and sealed with a sealant both durable and tolerant

- 26. Good Brickwork Practice Bricks should be handled and sorted in such a way as to minimize any damage. Bricks should be off-loaded onto a level hardstanding To ensure bricks are well blended, bricks should be taken from a minimum of three packs at one time. Correct proportioning of mortar constituents is necessary for both mortar strength and to avoid colour variations. All new and incomplete brickwork should be protected by waterproof sheeting.